Automotive Connecting Rod Bolt Market Expected to Hit $892.36 Million Globally by 2025: Precision Engineering Growth in Germany, Japan, and Mexico

The automotive connecting rod bolt market is driven by advancements in precision engineering, increasing demand for durable and high-performance vehicle parts, and evolving material science and manufacturing technologies. Electric vehicles are reshaping traditional demand patterns, while strict regulatory standards and geopolitical factors influence global supply chains. Regional variations reflect diverse automotive production and consumer preferences, with Germany, Japan, and Mexico playing key roles in innovation, quality manufacturing, and global trade. The market’s future outlook is promising, fueled by technological innovations and emerging materials.

- Last Updated:

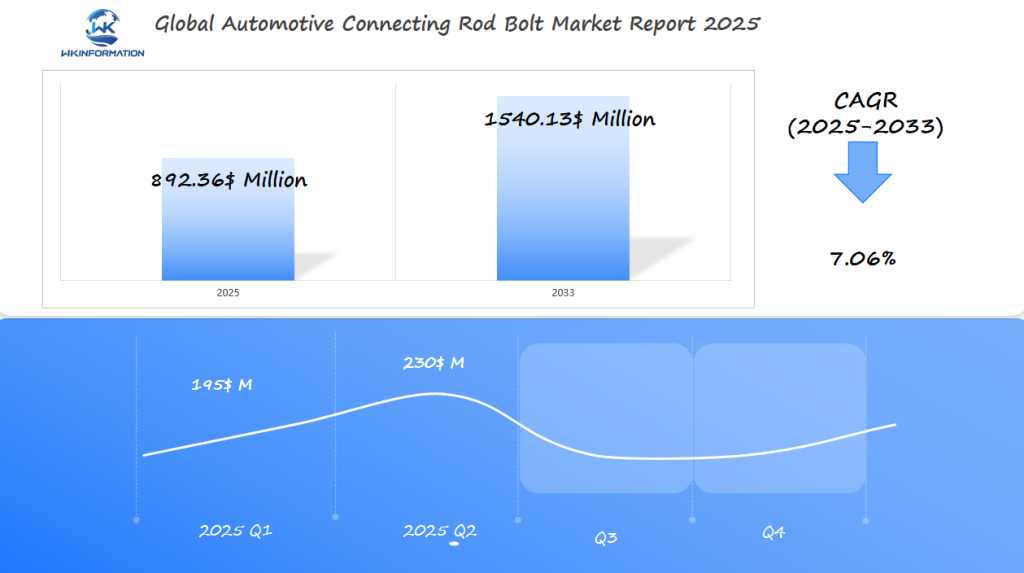

Automotive Connecting Rod Bolt Market Forecast for Q1 and Q2 2025

The Automotive Connecting Rod Bolt market is expected to reach $892.36 million in 2025, with a steady CAGR of 7.06% through 2033. In Q1 2025, the market size is projected at approximately $195 million, reflecting cautious production ramp-ups following year-end inventory adjustments. By Q2, market growth is expected to accelerate to around $230 million, driven by increasing automotive manufacturing activities and stricter quality standards. Germany, Japan, and Mexico are the primary markets due to their strong automotive manufacturing bases, advanced production technologies, and supply chain integration. These countries remain pivotal for tracking market developments and supplier innovations in early 2025.

Key Takeaways

- The global market is expected to hit $892.36 million by 2025.

- Precision engineering is a key driver of market growth.

- Increasing demand for high-performance vehicles is fueling the market.

- Durable automotive parts are becoming increasingly important.

- The market is driven by advancements in manufacturing technology.

Mapping the Upstream and Downstream Supply Chain of Connecting Rod Bolts

Mapping the supply chain of connecting rod bolts reveals the intricate relationships between suppliers, manufacturers, and distributors. The automotive connecting rod bolt industry is known for its complexity, involving various parties from raw material suppliers to end-users.

The supply chain can be broadly categorized into two segments: upstream and downstream. The upstream segment involves raw material suppliers and manufacturers, while the downstream segment includes distributors and end-users. Understanding how this supply chain works is important for finding potential problems and opportunities for growth.

Understanding the supply chain dynamics

The supply chain dynamics of automotive connecting rod bolts are influenced by various factors, including material costs, manufacturing technologies, and market demand. The industry relies heavily on high-quality raw materials, such as steel alloys, which are sourced from specialized suppliers.

| Supply Chain Stage Key Activities Major Players Upstream | Raw material sourcing, manufacturing | Raw material suppliers, manufacturers |

| Downstream | Distribution, sales | Distributors, retailers |

The manufacturing process involves precision engineering to meet stringent quality standards. Companies like Arconic and Norma Group are prominent players in the manufacturing segment, leveraging advanced technologies to produce high-quality connecting rod bolts.

The downstream segment is characterized by a network of distributors and retailers who supply connecting rod bolts to automotive manufacturers and repair shops. The demand in this segment is driven by the automotive industry’s production volumes and the aftermarket demand for replacement parts.

Understanding the supply chain dynamics of the automotive connecting rod bolt industry is essential for stakeholders to navigate the complexities of this market. By analyzing the upstream and downstream segments, companies can identify opportunities for optimization and growth.

Emerging trends influencing automotive connecting rod bolt design and demand

The automotive industry is on the brink of a major change, with new trends greatly affecting the design and need for connecting rod bolts. As vehicle technology improves, the standards for engine parts such as connecting rod bolts are becoming stricter.

Trends in Material Science and Manufacturing Technologies

Advances in material science and manufacturing technologies are playing a crucial role in shaping the future of connecting rod bolts. New materials and production techniques are enabling the creation of stronger, more durable bolts that can withstand the increasing demands of modern engines.

Key developments include:

- Advanced materials like titanium and high-strength steel alloys

- Innovative manufacturing processes such as 3D printing and precision forging

- Improved surface treatments for enhanced durability and resistance to fatigue

The rise of electric vehicles (EVs) is a significant trend affecting the demand for traditional connecting rod bolts. As the automotive industry shifts towards electrification, the demand for components used in internal combustion engines, including connecting rod bolts, is expected to decline.

| Trend | Impact on Connecting Rod Bolts |

| Electrification of Vehicles | Reduced demand for traditional connecting rod bolts |

| Advances in Material Science | Development of new materials and manufacturing processes |

| Increased Engine Efficiency | Higher performance requirements for connecting rod bolts |

However, this shift also presents opportunities for innovation in the design and manufacturing of connecting rod bolts for hybrid vehicles and other specialized applications.

Market restrictions including materials and manufacturing standards

Stringent materials and manufacturing standards govern the production of connecting rod bolts. The automotive industry is heavily regulated, and connecting rod bolts are no exception. These components are critical to engine performance and safety, necessitating strict adherence to industry standards.

The importance of regulatory compliance cannot be overstated. Manufacturers must ensure that their products meet or exceed industry standards for materials, manufacturing processes, and performance. This includes compliance with standards set by organizations such as the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO).

Regulatory compliance and industry standards

Regulatory bodies impose strict guidelines on the automotive industry to ensure safety, performance, and environmental sustainability. For connecting rod bolts, this means that manufacturers must adhere to specific materials standards and manufacturing processes. The use of high-quality materials and advanced manufacturing techniques is crucial for producing bolts that can withstand the stresses of engine operation.

Industry standards also play a significant role in shaping the market for automotive connecting rod bolts. Standards related to performance, durability, and safety influence the design and production of these components. Manufacturers that comply with these standards can ensure that their products are compatible with a wide range of engine types and models.

The impact of market restrictions is multifaceted. On one hand, they ensure that connecting rod bolts meet rigorous safety and performance criteria. On the other hand, they can create barriers to entry for new manufacturers and limit the use of innovative materials or processes that are not yet standardized.

To navigate these challenges, manufacturers must stay informed about evolving regulatory requirements and industry standards. This includes investing in research and development to improve manufacturing processes and materials, as well as collaborating with regulatory bodies to shape future standards.

Geopolitical factors shaping global automotive supply chains

Geopolitical factors have a significant impact on the global automotive supply chain, affecting its stability and efficiency. The complex network of suppliers, manufacturers, and distributors around the world is sensitive to changes in geopolitical situations.

Trade policies, such as tariffs and trade agreements, have a major influence on the automotive supply chain. For example, tariffs on imported steel and aluminum can raise the cost of raw materials for connecting rod bolts.

Impact of trade policies on automotive supply chains

The ongoing trade tensions between major economies have led to a reevaluation of supply chain strategies. Companies are now looking to diversify their supply sources to mitigate risks associated with geopolitical uncertainties.

Key strategies include:

- Nearshoring: Relocating production to countries closer to the final market.

- Diversification: Spreading suppliers across different regions to reduce dependency on any single market.

- Investing in local production: Enhancing local manufacturing capabilities to reduce reliance on imports.

The automotive connecting rod bolt market is intricately linked with the global geopolitical landscape. Understanding these dynamics is crucial for manufacturers and suppliers to navigate the complexities of the global supply chain.

Understanding Different Types of Automotive Connecting Rod Bolts

Automotive connecting rod bolts are not one-size-fits-all; they come in multiple types designed for specific applications.

The variety in connecting rod bolt types is driven by the need for different engine performances, durability, and design specifications. Understanding these types is crucial for manufacturers and suppliers to cater to the diverse needs of the automotive industry.

Types of Connecting Rod Bolts and Their Applications

There are several types of connecting rod bolts, each with its unique characteristics and applications:

- Standard Connecting Rod Bolts: These are the most commonly used bolts, suitable for a wide range of engine types.

- High-Performance Connecting Rod Bolts: Designed for high-performance engines, these bolts offer enhanced strength and durability.

- Specialty Connecting Rod Bolts: These bolts are designed for specific engine applications, such as racing engines or engines with unique design requirements.

The selection of the appropriate type of connecting rod bolt is critical for ensuring engine performance, reliability, and longevity. Manufacturers must consider factors such as material, design, and manufacturing process to meet the specific requirements of different engine types.

Applications across gasoline, diesel, and electric vehicle engines

The automotive connecting rod bolt market is diversifying due to the varying demands of gasoline, diesel, and electric vehicle engines. Each of these engine types has unique requirements for connecting rod bolts, driven by factors such as performance, efficiency, and durability.

Gasoline engines, for instance, require connecting rod bolts that can withstand high rotational speeds and stresses. Diesel engines, on the other hand, demand bolts that can handle even higher compression ratios and stresses. Electric vehicle engines, while different in many ways, still require high-performance bolts for their transmission systems.

Connecting rod bolt requirements for different engine types

The specific needs of each engine type are reflected in the design and manufacturing of connecting rod bolts. For example, bolts for diesel engines are often made with stronger materials to handle the higher compression ratios.

| Engine Type Material Requirements Performance Demands Gasoline | High-strength steel | High rotational speeds |

| Diesel | High-strength, high-toughness materials | High compression ratios, high stresses |

| Electric Vehicle | High-performance materials for transmission | High efficiency, reliability |

Connecting rod bolt applications

The differences in requirements across engine types have significant implications for connecting rod bolt manufacturers. They must be able to design and produce bolts that meet the specific demands of each engine type, whether it’s for a gasoline, diesel, or electric vehicle engine.

Manufacturers are responding by developing specialized bolts that cater to the unique needs of each engine type. This includes using advanced materials and manufacturing techniques to ensure that the bolts can withstand the stresses and performance demands of modern engines.

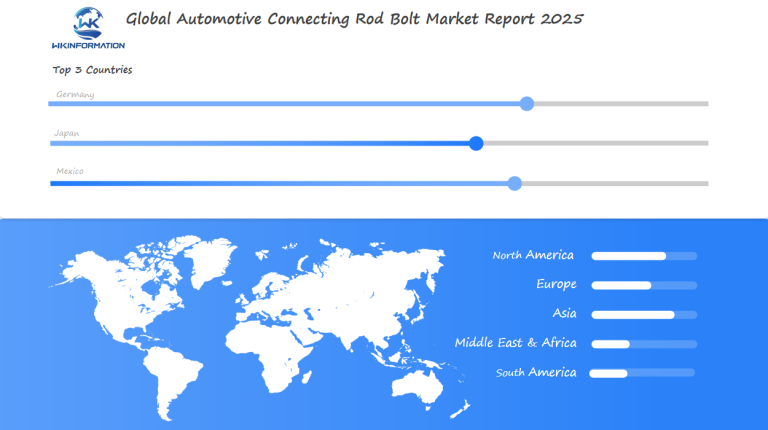

Regional market variations impacting automotive connecting rod bolt sales

The demand for automotive connecting rod bolts varies across regions due to differences in automotive production and consumer preferences. This variation significantly impacts the sales strategies of manufacturers.

Regional Demand Patterns and Market Characteristics

Different regions exhibit unique demand patterns influenced by factors such as automotive production volumes, regulatory environments, and consumer preferences. For instance, regions with high automotive production, such as North America and Asia-Pacific, tend to have a higher demand for connecting rod bolts.

North America

North America is a significant market due to its large automotive industry, with major manufacturers operating in the region. The demand here is driven by both original equipment manufacturers (OEMs) and the aftermarket.

Asia-Pacific

Asia-Pacific, led by countries like China, Japan, and India, is another major hub for automotive production. The region’s demand for connecting rod bolts is influenced by the growing automotive industry and increasing vehicle production.

Europe

In Europe, the demand is driven by the presence of premium automotive manufacturers and stringent regulatory standards. The region’s focus on electric vehicles (EVs) and hybrid vehicles also impacts the demand for specific types of connecting rod bolts.

- North America: High demand due to large automotive production.

- Asia-Pacific: Growing demand driven by increasing vehicle production.

- Europe: Demand influenced by premium automotive manufacturers and regulatory standards.

Understanding these regional demand patterns and market characteristics is crucial for manufacturers to develop targeted sales strategies and effectively cater to the needs of different markets.

Germany’s automotive industry driving bolt innovation

Germany’s automotive sector is a powerhouse of innovation, driving advancements in automotive connecting rod bolt technology. The country’s long history of automotive excellence has fostered a culture of precision engineering and quality manufacturing.

The German automotive industry is home to some of the world’s leading manufacturers, including BMW, Mercedes-Benz, and Volkswagen. These companies are known for their commitment to quality and performance, driving the demand for high-quality connecting rod bolts.

Role in the European Automotive Market

Germany plays a significant role in the European automotive market, with many manufacturers relying on German suppliers for critical components like connecting rod bolts. The country’s strong focus on research and development has led to significant advancements in bolt technology, including the use of new materials and manufacturing techniques.

Innovative manufacturing processes, such as those developed by companies like Schaeffler and Continental, are enhancing the performance and durability of connecting rod bolts. These advancements are crucial for meeting the increasingly stringent requirements of modern engines.

The emphasis on innovation in Germany’s automotive industry is also driving the development of more sustainable and efficient engine technologies. As the industry continues to evolve, the demand for high-performance connecting rod bolts is expected to grow, further solidifying Germany’s position as a leader in this market.

Overall, Germany’s automotive industry is a key driver of innovation in the connecting rod bolt market, with its focus on quality, performance, and sustainability setting the standard for the global industry.

Japan’s Advanced Manufacturing Shaping Market Demand

Advanced manufacturing in Japan is playing a crucial role in shaping the demand for automotive connecting rod bolts worldwide. Japan’s reputation for technological innovation and precision engineering has significantly influenced the global automotive industry.

Technological Advancements and Their Impact

Japan’s manufacturing sector is known for its cutting-edge technologies, including robotics, artificial intelligence, and advanced materials science. These technologies have enabled the production of high-quality connecting rod bolts that meet the stringent requirements of modern automotive engines.

Key Technological Advancements:

- Advanced materials processing

- Precision forging and machining

- Surface treatment technologies

The impact of these advancements is evident in the improved performance and durability of connecting rod bolts. For instance, the use of advanced materials and surface treatment technologies has enhanced the fatigue resistance of these components, leading to longer engine life and reduced maintenance costs.

Japan’s Advanced Manufacturing

The table below highlights some of the key statistics related to Japan’s manufacturing sector and its influence on the automotive connecting rod bolt market.

| Indicator | Value | Impact on Market |

| Production Volume | 1.2 million units | Increased global supply |

| Export Rate | 60% | Significant global market share |

| Average Price | $15/unit | Competitive pricing strategy |

Japan’s advanced manufacturing capabilities not only drive the domestic market but also significantly influence the global automotive connecting rod bolt market. The country’s commitment to innovation and quality sets a high standard for the industry.

Mexico’s Role in Automotive Bolt Production and Export

Mexico has become a key player in the global automotive industry, especially in the production and export of automotive connecting rod bolts. The country’s strategic location, bordering the United States, makes it an ideal spot for manufacturers looking to supply the North American market.

Mexico’s automotive industry has experienced significant growth in recent years, thanks to foreign investment and the country’s favorable business environment. An industry expert states, “Mexico is becoming a major hub for automotive manufacturing, with many international companies setting up production facilities.” This growth isn’t just limited to vehicle assembly; it also includes the production of automotive parts, such as connecting rod bolts.

Mexico’s automotive industry and its global connections

The country’s proximity to the U.S. market, coupled with its trade agreements such as the USMCA (United States-Mexico-Canada Agreement), provides a competitive edge in terms of logistics and export costs. As a result, Mexico has become a key player in the global automotive supply chain, with many manufacturers exporting their products to countries around the world.

Key factors contributing to Mexico’s success in automotive bolt production include:

- A skilled workforce with expertise in manufacturing

- State-of-the-art production facilities

- Favorable trade policies that reduce export costs

- Strategic location for serving the North American market

As the global demand for automotive connecting rod bolts continues to grow, Mexico is well-positioned to capitalize on this trend. The country’s strong manufacturing base, combined with its global connections, makes it an important player in the automotive industry.

Future outlook for automotive connecting rod bolt technologies

The future of automotive connecting rod bolts is being shaped by advancements in technology and materials science. As the automotive industry continues to evolve, the demand for high-performance, reliable, and durable connecting rod bolts is expected to grow.

Emerging technologies are playing a crucial role in this evolution. Advances in materials science, such as the development of high-strength, lightweight materials, are enabling the production of more efficient and durable connecting rod bolts. Additionally, innovations in manufacturing processes, including 3D printing and advanced machining techniques, are improving the precision and quality of these components.

Innovations driving market growth

Several key innovations are driving growth in the automotive connecting rod bolt market. These include:

- Advanced Materials: The development of new materials with enhanced strength, durability, and resistance to fatigue is critical.

- 3D Printing: Additive manufacturing techniques are allowing for the production of complex geometries and customized designs.

- Surface Treatment Technologies: Advances in surface treatment technologies are improving the performance and lifespan of connecting rod bolts.

These emerging technologies are not only improving the performance of connecting rod bolts but also contributing to the overall efficiency and sustainability of automotive engines.

The potential impact of these emerging technologies on the automotive connecting rod bolt industry is significant. With the development of more advanced materials and manufacturing processes, manufacturers will be able to produce higher-quality connecting rod bolts that meet the evolving needs of the automotive industry.

As the industry continues to adopt these new technologies, we can expect to see improvements in engine performance, fuel efficiency, and overall vehicle reliability.

Key competitors and market share analysis

When analyzing the automotive connecting rod bolt market, it is important to consider key competitors and their respective market shares. By understanding the competitive landscape, stakeholders can gain insights into market dynamics and identify opportunities for growth. Conducting a thorough analysis of key competitors will help in determining market trends, pricing strategies, and potential areas for collaboration or differentiation.

Key Players

- Federal-Mogul — United States

- Mahle — Germany

- Mubea — Germany

- Schaeffler Group — Germany

- NTN Corporation — Japan

- Metaldyne Performance Group — United States

- Thyssenkrupp — Germany

- Tenneco — United States

- Dana Incorporated — United States

- Aisin Seiki — Japan

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Automotive Connecting Rod Bolt Market Report |

| Base Year | 2024 |

| Segment by Type | ·Standard Connecting Rod Bolts

·High-Performance Connecting Rod Bolts ·Specialty Connecting Rod Bolts |

| Segment by Application | ·gasoline vehicle engines

·diesel vehicle engines ·electric vehicle engines |

| Geographies Covered | ·North America (United States, Canada)

·Europe (Germany, France, UK, Italy, Russia) ·Asia-Pacific (China, Japan, South Korea, Taiwan) ·Southeast Asia (India) ·Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The automotive connecting rod bolt market is about to experience significant growth, driven by technological advancements and changing consumer preferences. As the industry continues to evolve, it is crucial for stakeholders to understand the dynamics of this market.

Global Automotive Connecting Rod Bolt Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Automotive Connecting Rod Bolt Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Automotive Connecting Rod Bolt Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Automotive Connecting Rod Bolt Players and Regional Insights

-

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

-

- Key Differentiators and Strategic Moves

Chapter 3: Automotive Connecting Rod Bolt Market Segmentation Analysis

- Key Data and Visual Insights

-

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

-

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

-

- Historical Data and Growth Forecasts

- Regional Growth Factors

-

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Automotive Connecting Rod Bolt Emerging and Untapped Markets

- Growth Potential in Secondary Regions

-

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Automotive Connecting Rod Bolt Consumer Insights

- Demographics and Buying Behaviors

-

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Automotive Connecting Rod Bolt Market Insights

Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is driving the growth of the automotive connecting rod bolt market?

The growth of the automotive connecting rod bolt market is driven by:

- Advancements in precision engineering

- The rising need for durable automotive parts

- Increasing demand for high-performance vehicles

How do emerging trends in material science and manufacturing technologies impact the market?

Advances in material science and manufacturing technologies enable the production of more durable and efficient connecting rod bolts, influencing the market’s growth and design.

How do electric vehicles affect the demand for traditional connecting rod bolts?

The rise of electric vehicles is changing the landscape of the automotive industry, affecting the demand for traditional connecting rod bolts as the industry shifts towards different technologies.

What are the key market restrictions for automotive connecting rod bolts?

The market has strict materials and manufacturing standards that must be followed. It is essential for manufacturers to comply with regulations in order to ensure their products meet industry standards.

How do geopolitical factors influence the global automotive supply chains?

Geopolitical factors, including trade policies and tariffs, significantly impact global automotive supply chains, affecting the cost and availability of raw materials and finished goods.

What are the different types of connecting rod bolts and their applications?

Automotive connecting rod bolts come in various types, each designed for specific applications, and understanding these differences is essential for manufacturers and suppliers.

How do regional demand patterns and market characteristics vary across different regions?

The demand for automotive connecting rod bolts varies significantly across different regions, influenced by factors such as automotive production, consumer preferences, and regulatory environments.

What role does Germany play in driving innovation in the automotive connecting rod bolt market?

Germany’s strong focus on innovation and quality drives advancements in automotive connecting rod bolt technology, with many leading manufacturers based there.

How does Japan’s advanced manufacturing shape market demand?

Japan’s expertise in producing high-quality components shapes market demand and drives competition, with its advanced manufacturing technologies influencing the market.

What is Mexico’s role in the global automotive connecting rod bolt market?

Mexico has become an important player in the automotive industry, including the production and export of automotive connecting rod bolts, because of its strategic location and trade agreements.

What is the future outlook for automotive connecting rod bolt technologies?

The future is shaped by emerging technologies and innovations, with advances in mate