Automotive FPC Market Estimated to Hit $7.2 Billion Globally by 2025: Electrification and Lightweighting Trends Drive Growth in South Korea, India, and Italy

Explore the growing Automotive FPC Market driven by vehicle electrification and demand for lightweight components. Latest trends, key players, and market forecasts through 2025.

- Last Updated:

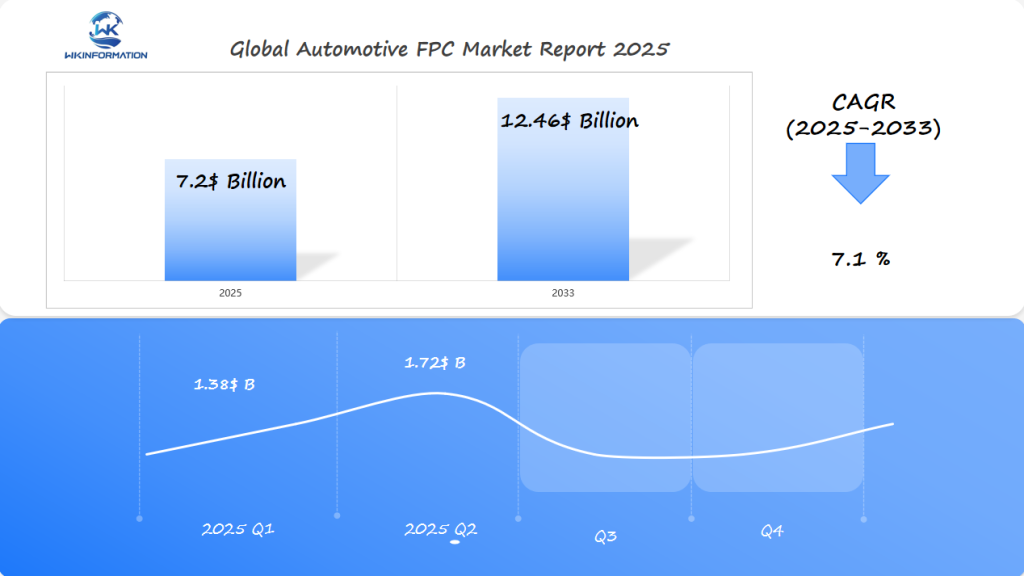

Automotive FPC Market Performance in Q1 and Q2 of 2025

The Automotive Flexible Printed Circuit (FPC) market is set to reach $7.2 billion in 2025, reflecting a strong CAGR of 7.1% from 2025 to 2033. Q1 earnings are projected at $1.38 billion, with Q2 rising to $1.72 billion, as vehicle electronics systems grow in complexity and EV demand surges. The shift toward high-density signal transmission in infotainment and ADAS platforms is a major growth driver.

Key Takeaways

- The Automotive FPC market is projected to reach $7.2 billion by 2025.

- The trend of vehicle electrification is driving the adoption of flexible printed circuits (FPCs).

- FPCs enable more compact and efficient automotive electronics, which is critical as we move towards more lightweight design solutions in automotive engineering.

- Furthermore, technological innovations are supporting advanced electronic system integration in vehicles.

Automotive FPC market upstream and downstream industry chain analysis

The world of automotive electronics is changing fast, thanks to new flexible printed circuit (FPC) technologies. The FPC supply chain is now key for the complex electrical systems in today’s cars.

Car electronics makers face a complex world of suppliers and detailed making processes. The need for top-notch flexible circuits is growing, especially with electric and smart cars becoming more common.

Raw Material Suppliers in FPC Production

Important materials for making automotive FPCs include:

- High-grade copper foils

- Advanced polyimide film substrates

- Specialized adhesive systems

- Precision-engineered conductive inks

Manufacturing Processes for Automotive FPCs

Modern manufacturing methods for automotive FPCs use advanced techniques for reliability and performance. These steps usually are:

- Precision substrate preparation

- Photolithographic circuit patterning

- Multi-layer circuit lamination

- Advanced surface finishing

End-Use Applications in Vehicles

Flexible printed circuits play a big role in many car systems, supporting key functions in modern vehicles:

- Infotainment systems

- Advanced driver-assistance systems (ADAS)

- Battery management modules

- Powertrain control interfaces

The ongoing growth of car electronics needs better FPC solutions. These solutions must handle tough conditions while keeping up high performance and reliability.

Trends in compact circuitry and flexible electronics in EVs

The electric vehicle (EV) revolution is leading to new innovations in car electronics. Compact circuitry and flexible PCBs are changing how cars are designed and built. They make it easier to add advanced systems to electric vehicles.

EV electronics are getting a big update with flexible printed circuit boards (FPCs). These advanced parts are key in tight spaces in cars.

Space-Saving Benefits of FPCs in Electric Vehicles

Flexible PCBs save a lot of space in electric cars. They let engineers:

- Make electronic parts smaller

- Route circuits in three dimensions

- Lighten the car

- Manage heat better

Integration of FPCs in Battery Management Systems

Battery management systems are a big use for compact circuitry. Flexible PCBs help monitor and control each battery cell. This boosts performance and battery life.

Car makers use flexible PCBs for smarter battery management. This helps meet the complex needs of car electrical systems.

Challenges in Automotive Electronics: Thermal Stability and Connector Reliability

The world of automotive electronics is tough for flexible printed circuits (FPCs). They face big challenges in managing heat and keeping connectors reliable. Cars need electronics that can handle extreme conditions, pushing the limits of science and engineering.

Companies are working hard to fix these problems in FPC design. The tough car environment puts a lot of stress on electronics. They need new ways to stay cool and keep connectors strong.

Heat Management Challenges in Automotive FPCs

Keeping FPCs cool is key in cars. The main issues are:

- Temperatures can drop to -40°C or rise to 125°C

- Hot spots near the engine

- Fast changes in temperature while driving

Improving Connector Durability for Harsh Environments

Connectors need smart design to last in harsh conditions. Modern FPCs use new materials that offer:

- Better protection against rust

- Stronger mechanical strength

- Top-notch electrical performance

New materials are making connectors that can handle shakes, moisture, and extreme temperatures. Specialized polymers and metal alloys are making electronics in cars last longer.

These advances mean FPCs can handle the tough demands of today’s cars. They provide steady performance from start to finish.

Geopolitical context of chip shortages and regional sourcing strategies

The global car industry is facing big challenges due to chip shortages. These shortages have changed how companies get parts, making regional sourcing key.

Chip shortages have shown how weak the car electronics supply chain is. Now, car makers are looking to spread out their parts sources. This is to avoid problems caused by making parts in just one place.

Impact of Global Semiconductor Shortages on FPC Production

Here are some big effects of the chip shortage:

- Car production is delayed a lot

- FPC parts cost more

- There’s a big need for new ways to get parts

Strategies for Diversifying FPC Supply Chains

Companies are trying different ways to fix supply chain issues:

- Spreading out where chips and FPCs are made

- Building local production sites

- Creating backup supply networks

- Working with partners strategically

The Asia Pacific is the biggest car-making area in the world. Regional sourcing is a big strategy for car makers to not rely too much on one supplier.

Automotive FPC market segmentation by type: single-sided, double-sided, multi-layer flexible printed circuits

The automotive flexible printed circuit (FPC) market is very diverse. It has three main types: single-sided, double-sided, and multi-layer flexible printed circuits. These types power the electronics in today’s cars.

Car engineers choose FPC types based on their needs and design limits. Each type has its own benefits for different car electronics.

Characteristics of FPC Circuit Types

- Single-sided FPC: The simplest with conductive layers on one side

- Double-sided FPC: Has conductive layers on both sides for more complex designs

- Multi-layer FPC: The most advanced with many interconnected layers

Market Share Analysis

Nowadays, more cars are using multi-layer FPCs. These circuits are better for complex systems like battery management and self-driving cars. They offer better signal quality and are more compact.

By 2025, multi-layer FPCs are expected to make up 45-50% of car electronics. They will be the main choice for future car systems.

Automotive FPC Market Segmentation by Application

The automotive flexible printed circuit (FPC) market is changing fast. Modern cars have more electronic systems. These systems need better and more reliable ways to connect.

Automotive FPCs are changing how we connect electronic systems in cars. The main areas where they’re growing include:

- Infotainment systems

- Battery management systems

- ADAS applications

- Lighting modules

Growth Trends in Specific Application Areas

Infotainment FPCs are growing fast. This is because car entertainment systems are getting more complex. Touchscreen displays, advanced navigation systems, and connectivity features need more detailed circuit designs.

Battery management systems are another key area. Electric cars need smart circuitry to check battery health and charge levels. FPCs help make these systems smaller and lighter, improving car efficiency.

Emerging Applications for Automotive FPCs

Advanced driver-assistance systems (ADAS applications) are opening up new uses for FPCs. Sensors, cameras, and control modules use FPCs for safer, smarter driving.

Automotive lighting modules are also getting a tech boost. LED and adaptive lighting systems need precise circuitry. FPCs offer this, making lighting more dynamic and energy-efficient.

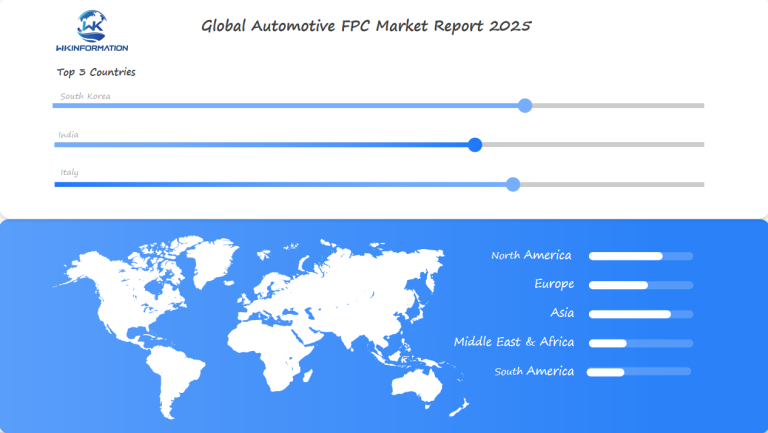

Global Impact of the Automotive FPC Market

The global FPC market for cars is changing fast. This is thanks to new tech and more electronics in cars. Different parts of the world are using flexible printed circuit technologies in their own ways.

Leading Regions in the FPC Market

- Asia-Pacific is leading the FPC market.

- China, Japan, and South Korea are at the forefront.

- They have advanced car making and electronics that help flexible circuits grow.

Regional Market Sizes and Growth Dynamics

There are big differences in how fast the FPC market is growing in different places:

- Asia-Pacific: Expected to grow by 12.5% each year

- North America: Expected to grow by 9.2%

- Europe: Expected to grow by 7.8%

Key Market Leaders Across Geographical Regions

There are top players in the FPC market for cars. They are big in their areas:

- Sumitomo Electric Industries (Japan): Big in Asia

- Flexible Circuit Technologies (United States): Big in North America

- Würth Elektronik (Germany): Big in Europe

Technology, car industry trends, and rules are all important. They help shape the FPC market in different places.

South Korea Automotive FPC market: advanced automotive electronics

The South Korean FPC market is a top spot for new tech in car electronics. Korean makers lead the world in making smart FPCs. These changes are making cars better and more fun to drive.

South Korean car tech stands out for its exactness. The Korean car world’s focus on FPCs gives them an edge worldwide.

Adoption of Flexible Printed Circuits in Korean Automotive Manufacturing

Flexible Printed Circuits (FPCs) are becoming increasingly popular in the Korean automotive industry. Here are some reasons why they are a great fit for car technology in Korea:

- Smaller electronic parts: FPCs allow for the design of compact and lightweight electronic components, which are essential for modern vehicles with limited space.

- Better electrical work: The flexibility of FPCs enables efficient routing of electrical connections, reducing signal loss and improving overall performance.

- Lighter cars: By replacing traditional rigid circuit boards with FPCs, manufacturers can significantly reduce the weight of vehicles, leading to improved fuel efficiency and reduced emissions.

- Better heat control: FPCs can be designed with specialized materials that offer better heat dissipation properties, ensuring optimal performance of electronic systems even in high-temperature environments.

Major Korean FPC Manufacturers and Technological Breakthroughs

Top Korean tech firms have made big leaps in FPCs. Their work shows off their skill:

| Manufacturer | FPC Innovation | Key Application |

| Samsung Electro-Mechanics | Ultra-thin multilayer FPCs | Advanced Driver Assistance Systems |

| LG Innotek | High-temperature resistant FPCs | Electric Vehicle Battery Management |

| Seil Circuit | Flexible substrate technologies | Infotainment Systems |

The South Korean FPC market keeps setting new tech standards. It’s a top name in car electronics innovation globally.

India Automotive FPC market: growing domestic production

The Indian car-making sector is going through big changes. Flexible printed circuit (FPC) tech is key to these changes. As cars become more common, the demand for FPCs in India is soaring.

This growth opens up new chances for both local and global suppliers. The changes in car making in India are creating many opportunities for FPCs.

- More electric cars are being made

- There’s a big need for advanced electronics

- Government support for making electronics in India

Expansion of Automotive Electronics Manufacturing

Major international companies are recognizing India’s potential in Flexible Printed Circuits (FPCs). For instance, HENN Connector Group has recently established a new factory in Chennai, indicating their confidence in India’s manufacturing capabilities.

Market Challenges and Opportunities

Companies coming into the Indian FPC market face unique hurdles:

- Prices are a big concern

- They need to make things locally

- Keeping up with fast tech changes

The Indian FPC market for cars is set to grow a lot. It’s a great chance for companies ready to invest in making things here and keeping up with new tech.

Italy Automotive FPC market: niche automotive design and customization

The Italian FPC market leads in automotive electronics, especially in luxury car design. Italian makers have found a special spot in making custom FPC solutions. They mix tech precision with artistic engineering.

Luxury car electronics in Italy are at the top of tech advancement. The country’s famous car brands use FPCs to make top-notch electronic systems. These systems make premium car experiences.

Premium Performance through Advanced Circuit Design

Italian auto suppliers focus on creating custom FPC solutions for tough electronic needs. They design circuits with:

- Ultra-compact designs

- Materials that can handle high temperatures

- Precise electronic interfaces

- Custom routes for complex systems

Innovative Manufacturing Strategies

The Italian auto electronics sector works on advanced flexible printed circuit technologies to meet complex car design needs. They invest heavily in research to create lightweight, compact circuits that enhance car performance and reliability.

Italian manufacturers’ strategy continues to push the boundaries of auto electronics while maintaining high quality and design innovation.

Future push for ultra-thin substrates and modular circuit integration

The world of car electronics is changing fast. New ultra-thin FPCs and smart circuit designs are leading the way. These innovations aim to make car electronics smaller, more efficient, and up to today’s high standards.

New trends in car FPCs are changing how we design electronics. These changes include:

- Smaller circuit parts

- Better heat handling

- Stronger electrical performance

- More flexible designs

Advancements in FPC Materials and Manufacturing Techniques

New FPC materials are opening up new design possibilities. Car makers are working on ultra-thin substrates. These substrates have amazing features for complex car electronics. They offer:

- Less weight

- Better signal quality

- Longer life in tough conditions

Trends Towards Modular and Scalable FPC Designs

Modular circuit designs are a big step forward in car electronics. Engineers are making circuits that can change and update easily. Scalable FPC designs meet the growing needs of electric and self-driving cars.

As cars get more complex, ultra-thin FPCs and modular designs will be key. They help create smarter, more efficient car electronics.

Competitive mapping across PCB and automotive electronics providers

Key players in the automotive FPC market are focusing on miniaturization, heat resistance, and signal integrity to support the increasing integration of electronics in advanced driver-assistance systems (ADAS), infotainment, and EV battery management. They are expanding into fast-growing automotive manufacturing regions such as Asia-Pacific and Central Europe, where demand for lightweight, space-saving electronic solutions is accelerating. Strategic collaborations with Tier 1 suppliers and investments in high-speed, multilayer FPC technology are helping these companies enhance product performance and solidify their market leadership.

Key Players:

-

Sumitomo Electric (Japan)

-

Yazaki Corporation (Japan)

-

Furukawa Electric (Japan)

-

Flex Ltd. (Singapore / USA )

-

Nippon Mektron (Japan)

-

Zhen Ding Technology (Taiwan)

-

TTM Technologies (USA)

-

AT&S (Austria)

-

LG Innotek (South Korea)

-

Samsung Electro-Mechanics (South Korea)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Automotive FPC Market Report |

| Base Year | 2024 |

| Segment by Type |

· Single-sided FPC · Double-sided FPC · Multi-layer FPC |

| Segment by Application |

· Infotainment Systems · Battery Management · ADAS · Lighting Modules |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Automotive FPC Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Automotive FPC Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Automotive FPC Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Automotive FPC Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Automotive FPC Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Automotive FPC Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Automotive FPC Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Automotive FPC Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market size for Automotive Flexible Printed Circuits (FPCs) by 2025?

The market for Automotive FPCs is expected to hit $7.2 billion by 2025. This growth is mainly due to more electric vehicles and the need for lighter designs in cars.

How are Flexible Printed Circuits (FPCs) improving electric vehicle design?

FPCs help make electric cars more efficient by saving space. They are key in battery systems, helping to monitor and control batteries better. This makes cars lighter and simpler.

What are the main challenges in automotive FPC manufacturing?

The main challenges in automotive FPC manufacturing are:

- Ensuring stability of FPCs under high temperatures

- Ensuring proper functioning of connectors

Cars can get extremely hot, which poses a risk to FPCs. Therefore, there is a need for new materials and designs to protect FPCs and ensure their optimal performance.

Which regions are leading in Automotive FPC production?

South Korea and India are leading in making Automotive FPCs in Asia. North America and Europe also have significant roles in the global market.

What types of Flexible Printed Circuits are used in automotive applications?

There are single-sided, double-sided, and multi-layer FPCs for cars. Each type is used in different areas like entertainment systems, battery control, safety features, and lights.

How are semiconductor shortages affecting the Automotive FPC market?

Shortages of semiconductors have made FPCs harder to get. Car makers are now looking to buy from more places and use local suppliers to avoid problems.

What emerging applications are being explored for Automotive FPCs?

New uses for FPCs include self-driving technology, communication modules, and improved interfaces for drivers and passengers. These applications require advanced and compact electronic solutions.

How are Automotive FPCs being developed for future technologies?

FPCs are being made thinner, more modular, and from new materials. This is to handle the tough car environment and support complex systems without adding weight or taking up space.

What role do FPCs play in advanced driver-assistance systems (ADAS)?

FPCs are essential for ADAS, offering small, light, and reliable circuits. They support the complex electronics needed for features like cruise control, lane-keeping, and avoiding collisions.

How are countries like South Korea and Italy unique in Automotive FPC development?

South Korea excels in combining advanced electronics in cars, while Italy focuses on high-end, custom FPCs for luxury and high-performance vehicles. These two nations exemplify different ways to leverage FPC technology in the automotive sector.