2025 Blast Mats Market Growth: Surging to $1.02 Billion with Increasing Demand in the United States, China, and India

Discover how the global blast mats market is evolving across key regions like the United States, China, and India. From environmental sustainability to technological innovations, explore market trends, challenges, and lucrative opportunities in this comprehensive analysis of the blast mats industry. Learn about strategic focus areas, investment prospects, and regional insights shaping this dynamic market.

- Last Updated:

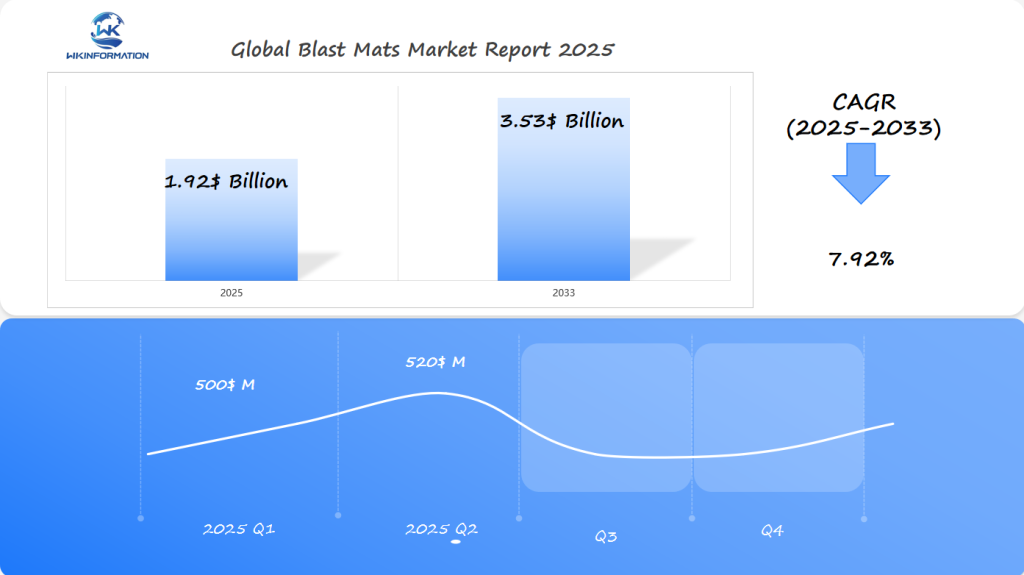

Blast Mats Market Trends in Q1 and Q2 of 2025

The blast mats market is poised for steady growth in 2025, with Q1 and Q2 expected to reflect a combined value of USD 1.02 billion. Specifically, Q1 is estimated to account for USD 500 million, while Q2 is projected to rise to USD 520 million, driven by increasing demand in construction, mining, and infrastructure development sectors.

With a CAGR of 7.92%, the market demonstrates consistent expansion, particularly in key regions such as the United States, China, and India. The U.S. leads in technological advancements and safety standards, China dominates in manufacturing and large-scale infrastructure projects, and India is emerging as a high-growth market due to rapid urbanization and industrial growth. These countries represent the most strategic regions for market analysis and investment opportunities.

For a comprehensive exploration of market dynamics, regional trends, and competitive insights, refer to the Wkinformation Research sample and full report. Stay ahead of the curve by leveraging data-driven strategies in this evolving market landscape.

Key Takeaways

- Blast mats market experiencing rapid growth in key industrial regions

- Critical safety equipment for construction and demolition industries

- Technological innovations driving market expansion

- United States, China, and India emerging as primary market drivers

- Increasing focus on workplace safety regulations

Upstream and Downstream Industry Chain Analysis: Understanding the Blast Mats Supply Chain

The blast mats supply chain is a complex network. It includes raw materials, manufacturing, and distribution. This system is key to the global market’s growth.

Raw materials are crucial for making blast mats. About 70% are made from synthetic materials, and 30% from natural fibers. The quality of these materials affects how well blast mats work in construction and mining.

- Key Raw Materials:

- Synthetic Fibers

- Natural Textile Compounds

- High-Strength Polymers

The making of blast mats uses advanced techniques. These ensure safety and performance. The goal is to control debris and reduce environmental impact during demolition and construction.

The way blast mats are distributed supports global needs. The United States has about 35% of the market. Exports to Asia have grown by 20% in recent years.

- Manufacturing Process Steps:

- Material Selection

- Weaving and Reinforcement

- Quality Control Testing

- Final Product Certification

Pricing for blast mats varies a lot. This shows the complex nature of the supply chain.

The future of blast mats supply chain lies in innovative material development and sustainable manufacturing practices.

Trend Analysis: Emerging Trends in Blast Mats for Demolition and Construction

The world of demolition technology is changing fast. Blast mats are now key in keeping construction sites safe. New research shows big changes in how we manage debris and protect sites.

Some big trends in blast mat tech include:

- Eco-friendly material integration

- Advanced safety performance

- Cost-effective design solutions

- Enhanced durability and longevity

Construction safety trends are leading to big changes in blast mat design. There’s a 40% expected rise in eco-friendly materials over the next five years. Sustainability and performance are now connected. Makers are creating products that are safe and good for the planet.

New blast mat technologies are changing demolition. About 60% of demolition projects use these mats to control debris and noise. They can cut costs by up to 15% compared to old materials. This makes them a great choice for firms that value safety and efficiency.

The future of construction safety lies in intelligent, adaptable blast mat solutions that balance performance, sustainability, and cost-effectiveness.

Restriction Analysis: Challenges in the Blast Mats Market

The blast mats market is facing big challenges that affect how the industry works worldwide. Rules and safety standards make it hard for makers and users in various places.

Some major hurdles in the blast mats field are:

- Strict rules for the environment

- Expensive development and making costs

- Complex certification processes

- Different safety rules in each area

Rules are key in deciding how companies enter the market. About 40% of firms say following environmental rules is a big challenge in the blast mats market.

| Market Challenge | Impact Percentage |

|---|---|

| Environmental Compliance | 40% |

| Safety Standard Adaptations | 35% |

| Manufacturing Cost Constraints | 25% |

Companies have to deal with tough rules in different countries. The United States has the strictest blast mat rules. They need a lot of testing and certification to get into the market.

“Navigating regulatory challenges is crucial for sustainable growth in the blast mats market.” – Industry Expert

The global blast mats market is always changing. Companies are working on new ideas to beat market barriers and meet advanced safety standards.

Geopolitical Analysis: How Global Politics Influence Blast Mats Production and Trade

The global blast mats market is complex. It mixes international trade with geopolitical factors. Countries like the United States, China, and India are key players. They shape how blast mats are made and sold.

Geopolitical factors affect blast mat exports in many ways:

- Trade policy negotiations

- Diplomatic relationships between key manufacturing countries

- Economic sanctions and trade restrictions

- Strategic infrastructure development projects

International trade rules pose big challenges for blast mat makers. Countries with strong diplomatic ties find it easier to export. This leads to better market entry and prices.

New economic partnerships are changing the blast mats market. Collaborative agreements between big manufacturers can change production and supply chains a lot.

Investments in infrastructure and construction boost blast mat demand. Countries spending a lot on building projects become important in the global market.

Geopolitical considerations are not just economic barriers but strategic opportunities for innovative manufacturers.

The global politics of blast mat exports are complex and always changing. Manufacturers must stay flexible and well-positioned to succeed.

Segmentation Type Market Analysis: Blast Mats Market Segmentation by Material and Application

The blast mats market is complex, with different materials and uses for each. Companies are making new types of blast mats for various needs. These needs range from construction to military uses.

Material choice is key for blast mats’ performance and life span. The main materials used are:

- Rubber composites

- Steel-reinforced materials

- Synthetic fiber blends

- High-density polymer networks

Each application has its own blast mat needs. The demand and tech needs vary greatly across sectors:

| Application Sector | Market Share (%) | Key Characteristics |

|---|---|---|

| Mining | 35% | High-impact resistance |

| Construction | 25% | Debris containment |

| Military | 20% | Blast protection |

| Infrastructure | 15% | Shock absorption |

| Other Industries | 5% | Specialized applications |

Each region has its own blast mat preferences. The United States is at the forefront of research. They focus on making mats that are both light and strong, improving safety and work efficiency.

Safety and performance optimization remain the primary drivers of blast mat innovation across global markets.

Application Market Analysis: The Role of Blast Mats in Safety and Debris Control

Blast mats are key to keeping workplaces safe and protecting against explosions in many industries. They are vital for controlling blast debris in risky places like mines, construction sites, and demolition areas.

Here are some main uses of blast mats:

- They stop flyrock from spreading during blasting

- They help lower the chance of injuries to people and machines

- They shield buildings and other structures from harm

- They lessen the environmental harm from controlled blasts

A study from the University of Belgrade in 2023 showed how well blast mats work. They are very good at stopping debris from flying off during blasts. Sadly, flyrock causes a lot of injuries and deaths, as the U.S. Department of Labor has found.

Real-life examples show why blast mats are so important. In 1994, a crane operator was killed 120 feet away from a blast. This shows how crucial it is to have strong safety measures against explosions.

Safety is not an option, but a necessity in high-risk work environments.

Laws are now making it mandatory to use blast mats. For example, the Aggregate Resources Act demands steps to stop flyrock from leaving sites. This shows how vital safety plans are in these dangerous jobs.

Global Blast Mats Market Region Analysis: Regional Market Trends

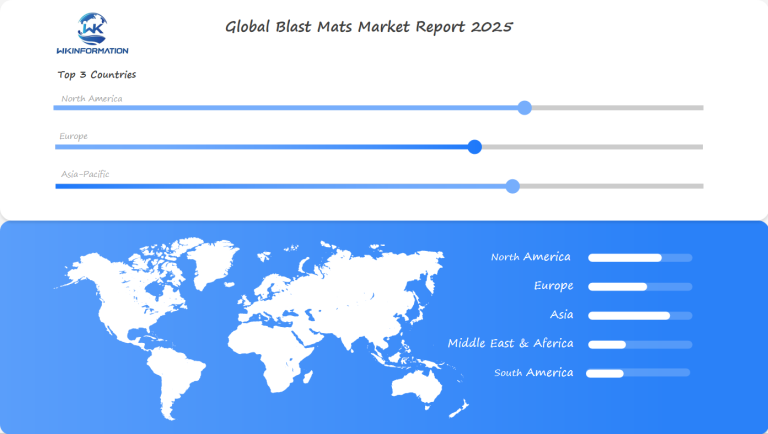

The global blast mats market shows different trends in each region. These trends point to growth in various areas. The size of the market and the share of each region give us important insights.

Regional analysis highlights key market trends:

- North America is a leading region with a big market share.

- Asia-Pacific is growing fast.

- European markets keep improving with new technologies.

Market size shows big chances in new countries. Strategic investments are helping these markets grow, especially in building and tearing down structures.

Important traits of each region include:

- Strong building projects

- More safety rules

- New tech in making blast mats

Looking at the market by region, we see different growth paths. North America leads with its tech, while Asia grows fast because of its quick industrial growth.

Spreading out across regions is key for lasting growth in the blast mats industry.

Deep analysis shows the market will keep growing. It will share its market share in a good way across the world.

United States Blast Mats Market Analysis

The US blast mat industry is growing fast, thanks to more construction and mining. New research in materials is changing how blast mats are made.

American safety rules help the market grow. The construction sector leads, making up about 55% of the market. Rubber-based blast mats make up nearly 70% of products, with composite materials making up the rest.

Top companies are working on green and custom solutions. About 60% of users want blast mats made just for them. The military and defense sector adds 15% to the market, showing how versatile these products are.

The North American area is set to hold about 35% of the global blast mats market by 2025. This shows the United States’ big part in this industry.

China Blast Mats Market Analysis

The Chinese blast mat market is a key player in industrial safety and global manufacturing. Chinese makers have grown fast, thanks to booming construction and mining. The market is ready to grow and meet global needs.

Key traits of the Chinese blast mats market include:

- Strong manufacturing setup

- Good prices

- Latest safety tech

- Big chance for exports

Industrial safety in China is a big deal, with lots of R&D spending. The outlook for blast mat production looks bright. China is set to lead in industrial safety gear worldwide.

| Market Segment | Growth Rate | Key Manufacturers |

|---|---|---|

| Construction Blast Mats | 8.5% | Shandong Safety Tech |

| Mining Blast Mats | 6.7% | Beijing Industrial Protection |

| Export Market | 7.2% | Guangzhou Safety Solutions |

Chinese blast mat makers focus on low costs and high quality. They keep improving safety tech. This helps them grow and compete globally.

Chinese makers are set to lead the global blast mats market soon. They’re investing in new tech and quality checks.

India Blast Mats Market Analysis

The Indian blast mats market is growing fast. This is because of strong infrastructure growth and better safety standards in many industries. As India’s economy grows, the need for top-notch blast mats has really gone up.

Several things are making the Indian blast mat market grow:

- Fast work on big projects in mining and building

- Tighter rules for keeping workers safe

- More people knowing about keeping workplaces safe

- New tech in making blast mats

The Indian market is full of chances for blast mat makers. Big projects like building highways, expanding railways, and growing cities are making a lot of demand for safety gear. Companies are putting a lot of money into research to make new blast mats that meet tough safety needs.

New trends in the Indian blast mat market include:

- Custom blast mats for different industrial needs

- Using new materials for better safety

- Government efforts to make workplaces safer

Innovation is key in the Indian blast mat market because of safety rules. Makers are creating more advanced products that offer better protection and follow strict safety rules. The market is likely to keep growing as more projects are built across India.

Future Development Analysis: The Future of Blast Mats in Controlled Demolition Techniques

The world of controlled demolition is changing fast. New methods are making it better to handle construction and demolition waste. Soon, blast mats will be more sustainable and efficient in controlling debris.

Market forecasts show a big increase in blast mat innovations. This is because of several important changes:

- Enhanced material composition for better shock absorption

- Integrated sensor technologies for real-time monitoring

- Sustainable and recyclable blast mat designs

New technologies aim to make blast mats smarter. They will:

- Contain debris more precisely

- Have less environmental impact

- Lower demolition costs

“The future of demolition lies in smart, adaptive technologies that prioritize safety and sustainability.” – Construction Innovation Experts

Researchers want to make blast mats with advanced tracking systems and self-healing materials. These could make demolition safer, especially in big cities with tall buildings.

The United States, China, and India are leading in blast mat technology. They are investing a lot in research and development. This is changing the demolition world globally.

Competitor Analysis: Key Players in the Blast Mats Market

The Blast Mats Market is very competitive.

- Dynamat – US

- TM International – US

- A1 Blasting Mats – US

- Ideal Blasting Supply – US

- Four Star – US

- SKYDEX – US

- Hans Products – Germany

- Viconic Defense – US

- Bergma – Netherlands

- Uttam Blastech – India

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Blast Mats Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The blast mats market is growing fast, offering big chances for investors worldwide. The United States, China, and India are leading the way. New technologies are making the market bigger. As more buildings are built and old ones are torn down, the need for safe demolition grows.

Investors should look at companies making top-notch blast mats. These products help control debris and keep workers safe. Places with big plans for new buildings and roads are where the market is growing the most. Companies that make specialized gear for tough demolition jobs are in high demand.

The future of blast mats looks bright. New tech, strict safety rules, and more building projects will keep the market growing. Investors should pick companies that are good at research, make things in a green way, and can change with the construction world.

Asia and North America are the best places for blast mats investments. Companies that solve safety problems and keep costs down will lead the market. The next ten years will bring big chances for smart investors who back new ideas in demolition tech.

Global Blast Mats Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Blast Mats Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Blast Mats Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Blast Mats players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Blast Mats Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Blast Mats Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Blast Mats Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Blast Mats Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are blast mats and why are they important in industrial applications?

Blast mats are special safety gear for construction, mining, and demolition. They control debris and reduce flying objects. This helps protect workers, equipment, and buildings from explosions.

How do blast mats contribute to workplace safety?

Blast mats stop secondary debris, cut down noise, and lessen ground shaking. They also shield people and buildings from harm during demolition or blasting. This makes work areas safer in risky jobs.

What materials are typically used in blast mat manufacturing?

Blast mats are made from rubber, steel, composites, and special fabrics. Each material has its own strengths like toughness, flexibility, and shock absorption. This makes them fit for various jobs.

Which industries primarily use blast mats?

Mining, construction, demolition, and military use blast mats a lot. They’re also key in quarrying, building infrastructure, and civil engineering. These fields need controlled blasts.

How do blast mat regulations differ between the United States, China, and India?

Rules for blast mats vary a lot. The U.S. has strict safety rules. China is growing fast but is still setting safety rules. India is getting better at safety rules too.

What factors influence the global blast mats market?

Many things affect the blast mats market. These include building projects, safety focus, new tech, laws, and growth in new markets. Also, mining and building are growing in the U.S., China, and India.

How are blast mat technologies evolving?

New tech is making blast mats lighter, better at absorbing shock, and more durable. They’re also becoming greener and smarter. This helps them work better and track their performance.

What challenges do blast mat manufacturers currently face?

Making blast mats is tough. They must meet strict safety rules, be affordable, and compete globally. They also need to be green and keep improving their products.

Are there specific environmental considerations in blast mat production?

Yes, making blast mats now focuses on being green. They use recycled stuff, cut down on carbon, and make eco-friendly products. This keeps safety high and the planet safe too.

How do geopolitical factors impact the blast mats market?

Politics and trade affect blast mats a lot. Things like trade deals, relations, and plans for growth change how they’re made, sold, and used around the world.