Automotive Paint Robots Market Projected to Reach $3.52 Billion Globally by 2025: Precision Automation in Japan, Germany, and the U.S.

Explore the expanding Automotive Paint Robots Market as it drives innovation in automated painting solutions, enhancing efficiency and quality in vehicle manufacturing through 2025.

- Last Updated:

Automotive Paint Robots Market Outlook for Q1 and Q2 2025 Highlighting Top Markets

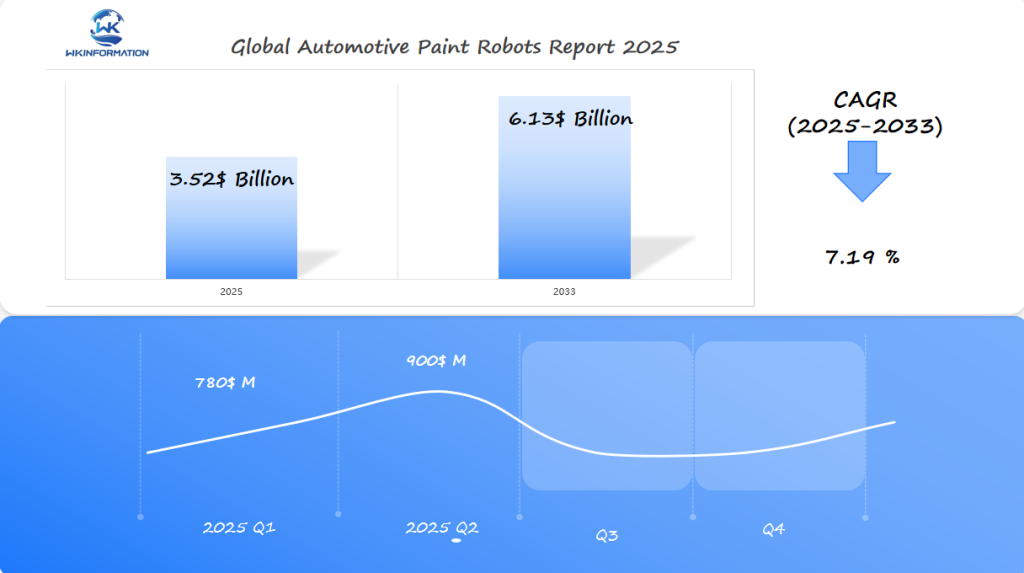

With a 2025 market size projected at $3.52 billion and a CAGR of 7.19%, Automotive Paint Robots continue to gain traction in automotive manufacturing. Q1 revenue is expected to reach around $780 million, supported by increased automation investments in vehicle assembly lines. Q2 sees further growth to $900 million, driven by demand for precision painting and efficiency improvements. Japan, Germany, and the U.S. dominate this market segment; Japan excels in robotics innovation, Germany leads in quality control, and the U.S. focuses on automation scalability.

Key Takeaways

- Automotive paint robots market projected to reach $3.52 billion by 2025

- Enhanced precision and efficiency in vehicle painting processes

- Reduced labor costs through advanced robotic automation

- Improved paint quality and consistency across manufacturing lines

- Growing technological investments in automotive manufacturing

Analyzing the upstream and downstream value chain of automotive paint robots

The automotive paint robot market is a complex web of players pushing tech forward. A value chain analysis shows how robot makers, car companies, and part suppliers work together. This teamwork shapes the industry’s direction.

Key players in the automotive paint robot value chain include:

- Robot manufacturers developing advanced painting technologies

- Automotive OEMs seeking precision painting solutions

- Component suppliers providing specialized equipment

- System integrators optimizing robotic painting processes

Upstream Activities: Focusing on Technology Development

The upstream part focuses on tech development. Robot makers spend a lot on research and engineering. They create advanced painting systems. These systems meet car companies’ needs for better efficiency, quality, and green practices.

| Value Chain Segment | Key Responsibilities | Technology Impact |

| Robot Manufacturers | Develop advanced robotic painting systems | High precision automation |

| Automotive OEMs | Implement painting technologies | Streamlined production processes |

| Component Suppliers | Provide specialized equipment | Enhanced system performance |

Downstream Activities: Implementing Technologies for Optimal Results

Downstream activities focus on putting these technologies to work. Car companies work with robot makers to add new painting tech to their lines. This ensures top quality and efficiency.

This teamwork creates a dynamic system. It pushes automotive paint robot tech to new heights of performance and complexity.

Emerging trends boosting automation and efficiency in vehicle painting

The automotive industry is undergoing significant transformations in paint efficiency due to the emergence of new automation trends. The introduction of Industry 4.0 technologies is revolutionizing the car painting process, making it more precise and productive.

Key advancements in automotive paint robotics

Several key advancements in automotive paint robotics are driving this change:

- Advanced artificial intelligence for checking paint quality in real-time

- Machine learning to improve how paint is applied

- Smart sensors for even coating thickness

- Predictive maintenance to cut down on equipment downtime

How robotic systems improve paint efficiency

Robotic systems utilize intelligent visual recognition to identify even the smallest imperfections. With these advanced capabilities, paint robots can make swift adjustments during the application process, resulting in reduced waste and increased paint efficiency.

The impact of Industry 4.0 on car manufacturing

The combination of Industry 4.0 principles and car manufacturing has given rise to smarter painting technologies. Now, every stage of the painting process can be monitored, analyzed, and enhanced through digital systems.

Benefits of new paint robot technologies

Recent developments in paint robot technologies are yielding significant benefits in various aspects:

- Enhanced color consistency and accuracy

- Reduction in material consumption

- Improved worker safety measures

- Decreased production timelines

As automobile manufacturers continue to invest in cutting-edge robotics, the outlook for car painting is becoming increasingly automated, efficient, and technologically advanced.

Regulatory and environmental restrictions affecting market growth

The automotive paint robots market is facing big challenges from strict environmental rules. Governments around the world are setting tough standards to cut down on harmful emissions in car making. These rules are changing how cars are painted.

Important rules are changing how the industry paints cars:

- Lower VOC emissions needed

- Tighter safety rules for workers

- More eco-friendly painting methods required

- Rules for using less energy

Companies are making advanced paint robots to lessen harm to the environment. Sustainable painting technologies use better filters and precise painting to cut down on waste and pollution.

The Environmental Protection Agency (EPA) has a big role in setting these standards. Car makers must buy the latest robotic systems to meet these strict rules.

These rules are actually pushing the market to get better. Companies are making more advanced robots. These robots not only follow the rules but also make painting cars better and faster.

Geopolitical factors shaping automotive manufacturing and robot supply

The automotive industry is seeing big changes in global trade. These changes come from complex political interactions. Manufacturers are now thinking differently about how they make things because of these shifts.

More companies are focusing on making things locally. This is because they want to avoid relying too much on imports. It’s a way to stay safe in uncertain times.

Trade policies reshaping automotive robot procurement

Trade policies are having a direct impact on how companies buy robotic equipment for their manufacturing processes. Tariffs and trade agreements can either encourage or discourage the importation of specific technologies, leading manufacturers to explore alternative sources or invest in local production capabilities.

Regional economic partnerships influence manufacturing decisions

Regional economic partnerships, such as free trade agreements between countries, play a significant role in shaping manufacturing decisions. These partnerships can create favorable conditions for companies operating within those regions, making it more attractive for them to source components or establish production facilities nearby.

Technological sovereignty becomes a key strategic consideration

As geopolitical tensions rise, there is an increasing emphasis on technological sovereignty among nations. Countries are recognizing the importance of developing their own advanced manufacturing capabilities and reducing dependence on foreign technologies. This shift in mindset is likely to impact global supply chains and drive investments in domestic robotics industries.

Important political factors affecting robot supply include:

- Tariff pressures making it harder to move equipment across borders

- Technological decoupling between major economic powers

- Strategic investments in domestic robotics capabilities

Companies are working on making their supply chains stronger. They need to be able to change quickly because of political changes. This means they have to manage risks well and be flexible.

Market Segmentation by Robot Type and Painting Technology

The automotive paint robots market is complex. It involves different robot types and painting technologies. Manufacturers focus on precise segmentation to meet various automotive production needs.

Robot Types

Robot types are key in defining market segments. The main categories include:

- 6-axis robots: They offer versatile movement for complex painting tasks.

- 7-axis robots: They provide better reach and flexibility in painting.

- Collaborative robots: They allow safer interaction with human workers.

Painting Technologies

Painting technologies are another important market segment. Manufacturers use new approaches to improve coating quality and efficiency:

- Electrostatic painting systems: They ensure uniform paint distribution.

- High-Volume Low-Pressure (HVLP) technologies: They reduce paint waste.

- Automated spray painting systems: They enhance precision and consistency.

The market segments show a lot of growth potential. Manufacturers are investing in research. They aim to develop more advanced robot types and painting technologies to meet growing automotive production demands.

Each market segment has its own challenges and opportunities for innovation. The future of automotive paint robotics will likely involve advanced sensors, AI-driven control systems, and sustainable painting solutions.

Application-based analysis of paint robots in vehicle production lines

Paint robots have transformed the automotive industry, revolutionizing the way cars are manufactured. With the integration of cutting-edge robotic systems, the painting process has become more precise and efficient than ever before.

Versatile Applications of Paint Robots in Car Manufacturing

Paint robots find extensive applications in various stages of car production, including:

- Primer application: These robots ensure microscopic accuracy in applying primer coats, preparing the surface for subsequent layers.

- Basecoat spraying: With advanced spraying techniques, paint robots achieve uniform color coverage across the vehicle body, eliminating any inconsistencies.

- Clear coat finishing: The final touch comes from clear coat applications, where robots provide enhanced protection and a glossy finish to the painted surfaces.

- Complex surface painting: For intricate vehicle components with complex shapes, specialized paint robots are employed to achieve precise and detailed finishes.

Benefits of Paint Robots in Automotive Painting

The introduction of paint robots into production lines brings forth significant advantages to the painting process:

- Reduction in errors: Robotic systems minimize human errors that can occur during manual painting, ensuring consistent quality throughout.

- Even paint application: With their programmed movements and controlled spraying techniques, paint robots guarantee an even distribution of paint on all surfaces.

- Cost savings: By optimizing paint usage and reducing wastage through precise application, these robots contribute to cost savings in material expenses.

- Improved aesthetics: The combination of advanced technology and skilled programming results in flawless finishes that enhance the overall appearance of vehicles.

Advantages of Integrating Paint Robots into Production Lines

In addition to the benefits specific to painting, incorporating paint robots into manufacturing processes offers several advantages:

- Higher productivity: Robotic systems can operate continuously without breaks or fatigue, leading to increased throughput and faster production cycles.

- Enhanced quality control: With their ability to perform repetitive tasks with high precision, paint robots ensure consistent quality standards are met across all vehicles.

- Lower labor costs: While initial investments may be required for robotic systems, long-term savings can be achieved through reduced labor costs associated with manual painting operations.

- Safer work environment: By delegating hazardous tasks such as spray painting to robots, manufacturers can create safer workplaces for human workers.

Industry Trends: Investment in Robotic Paint Technologies

To remain competitive in a rapidly evolving market, leading automotive manufacturers are making substantial investments in robotic paint technologies. These innovative systems represent a significant advancement towards achieving efficient and high-quality car production.

As the automotive industry continues to embrace automation and robotics, it is clear that paint robots will play a pivotal role in shaping the future of vehicle manufacturing.

Regional insights on automotive paint robot adoption and growth

The global automotive paint robot market shows interesting regional differences. These differences are seen in how quickly and widely these robots are used. Each area has its own pace, level, and pattern of adoption.

North America: Early Adopters

InNorth America, car makers quickly adopted robotic painting. They did this because of high labor costs, advanced factories, and strict quality standards. These factors pushed them towards using robots.

- High labor costs

- Advanced manufacturing infrastructure

- Consistent quality requirements

Asia-Pacific: Emerging Leaders

Asia-Pacific is another key area for growth in automotive paint robots. China and Japan are leading the way with their tech advancements. They are investing heavily in robotics, aiming for better efficiency in their factories.

Europe: Varying Adoption

In Europe, the use of automotive paint robots varies. Countries like Germany and Sweden are at the forefront. They focus on precision and being green.

What makes each region unique includes:

- Technological readiness

- Manufacturing complexity

- Economic infrastructure

- Investment in automation

New markets are also growing fast. They are investing more in car-making tech. This means we can expect to see more robots in their factories soon.

Japan's Advanced Robotics Driving Paint Automation

Japanese robotics lead in making cars look great with paint. They are known for their top-notch engineering and new tech. This tech changes how cars are made.

Japanese robotics are known for:

- Unbeatable precision in painting

- Top sensor tech for perfect paint

- AI control systems

- Robots that fit in small spaces

Japanese robotics are ahead because of lots of research and money spent on it. Companies like Fanuc and Yaskawa have made robots that paint better. These robots save paint, make surfaces even, and speed up making cars.

New robots from Japan are getting smarter. They learn to paint different cars and colors. This is setting new standards in car making.

The world’s car makers look up to Japan for paint tech. Japan keeps getting better at making robots for painting. They stay ahead in changing car making tech.

Germany's automotive sector pushing innovation

The German automotive industry leads in technology, making big strides in automotive paint robotics. BMW’s recent factory upgrade shows off German engineering’s precision. It highlights how European trends are changing manufacturing.

How German car makers are using robotics in production

German car makers are using top-notch robotics in their production. They combine several important things:

- Precision engineering techniques

- Advanced Industry 4.0 integration

- Smart factory design principles

- High-performance automation solutions

Germany’s automotive innovation goes beyond old manufacturing ways. Robotic paint systems now use artificial intelligence and machine learning. This makes production more efficient and quality better.

The importance of new paint automation tech for German robotics makers

German robotics makers are putting a lot of money into new paint automation tech. This is key to staying ahead in the global car market. It ensures precision, speed, and care for the environment.

The impact of partnerships between robotics firms and car makers

Partnerships between robotics firms and car makers are leading to big changes. This creates a world of advanced technology. It keeps pushing what’s possible in making cars.

U.S. market trends in automotive automation and robotics

The U.S. automotive industry is changing fast with robotics. Companies are using new tech to make things better and faster. Market trends show big growth in the automotive field.

Key changes in U.S. automotive robotics

Some key changes in U.S. automotive robotics include:

- More money going into smart manufacturing tech

- Focus on making things more precise and of higher quality

- Partnerships between tech firms and car makers

- Lowering labor costs with automation

The role of AI and machine learning in paint robot tech

Paint robot tech is getting a big boost from artificial intelligence and machine learning. This makes production smoother and more efficient.

North American makers leading in robotics innovation

North American makers are leading in robotics innovation. They want to bring jobs back and not rely so much on foreign suppliers. This is making the U.S. automotive industry use more robotics.

Future development outlook for automotive paint robot technology

The world of automotive paint robots is changing fast. New technologies and AI are leading the way. These smart painting systems are making cars better and faster to make.

There are many important areas being worked on in automotive paint robotics:

- Advanced AI-driven paint optimization algorithms

- Real-time quality control through augmented reality interfaces

- Adaptive learning systems for paint application

- Nano-material developments for robot components

Companies are putting a lot of money into smart painting systems. These systems can change how paint is applied. They use AI to quickly understand what they see and adjust accordingly.

New technologies are bringing big changes:

- Predictive maintenance capabilities

- Enhanced sensor integration

- Reduced human intervention

- Sustainable coating technologies

The future of automotive paint robots looks very promising. We can expect big improvements in how things are made, how well they work, and how good they are for the planet.

| Technology Aspect | Current Capability | Future Potential |

| AI Integration | Basic Pattern Recognition | Advanced Adaptive Learning |

| Paint Optimization | Standard Preset Configurations | Real-time Dynamic Adjustments |

| Quality Control | Manual Inspection | Automated Augmented Reality Checks |

Competitive landscape among key robotic manufacturers

Key players in the automotive paint robots market are focusing on technological advancements to enhance precision, efficiency, and environmental sustainability in vehicle finishing processes. They are expanding operations in regions such as Asia-Pacific and North America, where the demand for automated painting solutions is increasing due to the growth of electric vehicle production and the push for greener manufacturing practices.

Key Players:

-

KUKA (Germany)

-

Dürr (Germany)

-

FANUC (Japan)

-

B+M Surface Systems (Germany)

-

ABB (Switzerland / Sweden)

-

Kawasaki (Japan)

-

Yaskawa (Japan)

-

Stäubli (Switzerland)

-

Comau (Italy)

-

Epson Robots (Japan)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Automotive Paint Robots Market Report |

| Base Year | 2024 |

| Segment by Type |

· 6-axis Robots · 7-axis Robots · Collaborative Robots |

|

Segment by Application |

· Automotive · Industry |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Automotive Paint Robots Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Automotive Paint Robots Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Automotive Paint Robots Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Automotive Paint Robots Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Automotive Paint Robots Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Automotive Paint Robots Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Automotive Paint Robots Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Automotive Paint Robots Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market value for automotive paint robots by 2025?

The market for automotive paint robots is expected to hit $3.52 billion by 2025. This shows a big jump in automation and tech in car making.

How do automotive paint robots improve manufacturing efficiency?

These robots make car manufacturing better by:

- Painting evenly and reducing waste

- Saving on labor costs

- Improving paint quality

- Increasing production speed

What technologies are driving innovation in automotive paint robotics?

New technologies such as AI, machine learning, and advanced sensors are transforming the car painting process. These innovations also contribute to Industry 4.0, making automobile manufacturing more intelligent.

What regulatory challenges affect automotive paint robot implementation?

The car industry faces rules on emissions, worker safety, and being environmentally friendly. These regulations influence the design and usage of robots in the industry.

What types of paint robots are currently used in automotive manufacturing?

In automotive manufacturing, both 6-axis and 7-axis robots are commonly used for painting. These robots employ various painting technologies such as electrostatic and High Volume Low Pressure (HVLP) methods.

How are different regions adopting automotive paint robotics?

Regions such as North America, Europe, and Asia-Pacific are adopting automotive paint robotics at varying rates. This is influenced by factors such as car manufacturing levels, labor costs, and technology infrastructure.

What role do countries like Japan and Germany play in paint robot development?

Japan is at the forefront of robotic technology, while Germany is known for its precision and expertise in Industry 4.0. Both countries play a crucial role in improving paint robots.

What future technologies might transform automotive paint robotics?

New tech like AI for better painting and augmented reality for checking quality are coming. Even 3D printing cars could change painting forever.

How do paint robots integrate into vehicle production lines?

Robots are used at every step, from primer to clear coat. They ensure cars get a smooth, even paint job.

What environmental considerations impact automotive paint robot development?

Car makers are working to cut VOC emissions and make painting greener. They aim to make robots that are kinder to the planet, such as those depicted in this image.