$64.3 Million Biochar Pyrolysis Equipment Market Booms in 2025: Canada, Australia, and India Spearhead Growth

The Biochar Pyrolysis Equipment Market sees robust growth driven by sustainable agriculture demands, with major expansions in Canada, Australia, and India shaping the global landscape through 2025

- Last Updated:

Biochar Pyrolysis Equipment Market Q1 and Q2 2025 Forecast

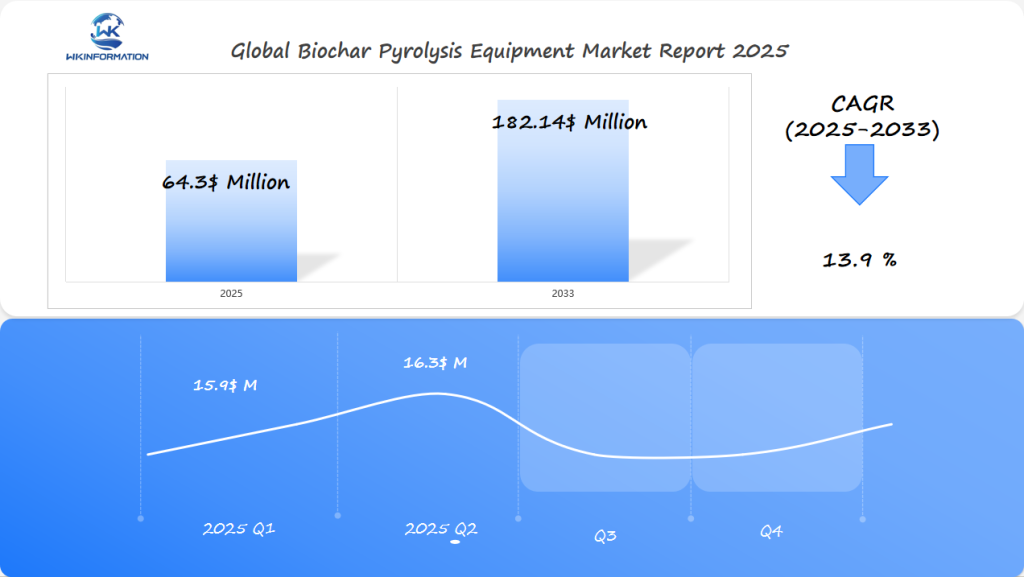

The Biochar Pyrolysis Equipment market is estimated to reach $64.3 million in 2025, with a CAGR of 13.9% from 2025 to 2033. In Q1 2025, the market is projected to generate approximately $15.9 million, driven by the growing interest in biochar production for carbon sequestration, soil improvement, and waste-to-energy applications in Canada, Australia, and India. Biochar, a byproduct of pyrolysis, is gaining attention for its environmental benefits and is increasingly used in agriculture, where it is applied to improve soil fertility and water retention. As climate change concerns rise, biochar is being recognized for its ability to reduce carbon footprints by locking carbon into the soil.

By Q2 2025, the market is expected to grow to $16.3 million, with India and Australia showing heightened interest in sustainable farming practices and waste management solutions. As government incentives for green energy technologies increase, demand for biochar pyrolysis equipment is expected to rise, particularly in regions seeking to meet their climate goals. The global push for renewable energy and waste-to-energy technologies is expected to further accelerate the growth of the biochar market.

Key Takeaways

- The global biochar pyrolysis equipment market is expected to reach $64.3 million by 2025.

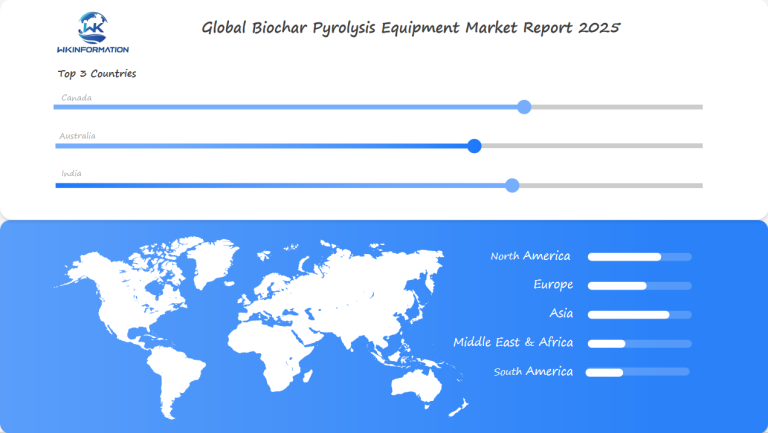

- Canada, Australia, and India are leading the development of the market.

- The technology supports sustainable agriculture and waste management.

- There is an increasing investment in advanced pyrolysis systems.

- There is significant potential for carbon sequestration and renewable energy production.

Understanding the Upstream and Downstream Industry Chains for Biochar Pyrolysis Equipment

The biochar pyrolysis equipment market is complex. It involves various stakeholders, including raw material providers, equipment manufacturers, and end-users. This industry chain relies on networks of production and innovation.

Upstream: Securing Quality Raw Materials

The upstream segment focuses on sourcing the right raw materials required for biochar production. These raw materials include:

- Agricultural waste residues

- Wood biomass materials

- Animal manure

- Forest management byproducts

By ensuring a steady supply of high-quality feedstock, upstream providers play a crucial role in determining the quality of biochar produced.

Downstream: Diverse Applications of Biochar Pyrolysis Equipment

The downstream segment showcases the versatility of biochar pyrolysis equipment and its wide-ranging applications. Some key areas where biochar is utilized include:

- Sustainable agricultural soil improvement

- Renewable energy production

- Environmental cleanup

- Waste management

These applications demonstrate how biochar can contribute to sustainable practices in agriculture, energy production, environmental remediation, and waste management.

Market Landscape: Key Players in the Biochar Pyrolysis Equipment Industry

The biochar pyrolysis equipment market consists of a mix of large and small players. This diversity is particularly evident in regions such as North America and Europe.

| Industry Segment | Key Characteristics | Market Impact |

| Upstream Providers | Raw material suppliers | Feedstock quality determination |

| Equipment Manufacturers | Technology developers | Innovation and scalability |

| End-User Sectors | Agriculture, energy, waste management | Market demand generation |

Advancements in technology and the adoption of environmentally friendly practices are reshaping the biochar pyrolysis equipment industry. These changes foster better collaboration between the upstream and downstream segments, leading to improved efficiency and effectiveness in the overall supply chain.

Key Trends Driving the Biochar Pyrolysis Equipment Market: Soil Enhancement and Carbon Sequestration

The biochar pyrolysis equipment market is growing fast. This is thanks to new ways of farming and caring for the environment. Farmers are now using sustainable methods to manage their soil and grow crops.

Biochar is a game-changer for soil. It’s full of carbon and makes soil better in many ways. It helps soil hold water, absorb nutrients, and even supports good bacteria.

- Increases soil water retention capacity

- Enhances nutrient absorption for crops

- Creates microhabitat for beneficial soil microorganisms

- Reduces dependency on chemical fertilizers

The Rise of Sustainable Agriculture Practices

Farmers are turning to biochar as a green solution. It makes soil better and helps crops grow well. This also means they use less chemicals.

| Biochar Benefit Agricultural Impact Soil Structure Enhancement | Improved root development |

| Nutrient Retention | Reduced fertilizer requirements |

| Microbial Activity | Enhanced soil ecosystem health |

Increasing Focus on Climate Change Mitigation

Biochar is seen as a way to fight climate change. The market is getting more money because people see its value. It helps keep carbon out of the air and makes farming better.

By turning waste into a soil booster, biochar equipment helps the planet and feeds people. It’s a win-win for our environment and food supply.

Challenges in Biochar Pyrolysis Equipment: Cost, Scalability, and Market Awareness

The biochar pyrolysis equipment market has big hurdles to overcome. High costs are a major problem for makers and investors. It takes a lot of money to build advanced pyrolysis systems.

Scalability is another big issue. It’s hard to make equipment that works well for both small and big biochar production. This makes it tough to use biochar widely in farming and industry.

Cost Challenges

- Initial equipment costs range from $50,000 to $500,000

- Limited production capacity for smaller agricultural operations

- Complex technological requirements

Not enough people know about biochar and pyrolysis equipment. This lack of knowledge stops more people from using biochar. It also slows down new technology.

| Challenge Category | Primary Barriers | Potential Solutions |

| Cost Challenges | High initial investment | Government subsidies, venture capital |

| Scalability Issues | Limited production flexibility | Modular equipment design |

| Market Awareness | Limited industry knowledge | Educational programs, demonstration projects |

Fixing these problems needs work from everyone. Manufacturers, researchers, and policymakers must team up. They should aim to make biochar pyrolysis tech more affordable and effective.

Geopolitical Influence on the Biochar Pyrolysis Equipment Market

The biochar pyrolysis equipment market is changing a lot because of complex global politics. Trade rules and government actions are changing how the industry works worldwide. This brings both problems and chances for those in the market.

Important global factors affecting the market include:

- Environmental rules from the EU Commission and US Environmental Protection Agency

- Working together on technology across borders

- National plans for being more sustainable

- Programs for carbon credits

Countries like Canada, Australia, and India are becoming key players in biochar tech. Their forward-thinking policies help create good conditions for new ideas and using pyrolysis equipment.

Trade deals are helping the market grow fast. Rules that encourage green farming are leading to more money in biochar pyrolysis tech in various places.

Partnerships between research groups, government bodies, and companies are key to moving biochar tech forward. These teams are important for solving tech hurdles and growing production.

Types of Biochar Pyrolysis Equipment: Batch, Continuous, and Mobile Systems

The biochar pyrolysis equipment market has many solutions for different needs. Each system has special features for turning biomass into biochar. They meet various scales and needs.

Specialized pyrolysis technologies help turn organic waste into sustainable resources. They use innovative equipment designs.

Batch Pyrolysis Systems: Small-Scale Flexibility

Batch pyrolysis systems are great for small farms and research. They process materials in batches. This allows for precise control over the conversion.

- Ideal for experimental research

- Lower initial investment costs

- Suitable for diverse feedstock types

- Enhanced quality control

Continuous Pyrolysis Systems: Large-Scale Efficiency

Continuous pyrolysis systems are for big-scale biochar production. They process organic materials without stopping. This means higher volumes.

- Consistent biochar quality

- Higher processing volumes

- Reduced labor requirements

- Streamlined operational workflow

Mobile Pyrolysis Units: Decentralized Production

Mobile pyrolysis units change biochar production by taking it to biomass sources. They are flexible for on-site conversion.

| Equipment Type | Processing Capacity | Primary Applications |

| Batch Pyrolysis | 50-500 kg/batch | Research, Small Farms |

| Continuous Pyrolysis | 1-10 tons/hour | Industrial Agriculture |

| Mobile Pyrolysis Units | 100-1000 kg/day | Remote Locations, Waste Management |

Each pyrolysis equipment type has its own benefits for sustainable biomass conversion. They support various environmental and agricultural goals.

Applications of Biochar Pyrolysis Equipment in Agriculture, Waste Management, and Renewable Energy

Biochar pyrolysis equipment is changing the game in many fields. It offers new ways to improve agriculture, manage waste, and produce clean energy. This technology is key to solving big environmental problems and making our tech more sustainable.

Agriculture: Improving Soil and Crop Health

In farming, biochar is a game-changer. It helps make soil better and crops grow stronger. Farmers use it to:

- Make soil richer in nutrients

- Keep water in the soil longer

- Use less fertilizer

- Help plants grow faster and stronger

Waste Management: Turning Waste into Value

For waste management, biochar pyrolysis is a big help. It turns waste into something valuable. By turning farm waste and plants into biochar, it cuts down on landfill waste and creates something useful.

Renewable Energy: Creating a Sustainable Loop

Renewable energy also gets a boost from biochar pyrolysis. These systems make energy while they work, creating a loop that uses resources wisely. The benefits are clear:

- It makes energy while it works

- It helps lock carbon away

- It cuts down on harmful emissions

- It makes clean energy

The Growing Market for Biochar Pyrolysis

New uses for biochar are popping up all the time. It’s being used to clean up pollution, make water safer, and even in building materials. The market for biochar pyrolysis is growing fast, showing it’s a big player in solving global problems.

Global Insights into the Biochar Pyrolysis Equipment Market

The global market for biochar pyrolysis equipment is changing fast. This is because of the high demand for organic food and meat.

Different places have their own market trends. What drives growth varies by region. Key factors include:

- Stringent environmental regulations

- Progressive agricultural policies

- Renewable energy initiatives

- Growing sustainability awareness

Experts predict the market will grow a lot. Technological advancements and more people caring about the environment are helping. This growth is happening in many places.

Investors and stakeholders should watch these trends closely. The biochar pyrolysis equipment market has a lot of potential for growth.

Canada's Leadership in Biochar Pyrolysis Research and Commercial Adoption

The Canadian biochar industry is a global leader in pyrolysis research and use. Pioneering work by research groups and companies has made Canada a top player in green carbon capture tech.

Important steps in the Canadian biochar scene include:

- Big investments in top-notch research projects

- Team-ups between universities and business partners

- Latest biomass conversion tech

A group of companies, like Airex Energy, Groupe Rémabec, and SUEZ, started building North America’s biggest biochar factory. This big move shows Canada’s strong support for green farming and the environment.

Canadian scientists are tackling big challenges head-on. They’re making new pyrolysis gear that turns more biomass into biochar and hurts the planet less. Schools across Canada are looking into using biochar in ways beyond farming, like in waste management and green energy.

Canada’s mix of lots of biomass, green policies, and tech know-how makes it a world leader in biochar pyrolysis. Scientists are always finding new ways to improve carbon capture and use resources better.

Australia's Growing Need for Biochar in Eco-Friendly Farming and Carbon Credits

The Australian biochar market is expanding rapidly, thanks to innovative farming methods. Farmers are discovering how biochar can address significant environmental issues. Studies indicate that biochar has the potential to improve soil health and enhance carbon sequestration.

Why Biochar is Beneficial for Australian Agriculture

There are several advantages of incorporating biochar into farming practices in Australia:

- It helps retain moisture in the soil

- It increases nutrient availability

- It reduces emissions of harmful gases

- It supports initiatives that generate carbon credits

Carbon credit programs are encouraging farmers to adopt biochar on a larger scale. Regions severely affected by drought and soil degradation are particularly interested. Western Australia and New South Wales are at the forefront of implementing biochar solutions tailored to their specific requirements.

Collaborations for Efficient Biochar Production

Researchers are joining forces with manufacturers of pyrolysis equipment to produce biochar more effectively. These collaborations contribute to the growth of sustainable agriculture and bolster efforts to combat climate change.

India's Growth in Biochar Pyrolysis Equipment for Rural and Industrial Use

The Indian biochar industry is growing fast, thanks to new ways to make farming more sustainable and manage waste better. Research shows a big chance for biochar pyrolysis to change how we handle crop waste and improve soil.

Key Developments in the Indian Biochar Sector

Important changes in the Indian biochar field include:

- Targeted solutions for crop residue management

- Sustainable waste conversion technologies

- Enhanced soil fertility techniques

- Climate-smart agricultural practices

Increasing Adoption of Pyrolysis Equipment

More companies are using pyrolysis equipment in different fields. Small farms are doing well by turning waste into biochar. These local efforts help the environment and create jobs for farmers.

Using better pyrolysis equipment helps manage waste better. Farms are seeing the good it does for the planet and their pockets by making biochar.

Government Support and Scientific Advancements

The government is helping the biochar industry grow with money and rules. Scientists are working on new pyrolysis tech to make better biochar from waste. This opens up new ways for rural areas to make money.

The Future of Biochar Pyrolysis Equipment: Advanced Gasification and Energy Recovery Technologies

The world of biochar pyrolysis equipment is changing fast. New technologies in advanced gasification and energy recovery are leading the way. These innovations are making biomass conversion more efficient and eco-friendly.

How Advanced Gasification is Improving Biochar Production

Advanced gasification is making biochar production better than ever. It brings new efficiency and environmental gains. The focus is on several key areas:

- Improved process control mechanisms

- Enhanced energy recovery techniques

- Precision monitoring of pyrolysis parameters

- Integration with renewable energy systems

The Role of Energy Recovery in Biomass Conversion

Energy recovery tech is getting smarter. Now, syngas and bio-oil can be used in many ways. This makes the most of what’s produced during pyrolysis.

The Impact of AI and Machine Learning on Gasification Technology

Artificial intelligence and machine learning are key in gasification tech. They help make biochar production smarter. This means more energy saved and less waste.

Competitive Landscape in the Biochar Pyrolysis Equipment Market

The biochar pyrolysis equipment market is very competitive. This is because of the innovative strategies used by key players. They are trying to get ahead by using advanced growth plans.

Key Players:

- Beston Group — China

- FEECO International — USA

- Henan Olten Environmental Sci-Tech Co., Ltd. — China

- Biogreen Energy — Taiwan

- PYREG GmbH — Germany

- ARTI — India

- New England Biochar LLC — USA

- Zhengzhou Dingli New Energy Technology Co., Ltd. — China

- Gongyi Beidou Machinery Technology Co., Ltd. — China

- Kingtiger Environmental Technology Co., Ltd. — China

Big companies are buying up smaller tech firms. This helps them grow their product range and improve their tech. They can offer better solutions for farming and the environment.

Companies are spending a lot on research to be unique. Small and medium-sized enterprises are also important. They bring new ideas that shake up the market.

The fight for market share is fierce in places like North America, Europe, and Asia-Pacific. These areas are seeing more investment in green tech. Companies that show they are efficient, good for the planet, and cost-effective will likely win more customers.

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Biochar Pyrolysis Equipment Market Report |

| Base Year | 2024 |

| Segment by Type |

· Continuous Pyrolysis · Batch Pyrolysis · Mobile Pyrolysis Units |

| Segment by Application |

· Agriculture · Waste Management · Renewable Energy · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The biochar pyrolysis equipment market is at an important stage. It combines environmental innovation with sustainable technology. The market size is expected to reach USD 64.3 million in 2025, growing at 13.9% annually. This shows great potential for investors and those focused on the environment.

Investment opportunities look promising in agriculture, waste management, and renewable energy. Countries like Canada, Australia, and India are leading in tech advancements. They demonstrate how biochar pyrolysis equipment can address climate issues.

This technology’s main goal is to help the planet. It helps store carbon, improves soil quality, and provides new energy solutions. It’s a key tool in combating environmental damage. But, we need more investment and research to overcome cost and scale challenges.

As the market expands, we must remain adaptable and forward-thinking. The combination of new technology, environmental requirements, and economic opportunities makes biochar pyrolysis equipment essential. It will play a significant role in sustainable development worldwide.

Global Biochar Pyrolysis Equipment Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Biochar Pyrolysis Equipment Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Biochar Pyrolysis EquipmentMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Biochar Pyrolysis Equipmentplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Biochar Pyrolysis Equipment Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Biochar Pyrolysis Equipment Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Biochar Pyrolysis Equipment Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofBiochar Pyrolysis EquipmentMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is biochar pyrolysis equipment?

Biochar pyrolysis equipment is specialized machinery that converts organic biomass into biochar through a process called pyrolysis. This process involves subjecting the biomass to high temperatures in the absence of oxygen, which prevents combustion and allows for the production of biochar.

The equipment is designed to handle various types of organic materials, including:

- Farm waste

- Wood

- Animal manure

By using biochar pyrolysis equipment, you can efficiently transform these materials into a valuable end product – biochar. Biochar is a carbon-rich substance that has multiple applications, such as improving soil fertility, sequestering carbon, and serving as a renewable energy source.

How does biochar benefit agriculture?

Biochar improves soil health by:

- Retaining moisture

- Making nutrients accessible

- Supporting beneficial microbes

These benefits lead to:

- Increased crop growth

- Reduced soil acidity

- Enhanced soil structure

Additionally, biochar plays a role in carbon sequestration, which helps mitigate greenhouse gas emissions and promotes sustainable farming practices.

What are the primary types of biochar pyrolysis systems?

There are mainly three types of biochar pyrolysis equipment:

- Batch systems: Good for small-scale use.

- Continuous systems: Better for big production.

- Mobile units: Offer flexibility for making biochar on-site.

Each has its own benefits based on the needs and scale of use.

Which countries are leading in biochar pyrolysis technology?

Canada, Australia, and India are at the forefront of biochar technology. They invest in research, develop new equipment, and implement policies that promote the use of biochar in agriculture, waste management, and energy production.

What challenges does the biochar pyrolysis equipment market face?

The market faces high costs, scaling issues, low awareness, and complex rules. To overcome these challenges, we need new technology, education, and government support to encourage biochar use.

How does biochar contribute to climate change mitigation?

Biochar helps fight climate change by storing carbon. When organic materials turn into biochar, they keep carbon out of the air. This cuts down on greenhouse gases and supports carbon storage.

Which industries can benefit from biochar pyrolysis equipment?

Several industries can benefit from using biochar pyrolysis equipment, including:

- Agriculture

- Waste management

- Energy production

- Construction

- Water treatment

- Environmental remediation

The versatility of biochar makes it an essential tool for promoting sustainability across various sectors.

What is the projected market growth for biochar pyrolysis equipment?

The market for biochar pyrolysis equipment is expected to grow to $64.3 million by 2025. This growth comes from more demand for green farming, waste solutions, and energy. Environmental awareness and government support will help it grow faster.