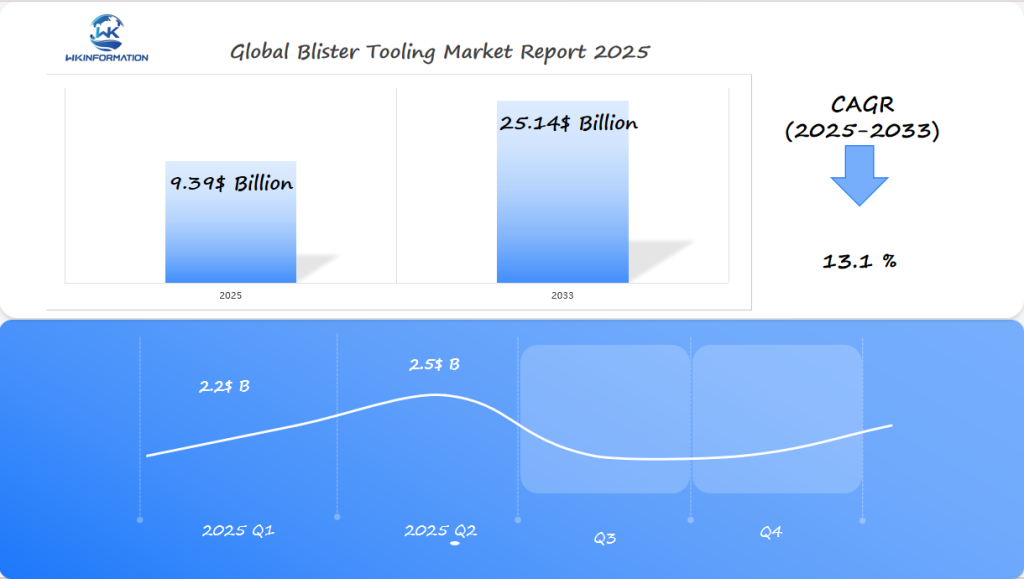

Blister Tooling Market to Reach $9.39 Billion by 2025: Precision Demand in India, Germany, and the U.S.

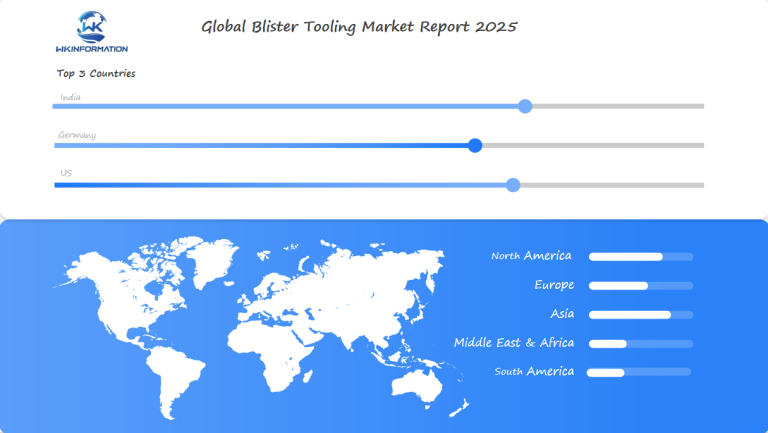

The Blister Tooling Market experiences robust growth driven by pharmaceutical packaging demands, with key manufacturers in India, Germany, and the U.S. leading innovation and expansion.

- Last Updated:

Blister Tooling Market Performance in Q1 and Q2 of 2025

The Blister Tooling market is projected to reach $9.39 billion in 2025, with a CAGR of 13.1% from 2025 to 2033. Q1 market size is expected to be around $2.2 billion, while Q2 is expected to rise to $2.5 billion, reflecting a gradual increase due to seasonal demand fluctuations. The growth trajectory in Q2 is driven by continued advancements in pharmaceutical packaging technologies and the expanding demand for consumer goods in emerging markets. India, Germany, and the U.S. are critical markets, with India seeing strong growth due to increased manufacturing in the pharmaceutical and consumer packaging sectors.

Key Takeaways

- Blister tooling market expected to reach $9.39 billion by 2025

- Pharmaceutical packaging driving market expansion

- 13.1% compound annual growth rate projected

- India, Germany, and U.S. leading market development

- Precision engineering critical for future market success

Blister Tooling Market Upstream and Downstream Industry Chain Insight

The blister tooling market is a complex web of connections. It links suppliers and consumers in various industries such as pharmaceuticals, electronics, and consumer goods.

Key Parts of the Chain

The key parts of the blister tooling industry chain are:

- Raw material makers who create special metals and parts

- Tooling design experts who craft detailed die setups

- Factories that make blister packs

- Companies that need special packaging

Upstream suppliers are vital for quality materials in blister tooling. They offer special steel, precise parts, and advanced tech. These help make products better and work better.

Downstream consumers have different needs for packaging:

- Pharmaceuticals need exact packaging for meds

- Electronics need protection for sensitive parts

- Food and drinks need to stay fresh

- Consumer goods want eye-catching packaging

Upstream and downstream work together to improve blister tooling. Changes in demand, rules, and tech drive this progress.

The whole industry is connected. Changes in one area affect the whole. This shows the need for teamwork and flexibility.

Trends in pharma packaging, automation, and material precision

The world of pharmaceutical packaging is changing fast. New technologies and better materials are leading the way. These changes are making a big impact on how medicines are packaged.

Pharmaceutical companies are using the latest tech to make their packaging better. They’re focusing on automation in blister tooling. This helps them work more efficiently and keep quality high.

Automation and Robotics in Blister Tooling

Robots are making a big difference in blister packaging. They bring speed and precision to the process. Some key advancements include:

- Automated tool changeover mechanisms

- Robotic inspection systems with machine vision

- Real-time process monitoring technologies

Advancements in Packaging Materials

New materials are significantly improving pharmaceutical packaging. Companies are exploring materials that:

- Keep products fresh for a longer period

- Have a longer shelf life

- Are more environmentally friendly

Precision Engineering in Tooling Design

Precision engineering is key for making advanced blister tools. New methods let makers create ultra-precise die configurations. These meet the strict needs of the pharmaceutical world.

Market constraints: tooling costs, format variability, and lead times

The blister tooling market has big challenges for makers and packaging experts. High tooling costs are a big hurdle for companies wanting to grow. The need for advanced tech adds to the financial burden, especially for small businesses with tight budgets.

Key market constraints include:

- High initial equipment expenditures

- Complex format variability challenges

- Extended production lead times

- Specialized engineering requirements

Format variability is another big challenge in blister packaging. Makers need flexible tools that can change for different products. Pharmaceutical and medical device industries need tools that can handle many packaging types.

Tooling costs can be from $5,000 to $50,000 per custom die. This is a big financial challenge for production teams. Small to medium-sized businesses often can’t afford these costs, which limits their growth and tech upgrades.

Strategies like using standard tool parts and advanced computer design can help. Companies that invest in flexible technologies will likely stay ahead in the fast-changing blister packaging world.

Geopolitical influences on tooling steel supply and pharma exports

The global blister tooling market faces many challenges due to geopolitical factors. These factors greatly affect the supply of tooling steel and the export of pharmaceuticals. International trade brings its own set of problems for those looking for reliable raw materials.

Several geopolitical factors are changing the blister tooling market:

- Trade policy changes in big manufacturing countries

- Fluctuations in tariffs that impact tooling steel buying

- Regional economic sanctions

- Rules for exporting pharmaceuticals

Emerging markets are seeing big changes in their pharmaceutical exports. Strategic geopolitical positioning is key to getting the tooling steel needed. Countries like India and Germany have found ways to keep their supply chains stable by finding new sources of raw materials.

Companies need to watch out for geopolitical risks that could disrupt tooling steel supplies. Tensions between big industrial countries make it hard for the pharmaceutical packaging industry. This forces companies to find better ways to get their materials.

Global markets are closely linked, so geopolitical changes can quickly affect pharmaceutical exports and tooling steel availability. Companies that can adjust their supply chains will likely stay ahead in this changing world.

Blister Tooling market segmentation by type: cold-form, thermoform, combination dies

Market segmentation is key to understanding the different types of blister tooling technologies. The global blister tooling market includes various specialized manufacturing methods. These methods meet the unique packaging needs of many industries.

- Cold-form tooling: Precision engineering for creating packaging with intricate designs and minimal material stress

- Thermoform tooling: Versatile solutions for high-volume packaging applications

- Combination dies: Integrated tooling systems offering enhanced flexibility

Tooling Type Key Characteristics Primary Applications Cold-form Tooling Low material stress, precise forming Pharmaceutical packaging, sensitive medical devices Thermoform Tooling High-speed production, versatile materials Consumer goods, electronics packaging Combination Dies Multi-functional, adaptable design Complex packaging requirements

Manufacturers are investing in advanced tooling technologies. This supports detailed market segmentation strategies. The need for specialized cold-form and thermoform tooling is increasing. This is because industries need precise packaging solutions.

Blister Tooling Market Segmentation by Application: Pharmaceuticals, Electronics, Food, Consumer Goods

The global blister tooling market covers many important industries. Each one has its own needs that drive innovation and precision. Pharmaceutical packaging is the biggest segment, where tool design is key to keeping medications safe and in compliance.

Key market applications include:

- Pharmaceutical packaging

- Electronics packaging

- Food packaging

- Consumer goods packaging

Pharmaceutical packaging needs the most precise blister tooling. Specialized dies create safe barriers for sensitive medicines. This prevents contamination and keeps the drug safe. Manufacturers work hard to make tools that meet strict rules.

| Industry Segment | Primary Tooling Requirements | Key Packaging Challenges |

| Pharmaceuticals | High precision, sterile conditions | Regulatory compliance, moisture protection |

| Electronics | Static-resistant materials | Component protection, custom sizing |

| Food | Food-grade materials | Shelf life extension, barrier properties |

| Consumer Goods | Versatile design flexibility | Brand presentation, cost-effectiveness |

Electronics packaging uses advanced blister tooling to protect sensitive parts. Specialized dies make custom enclosures. These enclosures prevent damage from electrostatic discharge and physical harm during transport and storage.

Food packaging uses blister tooling to keep products fresh longer. Manufacturers create new packaging solutions. These solutions balance protection with the need for sustainability.

Understanding the Global Blister Tooling Market

The global blister tooling market is intricate, with various regions exhibiting distinct characteristics. North America takes the lead, owing to its advanced pharmaceuticals and technology.

Factors Influencing the Global Market

Several elements contribute to the appeal of the worldwide market:

- Strong presence in developed pharmaceutical markets

- Increasing technological innovation in regional manufacturing

- Diverse regulatory environments influencing market dynamics

Regional Growth Drivers

Each region experiences growth at its own speed, shaped by several crucial factors:

- Local manufacturing capabilities

- Development of the pharmaceutical industry

- Investment in packaging technology

- Standards for regulatory compliance

Opportunities in Emerging Markets

Emerging markets present significant opportunities for expansion. Asia-Pacific is rapidly enhancing its blister tooling capabilities, introducing new competitors to the global stage. These regions are investing heavily in packaging technology to address rising healthcare demands.

Varied Market Strategies Across Continents

Market approaches differ across continents. North America leads in technology, Europe excels in precision, and Asia focuses on cost-effectiveness and swift technological adoption.

Adapting to Regional Needs

Companies are now producing flexible tooling that caters to various regional requirements. This demonstrates the intricacy of global markets.

India Blister Tooling Market: Generic Drug Packaging and Local Tooling Shops

The India blister tooling market is key in the global pharmaceutical packaging world. India leads in generic drug packaging thanks to its strong pharmaceutical industry. Local tooling shops are crucial in improving manufacturing skills.

Factors Driving Growth in the India Blister Tooling Market

What’s driving the growth in the India blister tooling market includes:

- More generic drug production

- More chances to export

- New manufacturing tech

- Cost-saving packaging

Local tooling shops are changing the pharmaceutical packaging market. They make special equipment for specific needs. These shops are vital for India’s pharmaceutical exports.

| Market Segment | Growth Potential | Key Characteristics |

| Generic Drug Packaging | High | Cost-efficient solutions |

| Local Tooling Manufacturers | Moderate to High | Customized precision engineering |

| Export-Oriented Packaging | Significant | International quality standards |

The India blister tooling market keeps growing. It’s driven by new tech and a need for better generic drug packaging. Local makers are focusing on research to stay ahead globally.

Local tooling shops will become even more important. They will help create advanced packaging that meets global standards.

Germany Blister Tooling Market: Advanced Machinery and Cleanroom Standards

The Germany blister tooling market is a leader in pharmaceutical packaging. It uses top engineering skills to innovate globally. German makers are known for their advanced machinery and strict cleanroom standards.

Key Traits of the German Blister Tooling Market

- Precision engineering in packaging equipment

- Cutting-edge automated manufacturing processes

- Rigorous quality control mechanisms

- Exceptional cleanroom technology implementation

Pharmaceutical companies around the world value Germany’s high-performance blister tooling solutions. The market focuses on advanced machinery. This ensures product quality and reduces contamination risks.

| Market Segment | German Technological Advantage | Global Impact |

| Precision Tooling | Micron-level accuracy | Industry benchmark for quality |

| Cleanroom Standards | ISO Class 5 compliance | Enhanced pharmaceutical safety |

| Automation | Robotic integration | Increased production efficiency |

German manufacturers keep improving, making blister tooling solutions for tough packaging challenges. They focus on precision and cleanliness.

U.S. Blister Tooling Market: High-Volume Production and Contract Packaging

The U.S. blister tooling market leads in pharmaceutical packaging innovation. It supports high-volume production in various sectors. Pharmaceutical companies use advanced contract packaging solutions to meet strict industry standards.

Key Traits of the U.S. Blister Tooling Market

- Strong manufacturing setup for complex packaging needs

- Top-notch tech for precise tooling design

- Big investments in automation and precision engineering

Contract packaging is vital in the U.S. market. It helps pharmaceutical firms streamline their production. The market is very flexible, with makers creating special tooling for different products.

The U.S. blister tooling market keeps growing, using the latest tech to boost efficiency and quality. Makers are working on flexible tooling that can handle quick changes and various packaging needs.

Blister Tooling future development: AI in die design and faster changeover

The blister tooling industry is about to undergo a significant transformation. With the advent of new technologies, manufacturing processes are becoming quicker and more efficient. One of the key drivers behind this evolution is artificial intelligence (AI), which plays a crucial role in designing dies and optimizing production workflows.

AI in Die Design

AI has emerged as a game-changer in the field of die design. By leveraging advanced algorithms and machine learning techniques, manufacturers can now create tool shapes with greater precision, minimize material wastage through intelligent design choices, and proactively identify potential issues before they arise.

Benefits of AI in Die Design

- Enhanced Accuracy: AI algorithms can analyze complex geometries and generate highly precise tool shapes that may be difficult for human designers to achieve.

- Material Optimization: With AI-powered design tools, manufacturers can explore various design alternatives and select the most efficient option that uses less material without compromising functionality.

- Predictive Problem-solving: By analyzing historical data and patterns, AI systems can predict potential problems in the production process, allowing manufacturers to take preventive measures.

Faster Changeover with New Technologies

In addition to AI-driven advancements in die design, new technologies are also revolutionizing the changeover process – the time it takes to switch from producing one product to another. This aspect is critical for manufacturers aiming to increase their flexibility and responsiveness to market demands.

How Machine Learning Helps with Changeovers

- Reduced Changeover Time: Machine learning algorithms can analyze past changeover activities and identify areas where time can be saved. By optimizing specific tasks or sequences involved in the changeover process, manufacturers can significantly reduce downtime.

- Quick Tool Setup: With machine learning insights, manufacturers can streamline tool setup procedures by eliminating unnecessary steps or automating certain actions. This leads to faster preparation for production runs.

- Improved Equipment Performance: Machine learning models can continuously monitor equipment performance during changeovers and provide real-time feedback on any deviations or inefficiencies. This allows operators to make quick adjustments and ensure smooth transitions between products.

The Impact of New Technologies

The introduction of these new technologies – both in die design and changeover processes – holds immense potential for improving blister tooling production.

By embracing AI-driven die design solutions and implementing machine learning techniques for faster changeovers, companies can expect:

- Increased Production Speed: With more efficient designs and quicker transitions between products, overall production speed is likely to increase.

- Cost Savings: Optimized material usage through AI-driven designs combined with reduced downtime during changeovers will result in significant cost savings.

- Competitive Advantage: Companies that adopt these new technologies early on will gain a competitive edge over their rivals by offering faster turnaround times at lower costs.

Competitor overview in the global Blister Tooling industry

Key players in the blister tooling market are focusing on precision engineering and modular design to meet the increasing demand for customized and high-efficiency packaging solutions. They are expanding their footprint in pharmaceutical and consumer goods sectors across regions like Asia-Pacific and Latin America, where blister packaging is becoming more prevalent. Strategic investments in CNC machining technologies and collaborations with packaging machinery manufacturers are enabling these companies to improve turnaround times and strengthen their market position.

Key Players:

-

Meusburger (Austria)

-

Hasco (Germany)

-

Formech (UK)

-

Wilson Tool (USA)

-

Prodieco (Ireland)

-

PTI – Pharmaceutical Technology Industries (USA)

-

Elizabeth Tooling (USA)

-

Thomas Engineering (USA)

-

Natoli Engineering (USA)

-

HPT Pharma (USA)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Blister Tooling Market Report |

| Base Year | 2024 |

|

Segment by Type |

· Cold-form Tooling · Thermoform Tooling · Combination Dies |

| Segment by Application |

· Pharmaceuticals · Electronics · Food · Consumer Goods |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Blister Tooling Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Blister Tooling Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Blister Tooling Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Blister Tooling Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Blister Tooling Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Blister Tooling Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Blister Tooling Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Blister Tooling Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market size for blister tooling by 2025?

The blister tooling market is expected to grow to about $9.39 billion by 2025. This growth is driven by more demand in pharmaceutical packaging. It’s also due to the need for precision in India, Germany, and the United States.

What are the key types of blister tooling dies?

There are three main types of blister tooling dies: cold-form, thermoform, and combination dies. Each type is used for different packaging needs. You’ll also find variations like seal tools, guide tracks/rails, and perforation & scoring dies.

How are emerging technologies impacting blister tooling production?

New technologies like artificial intelligence and automation are changing blister tooling. They make die design better, increase production speed, and cut down on waste. Advanced robotics and precision engineering are also making a big difference in how things are made.

What industries primarily use blister tooling?

Industries like pharmaceuticals, electronics, food packaging, and consumer goods use blister tooling a lot. The pharmaceutical sector is the biggest user. It needs safe and compliant packaging for drugs.

What are the main challenges in the blister tooling market?

The main challenges are high initial costs, complex formats, long lead times, and the need for flexible solutions. These challenges arise from changing product lines and seasonal demands.

How do geopolitical factors affect the blister tooling market?

Geopolitical factors affect tooling steel supply, trade policies, tariffs, and pharmaceutical exports. These factors can change raw material availability, production costs, and market dynamics in different regions.

Which regions are leading in blister tooling technology?

Germany, the United States, and India are at the forefront of blister tooling technology. Germany is recognized for its expertise in precision engineering and cleanroom standards. The U.S. stands out in high-volume production capabilities. India has established itself as a major player in tooling for generic drug packaging.

What future developments are expected in blister tooling?

Future developments include using artificial intelligence in die design, advanced changeover technologies, and sustainable materials. We can also expect smart packaging solutions and more automation to boost production efficiency.

How are packaging materials evolving in blister tooling?

Packaging materials are getting better with high-performance polymers, specialized coatings, and new material technologies. These advancements improve durability, protection, and compatibility with various product needs.

What role does precision engineering play in blister tooling?

Precision engineering is key in meeting strict pharmaceutical packaging standards. It ensures exact specifications, reduces defects, and keeps high-quality standards throughout production.