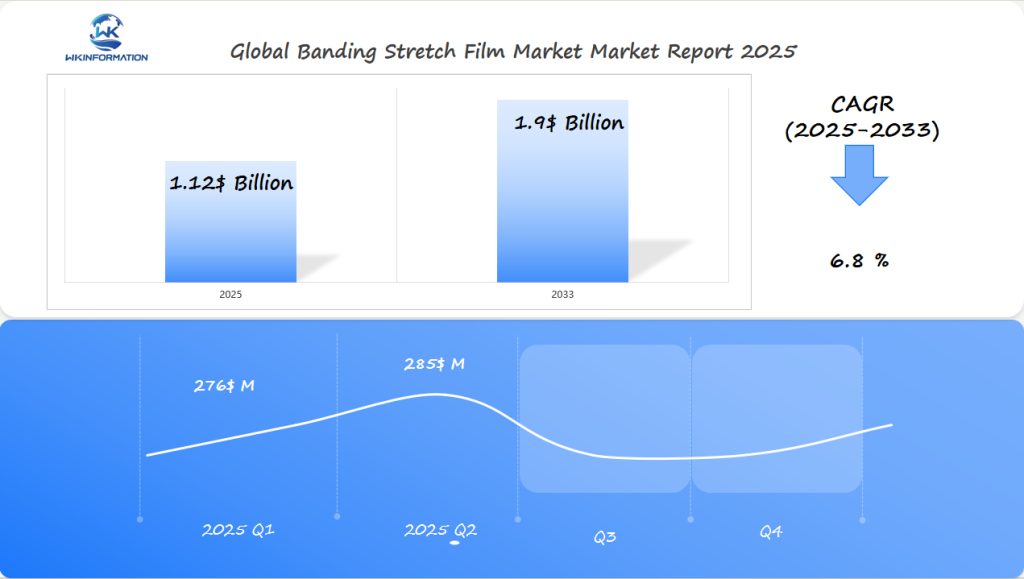

Banding Stretch Film Market to Exceed $1.12 Billion by 2025: Key Markets in the U.S., China, and India

Explore the Banding Stretch Film Market growth trends, driven by e-commerce packaging demands and industrial applications. Get insights on regional expansion and key players.

- Last Updated:

Banding Stretch Film Market Maintains Solid Momentum in Q1 and Q2 2025

The global Banding Stretch Film market is set to hit $1.12 billion in 2025, registering a CAGR of 6.8% from 2025 to 2033. Estimated revenue for Q1 2025 was around $276 million, climbing to $285 million in Q2, backed by growing logistics, e-commerce packaging needs, and industrial pallet wrapping.

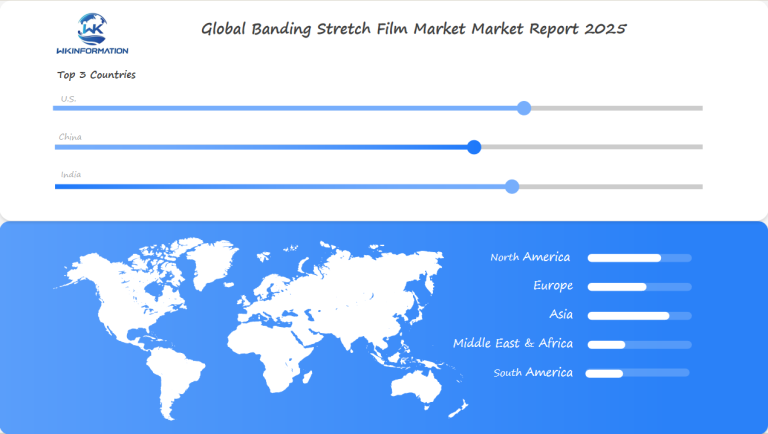

In the U.S., sustainability-focused manufacturers increased Q1 procurement of recyclable film rolls to meet green packaging standards. China maintained its lead as a production hub, with high output volumes supporting both domestic distribution and export logistics. India is emerging as a fast-growing consumer in Q2, as retail distribution chains and consumer goods sectors expand in urban and tier-2 cities.

Key Takeaways

- Projected market value of $1.12 billion by 2025

- Strong growth in U.S., China, and India markets

- Increased demand from e-commerce and logistics sectors

- Technological innovations driving market expansion

- Significant investment in packaging solutions

Banding Stretch Film market upstream and downstream industry chain analysis

The banding stretch film market has a complex supply chain. It connects raw materials suppliers to end-users in many industries. Knowing this network helps improve how products are made and delivered.

Upstream: Key Raw Materials for Banding Stretch Film

The upstream part of the chain deals with key raw materials for making banding stretch film. These include:

- High-density polyethylene (HDPE)

- Linear low-density polyethylene (LLDPE)

- Specialized polymer additives

- Chemical stabilizers

Raw materials suppliers are vital for the quality and performance of banding stretch film. Their work leads to new technologies in film making.

| Supply Chain Stage | Key Players | Primary Functions |

| Upstream | Polymer Manufacturers | Raw Material Production |

| Midstream | Film Manufacturers | Film Processing and Manufacturing |

| Downstream | Distributors and End-Users | Product Distribution and Application |

Downstream: Users of Banding Stretch Film

The downstream part includes distributors and end-users who use banding stretch film. They use it for packaging, logistics, and in industries. Key users are in warehousing, shipping, manufacturing, and online stores.

Partnerships between raw materials suppliers and end-users make the supply chain strong. These partnerships lead to better products, innovation, and fast responses to market needs.

Trends in Banding Stretch Film for Packaging and Logistics in 2025

The packaging trends for banding stretch film are changing fast. This is thanks to new technologies and what the industry needs. By 2025, makers aim to create better, greener solutions for tough logistics problems.

Logistics innovations affecting the banding stretch film market:

- Ultra-thin film technologies with enhanced strength

- Recyclable and biodegradable material compositions

- Smart packaging solutions with embedded tracking capabilities

- Automated application systems for increased efficiency

The market forecast shows big growth in special stretch film uses. Companies are making films that can handle extreme temperatures and keep loads stable.

New packaging trends mean more focus on precision. Stretch films are getting thinner but stronger. This cuts down on material use while keeping up with tough logistics needs.

Sustainability is key, with companies working on stretch films that are good for the planet. They want to reduce environmental harm without losing performance.

Challenges in the Production and Distribution of Banding Stretch Film

The banding stretch film industry faces many challenges. These issues affect manufacturers and distributors all over the world. One big problem is the changing prices of raw materials. This makes it hard for companies to keep their prices steady and make a profit.

Production Challenges

Some of the main production challenges are:

- Fluctuating petroleum-based raw material costs

- Limited manufacturing capacity

- Technological infrastructure constraints

- Energy efficiency requirements

Distribution problems also make things harder for the industry. Companies have to deal with complex shipping routes, managing inventory, and high quality standards.

| Challenge Category | Impact Level | Potential Mitigation Strategy |

| Raw Material Pricing | High | Long-term supply contracts |

| Production Capacity | Medium | Technology upgrades |

| Shipping Logistics | High | Optimization of transportation routes |

Industry hurdles need creative solutions. Companies are working on new ways to make production more efficient. They are also looking for different raw materials.

Strategic adaptation remains crucial for companies seeking to overcome these multifaceted challenges in the banding stretch film market.

Geopolitical Factors Influencing the Banding Stretch Film Market

The banding stretch film market is greatly affected by complex global politics. Rules and trade policies from around the world change how the industry works. This creates both problems and chances for those who make and sell these films.

Important global factors that affect the market include:

- Trade tariffs between big manufacturing countries

- Changes in diplomatic ties

- Local economic plans

- Risks of supply chain disruptions

Politics between the United States, China, and India really change how banding stretch film is made and sold. International rules on packaging and the environment are key to the market’s growth.

| Country | Geopolitical Impact | Market Influence |

| United States | Protective trade policies | More domestic production |

| China | Strategies focused on exports | Lower prices |

| India | Expanding manufacturing | Growing market |

Companies need to be smart about how they make and sell banding stretch film. Knowing about global trade is key to staying ahead in this market.

Type Segmentation: Machine-Wrapped vs. Hand-Wrapped Banding Stretch Film

The banding stretch film market has two main types: machine-wrapped and hand-wrapped film. Each type meets different needs in industries, with its own features and uses.

1. Machine-Wrapped Film

Machine-wrapped film is a fast and efficient way to package goods in big factories and warehouses. It wraps items consistently with little human help. Its main benefits are:

- Precise tension control

- Higher packaging speed

- Reduced labor costs

- Enhanced load stability

2. Hand-Wrapped Film

Hand-wrapped film is better for smaller businesses and special packaging needs. People can control the wrapping process, which is great for odd or fragile items. Hand-wrapped film’s key traits are:

- Greater manual control

- Adaptability to unique product shapes

- Lower initial equipment investment

- Suitable for small to medium batch sizes

More companies are choosing machine-wrapped film for automated packaging. New tech makes films better and more eco-friendly, meeting many industry needs.

Applications of Banding Stretch Film in Packaging, Distribution, and Logistics

Banding stretch film is key in today’s packaging world. It helps keep products safe during transport and storage. Its tight, stable bundles are vital for logistics.

Here are some main uses of banding stretch film:

- Pallet stabilization in warehouses

- Product bundling for retail and manufacturing

- Protecting fragile items during shipping

- Consolidating packages for efficient distribution

Specialized banding stretch films meet specific industry needs. Automotive, electronics, and pharmaceutical sectors benefit a lot. These films keep loads secure and cut down on waste.

Distribution uses go beyond basic packaging. Banding stretch film is now used for:

- Less shipping damage

- Better inventory management

- Improved product security

- Smarter warehouse operations

The flexibility of banding stretch film keeps packaging and logistics evolving. Its strong yet light design helps businesses save on supply chain costs.

Global Market Overview: Regional Growth and Demand for Banding Stretch Film

The global banding stretch film market is very diverse. Each region has its own growth patterns. Market research shows big differences in demand and market share across continents.

Regional Trends in Banding Stretch Film Market

Regional market performance shows different trends:

- Asia Pacific leads with the most substantial market share, driven by industrial expansion in India and Southeast Asian countries

- North America shows robust growth through increasing packaging and logistics applications

- European markets exhibit steady demand from commercial and industrial sectors

Factors Influencing the Competitive Landscape

The competitive landscape of banding stretch film is shaped by regional economic conditions, technological advancements, and sector-specific requirements. Emerging markets present significant opportunities for manufacturers seeking to expand their global footprint.

Importance of Strategic Investments

Strategic investments in production capabilities and innovative film technologies will be critical for companies aiming to capitalize on regional market growth. Understanding local market nuances becomes essential for businesses targeting international expansion in the banding stretch film industry.

U.S. Market Insights: Strong Demand for Banding Stretch Film in E-Commerce and Logistics

The U.S. market for banding stretch film has experienced significant growth due to the rapid rise of e-commerce and shifts in the logistics industry. The swift transition to digital shopping has led to an increased demand for improved packaging solutions across the board.

Several factors are driving the growth of the U.S. market:

- Online shopping is experiencing a surge

- There is a growing need for secure shipping methods

- There is a greater emphasis on sustainable packaging materials

- Logistics systems are becoming more efficient

To address these demands, companies are developing innovative banding stretch film technologies. Lightweight yet durable packaging is crucial for businesses aiming to reduce costs and minimize their environmental impact.

The U.S. logistics sector is also advocating for greater adoption of banding stretch film. Businesses are investing in cutting-edge packaging technologies that ensure product safety, reduce waste, and streamline shipping processes.

Market research indicates substantial potential for growth, particularly in e-commerce packaging. Companies are planning to allocate more resources towards research and development, which will likely result in further advancements in banding stretch film technology.

China's Production and Export Growth of Banding Stretch Film

Chinese manufacturers are leading the global banding stretch film market. They show great production capacity and export trends. Their strategic approach makes them a major force in packaging.

Their growth comes from several key factors:

- Strong government support for industry growth

- Low production costs

- Latest manufacturing technologies

- Wide supply chain networks

Export trends show a big jump in international markets. Chinese banding stretch film makers use cost-effective manufacturing to enter global markets. Their production has grown by 15-20% each year for the last five years.

Key areas boosting China’s exports are:

- Southeast Asia

- The European Union

- North America’s packaging industry

- The Middle East’s logistics sector

Technology is key to China’s success. Manufacturers keep investing in R&D. They create top-notch banding stretch film that meets global standards.

Chinese manufacturers are set for more growth in the global banding stretch film market. They are expected to keep growing and expanding in the coming years.

India's Expanding Manufacturing and Packaging Sectors Driving Banding Stretch Film Adoption

The demand for banding stretch film in India is growing fast. This is thanks to quick industrial growth and more people wanting products. India is becoming a leader in new packaging ideas.

What’s driving this growth?

- Fast economic growth

- More online shopping

- Bigger manufacturing

- More focus on exports

The manufacturing sector is key in improving banding stretch film technology. New industrial areas in big cities offer chances for new packaging ideas. Small and medium businesses are using better packaging to protect products and make shipping smoother.

Investments in infrastructure are helping the packaging industry grow. Programs like ‘Make in India’ push for more local production and better stretch film technology. This creates a strong base for using banding stretch film in many industries.

But, there are still challenges. Like making sure products meet quality standards and keeping up with new tech. Yet, India’s packaging market is still attracting a lot of investment and new ideas.

Future Development: Sustainability and Technological Advancements in Banding Stretch Film

The banding stretch film industry is changing fast. It’s moving towards sustainable materials and new technologies. Companies are focusing on eco-friendly options that don’t harm the environment but still pack well.

Some big changes coming to banding stretch film include:

- Advanced biodegradable film compositions

- Recyclable packaging technologies

- Smart packaging integration with tracking capabilities

- Reduced carbon footprint manufacturing processes

New technologies are changing what these films are made of. Scientists are working on films that are stronger and use less plastic. Sustainable materials are now being used, like plant-based polymers and recycled content. This makes packaging better for the planet.

| Innovation Category | Key Developments | Potential Impact |

| Biodegradable Films | Plant-based polymer integration | 50% reduced environmental footprint |

| Smart Packaging | Digital tracking capabilities | Improved logistics efficiency |

| Recycling Technologies | Advanced material recovery | Circular economy support |

The banding stretch film market is set for big changes. It’s moving towards greener packaging that’s good for the planet and still works well. This shift is all about finding a balance between being eco-friendly and keeping things efficient.

Competitive Landscape: Key Players in the Banding Stretch Film Market

The banding stretch film market is full of life, with many big names leading the way. These leaders are making big moves by investing in new tech and innovation. They aim to grow the market and stay ahead.

Key Players:

-

International Plastics Inc — USA

-

U.S. Packaging & Wrapping LLC — USA

-

Trans-Consolidated Distributors — USA

-

Tilak Polypack Private Ltd. — India

-

Intertape Polymer Group — Canada

-

Best Packaging — USA

-

BGR Packing Supply Chain Experts — USA

-

Sigma Supply of North America — USA

-

COMPACK — India

-

Chu’s Packaging Supplies — USA

These companies are using smart strategies to keep their lead:

- Product Innovation: They’re creating stretch films that are better for the planet and work really well.

- Geographic Expansion: They’re moving into new markets where there’s a big need for packaging.

- Strategic Partnerships: They’re teaming up with companies that handle logistics and packaging.

- Research Investment: They’re putting money into research to improve their materials and how they make things.

Market leaders are focusing a lot on green packaging. They know people care more about the environment. So, they’re working on making packaging that’s better for the planet without losing quality.

New companies are coming in and shaking things up. They’re making special stretch films for certain industries. This is changing the game and pushing the market to get better.

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Banding Stretch Film Market Report |

| Base Year | 2024 |

| Segment by Type |

· Machine-Wrapped Banding Stretch Film · Hand-Wrapped Banding Stretch Film |

| Segment by Application |

· Packaging · Distribution · Logistics · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The banding stretch film market is growing fast, offering great chances for investors and businesses. Forecasts show it will expand a lot, thanks to more demand in packaging, logistics, and online shopping. Investing in green tech and better production methods is key to success.

New tech is changing the banding stretch film world. Companies that make eco-friendly products and use new ways to make them will stand out. The market is expected to hit over $1.12 billion by 2025, with big growth in machine and hand-wrapped films.

Investing in places with growing factories and distribution is a good idea. The U.S. market is strong because of online shopping, while China and India are full of potential. Look for companies that care about the environment, innovate, and can change their production easily.

Global Banding Stretch Film Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Banding Stretch Film Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Banding Stretch Film Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Banding Stretch Film Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Banding Stretch Film Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Banding Stretch Film Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Banding Stretch Film Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Banding Stretch Film Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market size for banding stretch film by 2025?

The banding stretch film market is expected to hit $1.12 billion by 2025. This growth is driven by increasing demand in e-commerce, logistics, and industrial packaging. Major markets such as the United States, China, and India are leading this trend.

What are the primary applications of banding stretch film?

Banding stretch film is mainly used for securing pallets and bundling products. It also protects goods during transit. This film is vital for keeping products safe and making shipping smoother.

What types of banding stretch film are available?

There are two main types: machine-wrapped and hand-wrapped. Each has its own benefits and is suited for different uses. Advances in technology are making these films more efficient and effective.

How are geopolitical factors impacting the banding stretch film market?

Trade policies, tariffs, and international rules are significant factors in the market. The relationships between major markets like the U.S., China, and India influence the production and use of banding stretch film globally.

What challenges do manufacturers face in the banding stretch film industry?

Manufacturers deal with price changes in raw materials, limited production capacity, and complex logistics. These issues can slow growth, so companies are looking for new ways to adapt and innovate.

Which regions are driving growth in the banding stretch film market?

The U.S., China, and India are leading the way in growth. Their expansion is driven by e-commerce growth, industrial development, and increased packaging needs.

What emerging trends are shaping the banding stretch film industry?

New trends include better film technology and a focus on sustainability. Innovations aim to make packaging more efficient and eco-friendly.

How is the supply chain structured for banding stretch film?

The supply chain includes raw material suppliers, manufacturers, distributors, and end-users. Each part plays a role in shaping the market and industry.

What role is sustainability playing in banding stretch film development?

Sustainability is key, with a focus on eco-friendly materials and recycling. Manufacturers are working on smart packaging that’s good for the environment and keeps products safe.

How is technology influencing banding stretch film production?

Technology is making films stronger, thinner, and more versatile. These advancements help create better products that are more efficient and adaptable.