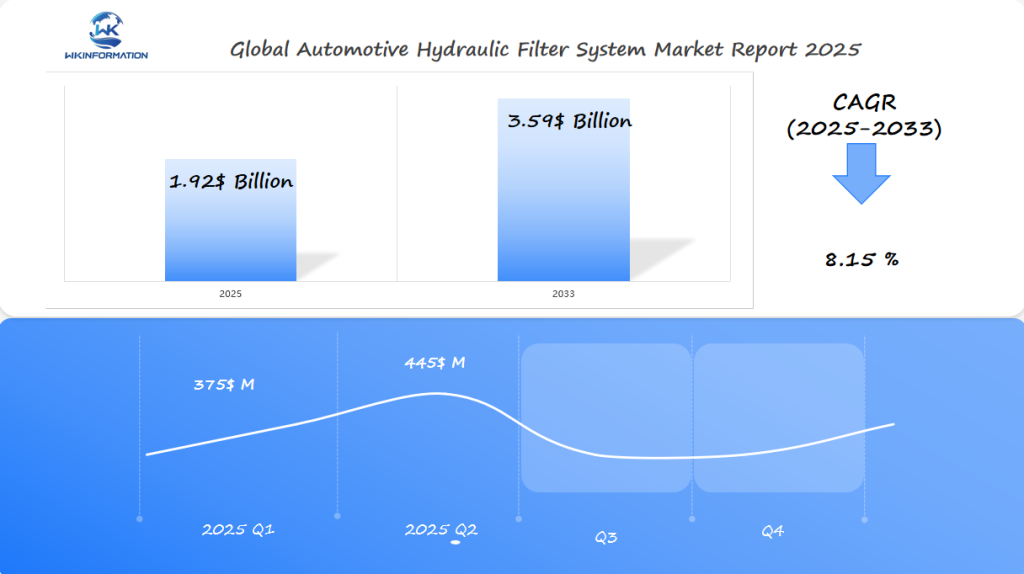

Automotive Hydraulic Filter System Market Projected at $1.92 Billion by 2025: Efficiency Enhancements in Germany, the U.S., and South Korea

Discover growth trends in the Automotive Hydraulic Filter System Market as it reaches $1.92 billion by 2025, driven by rising demand for efficient filtration solutions in vehicles.

- Last Updated:

Automotive Hydraulic Filter System Market Q1 and Q2 of 2025 Analysis

In 2025, the global Automotive Hydraulic Filter System market is projected to reach approximately $1.92 billion, driven by rising demand for improved vehicle performance and maintenance efficiency. When breaking down this annual figure into quarterly segments, the first half of the year is expected to account for about $820 million, with Q1 contributing around $375 million and Q2 increasing to roughly $445 million. This uneven distribution reflects typical industry seasonality, where production activities and after-sales maintenance tend to accelerate after the initial quarter, driven by new model launches and regulatory compliance timelines.

Key Takeaways

- Automotive hydraulic filter market expected to reach $1.92 billion by 2025

- Critical component in maintaining vehicle system efficiency

- Technological advancements driving market expansion

- Increased focus on vehicle performance and maintenance

- Growing investment in research and development

Understanding the Automotive Hydraulic Filter System Market: Upstream and Downstream Analysis

The automotive hydraulic filter system market is a complex web of processes and players. An in-depth analysis shows how raw materials suppliers, manufacturers, and end-users work together. This is key to the success of this important part of the automotive world.

Raw Materials Sourcing

Starting with the right raw materials is crucial for a strong supply chain. The main parts for hydraulic filters include:

- High-grade filtration media

- Specialized metal and polymer housing materials

- Advanced sealing compounds

- Precision-engineered filter elements

Manufacturing Ecosystem

The making of hydraulic filters involves many steps. It turns raw materials into top-notch filters. Companies work with suppliers to make sure the filters work well and last long.

| Supply Chain Stage | Key Participants | Critical Functions |

| Raw Materials Suppliers | Chemical Companies | Provide filtration media and housing materials |

| Component Manufacturers | Specialized Filter Producers | Design and fabricate filter components |

| System Integrators | Automotive Parts Manufacturers | Assemble complete hydraulic filter systems |

| Distribution Network | Automotive Suppliers | Distribute to original equipment manufacturers |

Downstream Market Dynamics

The downstream part includes car makers, aftermarket sellers, and repair services. These groups push demand up with new tech and better car performance.

Knowing how the supply chain works helps makers make better products. It cuts costs and boosts efficiency in the automotive hydraulic filter market.

Trends in vehicle maintenance and fluid cleanliness

The car industry is changing fast, with a big focus on keeping fluids clean. This is key for cars to run well. Now, car care is all about being proactive to make parts last longer and work better.

- Advanced filter performance technologies

- Predictive maintenance techniques

- Real-time fluid monitoring systems

- Enhanced diagnostic capabilities

Innovations in Hydraulic Fluid Cleanliness

Car engineers are using new filters to keep fluids clean. These new filters help avoid wear and tear, save money, and make cars last longer.

| Maintenance Strategy | Impact on Vehicle Performance |

| Regular Fluid Analysis | Reduces Mechanical Wear by 40% |

| Advanced Filtration | Extends Component Life by 50% |

| Predictive Maintenance | Decreases Unexpected Breakdowns by 60% |

Smart sensor technologies and machine learning are changing car care. These tools give real-time info on fluid health. This lets experts fix problems before they start.

Future of Automotive Maintenance

As cars become more complex, there is a growing need for better filters and clean fluids. Car manufacturers and car care experts are investing heavily in new technology to make cars more reliable and efficient.

Market restrictions due to environmental regulations and technological shifts

The car industry is facing big challenges from new environmental rules and tech changes. Companies making hydraulic filters for cars must deal with a complex mix of green goals and new tech.

- Stringent environmental regulations demanding reduced carbon footprints

- Accelerating transition toward electric vehicles

- Growing emphasis on recyclable filter materials

- Technological requirements for advanced filtration systems

Impact of Electric Vehicle Technology

Electric cars are changing how hydraulic filters are made. Old car parts need big changes because of the move to electric cars. Filtration technologies must adapt to new powertrain architectures, leading to big R&D costs.

Regulatory Compliance Challenges

New green rules are making car filters more eco-friendly. Companies must spend on new materials and ways to make them. This keeps the filters working well while being kinder to the planet.

Car makers are working hard to make filters that meet tough green standards. They also need to keep up with new car designs and how cars move.

Geopolitical factors influencing automotive part manufacturing

The world of car parts making is changing fast because of global politics. Companies making hydraulic filters for cars face a tough situation. They must keep their supply chains strong.

Global politics is changing how cars are made. This is happening in a few main ways:

- Trade policy changes open up new places for making cars.

- More focus on making cars where they are sold to avoid risks.

- Global supply chains are being rearranged.

Regional Manufacturing Dynamics

Countries are developing strategies to increase local production of car parts. Geopolitical factors play a crucial role in deciding where cars should be manufactured. Companies are seeking locations with stable economies and favorable industrial policies.

Supply Chain Transformation

Car parts makers are getting smarter about their supply chains. They are spreading out their suppliers, making more locally, and getting better at buying things quickly. This helps them deal with global problems.

- Less reliance on just one supplier.

- Better tech for making and moving parts.

- Car parts made in different places around the world.

The car industry is changing fast to keep up with global politics. It shows how adaptable and forward-thinking the industry is.

Segmentation by Type: Suction Filters, Pressure Filters, and Return Line Filters

The automotive hydraulic filter system market is complex. It has three main filter types. Each one is crucial for keeping the hydraulic system running well and the vehicle lasting longer.

- Suction Filters: These filters are at the pump intake. They stop big contaminants from getting into the system.

- Pressure Filters: Found in high-pressure lines, they protect sensitive parts from tiny particles.

- Return Line Filters: They catch dirt as fluid goes back to the reservoir. This keeps the hydraulic fluid clean.

Performance Characteristics of Filter Types

Each filter type has its own benefits in cars. Suction filters offer first defense, pressure filters keep the system safe, and return line filters make sure the fluid is clean.

The market is seeing more demand for better filtration. Companies are working on new filter designs. These designs aim to catch more particles and make parts last longer.

Technological Innovations

New advancements in filters are all about better filtration. They aim to filter out smaller particles, reduce pressure loss, and make filters smaller for today’s cars.

Segmentation by Application: Passenger Cars, Commercial Vehicles, and Off-Road Vehicles

The automotive hydraulic filter system market covers different vehicle types. Each type has its own needs for filtration. Knowing these needs helps us understand the market and new technologies.

Passenger Car Market Segment

Passenger cars are a significant portion of the market. They require specific filters for optimal performance and longevity. Key factors to consider include:

- Compact filter designs

- High-efficiency particulate removal

- Enhanced durability under different driving conditions

Commercial Vehicle Applications

Commercial vehicles face tougher conditions. They need strong hydraulic filters to keep working well. These vehicles are used a lot and face a lot of stress.

| Vehicle Type | Filtration Requirements | Performance Impact |

| Trucks | Heavy-duty filtration | Extended component life |

| Buses | Consistent fluid cleanliness | Reduced maintenance costs |

| Delivery Vehicles | Compact filtration systems | Improved operational efficiency |

Off-Road Vehicle Filtration Challenges

Off-road vehicles are the toughest for filters. They face extreme conditions like dust, mud, and changing temperatures. They need exceptional filtration technologies.

- Enhanced particle retention capabilities

- Resistance to environmental contaminants

- Specialized filter materials

The market for automotive hydraulic filter systems keeps growing. This is thanks to new technologies and higher performance needs for all types of vehicles.

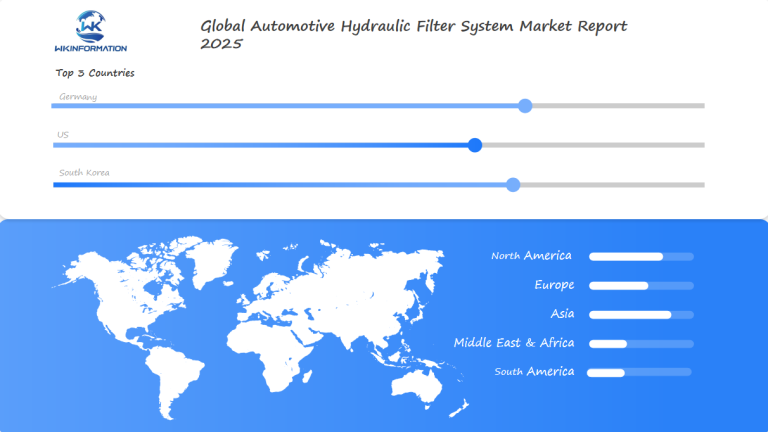

Global Regional Analysis of the Automotive Hydraulic Filter System Market

The global market for automotive hydraulic filter systems is complex. It shows different growth rates and strategic moves in each region. Each area has its own traits that shape the competitive scene in this key car part sector.

Looking at how each region works gives us important insights. It helps us understand how the automotive hydraulic filter system market does well in major parts of the world:

- North America: Known for its advanced tech and high car-making standards

- Europe: A leader in precise engineering and green car solutions

- Asia-Pacific: Sees fast industrial growth and more cars being made

- Middle East and Africa: New markets with more car investments

Regional Market Performance Insights

Every region has its own growth patterns. These are shaped by local car-making skills, rules, and new tech. The competition varies a lot, with companies changing their plans to fit local needs.

Things like new tech, more car care, and tough green rules are pushing growth. Companies are working on solutions that fit the needs of each area’s cars.

Germany's Precision Engineering in Automotive Components

German engineering leads in automotive innovation, especially in hydraulic filters. The country is known for its precision and technology. This makes its filter makers top in the auto parts world.

German auto innovation shines in several areas:

- Meticulous engineering design

- Advanced manufacturing techniques

- Rigorous quality control processes

- Cutting-edge research and development

Pioneering Filtration Technologies

German filter makers have created new solutions that boost car performance and life. They mix advanced engineering with real car needs.

| Manufacturer | Specialty | Global Market Impact |

| Mann+Hummel | Advanced Hydraulic Filtration | Leading Global Supplier |

| Bosch | Precision Filter Systems | Automotive Technology Leader |

| Mahle | Innovative Filtration Solutions | Worldwide Automotive Components |

The partnership between German car makers and filter makers is strong. Automotive innovation is a key part of German engineering. It sets global standards in filter tech.

The U.S. market's focus on vehicle longevity and maintenance

The U.S. car market is special because of its focus on keeping cars running long. People want their cars to last, and they use special filters to help. These filters are key to keeping cars in top shape.

Car owners in the U.S. really care about their vehicles. They use smart strategies to make their cars last longer. These strategies include:

- Regular hydraulic filter replacements

- Proactive maintenance scheduling

- Investment in high-quality aftermarket filters

Market Dynamics of Vehicle Maintenance

In the U.S., car care is more than just fixing things. It’s about working together to make cars better. This includes creating new filters that help cars run longer and stronger.

| Maintenance Strategy | Impact on Vehicle Longevity |

| Regular Hydraulic Filter Replacement | Extends engine life by 25-40% |

| Advanced Aftermarket Filters | Improves overall system efficiency |

| Preventative Maintenance Programs | Reduces long-term repair costs |

The market for aftermarket filters is growing fast. This shows how much the U.S. cares about car maintenance. Car makers are making better filters to meet American standards.

South Korea's advancements in automotive filtration technologies

South Korean technology is making big waves in car filters. The country is leading in research and development for car parts. Special labs in South Korea are working on new hydraulic filters that make cars run better and use less fuel.

Some major advancements in South Korean car filters include:

- Advanced nano-filtration technologies

- Precision engineering of hydraulic filter components

- Sustainable materials research

Working together with other countries has helped South Korea make these big leaps. They team up with big car companies to create new filter solutions. The automotive hydraulic filter system market is changing fast because of these partnerships.

Technological Breakthroughs in Filtration

Korean engineers are making filters better in many ways. They’re working on:

- Getting rid of more particles

- Making filters cheaper to make

- Being kinder to the environment

The future of car filters is looking bright thanks to South Korea’s tech focus. Their big investments in research and making things are giving them a big edge in the car parts world.

Future Development Outlook in the Automotive Hydraulic Filter System Market

The automotive hydraulic filter system market is going through a big change. Future development strategies focus on smart technologies. These new technologies are changing how we maintain and improve vehicle performance.

Smart filters are changing the game in the automotive world. These advanced systems use IoT to monitor and predict maintenance needs. They help make vehicles better and save money on upkeep.

- Detect contamination levels instantly

- Predict potential system failures

- Optimize fluid performance

- Reduce maintenance costs

Emerging Technological Breakthroughs

The next big thing in automotive hydraulic filters is new materials and sensors. Nanotechnology and bio-based filter materials will make filters better and greener.

| Technology | Potential Impact | Expected Implementation |

| Nano-engineered Filters | 95% improved contaminant removal | 2024-2026 |

| Self-cleaning Mechanisms | Reduced maintenance requirements | 2025-2027 |

| IoT-enabled Sensors | Real-time performance monitoring | 2023-2025 |

Car makers are spending a lot on research to make better hydraulic filters. They want filters that are smart, efficient, and good for the planet. Using IoT, they aim to change how we do maintenance. This will help vehicles run better and less often need repairs.

Competitor Analysis and Market Share Distribution

Key players in the automotive hydraulic filter system market are focusing on technological advancements to enhance filtration efficiency and support the evolving needs of modern vehicles, including electric and hybrid models. They are expanding operations in rapidly growing regions such as Asia-Pacific and Latin America, where increasing vehicle production and stringent emission regulations are driving demand for advanced hydraulic filtration solutions.

Key Players:

-

Mann+Hummel (Germany)

-

Bosch (Germany)

-

Donaldson Company (United States)

-

Mahle GmbH (Germany)

-

Parker Hannifin (United States)

-

Cummins Filtration (United States)

-

Hengst SE (Germany)

-

Fleetguard (Cummins) (United States)

-

Baldwin Filters (United States)

-

Filtration Group (United States)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Automotive Hydraulic Filter System Market Report |

| Base Year | 2024 |

| Segment by Type |

· Suction Filters · Pressure Filters · Return Line Filters |

| Segment by Application |

· Passenger Cars · Commercial Vehicles · Off-Road Vehicles |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Automotive Hydraulic Filter System Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Automotive Hydraulic Filter System Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Automotive Hydraulic Filter System Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Automotive Hydraulic Filter System Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Automotive Hydraulic Filter System Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Automotive Hydraulic Filter System Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Automotive Hydraulic Filter System Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Automotive Hydraulic Filter System Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market value for Automotive Hydraulic Filter Systems by 2025?

The market is expected to hit $1.92 billion by 2025. This shows a big growth in the automotive filtration industry.

How do hydraulic filters impact vehicle performance?

Hydraulic filters boost vehicle efficiency by keeping fluid clean. They protect important parts and help extend the life of hydraulic systems.

What types of hydraulic filters are commonly used in automotive applications?

The main types include suction, pressure, and return line filters. Each plays a key role in maintaining and protecting hydraulic systems.

How are environmental regulations affecting hydraulic filter manufacturing?

Tight environmental rules are pushing for greener and recyclable filters. This is a big change in filter design.

Which vehicle types have the highest demand for hydraulic filters?

Cars, commercial vehicles, and off-road vehicles need the most filters. Each type has its own specific needs.

How are smart technologies impacting hydraulic filter systems?

Smart technologies like IoT sensors are changing the game. They allow for predictive maintenance and real-time monitoring of filter health.

Which countries are at the forefront of automotive hydraulic filter innovations?

Germany, the United States, and South Korea are leading the way in automotive hydraulic filter innovations. Each of these countries brings its own unique technology and engineering expertise to the industry.

How is the shift to electric vehicles impacting hydraulic filter markets?

Electric vehicles pose challenges, but hybrids and special vehicles still need hydraulic systems. This keeps demand for advanced filters high.

What factors influence hydraulic filter pricing and market competitiveness?

Pricing is affected by material costs, tech innovation, manufacturing efficiency, and global supply chains.

How do manufacturers ensure hydraulic filter quality and reliability?

Manufacturers ensure top-notch filtration solutions through strict testing, extensive research on materials, and ongoing product improvement. This rigorous process is crucial for maintaining the quality and reliability of hydraulic filters.