2025 Bright Annealing Furnace Market: Igniting $5.26 Billion Global Growth, Fueling Industrial Advancements in China, USA & India

Explore the evolving Bright Annealing Furnace Market with insights into growth trends, technological advancements, and regional developments in China, USA, and India. Learn about the benefits of bright annealing, market challenges, and future opportunities as the industry embraces sustainability and Industry 4.0 principles through 2025 and beyond.

- Last Updated:

Bright Annealing Furnace Market Forecast for 2025

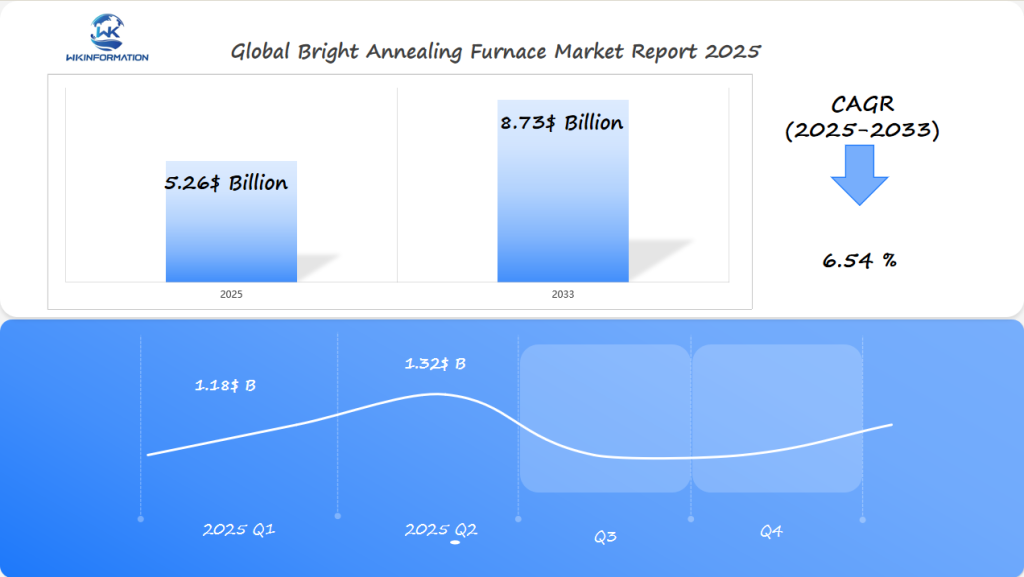

The Bright Annealing Furnace market is projected to reach a valuation of USD 5.26 billion in 2025, with a CAGR of 6.54% expected between 2025 and 2033. Based on market dynamics, the sector is estimated to generate approximately USD 1.18 billion in Q1 of 2025 and USD 1.32 billion in Q2 of 2025, reflecting varying demand trends across industrial applications.

Among the key regions, China, the United States, and India emerge as the most critical markets for analysis, driven by rapid advancements in manufacturing, infrastructure development, and increasing adoption of precision heat treatment processes. These markets are expected to play a pivotal role in shaping industry growth, presenting significant opportunities for market participants and investors.

Understanding the Bright Annealing Furnace Supply Chain

The bright annealing furnace market is crucial for industries as it provides controlled heat treatment for materials like metals, plastics, and semiconductors. These furnaces improve the properties of materials, making them essential in various industries.

Factors Driving Growth

The market is expected to grow significantly due to:

- Increasing demand for high-quality heat treatment solutions

- Ongoing technological advancements

The focus on automation and Industry 4.0 integration is transforming production capabilities, resulting in more efficient operations.

Importance of Bright Annealing Furnaces

Bright annealing furnaces are vital in enhancing material properties through precise thermal treatment. They play a significant role in industries where specific material characteristics are critical for performance.

Future Outlook

The bright annealing furnace market is projected to experience substantial growth by 2025. This expansion is primarily driven by industrialization and technological innovation in countries such as China, the USA, and India.

The future of this market indicates that advanced manufacturing processes will be crucial for industrial success. As industries continue to evolve and demand for specialized materials rises, bright annealing furnaces will remain integral to achieving desired material properties.

Trend Analysis: Innovations and Trends in Bright Annealing Furnace Technology

Supply Chain Components

The bright annealing furnace market’s supply chain is intricate, involving multiple stakeholders from different stages of production. Key suppliers play a crucial role by providing essential components such as heat-resistant materials, control systems, and insulation products. Prominent manufacturers like OTTO JUNKER and SECO/WARWICK stand out by integrating cutting-edge technology into their furnace designs, ensuring high performance and efficiency.

- Upstream Suppliers: Raw material providers are pivotal for maintaining the quality and durability of furnace components.

- Manufacturers: Companies such as OTTO JUNKER focus on innovative technology and environmental protection to produce state-of-the-art furnaces.

- Distribution: Effective logistics strategies ensure timely delivery to various global markets.

Downstream Applications

Bright annealing furnaces find applications across several industries due to their ability to enhance material properties through controlled heat treatment. These furnaces are particularly vital in sectors that require precise metallurgical changes.

- Metals Industry: Used extensively for stress relief and stabilization of steel and other metals, improving durability and performance.

- Plastics Sector: Enhances the crystallization process, crucial for achieving desired material characteristics.

- Semiconductors: Vital for processes requiring high purity and precision, underscoring the importance of controlled atmospheres during manufacturing.

The demand for bright annealing furnaces continues to grow as industries seek more efficient and sustainable heat treatment solutions. This trend is propelled by technological advancements that promise enhanced performance and reduced environmental impact. As these innovations unfold, they redefine the landscape of industrial heating applications.

Restriction Analysis: Challenges Facing the Bright Annealing Furnace Industry

The bright annealing furnace industry is facing several challenges, mainly due to rapid technological advancements and the need for sustainability. Automation and Industry 4.0 are at the forefront of these developments, bringing both opportunities and difficulties for manufacturers.

Technological Advancements

1. Automation

The integration of automated systems within bright annealing furnaces enhances efficiency but requires significant investment in new infrastructure and employee training. This transition to automation can be capital-intensive, posing a barrier for smaller manufacturers.

2. Industry 4.0

Embracing Industry 4.0 involves adopting smart technologies like IoT and AI to optimize furnace operations. While these innovations promise enhanced performance and reduced downtime, they also demand substantial upgrades in technology frameworks and skilled personnel to manage complexities associated with smart systems.

Sustainable Practices

The push towards sustainability is reshaping the industry landscape as environmental regulations become stringent.

1. Energy Efficiency

Companies are investing in energy-efficient furnace designs to reduce carbon footprints. The challenge lies in balancing cost-efficiency with sustainable practices, often requiring innovative approaches to design and operation.

2. Material Use

Sustainable material usage within furnaces is becoming crucial. Manufacturers are exploring eco-friendly materials that do not compromise on durability or performance, which necessitates research and development investments.

Environmental Impact Minimization

Efforts to minimize environmental impact include adopting green manufacturing techniques, such as recycling heat energy within processes. This approach demands technological adaptations and can entail higher initial costs, yet it aligns with global sustainability goals.

Navigating these challenges requires a strategic focus on innovation while ensuring compliance with regulatory standards. The industry’s future hinges on its ability to harmonize cutting-edge technology with sustainable practices.

Geopolitical Analysis: The Impact of Global Politics on Bright Annealing Furnace Production and Trade

Navigating the Bright Annealing Furnace Market involves grappling with several challenges, primarily rooted in geopolitical dynamics. Manufacturers face a complex landscape where regulatory constraints play a pivotal role. Countries impose stringent regulations on industrial processes to ensure environmental safety and compliance, which can significantly impact the production costs and timelines for furnace manufacturers.

Economic factors further compound these challenges. Fluctuating currency values, tariffs, and trade barriers can lead to increased costs for raw materials and components essential for manufacturing bright annealing furnaces. These economic hurdles necessitate strategic planning and adaptability from industry players to maintain profitability.

Competition within the market is another critical aspect influencing the industry’s dynamics. With major players like OTTO JUNKER and SECO/WARWICK driving innovation, other companies must continuously innovate to maintain their competitive edge. This competitive environment fosters a culture of continuous improvement but also places pressure on smaller manufacturers struggling to keep pace with technological advancements.

The implications of geopolitical tensions extend beyond individual companies to affect entire supply chains. Trade policies between leading industrial nations dictate the flow of goods and services, impacting how quickly and efficiently products reach their markets. Regional collaborations or disputes can either bolster or hinder market growth depending on their nature.

In this rapidly evolving landscape, industry stakeholders must remain vigilant, adapting strategies to mitigate risks posed by these geopolitical factors while seizing opportunities for growth in global markets.

Segmentation Type Market Analysis: Bright Annealing Furnace Market Segmentation by Type and Application

The bright annealing furnace market is significantly influenced by geopolitical factors and global industry dynamics. International trade policies play a crucial role in shaping the growth trajectory of this market. Trade agreements or restrictions can directly affect the import and export of bright annealing furnaces, impacting pricing, availability, and technological exchange between countries.

Influence of International Trade Policies

Favorable trade policies facilitate smoother transactions and collaborations between manufacturers and suppliers across borders. Tariffs or restrictions, however, can lead to increased costs and reduced competitiveness for companies operating in regions with stringent trade barriers.

Effects of Geopolitical Tensions on Supply Chains

Geopolitical tensions often create uncertainties that disrupt supply chains. For instance, conflicts or diplomatic strains can lead to delays in raw material procurement or finished product delivery. This affects production timelines and may increase operational costs for manufacturers relying on cross-border supply chains.

Regional collaborations are also impacted by these geopolitical factors, affecting how companies strategize their operations. With increasing awareness of such impacts, some industry players are diversifying their supply chains to mitigate risks associated with geopolitical tensions.

In essence, understanding the trade impacts and navigating the complexities of international relations is vital for stakeholders in the bright annealing furnace market. Companies that adapt to these challenges by leveraging strategic partnerships and flexible operations are better positioned to thrive amidst changing global industry dynamics.

This analysis highlights the intricate relationship between geopolitical factors and market segmentation by type and application, offering insights into how these elements shape the industry’s evolution.

Application Market Analysis: The Role of Bright Annealing Furnaces in Metal Processing

Bright annealing furnaces play a critical role in metal processing, primarily through the enhancement of material properties via heat treatment processes. These furnaces are instrumental in stress relief, stabilization, and crystallization of metals, ensuring improved quality and performance.

Types of Bright Annealing Furnaces

1. Batch Systems

Ideal for smaller productions, batch systems are designed for versatility. They allow for the treatment of diverse materials and are often used when flexibility is required across different types of metals. Batch furnaces typically involve loading materials into a chamber where they are treated under controlled conditions.

2. Continuous Systems

Best suited for large-scale operations, continuous systems offer seamless processing with efficiency and consistency. Metals pass through the furnace at a steady rate, making these systems highly effective for industries demanding high throughput and uniformity in heat treatment.

Applications Across Sectors

Bright annealing furnaces find applications across various industries:

- Metals Industry: Crucial for improving mechanical properties and corrosion resistance. These furnaces ensure the removal of internal stresses, resulting in metals that are more pliable and durable.

- Plastics Sector: Utilized to enhance thermal stability and clarity in polymers, bright annealing processes help in achieving desired physical properties.

- Semiconductor Manufacturing: Vital for precision and consistency, annealing processes ensure semiconductor components meet strict performance standards by stabilizing their structures.

The impact of bright annealing furnaces on metal processing is profound. By leveraging advanced technology, these systems contribute significantly to enhancing material properties while supporting efficient production practices. This makes them indispensable in modern industrial applications.

Global Bright Annealing Furnace Market Region Analysis: Regional Market Dynamics

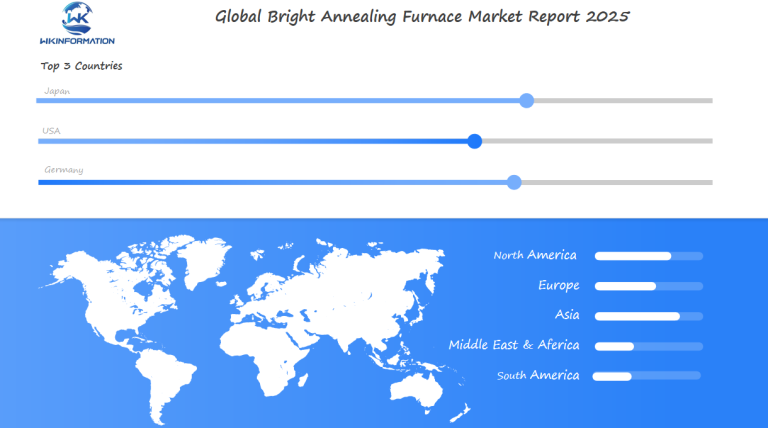

In the Bright Annealing Furnace Market, regional dynamics play a significant role in shaping market trends and growth opportunities. Key regions contributing to the market’s expansion include China, the USA, and India. Each of these areas exhibits unique characteristics that drive their demand for bright annealing solutions.

China

- Industrialization Surge: China’s rapid industrialization fuels the need for advanced heat treatment solutions like bright annealing furnaces.

- Technological Advancements: Investment in technology enhances furnace efficiency, meeting the demands of sectors like automotive and electronics.

- Government Support: Policies encouraging manufacturing advancements bolster market growth.

USA

- Innovation Hub: The USA remains at the forefront of technological innovation, with a strong focus on Industry 4.0 and automation in manufacturing.

- Diverse Applications: Sectors such as aerospace, automotive, and semiconductor industries rely heavily on bright annealing processes.

- Sustainability Initiatives: Emphasis on sustainable practices aligns with environmental regulations, driving demand for eco-friendly furnace solutions.

India

- Growing Manufacturing Sector: India’s expanding manufacturing capabilities increase demand for efficient heat treatment technologies.

- Cost-Efficiency Focus: Demand for cost-effective yet advanced solutions drives innovation in furnace technology.

- Infrastructure Development: Ongoing infrastructure projects create a need for high-quality materials processed through bright annealing furnaces.

Comparing these regions reveals distinct trends shaping the global bright annealing furnace market. While China’s growth is driven by industrial expansion and government policies, the USA’s focus lies in technological advancements and sustainability. Meanwhile, India’s burgeoning manufacturing sector emphasizes cost-efficient technologies to cater to its growing infrastructure needs. This regional analysis highlights how diverse factors contribute to the dynamic landscape of the bright annealing furnace market across different global regions.

Japan Bright Annealing Furnace Market Analysis

Japan is a major player in the bright annealing furnace market, with a focus on future developments and manufacturing trends.

Predictions for Future Technological Advancements by 2025

- Automation and Industry 4.0 Integration: Expect significant strides in the incorporation of automation within annealing processes. Japanese manufacturers are likely to implement advanced control systems and IoT solutions to optimize operational efficiency.

- Energy Efficiency Innovations: As sustainability becomes increasingly important, advancements will include energy-efficient designs that reduce consumption while maintaining performance standards.

- Material-Specific Technologies: With Japan’s strong presence in semiconductor and electronics manufacturing, there’s potential for bespoke furnace technologies tailored to these industries’ specific needs.

Potential Impacts on Manufacturing Processes

- Enhanced Production Quality: These technological advancements promise improved consistency in heat treatment outcomes, ensuring higher-quality products across industries such as automotive and aerospace.

- Reduced Operational Costs: Automation and energy-efficient designs can lead to lower production costs, offering Japanese manufacturers a competitive edge in global markets.

- Increased Flexibility: The ability to quickly adapt furnace parameters will allow manufacturers to respond swiftly to changes in material requirements or production demands.

Japan’s commitment to innovation and quality positions it well to leverage these advancements, enhancing its role as a leader in industrial furnace technology. The nation’s focus on R&D and sustainable practices aligns with global trends, ensuring ongoing relevance in the ever-evolving industrial landscape.

United States Bright Annealing Furnace Market Analysis

The United States remains a significant player in the bright annealing furnace market, driven by innovation and strategic collaborations. Two key competitors, OTTO JUNKER and SECO/WARWICK, have established themselves as industry leaders through their commitment to advanced technology and customer-focused strategies.

OTTO JUNKER

- Innovative Technology: OTTO JUNKER’s focus on cutting-edge technology ensures that their industrial furnace systems meet the demands of modern industries. Their emphasis on environmental protection aligns with the growing trend towards sustainable industrial practices.

- Strategies for Competitive Advantage: The company maintains its edge through continuous technical expertise development, expanding its market presence while prioritizing quality and customer satisfaction.

SECO/WARWICK

- Customized Solutions: SECO/WARWICK excels in providing tailored metallurgical and heat treatment technologies across sectors such as aviation, automotive, and medical. This versatility allows them to cater to diverse industry needs.

- Focus on R&D: A strong emphasis on research and development keeps SECO/WARWICK at the forefront of manufacturing trends, ensuring they deliver innovative solutions that enhance production efficiency.

Industry Collaborations and Partnerships

Collaborations play a crucial role in shaping the U.S. bright annealing furnace market landscape. By forming strategic partnerships:

- Companies can share resources, resulting in cost-effective production processes.

- Joint ventures often lead to technological advancements, allowing firms to stay ahead of competition.

These dynamics highlight how collaboration becomes a strategic tool for maintaining competitiveness in a rapidly evolving industry. The focus on innovation and partnership-driven growth positions the United States as a key market player ready to meet future challenges.

Germany Bright Annealing Furnace Market Analysis

The Germany Bright Annealing Furnace Market is expected to grow significantly by 2025. With Germany’s strong industrial base and innovative capabilities, the market outlook remains positive. Advancements in technology are leading to more efficient and sustainable furnace solutions that align with Industry 4.0 standards.

Key trends shaping the future of this market include:

- Technological Innovations: Emphasizing automation and digitalization, these innovations aim to enhance efficiency and reduce operational costs.

- Sustainability Focus: Increasing demand for eco-friendly solutions drives companies to adopt practices minimizing environmental impact.

For stakeholders, staying informed about these developments is crucial. Engaging in partnerships and exploring investment opportunities within the German market can provide significant competitive advantages. As the industry evolves, active participation in market trends ensures positioning at the forefront of technological advancements.

Future Development Analysis: The Future of Bright Annealing Furnaces in Advanced Manufacturing

Bright annealing furnaces are set to play a crucial role in the future of advanced manufacturing. With Industry 4.0 leading the way, these furnaces will become an integral part of smart factory environments, providing improved automation and connectivity. This transition promises increased efficiency and accuracy in heat treatment processes.

Key Developments to Watch:

- Automation and IoT Integration: Expect brighter prospects with the incorporation of IoT technologies, enabling real-time monitoring and adjustments for optimal performance.

- Sustainable Practices: As industries move towards greener operations, bright annealing furnaces will incorporate eco-friendly technologies, reducing energy consumption and emissions.

- Advanced Materials Processing: With innovations in material science, these furnaces will adapt to new materials requiring unique heat treatment parameters.

- Customization and Flexibility: Future designs will likely offer increased flexibility to cater to various industrial needs, from small-scale operations to large-volume production.

This evolution in bright annealing technology not only enhances manufacturing capabilities but also aligns with global trends towards sustainability and digitalization. Industry stakeholders should remain proactive, engaging with emerging technologies and market shifts to harness new opportunities in this evolving landscape.

Competitor Analysis: Major Players in the Bright Annealing Furnace Market

- Seco/Warwick

- SIMUWU

- Ipsen

- ECM

- Tav Vacuum Furnaces

- Nitrex

- ALD Vacuum Technologies

- Tenova

- Abbott Furnace Company

- Gasbarre

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Bright Annealing Furnace Market Report |

| Base Year | 2024 |

| Segment by Type |

· Horizontal · Vertical |

| Segment by Application |

· Metal Processing · Glass Melting · Chemical Process · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Adapting to emerging trends such as Industry 4.0 and circular economy principles can significantly impact the Bright Annealing Furnace Market. These concepts offer immense potential when strategically embraced by stakeholders.

Opportunities from Industry 4.0

Industry 4.0, with its focus on automation, data exchange, and smart technologies, presents opportunities to enhance efficiency and productivity in furnace operations. Incorporating these advanced technologies can lead to more precise control over the annealing process, resulting in higher quality outputs.

Benefits of Circular Economy Principles

Similarly, adopting circular economy principles encourages sustainable manufacturing practices. This approach not only reduces waste but also enhances resource efficiency, aligning with global environmental goals. By prioritizing sustainability, manufacturers can meet regulatory requirements while also appealing to environmentally-conscious consumers.

It is crucial for industry professionals and investors to stay informed about these changes within their respective markets. Engaging with ongoing developments allows them to leverage opportunities effectively and make informed business decisions. By keeping abreast of technological innovations and market dynamics, stakeholders can maintain a competitive edge in this rapidly evolving industry.

Industry professionals are encouraged to explore these trends actively and consider integrating them into their strategic plans. Doing so can unlock new growth avenues and ensure long-term success in the ever-evolving bright annealing furnace market.

Global Bright Annealing Furnace Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Bright Annealing Furnace Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Bright Annealing FurnaceMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Bright Annealing Furnaceplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Bright Annealing Furnace Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Bright Annealing Furnace Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Bright Annealing Furnace Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofBright Annealing FurnaceMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the significance of the bright annealing furnace market in industrial processes?

The bright annealing furnace market plays a crucial role in various industrial processes by enhancing the properties of metals and other materials through precise heat treatment. Its significance lies in its ability to improve product quality, reduce oxidation, and ensure uniform heating, which is essential for industries such as metals, plastics, and semiconductors.

What trends are currently shaping the technology of bright annealing furnaces?

Current trends in bright annealing furnace technology include advancements in automation and Industry 4.0 integration, which enhance operational efficiency and precision. Additionally, there is a growing focus on sustainable practices aimed at minimizing environmental impact while maintaining high production standards.

What challenges does the bright annealing furnace industry face?

Manufacturers in the bright annealing furnace market encounter several challenges, including regulatory constraints that can complicate production processes and economic factors that influence production costs. Furthermore, competition within the market can affect pricing strategies and innovation efforts.

How does geopolitical analysis affect the bright annealing furnace supply chain?

Geopolitical analysis reveals that international trade policies significantly impact the growth of the bright annealing furnace market. Geopolitical tensions can disrupt supply chains and regional collaborations, leading to fluctuations in availability and costs of raw materials and finished products.

What are the different types of bright annealing furnaces available in the market?

The market offers various types of bright annealing furnaces, primarily categorized into batch systems and continuous systems. Each type serves different applications across sectors by providing tailored heat treatment solutions to enhance material properties.

What are the future developments anticipated for bright annealing furnaces by 2025?

Predictions for future developments in bright annealing furnaces by 2025 include significant technological advancements in design and operation. These innovations are expected to streamline manufacturing processes across industries, improve energy efficiency, and further enhance product quality.