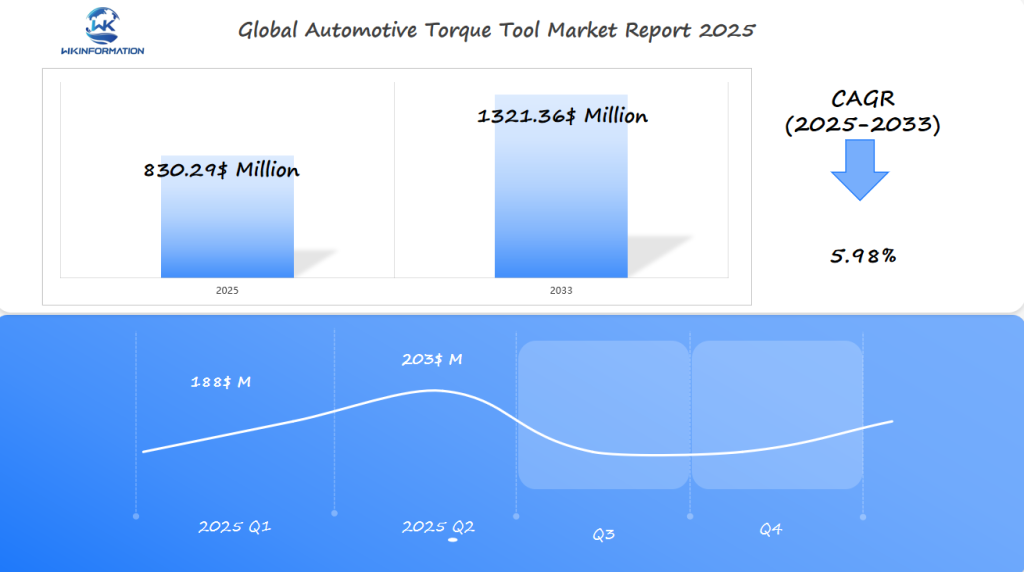

Automotive Torque Tool Market Projected to Reach $830.29 Million Globally by 2025 as Precision Engineering Expands in Germany, the U.S., and South Korea

Automotive Torque Tool Market projected to reach $830.29 million globally by 2025 as precision engineering boosts demand.

- Last Updated:

Automotive Torque Tool Market Dynamics and Q1 and Q2 of 2025 Forecast

The Automotive Torque Tool market is estimated to reach $830.29 million in 2025, registering a CAGR of 5.98% through 2033. Q1 revenues are projected at $188 million, increasing to roughly $203 million in Q2, supported by heightened vehicle production and aftermarket demand.

Leading Markets

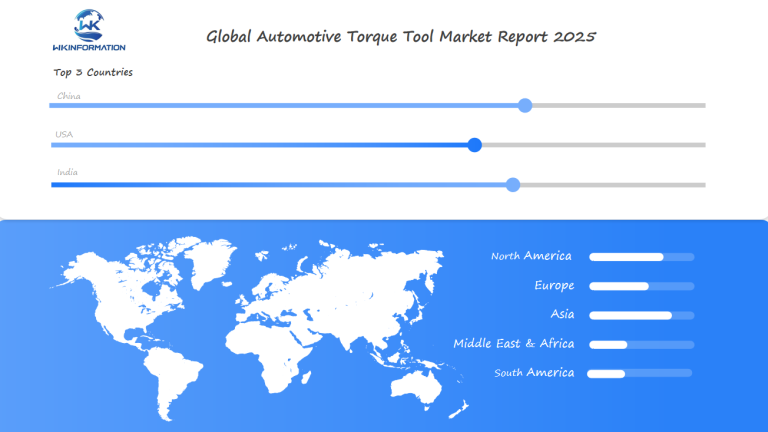

Germany, the U.S., and South Korea are leading markets, driven by automotive manufacturing clusters and investments in automated assembly lines.

High Demand for Digital Torque Tools

Digital torque tools with data logging and precision calibration are in high demand, especially among OEMs.

Impact of Electric Vehicle (EV) Production

The push for electric vehicle (EV) production is also encouraging the adoption of torque tools tailored for lighter, high-precision assembly tasks.

Regulatory Requirements Driving Investment

Additionally, regulatory requirements on torque accuracy and workplace safety are pushing manufacturers to invest in higher-end, compliance-ready torque solutions.

Understanding Supply Chain Dynamics in the Automotive Torque Tool Market

To fully understand the complexities of the automotive torque tool market, it’s essential to have a comprehensive view of the supply chain dynamics at play. The structure of this market is heavily influenced by the interactions between upstream component suppliers and downstream vehicle assembly lines.

Understanding the Supply Chain Dynamics

The automotive industry trends indicate a growing reliance on precision engineering, which in turn affects the demand for high-quality torque tools. Component suppliers are at the forefront of this trend, providing critical parts that meet the stringent requirements of vehicle manufacturers.

Role of Component Suppliers in the Automotive Torque Tool Market

Component suppliers play a vital role in the automotive torque tool market by ensuring the availability of high-precision parts. Their ability to meet the evolving needs of vehicle assembly lines directly impacts the efficiency and quality of the manufacturing process.

The collaboration between component suppliers and downstream vehicle assembly lines is essential for maintaining the high standards of the automotive industry. This synergy enables the development of innovative torque tools that cater to the increasingly complex requirements of modern vehicle manufacturing.

- Component suppliers provide high-quality parts.

- Downstream vehicle assembly lines rely on these parts for efficient manufacturing.

- The synergy between suppliers and assembly lines drives innovation in torque tools.

Emerging Trends in Digital Torque Control, Automation, and Safety Compliance

Digital torque control is transforming the automotive industry, bringing with it automation and improved safety compliance. The automotive sector is experiencing a significant shift towards digitalization, with a growing focus on precision and accuracy in torque measurement.

The integration of digital torque control systems is enhancing the efficiency and reliability of torque measurement tools. These systems allow for real-time monitoring and adjustments, ensuring that torque specifications are met with high precision.

Impact of Digitalization on Torque Control

Digitalization has a significant impact on torque control, bringing improvements in precision, reduction of human error, and enhancement of safety. Digital torque control systems come with advanced features like data logging and analysis, which enable better quality control and adherence to safety standards.

Role of Automation in Torque Control

Automation is a key factor in today’s torque control systems. It allows for the automated measurement and adjustment of torque, leading to:

- Increased efficiency

- Reduced chances of human error

- Improved overall safety

- Better compliance with regulations

Automation and Safety Compliance in the Automotive Industry

Automation and safety compliance are becoming more interconnected in the automotive industry. The implementation of automated torque control systems guarantees that torque specifications are consistently met, resulting in enhanced safety and decreased risk of mechanical failures.

| Feature | Digital Torque Control | Traditional Torque Control |

| Precision | High | Variable |

| Automation | Integrated | Limited |

| Safety Compliance | Enhanced | Basic |

The table above illustrates the benefits of digital torque control compared to traditional methods, especially regarding precision, automation, and safety compliance.

As the automotive industry continues to evolve, it is anticipated that the adoption of digital torque control and automation will increase. This growth will be driven by the demand for improved precision, efficiency, and safety compliance.

Limitations Related to Calibration, Cost Efficiency, and Tool Durability Standards

The automotive torque tool market faces several challenges, including calibration issues and cost inefficiencies. As the industry continues to evolve, manufacturers and users alike must navigate these limitations to ensure the effective use of torque tools. These challenges are often visually represented in graphs and charts, such as this one illustrating some of the calibration-related issues. Additionally, the need for cost efficiency is paramount, as shown in this chart, which outlines some of the cost-related challenges faced by the industry.

Challenges in Calibration and Cost Efficiency

Calibration is a critical aspect of maintaining the accuracy and reliability of torque tools. However, the process can be complex and time-consuming, leading to increased costs. Cost efficiency is essential for manufacturers to remain competitive in the market. The challenge lies in balancing the need for precise calibration with the economic pressures of production.

To address these challenges, manufacturers are exploring innovative solutions, such as digital calibration tools and more efficient production processes. Advanced technologies are being integrated into torque tools to enhance their accuracy and reduce the need for frequent calibration.

Importance of Tool Durability Standards

Tool durability standards are vital to ensure that torque tools can withstand the demands of the automotive industry. Durable tools not only reduce the need for frequent replacements but also contribute to overall cost efficiency.

- High-quality materials and construction are essential for tool durability.

- Regular maintenance and proper usage can extend the lifespan of torque tools.

- Adherence to industry standards for tool durability is crucial for ensuring reliability and performance.

By focusing on calibration, cost efficiency, and tool durability, the automotive torque tool market can overcome its current limitations and continue to grow. As the industry moves forward, it is likely that we will see advancements in technology and manufacturing processes that address these challenges.

Geopolitical Factors Shaping Auto Production Hubs and Export Demand

1. Trade Policies and Tariffs

-

Example: The U.S.-China trade tensions led to tariff hikes on automotive imports and parts, prompting some automakers to shift production to neutral regions like Mexico or Southeast Asia to avoid penalties.

2. Regional Trade Agreements

-

Example: Agreements like the USMCA (United States-Mexico-Canada Agreement), EU–Japan EPA, and RCEP (Regional Comprehensive Economic Partnership) facilitate smoother cross-border trade, making some regions more attractive for auto production and export.

3. Sanctions and Export Controls

-

Example: Sanctions on Russia post-Ukraine conflict significantly disrupted parts supply chains and automotive exports to and from the country, leading companies to reroute sourcing and assembly operations.

4. Political Stability and Investment Climate

-

Countries with stable governments and pro-manufacturing policies (e.g., Germany, South Korea) are seen as reliable production bases. Political unrest (e.g., in parts of Africa or Latin America) deters investment and long-term production planning.

5. National Industrial Policies and Subsidies

-

China’s NEV (New Energy Vehicle) subsidies and U.S. Inflation Reduction Act (IRA) encourage EV manufacturing domestically, impacting global production distribution and shifting export competitiveness.

Segmentation by Tool Type Including Click, Dial, Digital, and Pneumatic

The automotive torque tool market is divided into different types of tools: click, dial, digital, and pneumatic. Each type has its own special features and uses. Knowing how much of the market each type holds is important for finding out which tools are most popular and what trends are happening in the market. The overall size of the torque tool market is affected by how much demand there is for these various types of tools.

Overview of Different Tool Types

The click type torque tools are widely used for their simplicity and ease of use. They provide a clear indication when the desired torque is reached, making them suitable for applications where precision is crucial.

Dial type torque tools offer a high level of accuracy and are often used in critical assembly operations. They allow for precise torque measurement and are favored in industries where high precision is required.

Digital torque tools are gaining popularity due to their advanced features, such as digital displays and data logging capabilities. They offer high accuracy and are used in various applications, from assembly to maintenance.

Pneumatic torque tools are known for their high torque output and are commonly used in heavy-duty applications. They are preferred in industries where high torque is required, such as in the assembly of large machinery.

Market Share of Each Tool Type

The market share of each tool type varies based on factors such as industry demand, application, and geographical region. Digital torque tools are experiencing significant growth due to their advanced features and accuracy.

- Click type tools hold a significant share due to their widespread use in various industries.

- Dial type tools are preferred in high-precision applications, contributing to their market share.

- Digital tools are gaining ground due to their technological advancements.

- Pneumatic tools maintain a strong presence in heavy-duty applications.

Understanding the market share of each tool type is crucial for manufacturers and suppliers to tailor their products and strategies to meet the specific needs of different industries and applications.

Application Usage in Assembly, Maintenance, and Engine Calibration

The automotive industry relies heavily on torque tools for various applications, including assembly, maintenance, and engine calibration. These tools are crucial for ensuring precision and efficiency in the manufacturing and repair processes.

Torque Tools in Assembly and Maintenance

In the automotive industry, torque tools are used extensively in assembly and maintenance tasks. They ensure that bolts and nuts are tightened to the correct specification, which is critical for safety and performance. Proper torque application prevents damage to components and ensures that vehicles operate as intended.

The use of torque tools in maintenance is equally important, as it helps technicians to accurately tighten parts during repairs. This not only enhances safety but also reduces the likelihood of costly rework due to improper tightening.

Role of Torque Tools in Engine Calibration

Engine calibration is another critical area where torque tools play a vital role. Torque tools are used to measure and adjust the engine’s performance, ensuring that it operates within specified parameters. This is crucial for achieving optimal engine performance, fuel efficiency, and emissions compliance.

In engine calibration, precise torque measurements are essential for adjusting components such as engine mounts, cylinder heads, and other critical parts. The accuracy provided by torque tools helps in fine-tuning the engine’s performance, thereby enhancing overall vehicle efficiency.

Global Distribution of Tool Usage Across OEMs and Repair Ecosystems

The global automotive torque tool market is significantly influenced by the distribution of tool usage across OEMs and repair ecosystems. Understanding this distribution, illustrated in the following image, is crucial for manufacturers and stakeholders to identify market trends and opportunities.

The insights gained from this data can help in strategizing product development and marketing efforts to align with the identified trends.

OEMs and Their Role in the Automotive Torque Tool Market

Original Equipment Manufacturers (OEMs) play a crucial role in driving the demand for torque tools. They require high-precision tools for assembly and testing, which contributes significantly to the market size. OEMs’ specifications and requirements often set the standard for the industry, influencing the type and quality of tools used.

The relationship between OEMs and torque tool manufacturers is critical. OEMs demand tools that meet specific standards, driving innovation and quality in the tools produced. This demand also affects the global distribution of these tools, as manufacturers strive to meet the needs of OEMs worldwide.

Repair Ecosystems and Their Impact on Tool Usage

Repair ecosystems, including independent repair shops and service centers, also significantly impact the torque tool market. These entities require a variety of tools for maintenance and repair, contributing to the overall demand. The diversity in repair ecosystems globally means that tool manufacturers must cater to a wide range of needs and standards.

The impact of repair ecosystems on tool usage is multifaceted. They not only drive demand but also influence the types of tools developed. For instance, the need for durable and versatile tools in repair shops can lead to innovations in tool design and functionality.

By understanding the dynamics between OEMs, repair ecosystems, and tool manufacturers, we can better grasp the global distribution of torque tool usage. This understanding is essential for stakeholders to navigate the complex landscape of the automotive torque tool market.

Germany’s Leadership in High-Precision Assembly and Tool Innovation

Germany’s automotive industry is known for its precise engineering, making it a leader in high-precision assembly and tool innovation. The country’s strong emphasis on quality and accuracy has led to improvements in torque tool technology, benefiting the worldwide automotive industry.

Overview of Germany’s Automotive Industry

The German automotive industry plays a crucial role in the country’s economy, with a strong focus on producing top-notch vehicles. This commitment to quality is reflected in the manufacturing process, where high-precision assembly tools are essential.

Key Factors Behind Germany’s Automotive Success

Several factors contribute to Germany’s success in the automotive industry:

- Advanced manufacturing technologies

- High-precision assembly tools

- Strong emphasis on quality and precision

- Innovation in tool technology

Innovation in High-Precision Assembly

Germany’s innovation in high-precision assembly is driven by the need for precision and reliability in vehicle manufacturing. This has led to the development of advanced torque tools that meet the stringent requirements of the automotive industry.

The use of advanced torque tools in German automotive manufacturing has resulted in improved efficiency and reduced production costs. This has also driven the adoption of similar technologies in other countries.

| Aspect | Traditional Assembly | High-Precision Assembly |

| Precision Level | Standard | High |

| Tool Technology | Basic | Advanced |

| Production Efficiency | Moderate | High |

As the automotive industry continues to evolve, Germany’s leadership in high-precision assembly and tool innovation is expected to drive further advancements in torque tool technology.

U.S. Market Demand Fueled by EV Assembly and Commercial Vehicle Maintenance

The increasing popularity of electric vehicles in the U.S. is driving up the demand for advanced torque tools, which are crucial for accurate assembly and maintenance. This shift is having a major effect on the automotive torque tool market, leading to growth and new developments.

Electric Vehicle Assembly and Its Impact on Torque Tool Demand

The shift towards electric vehicles (EVs) is transforming the automotive landscape. EV assembly requires specialized torque tools that can handle the unique demands of electric vehicle manufacturing, such as precision and reliability. As a result, the demand for advanced torque tools is on the rise.

Key Features of Torque Tools for EV Assembly:

- High precision and accuracy

- Advanced digital control systems

- Durability and reliability

The increasing production of electric vehicles is driving the demand for these specialized tools. Manufacturers are investing in advanced torque tool technology to meet the needs of the growing EV market.

Commercial Vehicle Maintenance and Its Role in the Market

Commercial vehicle maintenance is another significant factor driving the demand for torque tools in the U.S. market. Regular maintenance is crucial for ensuring the safety and efficiency of commercial vehicles, and torque tools play a vital role in this process.

| Application | Torque Tool Type | Benefits |

| Commercial Vehicle Maintenance | Pneumatic and Digital Torque Tools | Improved Efficiency, Reduced Downtime |

| EV Assembly | Advanced Digital Torque Tools | High Precision, Reliability |

The U.S. market demand for torque tools is expected to continue growing, driven by the ongoing shift towards electric vehicles and the need for efficient commercial vehicle maintenance. As the market evolves, manufacturers will need to innovate and adapt to meet the changing demands of the industry.

South Korea’s Integration of Smart Torque Systems in Robotics and Auto Plants

With the integration of smart torque systems, South Korea is setting new standards in the automotive industry, particularly in robotics and auto plants.

smart torque systems in South Korea

South Korea’s automotive industry is known for its innovative manufacturing processes. The adoption of smart torque systems is a significant step towards enhancing the efficiency and accuracy of torque measurement. These systems are revolutionizing how automotive assembly lines operate, providing precise torque control which is crucial for the assembly of various car components.

The implementation of these advanced technologies not only streamlines the production process but also significantly reduces the margin for error, ensuring that every vehicle produced meets the highest standards of quality and safety.

South Korea’s Automotive Industry Overview

The country’s focus on technological advancement is evident in its automotive manufacturing processes. Smart torque systems play a crucial role in this context.

Smart Torque Systems in Robotics and Auto Plants

The integration of smart torque systems in robotics and auto plants is improving manufacturing processes. Key benefits include:

- Enhanced Precision: Smart torque systems ensure that the torque applied is precise, reducing the risk of damage to components.

- Increased Efficiency: Automated torque measurement systems streamline the manufacturing process, reducing production time.

- Data Analysis: Smart torque systems provide valuable data that can be analyzed to optimize manufacturing processes further.

| Feature | Traditional Torque Systems | Smart Torque Systems |

| Precision | Manual calibration, prone to human error | Automated calibration, high precision |

| Efficiency | Time-consuming, labor-intensive | Streamlined process, reduced labor |

| Data Analysis | Limited data collection | Comprehensive data for analysis and optimization |

Future Developments in Wireless and Cloud-Enabled Torque Measurement

Future developments in torque measurement are being driven by advancements in wireless and cloud-enabled technologies. The automotive industry is witnessing a significant shift towards more efficient, accurate, and reliable torque measurement solutions.

Wireless Torque Measurement

Wireless torque measurement is changing how torque data is collected and analyzed. This technology does away with bulky cables, making it more flexible and reducing the chances of damage or interference. The use of wireless telemetry systems in this field is a prime example of this shift.

Benefits of Wireless Torque Measurement

- Increased flexibility: Wireless systems allow for easier installation and data collection in complex or hard-to-reach areas.

- Improved accuracy: By reducing the potential for cable-related interference, wireless torque measurement can provide more accurate data.

- Enhanced safety: Wireless systems can reduce the risk of accidents caused by cables or connectivity issues.

Cloud-enabled torque measurement takes data analysis and storage to the next level by using cloud computing. This allows for real-time data access, advanced analytics, and secure data storage.

Advantages of Cloud-Enabled Torque Measurement

- Real-time data access: Cloud connectivity enables users to access torque data in real-time, facilitating immediate decision-making.

- Advanced analytics: Cloud-based systems can apply sophisticated analytics to torque data, providing deeper insights into performance and potential issues.

- Secure data storage: Cloud storage ensures that critical torque data is securely backed up and protected against loss or corruption.

The combination of wireless and cloud-enabled technologies in torque measurement is expected to have a significant impact on the automotive torque tool market. As these technologies continue to develop, we can anticipate even more innovative uses and improvements in efficiency and accuracy.

Competitive Overview of Global and Niche Tool Manufacturers

The competitive dynamics of the automotive torque tool market are shaped by both global and niche tool manufacturers. This diverse landscape is characterized by a mix of large corporations with extensive resources and smaller, specialized firms that offer unique products or services.

- Norbar Torque Tools – United Kingdom

- Apex Tool Group – United States

- Ingersoll Rand – United States

- Sturtevant Richmont – United States

- Torque-Tech Precision – United States

- Adrec Corp. – United States

- Mountz Torque – United States

- TorcStark – China

- Trotec GmbH – Austria

- HYTORC – United States

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Automotive Torque Tool Report |

| Base Year | 2024 |

| Segment by Type |

· Click · Dial · Digital · Pneumatic |

| Segment by Application |

· Assembly · Maintenance · Engine Calibration |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Automotive Torque Tool Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Automotive Torque Tool Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Women’s ActivewearMarket Segmentation Overview

Chapter 2: Competitive Landscape

- GlobalAutomotive Torque Tool players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Automotive Torque Tool Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Automotive Torque Tool Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Automotive Torque Tool Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofWomen’s ActivewearMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is driving the growth of the automotive torque tool market?

The growth of the automotive torque tool market is driven by the increasing demand for precision engineering in the automotive industry, particularly in vehicle assembly and maintenance.

What are the emerging trends in the automotive torque tool market?

Emerging trends in the automotive torque tool market include digital torque control, automation, and safety compliance, which are improving the efficiency and accuracy of torque measurement.

What are the limitations related to calibration, cost efficiency, and tool durability standards?

Calibration is a critical aspect of torque tool maintenance, and cost efficiency is essential for manufacturers to remain competitive. Tool durability standards are also vital to ensure that torque tools can withstand the demands of the automotive industry.

What are the different types of torque tools used in the automotive industry?

The automotive industry uses various types of torque tools, including:

- Click torque wrenches

- Dial torque wrenches

- Digital torque wrenches

- Pneumatic torque tools

Each type has its unique characteristics and applications.

How are torque tools used in assembly, maintenance, and engine calibration?

Torque tools are used to ensure accurate tightening of bolts and nuts in assembly and maintenance, and to measure and adjust the engine’s performance in engine calibration.

The Role of OEMs and Repair Ecosystems in the Automotive Torque Tool Market

OEMs play a significant role in driving the demand for torque tools, while repair ecosystems also contribute to the market growth.

What is expected to shape the future of torque measurement?

The future of torque measurement is expected to be shaped by wireless and cloud-enabled technologies, which are improving data analysis and storage.

Who are the key players in the automotive torque tool market?

The automotive torque tool market is competitive, with both global and niche tool manufacturers operating in the market, including manufacturers of precision engineering tools and automotive assembly equipment.