2025 Automotive Connectors Market Growth: Surging to $14.1 Billion with Electric Vehicle Advancements in U.S., Germany, and China

Explore the dynamic automotive connectors market forecast for Q1-Q2 2025, analyzing growth drivers like advanced connectivity demands and safety features. Discover regional insights focusing on Asia-Pacific dominance, US market developments, and European trends, plus learn how electric vehicles and ADAS are shaping the industry’s future.

- Last Updated:

Automotive Connectors Market: Q1 and Q2 2025 Predictions

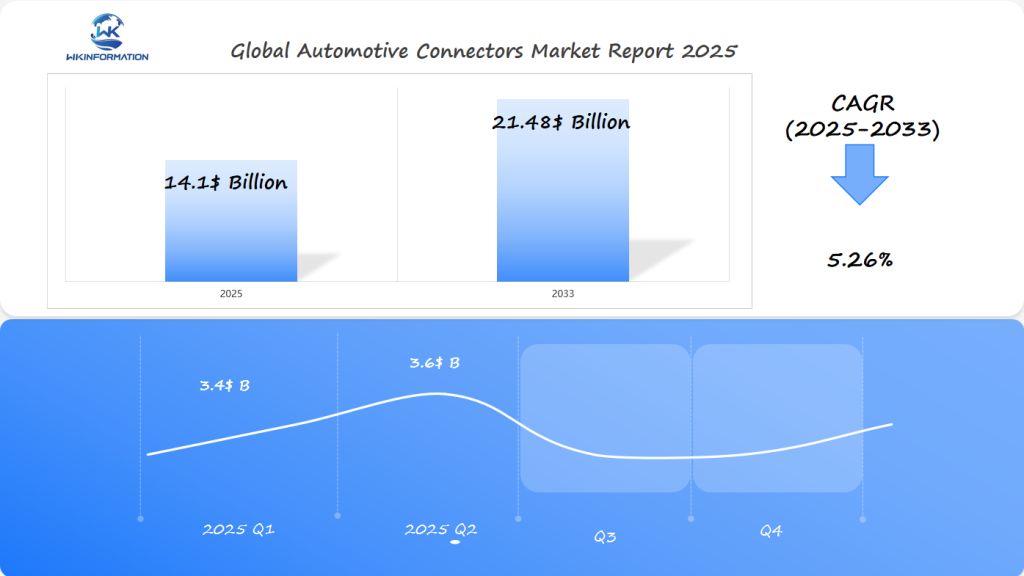

The Automotive Connectors market, valued at USD 14.1 billion in 2025, is expected to grow at a CAGR of 5.26%.

In Q1 2025, the market is projected to reach around USD 3.4 billion, driven by the increasing complexity of automotive electronics and connectivity. By Q2 2025, this is expected to rise to approximately USD 3.6 billion, supported by growing demand for electric vehicles and advanced safety features, particularly in the U.S., Germany, and China.

Understanding the Automotive Connectors Market: Supply Chain Dynamics

To fully understand the complexities of the automotive connectors market, it’s essential to analyze the dynamics of its supply chain. This journey begins with the procurement of raw materials, which includes metals such as copper and plastic components. Here are the key stages involved:

- Manufacturing Process: This stage involves stamping, molding, and assembling connectors to meet specific requirements of vehicles.

- Quality Assurance: Ensuring that each batch of connectors meets industry standards for durability and performance.

- Distribution Network: Connectors are transported from manufacturers to automotive OEMs (Original Equipment Manufacturers) through a well-coordinated network.

The Role of Key Players in Shaping Market Dynamics

The automotive connectors market is influenced by various players who have a significant impact on its dynamics. Leading companies such as TE Connectivity, Aptiv, and Molex dominate the manufacturing sector by utilizing advanced technologies to produce high-performance connectors. On the distribution side, firms like Arrow Electronics play a crucial role in ensuring timely delivery to major automotive manufacturers.

The Importance of a Strong Supply Chain

For vehicles to seamlessly integrate these components, there needs to be a robust supply chain in place. This supply chain should efficiently connect upstream suppliers (those providing raw materials) with downstream users (automotive manufacturers). As the demand for electric vehicles continues to grow, these market dynamics are constantly evolving. This evolution requires stakeholders to be agile and innovative in their approach.

Key Trends Transforming the Automotive Connectors Industry

Rise of Electric Vehicle Adoption

The rise of electric vehicle adoption is significantly influencing the demand for automotive connectors. As automakers pivot towards electrification, connectors play a critical role in managing the electrical architecture of these vehicles. They ensure efficient power distribution, support high-voltage systems, and facilitate the integration of new technologies. This shift is particularly evident in regions like the U.S., Germany, and China, where policies promoting EVs are driving increased production and sales.

Integration of Advanced Safety Systems

Integration of advanced safety systems is another pivotal trend reshaping the automotive connectors industry. Modern vehicles are equipped with sophisticated features such as adaptive cruise control, lane-keeping assistance, and collision avoidance systems. These advancements necessitate reliable connectors that can handle complex wiring configurations and ensure seamless communication between various electronic components.

Importance of Connectivity

Connectivity also emerges as a crucial aspect, as consumers demand more integrated and connected vehicle experiences. This trend pushes manufacturers to innovate and produce connectors that not only meet current technological requirements but also anticipate future needs.

Industry players focusing on these trends are strategically positioned to capitalize on the evolving landscape, ensuring robust growth and sustained relevance in this dynamic market.

Overcoming Challenges and Restrictions in Automotive Connector Production

Manufacturing automotive connectors comes with its own set of production challenges, demanding precision and adherence to strict standards.

1. Quality Control

Quality Control is paramount. Ensuring that connectors meet high reliability and safety standards is critical. Variations in design or material can lead to defects, resulting in costly recalls or failures. Implementing rigorous testing protocols helps maintain consistent quality across production batches.

2. Regulatory Compliance

Regulatory Compliance presents another hurdle for manufacturers. Navigating the complex landscape of automotive regulations requires constant updates and adaptations. Compliance with regional standards—such as the European Union’s directives on electronic waste and hazardous substances—demands ongoing attention to material selection and manufacturing processes.

3. Supply Chain Constraints

The Automotive Connectors Market also faces supply chain constraints. Sourcing raw materials like copper and specialized plastics can be challenging due to fluctuating market prices and geopolitical factors. Manufacturers must adopt strategic sourcing and inventory management practices to mitigate these risks.

4. Continuous Innovation

Lastly, advancing technologies necessitate continuous innovation. As vehicles become more sophisticated, connector designs must evolve to support higher data transmission speeds and power requirements, pushing manufacturers to invest in research and development. Embracing these challenges is essential for staying competitive in this dynamic industry landscape.

Geopolitical Impacts on the Automotive Connectors Market

Trade Policies and Their Effects

Trade policies play a crucial role in shaping the automotive connectors market, affecting both availability and pricing. Changes in international trade agreements can lead to disruptions in the global supply chain, which impact the flow of raw materials needed for manufacturing connectors. When tariffs or sanctions are imposed, production costs often increase, ultimately influencing the pricing strategies of manufacturers.

Economic Factors at Play

Economic factors also significantly contribute to this dynamic. Economic downturns in key regions can reduce consumer purchasing power, affecting vehicle sales and consequently the demand for automotive connectors. On the other hand, favorable economic conditions may boost investments in electric vehicles (EVs), driving up connector demand.

Trade Policies in North America and Europe

In regions like North America and Europe, strict trade policies ensure that quality standards are maintained. However, these regulations can sometimes create barriers for manufacturers seeking to enter new markets or expand their operations globally.

Geopolitical Sensitivity of the Automotive Industry

The automotive industry is particularly sensitive to geopolitical tensions. Conflicts or diplomatic disputes between major economic powers can create an uncertain business environment, prompting companies to reassess their supply chain strategies and explore alternative sourcing options to mitigate risks associated with geopolitical instability.

As the market evolves, understanding these geopolitical influences becomes crucial for stakeholders aiming to navigate the complexities of global trade effectively.

Market Segmentation: Different Types of Automotive Connectors and Their Applications

The automotive connectors market is divided into various types, each playing a crucial role in modern vehicle systems. Wire-to-Wire Connectors and Wire-to-Board Connectors are among the key categories.

1. Wire-to-Wire Connectors

These connectors are essential for enabling electrical connections between two wires. They are integral to vehicle power distribution and signal transmission. Common applications include:

- Connecting lighting systems

- Power seats

- Other in-vehicle electronic components requiring robust and reliable connectivity

2. Wire-to-Board Connectors

These connectors facilitate connections between wires and printed circuit boards (PCBs). They are crucial for more complex electronic systems like infotainment setups and advanced driver-assistance systems (ADAS). Wire-to-Board Connectors are designed to handle high-density signal requirements, catering to the growing demand for sophisticated automotive electronics.

Applications of Automotive Connectors

Automotive connectors have several critical applications in vehicle functions:

- Powertrain Systems: Ensuring efficient energy transfer and management.

- Safety Controls: Supporting advanced safety features through reliable connectivity.

- Infotainment Systems: Enabling seamless multimedia experiences within the vehicle.

- Battery Management: Vital in electric vehicles for optimal battery performance and safety.

The diversity of connector types reflects the increasing complexity of automotive electronics, emphasizing the need for specialized solutions in different vehicle areas. This segmentation is pivotal in addressing the unique demands of each application, supporting innovation in electric and autonomous vehicles.

Automotive Connectors in Electric and Autonomous Vehicles

Automotive connectors play a crucial role in the development of electric vehicle (EV) technology and the complex systems used in autonomous vehicles. These connectors are essential for the functioning of vehicles, enabling smooth communication and power distribution between different parts.

Key Functions of Connectors in EVs:

1. High-Voltage Systems Management

Connectors are vital for handling high-voltage electrical systems, which are necessary for driving electric motors and battery packs. They guarantee safe and effective energy transfer, meeting the significant power requirements of electric vehicles.

2. Battery Management Control

Dependable connectors assist in controlling battery connections, providing stability and safety. They are instrumental in monitoring battery status and ensuring peak performance.

Autonomous Vehicle Systems Support:

1. Data & Signal Transmission Facilitation

In self-driving cars, connectors allow quick data transfer between sensors, control units, and actuators. This communication is critical for immediate decision-making processes that steer autonomous technology.

2. Safety Systems Integration Support

Connectors aid in incorporating advanced safety features such as LIDAR, radar, and camera systems. These elements depend on secure connections to operate efficiently, maintaining the vehicle’s functionality.

Market Implications:

The increasing need for high-voltage connectors in the automotive connectors market indicates a shift in the industry towards electrification and autonomy. As these technologies progress, innovations in connectors will further enhance vehicle design and capabilities.

Regional Growth Insights: Automotive Connectors Market by Region

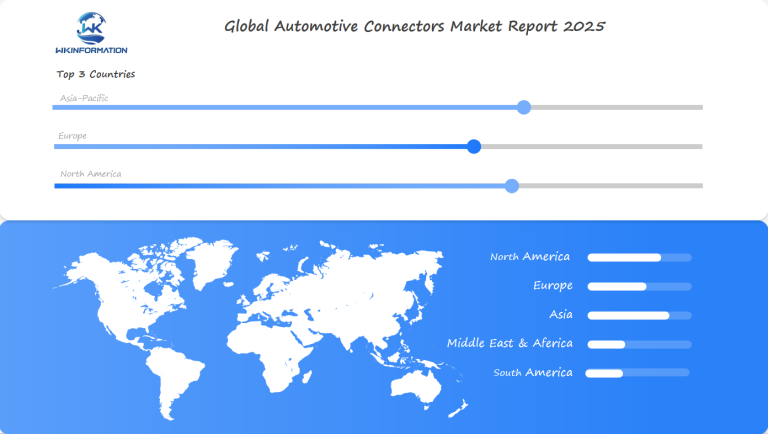

The regional analysis of the automotive connectors market reveals distinct trends shaping demand across Asia-Pacific, Europe, and North America. Understanding these regional dynamics is crucial to gauge the market’s evolution.

Asia-Pacific

- Market Leadership: The region is anticipated to dominate due to rapid electrification initiatives.

- China’s Influence: With its leadership in global EV sales, China spearheads connector demand, driven by aggressive policies supporting electric vehicle production.

- Technological Advancements: Countries like Japan and South Korea continue to innovate in automotive technologies, further boosting the market.

Europe

- Regulatory Environment: Stringent regulations aimed at carbon emissions reduction are pivotal in driving the market.

- Germany’s Role: As a leader in automotive technology, Germany significantly contributes through advanced manufacturing capabilities and innovation in connector designs.

- Sustainable Practices: The focus on sustainability accelerates the adoption of electric vehicles across European nations.

North America

- U.S. Market Dynamics: Characterized by a high adoption rate of connected vehicles, the U.S. sees increasing investments from automakers in EV technologies.

- Innovation Hub: With significant technological advancements being made, North America remains a key player in developing next-generation connector solutions.

- Infrastructure Development: Efforts to enhance EV infrastructure underpin growth prospects for automotive connectors.

These regional trends collectively shape the landscape of the automotive connectors market, reflecting varied growth trajectories influenced by local policies and technological innovations.

USA’s Leading Role in Automotive Connector Technology and Adoption

The U.S. market plays a crucial role in advancing automotive connector technology, driven by the nation’s commitment to innovation and sustainability. As a global leader in connected vehicles adoption, the U.S. has created an environment where technological advancements in automotive connectors can thrive.

Key Factors Driving U.S. Market Leadership:

- Investment in R&D: Major U.S. automakers and tech companies invest heavily in research and development to enhance connector performance, focusing on reliability and efficiency.

- Government Support: Policies encouraging electrification and connectivity boost demand for advanced connectors, essential for integrating complex vehicle systems.

- Technological Innovation: The U.S. leads in developing cutting-edge connector technologies, such as quick-charging solutions that support the growing EV market’s infrastructure needs.

Impact on Connector Technology:

- Integration with Advanced Systems: Connectors are crucial for integrating advanced driver-assistance systems (ADAS) and infotainment features, reinforcing their role in vehicle safety and connectivity.

- Collaboration with Tech Giants: Partnerships between automakers and tech companies accelerate the development of innovative connectors, ensuring seamless communication across vehicle systems.

The U.S.’s proactive approach to technology adoption not only shapes its domestic market but also influences global standards, setting a benchmark for connector performance and innovation worldwide. This is evident from the growing trend of automotive connector technology, which is increasingly being adopted globally due to its pivotal role in enhancing vehicle functionality and user experience.

China’s Impact on Automotive Connectors for EVs and Smart Cars

1. Growth of the Chinese EV Market

The growth of the Chinese electric vehicle (EV) market is reshaping the global landscape, with China leading the way in producing and adopting electric vehicles. This rapid shift towards electrification is driven by government policies aimed at reducing carbon emissions and increasing energy efficiency. To encourage the use of electric vehicles, the Chinese government has implemented various incentives such as subsidies and tax breaks.

2. Surge in Demand for Connectors

As a result of the significant increase in electric vehicle production, there is a notable trend in the automotive connectors market: a surge in demand for connectors. This demand for reliable and efficient connectors is crucial because these components play a vital role in ensuring smooth power distribution and data communication between different electronic systems within vehicles.

3. Unprecedented Growth of Automotive Connectors Market in China

The automotive connectors market in China is experiencing unprecedented growth. This expansion reflects the country’s commitment to technological advancement and sustainability. Chinese automakers are focusing on integrating advanced safety features and connectivity solutions, which further drives the need for high-quality automotive connectors.

4. China’s Influence on Global Connector Demand

China’s position as a leader in the electric vehicle market highlights its impact on global connector demand. The emphasis on innovation and capacity building in connector technology is critical to meeting the evolving needs of smart cars and electric vehicles, setting an example for other countries to follow.

Germany’s Strength in Automotive Connector Manufacturing and Innovation

Germany is known for its engineering excellence in the automotive connector market. With strong manufacturing capabilities, German companies are leading the way in developing connector technologies. The country’s focus on precise engineering and quality control plays a significant role in maintaining its top position.

1. German Engineering Excellence

German manufacturers prioritize accuracy and durability, ensuring that connectors meet the stringent demands of modern vehicles. This focus results in components that enhance vehicle safety and efficiency.

2. Manufacturing Innovations

Germany’s commitment to innovation drives continuous improvement in production processes. Advanced automation and cutting-edge technology are integral to manufacturing connectors that support both traditional and electric vehicles.

Several leading automotive connector companies are based in Germany, leveraging the nation’s industrial expertise to deliver high-performance solutions. These organizations invest heavily in research and development, fostering innovations that address the evolving needs of the automotive industry.

The German market’s strategic focus on sustainability aligns with global trends towards electrification and connectivity, further cementing its role as a pivotal player in shaping the future of automotive connectors. The combination of engineering skill and innovative practices ensures that Germany remains a leader in this ever-changing industry.

Future Trends and Innovations in Automotive Connector Technologies

The automotive connectors market is about to undergo significant changes driven by new technologies and upcoming innovations. As the automotive industry grows, so does the need for advanced connector solutions designed to support new vehicle technologies.

1. Quick-Charging Technologies

One of the most anticipated advancements in automotive connectors is the development of quick-charging technologies. These innovations are crucial for enhancing electric vehicle (EV) charging infrastructure. Expect connectors that can handle higher voltages and currents, facilitating faster charging times and improving overall EV usability.

2. High-Speed Data Transmission

As vehicles become more connected, there’s an increasing need for connectors capable of supporting high-speed data transmission. Advanced safety systems, infotainment, and autonomous driving features rely heavily on swift and reliable data exchange facilitated by cutting-edge connector designs.

3. Miniaturization and Flexibility

With modern vehicles packing more electronics into limited space, the trend toward miniaturization is set to continue. Future connectors will likely be smaller yet more robust, offering greater flexibility in design while maintaining performance under challenging conditions.

4. Sustainability Initiatives

Manufacturers are exploring eco-friendly materials and production methods to align with global sustainability goals. The future will see a rise in biodegradable or recyclable connector components that do not compromise durability or functionality.

The continuous innovation in this field is vital for supporting the growing complexity and demands of next-generation vehicles.

Major Competitors in the Automotive Connectors Market

Key players in the market:

- TE Connectivity

- Yazaki Corporation

- Amphenol Corporation

- Aptiv PLC

- Sumitomo Electric Industries Ltd.

- Hirose Electric Co. Ltd.

- Molex LLC

- Japan Aviation Electronics Industry Ltd.

- Delphi Technologies

- Rosenberger Hochfrequenztechnik GmbH & Co. KG

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Automotive Connectors Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The automotive connectors market is on an impressive trajectory, with forecasts predicting growth to $14.1 billion by 2025. This expansion is anchored by key drivers such as the rise of electric vehicles (EVs), which demand more sophisticated connector solutions to support their complex electrical systems.

Key Drivers:

- Electrification: The shift towards EVs is largely spurred by environmental incentives and regulatory pushes in major markets like the U.S., Germany, and China.

- Safety Features: Modern vehicles integrate advanced safety and connectivity features, requiring reliable connectors for seamless power distribution.

Regional Insights:

- Asia-Pacific is leading with rapid EV adoption, especially in China.

- Europe benefits from stringent emission regulations promoting electric mobility.

- North America sees a high uptake of connected vehicles, driven by technological investments.

Innovation and Technology:

Advancements in connector technology are crucial. Quick-charging connectors are gaining prominence as manufacturers emphasize charging efficiency and system reliability.

The landscape of the automotive connectors market reflects the broader evolution of the automotive industry itself, marked by significant shifts towards sustainable and connected technologies. As these trends continue to evolve, the demand for innovative connector solutions is set to rise, making this market a pivotal component of future automotive advancements.

Global Automotive Connectors Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Automotive Connectors Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Automotive Connectors Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Automotive Connectors Players and Regional Insights

-

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

-

- Key Differentiators and Strategic Moves

Chapter 3: Automotive Connectors Market Segmentation Analysis

- Key Data and Visual Insights

-

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

-

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

-

- Historical Data and Growth Forecasts

- Regional Growth Factors

-

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Automotive Connectors Emerging and Untapped Markets

- Growth Potential in Secondary Regions

-

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Automotive Connectors Consumer Insights

- Demographics and Buying Behaviors

-

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Automotive Connectors Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected growth of the automotive connectors market by 2025?

The automotive connectors market is projected to grow to $14.1 billion by 2025, highlighting its significance in modern vehicles.

What are the key types of automotive connectors and their applications?

There are various types of automotive connectors including wire-to-wire and wire-to-board connectors, each serving critical functions in vehicle electrical systems.

How do geopolitical factors influence the automotive connectors market?

Geopolitical factors such as trade policies and global supply chain disruptions can significantly affect the availability and pricing of automotive connectors.

What challenges are faced in the production of automotive connectors?

Manufacturers encounter several challenges including production difficulties, quality control issues, and regulatory compliance requirements in the automotive connectors market.

How is electric vehicle adoption impacting the demand for automotive connectors?

The rise of electric vehicles is driving increased demand for specialized connectors that support EV technology and infrastructure needs.

What role does Germany play in the automotive connector manufacturing industry?

Germany is recognized for its engineering excellence and innovation in manufacturing, positioning itself as a leader in the automotive connector technology sector.