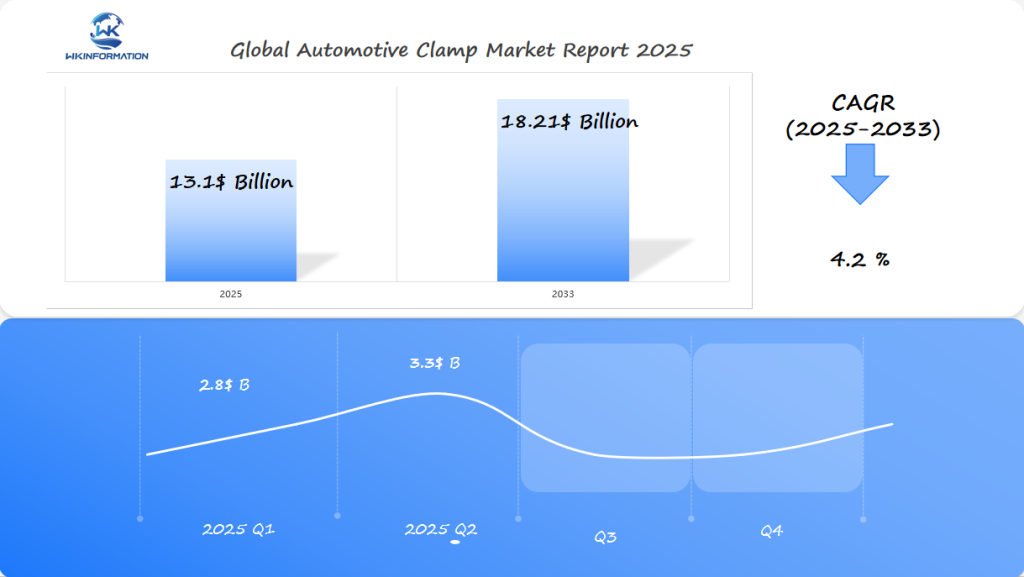

Automotive Clamp Market Estimated at $13.1 Billion by 2025: Engine Efficiency and EV Growth Drive Adoption in South Korea, Germany, and Thailand

The Automotive Clamp Market expands with rising demand for engine efficiency and electric vehicles, driven by automotive manufacturers’ focus on lightweight components and durability.

- Last Updated:

Automotive Clamp Market Performance in Q1 and Q2 of 2025

The Automotive Clamp market is projected to reach $13.1 billion in 2025, maintaining a CAGR of 4.2% from 2025 to 2033. Based on current dynamics, Q1 revenue is estimated at $2.8 billion, with Q2 likely to reach $3.3 billion, boosted by seasonal vehicle production cycles and aftermarket activity. The increasing complexity of automotive systems, especially in electric vehicles, is spurring demand for specialized clamping solutions.

Key Takeaways

- Automotive clamp market expected to reach $13.1 billion by 2025

- Electric vehicle growth driving market expansion

- Increasing focus on engine efficiency and lightweight design

- Technological innovations transforming clamping solutions

- Critical role in managing advanced vehicle systems

Automotive Clamp Market Upstream and Downstream Industry Chain Analysis

Upstream Industry Chain

- Raw Materials Suppliers

- Metals (steel, stainless steel, aluminum)

- Polymers and plastics for specialized clamps

- Advanced lightweight materials for innovation

- Component Manufacturers

- Precision metal forming and stamping companies

- Plastic molding firms for polymer clamp components

- Technology Providers

- R&D in smart self-adjusting clamp technology

- Material science firms developing lightweight, durable compounds

- Design and Engineering Services

- Specialized engineering to meet emission control and fuel-line safety standards

- Custom clamp design for electric vehicle (EV) and hybrid platforms

Core Manufacturing Process

- Metal stamping, forming, and machining

- Assembly of multi-component clamps (spring, worm gear, V-band)

- Quality control focused on durability under extreme automotive conditions

Downstream Industry Chain

- Automotive OEMs (Original Equipment Manufacturers)

- Integration of clamps into fuel systems, exhaust systems, coolant lines, and battery packs

- Collaboration with clamp manufacturers for customized solutions tailored to combustion engines, hybrids, and EVs

- Tier 1 & Tier 2 Suppliers

- Suppliers who incorporate clamps into larger assemblies such as fuel lines or cooling modules

- Aftermarket and Replacement Parts Vendors

- Distribution channels serving vehicle maintenance and repair sectors

- Automotive Service Providers

- Workshops requiring reliable supply of replacement clamps to ensure vehicle safety and performance

Trends Driven by Emission Control, Fuel-Line Safety, and E-Mobility Needs

The automotive industry is changing fast. This is because of important trends in emission control and e-mobility. Car makers are making new clamps to follow strict rules on the environment and safety.

Key Trends in the Automotive Clamp Market

Key trends in the automotive clamp market include:

- Advanced emission control technologies needing precise clamps

- Improved fuel-line safety for better car reliability

- Clamps made just for electric and hybrid cars

The Importance of Emission Control

Emission control is a big deal for car engineers now. Clamp makers are coming up with new ideas. These ideas help cars use less carbon while still performing well.

| Trend Category | Key Developments | Impact on Clamp Design |

| E-Mobility | Battery pack integration | Lightweight, corrosion-resistant materials |

| Fuel-Line Safety | Pressure resistance | High-strength composite clamps |

| Emission Control | Reduced environmental impact | Precision-engineered sealing mechanisms |

The Rise of E-Mobility

The move to e-mobility is opening up new chances for clamp makers. Electric cars need specialized clamp solutions for their unique heat and stress issues.

The Continued Importance of Fuel-Line Safety

Fuel-line safety is still very important. Car makers are spending a lot on making clamps that seal well and last long in many car types.

Restrictions include design complexity and compatibility across vehicle platforms

The automotive clamp market faces big challenges due to advanced vehicle designs. Design complexity is key in making effective clamps for different vehicles.

Manufacturers face many hurdles in making universal clamps:

- Diverse vehicle platform specifications

- Varying material requirements

- Performance optimization demands

- Cost-effective production constraints

Vehicle platform compatibility is a big engineering challenge. Automotive designers must make clamps that work on many vehicle types. They need to keep performance consistent.

| Design Challenge | Impact on Clamp Development |

| Material Variation | Requires flexible engineering approaches |

| Thermal Resistance | Critical for high-performance applications |

| Weight Optimization | Demands innovative lightweight solutions |

Precision engineering is crucial in solving these complex design challenges. Automotive makers need to invest in advanced research. They must create clamping systems that meet strict performance needs.

Geopolitical shifts in automotive supply chains and emissions policy

The automotive industry is going through big changes because of complex global politics. Supply chains are being reorganized as trade patterns change. This brings new challenges and chances for makers all over the world.

Important global politics are changing the car world in big ways. These include:

- Regional trade deals affecting where parts come from

- New economic powers challenging old manufacturing centers

- Changes in how international manufacturing networks are set up

Emissions rules are also playing a big role in these changes. Different rules in different places are making car makers change how they make and get parts. Strict green rules in the European Union and California are making companies change how they make and get parts.

The mix of global politics and emissions rules is making a fast-changing world. This world is:

- Seeing more electric cars being made

- Making supply chains strong and flexible

- Speeding up tech to meet green rules

Car makers are making their supply chains more flexible and quick to change. This helps them deal with trade issues, rule changes, and economic ups and downs.

Automotive Clamp market segmentation by type: hose clamps, spring clamps, V-band clamps, worm gear clamps

The automotive clamp market is key to vehicle engineering. It uses different technologies for various needs. Manufacturers keep improving to make clamps more efficient and reliable.

Automotive clamps are vital for connecting and securing vehicle systems. Each type has special features for different challenges.

Hose Clamps: Versatile Fluid System Connectors

Hose clamps are essential for fluid transfers in cars. They ensure:

- Secure seal for coolant lines

- Reliable fuel system connections

- Consistent pressure management

Spring Clamps: Precision Flexible Fastening

Spring clamps offer dynamic compression in tight spaces. Their benefits include:

- High resilience under temperature changes

- Quick installation

- Less material weight

V-band Clamps: Heavy-Duty Performance Connectors

V-band clamps are great for high-pressure and high-temperature situations. They are preferred for:

- Exhaust system connections

- Turbocharger interfaces

- Industrial-grade sealing needs

Worm Gear Clamps: Precision Engineering Solutions

Worm gear clamps offer great adjustability and consistent force. They are used for:

- Complex piping systems

- Intricate fluid transfer networks

- Precision mechanical assemblies

The ongoing evolution of automotive clamp technologies continues to drive innovation in vehicle design and performance.

Automotive Clamp market segmentation by application: fuel systems, exhaust systems, coolant lines, battery packs

The automotive clamp market is key for many vehicle systems. These parts help keep connections strong and seals tight. They work in everything from old engines to new electric cars.

Car makers need exact clamps for good performance and safety. The market has several areas:

- Fuel systems

- Exhaust systems

- Coolant lines

- Battery packs

Fuel Systems Engineering

Fuel systems require clamps that can withstand high temperatures and chemicals. These clamps prevent fuel leaks and maintain optimal pressure in modern vehicles.

Exhaust System Performance

Exhaust system clamps are subjected to high temperatures and vibrations. Advanced metallurgical designs ensure their durability while also complying with emission regulations.

Coolant Line Reliability

Coolant line clamps stop leaks and keep fluid moving. Engineers choose materials that don’t rust and keep seals tight, even in extreme temperatures.

Battery Pack Integration

Electric car battery packs need special clamps for safe and strong connections. These clamps help with heat control and safety in electric cars.

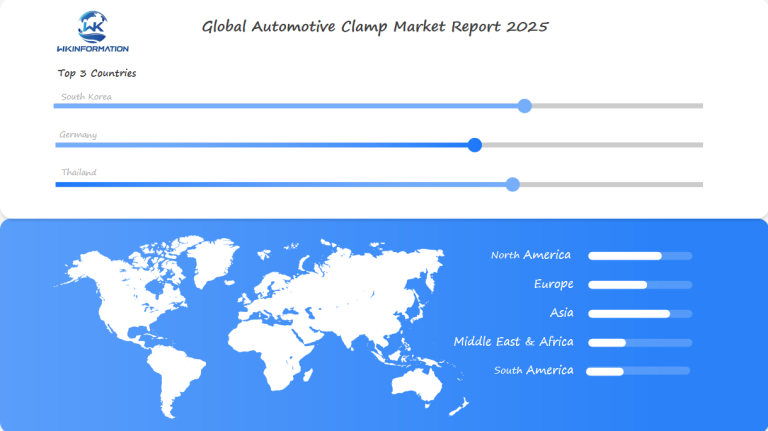

Global perspective of the Automotive Clamp market

The global automotive clamp market is a complex mix of technology and trade. Different regions have their own ways of shaping the market. This leads to unique patterns in each area.

Key traits of the global market include:

- Rapid technological changes in making clamps

- More demand for light and strong clamps

- Shifts in where clamps are made

- More focus on reducing emissions

Companies face complex trade rules and tech needs. The market grows due to several key factors:

- More electric cars

- Tighter fuel standards

- New materials

- Global supply chains

Each region has its own way of using and improving automotive clamps. In the West, there’s a focus on precision. In Asia, it’s about keeping costs low.

| Region | Market Characteristic | Growth Potential |

| North America | High-precision engineering | Moderate |

| Europe | Emission technology focus | Steady |

| Asia-Pacific | Cost-effective manufacturing | High |

The global market needs constant innovation and flexibility. Companies must stay ahead to keep their edge.

South Korea Automotive Clamp market: EV production and precision parts

The South Korea automotive industry is leading in technology, especially in electric vehicles (EVs). Precision parts are key to their success, with clamps playing a big role in new car tech.

Advanced Clamp Designs by South Korean Manufacturers

South Korean makers have created advanced clamp designs. They focus on important areas like:

- High-performance EV battery systems

- Advanced cooling mechanisms

- Lightweight and durable component connections

Hyundai and Kia’s Role in EV Innovation

Hyundai and Kia are at the forefront of this innovation. They push the limits of precision parts for EVs. Their work has led to the creation of specialized clamps that meet high standards.

Strengths of South Korea’s Clamp Making Industry

South Korea’s clamp making has several strengths:

- Exceptional engineering precision

- Advanced materials research

- Robust quality control processes

Importance of South Korea’s Skills in Precision Parts for the Future of Car Making

With more people wanting electric cars, South Korea’s skills in precision parts are crucial. The country is set to play a big role in car making’s future.

Germany's Automotive Clamp Market: Internal Combustion and Hybrid Engineering

The German automotive industry is at the forefront of engineering innovation, particularly in the field of automotive clamp technology. With a reputation for precision and advanced manufacturing techniques, Germany sets global standards in both internal combustion and hybrid vehicle technology.

Advanced Clamp Designs by German Manufacturers

German manufacturers have developed cutting-edge clamp designs to address the complexities of modern automotive systems. Their expertise spans across various domains:

- High-performance internal combustion engine components

- Advanced hybrid vehicle interconnection systems

- Precision-engineered fastening solutions

The growth of automotive clamps signifies Germany’s commitment to engineering excellence. Precision engineering plays a vital role in their craftsmanship, resulting in clamps that:

- Endure high temperatures

- Exhibit superior mechanical strength

- Are lightweight

Innovations Driven by Hybrid Vehicle Technology

The emergence of hybrid vehicle technology has brought about significant advancements in clamp design. German manufacturers are now producing specialized clamps tailored for electric and hybrid cars, further solidifying their position as leaders in automotive engineering.

Germany’s expertise in clamp technology combines traditional skills with modern advancements. This unique blend positions Germany as a global frontrunner in the design of automotive components.

Thailand Automotive Clamp Market: Regional Automotive Export Hub

Thailand has become a key player in Southeast Asia, known as a major automotive export hub. The country’s automotive industry uses its strong manufacturing and supply chain networks well.

Strengths of Thailand’s Automotive Clamp Market

Thailand’s automotive clamp market has several strengths:

- It’s in a strategic location in Southeast Asia.

- It has advanced manufacturing facilities.

- Production costs are competitive.

- The government supports automotive manufacturing a lot.

International Investment in Thailand’s Clamp Sector

International companies see Thailand’s value and invest a lot here. The country’s clamp sector gets benefits from:

- It has advanced engineering skills.

- It makes high-quality parts.

- It has a good export setup.

- It uses flexible production methods.

Big names like Toyota, Honda, and Ford have big bases here. They push for better clamp production. This makes Thailand known for making top-notch automotive parts.

Adaptability and Innovation in Thailand’s Auto Industry

Thailand’s auto industry is very strong and keeps up with new tech and market needs. It focuses a lot on research, development, and making precise parts. This keeps Thailand a top player in the global auto market.

Future innovations in lightweight materials and smart self-adjusting clamps

The car industry is changing fast. Lightweight materials are key for better performance and efficiency. New tech is making clamps smarter, with self-adjusting tech that’s changing car design.

How new materials are affecting clamp design

New materials are changing how clamps are made. Scientists are working on composites that are lighter but still strong. These materials bring many benefits:

- Improved fuel efficiency

- Reduced vehicle emissions

- Enhanced performance capabilities

- Greater durability under extreme conditions

The impact of smart self-adjusting technology on vehicles

Smart clamps are a big step forward in car tech. They use sensors and adjust themselves automatically. This tech lets cars adjust in real-time, improving how they work.

Smart self-adjusting tech is set to change car engineering. These new ideas will help make cars more efficient and smart.

Competitive outlook in the automotive fastener industry

Key players in the hose clamps market are focusing on innovation in material strength, corrosion resistance, and tool-free installation to meet the evolving needs of automotive, industrial, and plumbing applications. They are expanding into fast-growing regions such as Asia-Pacific and Eastern Europe, where industrialization and vehicle production are accelerating. Strategic partnerships with OEMs and aftermarket distributors, along with investments in automated manufacturing and customized solutions, are helping these companies improve global reach and strengthen their competitive position.

Key Players:

-

Norma Group (Germany)

-

Oetiker Group (Switzerland)

-

Gates Corporation (USA)

-

Eaton Corporation (USA)

-

ABA Group (Sweden)

-

Ideal-Tridon (USA)

-

Mikalor (Spain)

-

Rosta (Switzerland)

-

BSB Group (UK)

-

Serflex (France)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Automotive Clamp Market Report |

| Base Year | 2024 |

| Segment by Type |

· Hose Clamps · Spring Clamps · V-band Clamps · Worm Gear Clamps |

|

Segment by Application |

· Fuel Systems · Exhaust Systems · Coolant Lines · Battery Packs |

|

Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Automotive Clamp Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Automotive Clamp Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Automotive Clamp Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Automotive Clamp Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Automotive Clamp Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Automotive Clamp Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Automotive Clamp Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Automotive Clamp Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market value for automotive clamps by 2025?

The market for automotive clamps is expected to hit $13.1 billion by 2025. This growth is due to the need for better engine efficiency and the rise in electric vehicle production.

What are the primary types of automotive clamps?

The main types of automotive clamps include:

- Hose clamps: Used to secure hoses in place.

- Spring clamps: Designed to hold components together with spring tension.

- V-band clamps: Ideal for connecting exhaust pipes or other cylindrical parts.

- Worm gear clamps: Versatile clamps that can be adjusted to fit various sizes.

Each type of clamp serves a specific purpose in vehicles and is made for different uses.

How are emission control regulations impacting automotive clamp design?

Tighter emission rules are pushing for better clamp materials and designs. This is to help reduce emissions and boost vehicle performance.

What application areas are most critical for automotive clamps?

Fuel systems, exhaust systems, coolant lines, and battery packs are key areas. Each needs special clamp designs to meet specific needs.

How are electric vehicles changing the automotive clamp market?

Electric vehicles are driving demand for clamps designed for battery systems and high-voltage connections. They also need lightweight, precise components.

What challenges do manufacturers face in automotive clamp production?

Manufacturers face challenges like managing complex designs and ensuring compatibility. They also need to balance cost and performance while keeping up with new technologies.

Which regions are leading in automotive clamp innovation?

South Korea, Germany, and Thailand are leading in clamp innovation. They bring strengths like EV production, precision engineering, and local manufacturing.

What future innovations are expected in automotive clamps?

Future innovations include clamps made from lightweight materials and smart, self-adjusting designs. These will support autonomous vehicles and new powertrain technologies.

How are geopolitical shifts affecting the automotive clamp market?

Global trade changes, emissions policies, and supply chain shifts are big influences. They affect clamp manufacturing, sourcing, and market trends.

What is driving the growth of the automotive clamp market?

Growth is driven by a focus on engine efficiency, emissions, safety, and the shift to electric and hybrid vehicles. This shift towards more sustainable vehicle options is reflected in the increasing demand for specialized automotive components, such as clamps, which are essential for the efficient functioning of these advanced engines.