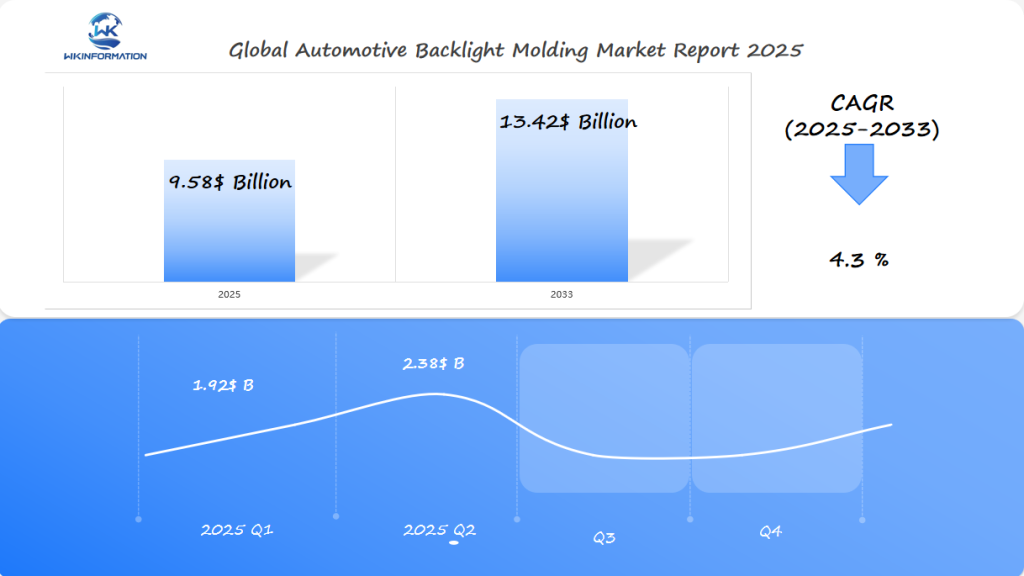

Automotive Backlight Molding Market on Track for $9.58 Billion by 2025: Vehicle Cockpit Design and Lighting Integration Advance in the U.S., Mexico, and Germany

The Automotive Backlight Molding Market shows strong growth potential, driven by increasing demand for advanced vehicle lighting systems and innovative cockpit designs across luxury and economy segments

- Last Updated:

Automotive Backlight Molding Market Performance in Q1 and Q2 of 2025

The Automotive Backlight Molding market is projected to reach $9.58 billion in 2025, with a CAGR of 4.3% from 2025 to 2033. Q1 performance is estimated at $1.92 billion, while Q2 is likely to climb to $2.38 billion, in line with seasonal OEM production cycles and aftermarket demand for enhanced visibility systems. The technology’s expansion into electric and luxury vehicle segments is accelerating demand for precision-molded backlight modules.

Key Takeaways

- Market expected to reach $9.58 billion by 2025

- Increasing focus on advanced vehicle cockpit design

- Growing demand for sophisticated lighting solutions

- Technological innovations driving market expansion

- Integration of complex molding techniques in automotive manufacturing

Analysis of the Upstream and Downstream Industry Chain in the Automotive Backlight Molding Market

The automotive backlight molding industry is a complex web of players. They all work together to bring new ideas and products to life. Suppliers at the top of the chain give raw materials and special parts needed for top-notch backlighting.

Key Upstream Suppliers in the Automotive Backlight Molding Market

Key upstream suppliers in the automotive backlight molding market include:

- Polymer manufacturers specializing in high-performance plastics

- Electronic component producers

- Precision material engineering firms

- Chemical compound developers

At the bottom, car makers are the main buyers. They look for the latest in lighting tech. Their needs and new ideas push the industry forward.

| Supply Chain Segment | Key Players | Primary Contributions |

| Upstream Suppliers | BASF, Dow Chemical | Advanced material development |

| Midstream Manufacturers | Automotive Lighting Specialists | Molding and component integration |

| Downstream Customers | Tesla, BMW, Ford | Final product implementation |

Looking at the industry chain shows how closely linked everyone is. Strategic collaborations are key to keeping up with new demands and designs.

New tech and materials are changing what suppliers can do. This leads to better and more efficient backlight molding for car makers.

Interior aesthetic trends and functional lighting boost demand

The car industry is changing fast, thanks to what people want in their vehicles. Now, car interiors are smarter and look better. Lighting is key, not just for seeing but for making the car look good and feel right.

Today’s car design focuses on lighting that wraps you in an experience. Car makers use new tech to make the inside of cars better. They mix:

- Ambient mood lighting

- Intuitive information displays

- Seamless ergonomic interfaces

What people want from their cars is changing fast. Functional lighting does more than just light up the space. It also:

- Creates a mood

- Makes the car safer

- Helps you use the car’s features

Car designers are using cool backlighting tricks to change how we see the inside of cars. These new ideas meet what people want: cars that are smart, fit to you, and look great.

The mix of looks and lighting is a big step forward in car design. It’s leading to cars that are more personal and react to you in the future.

Challenges from thermal deformation and material adhesion

Automotive backlight molding faces big challenges that affect product quality and how fast it’s made. Thermal deformation is a major problem in making these parts. It makes it hard for engineers and designers to do their jobs well.

Some of the main challenges are:

- Keeping control over how materials react to heat

- Reducing problems with the structure when it cools down

- Dealing with how materials stick together

Material adhesion is also a big technical problem. Car makers need to make sure materials bond well together in backlight parts. They use special polymers and advanced materials that need careful handling to work right.

Studies show that thermal deformation can hurt:

- How well parts fit together

- The light quality of backlight systems

- How long parts last mechanically

New solutions are coming from better materials and precise engineering. Cutting-edge molding technologies use advanced heat control and smart material choices. These help solve the problems of making backlight parts.

Geopolitical implications from automotive trade and design IP

The automotive backlight molding market is at a key spot where global trade and intellectual property meet. Geopolitical factors are changing the industry’s shape. They create complex situations for makers and suppliers all over the world.

How geopolitical factors affect the market

Geopolitical factors affect the market in several ways:

- International trade agreements impact raw material sourcing

- Cross-border intellectual property protection strategies

- Regional manufacturing incentives for automotive technologies

- Technology transfer restrictions between countries

Intellectual property is now a key asset in automotive design. Companies spend a lot to protect their backlight molding tech. They know that new designs can give them a big edge over others.

Trade policies are very important for market access and tech exchange. Governments are watching tech transfers closely, especially in areas like automotive backlight molding. This attention brings both challenges and chances for global makers wanting to grow.

Automotive companies need to plan carefully. They must balance protecting their innovations with growing globally.

Automotive Backlight Molding market segmentation by type: injection molding, insert molding, compression molding

The automotive backlight molding market has three main techniques. Each one helps create advanced vehicle lighting designs. These methods offer unique benefits for making sophisticated backlights.

Injection molding is the most common method used in making backlights. It involves pouring molten material into a mold. This way, makers can create complex shapes with great accuracy and speed.

- High-volume production capabilities

- Excellent dimensional accuracy

- Reduced material waste

Insert molding lets makers mix different materials and parts. They add pre-made metal or electronics into the mold first. This makes it easy to create detailed backlight units with smooth connections inside.

Compression molding is perfect for advanced backlight designs. It uses high pressure and heat to shape raw materials. This method makes parts strong enough for tough car uses.

Car designers use these molding methods to make new backlight ideas. They aim for designs that look good and work well. The choice of molding method depends on the material, design, and how many parts are needed.

| Molding Technique | Key Advantages | Typical Applications |

| Injection Molding | High-speed production | Standard backlight panels |

| Insert Molding | Multi-material integration | Complex electronic backlights |

| Compression Molding | Superior structural strength | High-performance lighting systems |

As car lighting gets better, these molding methods will be key. They help make top-notch backlight solutions. These solutions meet the latest design and performance needs.

Automotive Backlight Molding market segmentation by application: dashboard panels, infotainment systems, ambient lighting

The automotive backlight molding market has clear divisions in key areas: Dashboard panels, infotainment systems, and ambient lighting. These applications are leading the way in innovation and enhancing the driving experience in modern vehicles.

Dashboard Panels

Dashboard panels serve as the primary visual interface for drivers. They utilize advanced backlighting techniques to create an aesthetically pleasing and easily readable display. Automotive manufacturers are actively striving to design these panels in a sleek and informative manner.

- Enhanced visibility in various lighting conditions

- Customizable color schemes

- Improved user interaction through intuitive design

Infotainment Systems

Infotainment systems have undergone a transformation from basic screens to comprehensive multimedia centers. Backlight molding plays a crucial role in these systems by providing:

- Crisp, high-contrast displays

- Touch-sensitive interfaces

- Seamless integration with vehicle controls

Ambient Lighting

Ambient lighting represents the most innovative application of backlight molding in the automotive industry. Manufacturers are leveraging cutting-edge lighting technology to create an immersive environment within vehicles, tailoring it to individual preferences and external factors such as weather conditions.

These three segments highlight the significance of backlight molding in enhancing car interiors. By seamlessly merging technology, comfort, and aesthetics, it offers a unique proposition that has never been witnessed before.

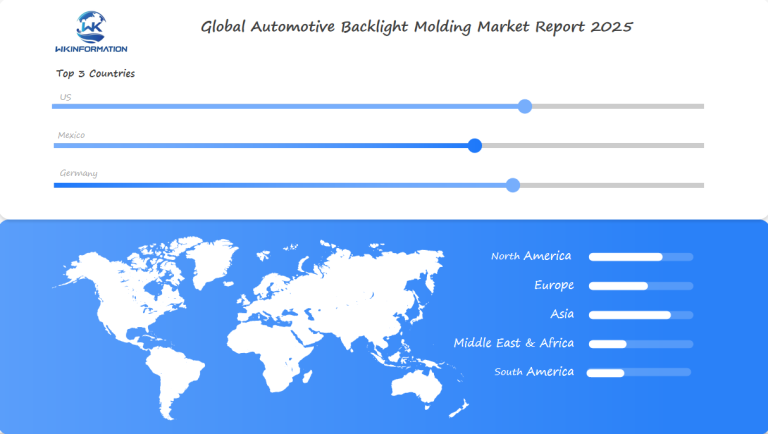

Global scope of the Automotive Backlight Molding market

The automotive backlight molding market is very active worldwide. It has different growth patterns in each region. Companies are working hard to grow their presence in many places.

Looking at the global market, we see big differences in each area. These differences play a big role in how the industry grows:

- Asia-Pacific is a leader in making things and coming up with new ideas.

- In North America, there’s a focus on design and using new materials.

- Europe is all about making things precise and using eco-friendly ways to make things.

To succeed, companies need to understand what each region needs. Automotive backlight molding technologies must fit local rules, what people want, and how things are made. The market keeps changing because of new tech and changes in car designs.

Companies are spending a lot on research to make molding solutions that work everywhere. This helps them make things faster and stay ahead in the car world.

U.S. Automotive Backlight Molding market: EV interiors and design upgrades

The U.S. market for automotive backlight molding is changing fast. Electric vehicles and new interior designs are leading this change. Car makers are working hard to create better and more advanced cockpits. They want to mix beauty with function perfectly.

Important changes in electric vehicles in the U.S.

Some important changes happening in electric vehicles in the U.S. include:

- Advanced backlight molding techniques for complex dashboard configurations

- Enhanced ambient lighting integration

- Improved thermal management for electronic components

Designers are now focusing on making premium interiors for electric cars. They want to make these cars stand out from gas-powered ones. This means using new molding tech to fit complex designs.

| Molding Technology | EV Interior Application | Market Potential |

| Injection Molding | Dashboard Panels | High Growth |

| Insert Molding | Electronic Interfaces | Moderate Growth |

| Compression Molding | Ambient Lighting Structures | Emerging Potential |

The world of interior design is always getting better. This pushes car makers to find new ways to make backlight molding. They need to meet the high standards of today’s electric car buyers.

Mexico Automotive Backlight Molding market: Tier-1 supplier expansion

The Mexico market for automotive backlight molding is growing fast. This is thanks to strategic manufacturing growth. Tier-1 suppliers are quickly setting up shops across the area. They see Mexico as a great place to make cars.

Several things are pushing this growth:

- Being close to big North American car markets

- Lower costs for making things compared to other places

- A skilled workforce with the right training

- Strong industrial setup for car making

Big Tier-1 suppliers from around the world are putting a lot of money into Mexico. This growth offers great chances for both local and global companies. They can find ways to make things more efficiently.

Mexico’s spot in the car supply chain is drawing in big investments. Automotive backlight molding is a key area. It combines precise making with affordable ways to produce.

Germany's Automotive Backlight Molding Market: Precision Lighting for Luxury Vehicles

The Germany market leads in automotive lighting innovation, especially in luxury vehicles. Brands like Mercedes-Benz and BMW are at the forefront. They are introducing precision lighting technologies that change how interiors look and function.

The Role of German Engineering

German engineering is key to these advancements in backlight molding. Luxury car makers are spending a lot on new lighting solutions. These solutions offer:

- Enhanced visual sophistication

- Adaptive ambient lighting systems

- Seamless integration of electronic interfaces

Precision Lighting: A Key Feature in Luxury Cars

Precision lighting is now a key feature in luxury cars. The detailed molding allows for complex light designs. These designs show off the brand’s identity and tech skills.

More Customization with Advanced Backlight Molding Methods

These advanced backlight molding methods also mean more customization. Intelligent lighting systems can change color, brightness, and pattern based on driving conditions, passenger choices, and the time of day.

Setting New Standards in the Auto Industry

The German auto industry keeps setting new standards. Backlight molding is now a key design element that makes driving a luxury experience.

Future developments in multi-material molding and OLED integration

The automotive lighting industry is about to undergo significant changes. New molding techniques are transforming the way lights are manufactured, offering greater flexibility and performance.

Key future trends in automotive backlight molding include:

- Advanced OLED integration for enhanced visual experiences

- Lightweight multi-material component development

- Improved thermal and structural performance

- Enhanced design complexity and customization

OLED integration represents a significant advancement in car lighting technology. These organic light-emitting diodes (OLEDs) are highly energy-efficient, providing design flexibility and superior light quality compared to traditional lighting solutions.

| Technology | Performance Benefit | Design Impact |

| Multi-Material Molding | Weight Reduction | Complex Geometries |

| OLED Integration | Energy Efficiency | Seamless Aesthetic |

| Hybrid Lighting Systems | Adaptive Illumination | Customizable Experiences |

Car manufacturers are investing more in research to enhance molding techniques. These innovative methods will produce lights that not only perform well but also have an appealing appearance and incorporate cutting-edge technology.

New technologies will continue to improve car lights, leading to more environmentally friendly, efficient, and visually striking car interiors.

Competitive insights into molding system providers and OEM collaborators

Key players in the automotive backlight molding market are focusing on precision manufacturing and advanced lighting integration to meet the growing demand for sleek, energy-efficient, and customizable interior displays. They are expanding into key automotive hubs in Asia-Pacific and Eastern Europe, where electric and smart vehicle production is accelerating. Strategic partnerships with OEMs and investments in technologies like overmolding, laser etching, and light guide film are enabling these companies to deliver high-performance solutions and enhance their competitive edge.

Key Players:

-

Magna International (Canada)

-

Valeo (France)

-

Lear Corporation (USA)

-

Faurecia (France – now part of Forvia Group)

-

Denso (Japan)

-

Bosch (Germany)

-

Continental (Germany)

-

ZKW Group (Austria – subsidiary of LG Electronics, South Korea)

-

Hella (Germany – part of Forvia Group)

-

Koito Manufacturing (Japan)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Automotive Backlight Molding Market Report |

| Base Year | 2024 |

| Segment by Type |

· Injection Molding · Insert Molding · Compression Molding |

| Segment by Application |

· Dashboard Panels · Infotainment Systems · Ambient Lighting |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Automotive Backlight Molding Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Automotive Backlight Molding Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Automotive Backlight Molding Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Automotive Backlight Molding Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Automotive Backlight Molding Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Automotive Backlight Molding Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Automotive Backlight Molding Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Automotive Backlight Molding Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market value for automotive backlight molding by 2025?

The market for automotive backlight molding is expected to hit $9.58 billion by 2025. This growth is fueled by new designs in vehicle cockpits and advanced lighting systems.

What are the key technical challenges in automotive backlight molding?

The main hurdles include thermal deformation and material adhesion. These issues can affect product quality and efficiency. Researchers are working on new materials and processes to solve these problems.

What molding techniques are used in automotive backlight production?

The main methods are injection molding, insert molding, and compression molding. Each has its own benefits and is used for specific tasks in making automotive backlights.

How are interior design trends affecting automotive backlight molding?

Trends like ambient lighting and integrated displays are boosting demand for advanced backlight molding. These innovations improve both looks and function of car interiors.

What role do geopolitical factors play in the automotive backlight molding market?

Global politics, such as trade policies and IP concerns, have an impact on the market and supply chain. Protecting design IP is crucial for maintaining competitiveness.

How is the U.S. market approaching automotive backlight molding?

The U.S. is focusing on electric vehicle (EV) interiors and design upgrades. Backlight molding is crucial for enhancing the appearance and functionality of future cars.

What future developments are expected in automotive backlight molding?

Expect advancements in multi-material molding and OLED technology. These will open up new design, function, and energy efficiency possibilities.

How are different regions approaching automotive backlight molding?

Regions have different strategies:

- Germany aims for luxury lighting precision

- Mexico is expanding Tier-1 supplier capabilities

- Others are following local trends

What applications are driving demand for automotive backlight molding?

Demand is rising for dashboard panels, infotainment systems, and ambient lighting. These areas are in demand due to consumer desire for more advanced interiors.

How does the supply chain impact automotive backlight molding?

The supply chain, which includes raw material suppliers and car manufacturers, plays a crucial role in the automotive backlight molding process. The relationships between these groups shape market trends and innovations. For instance, the quality of raw materials supplied can directly affect the durability and performance of backlights in vehicles.