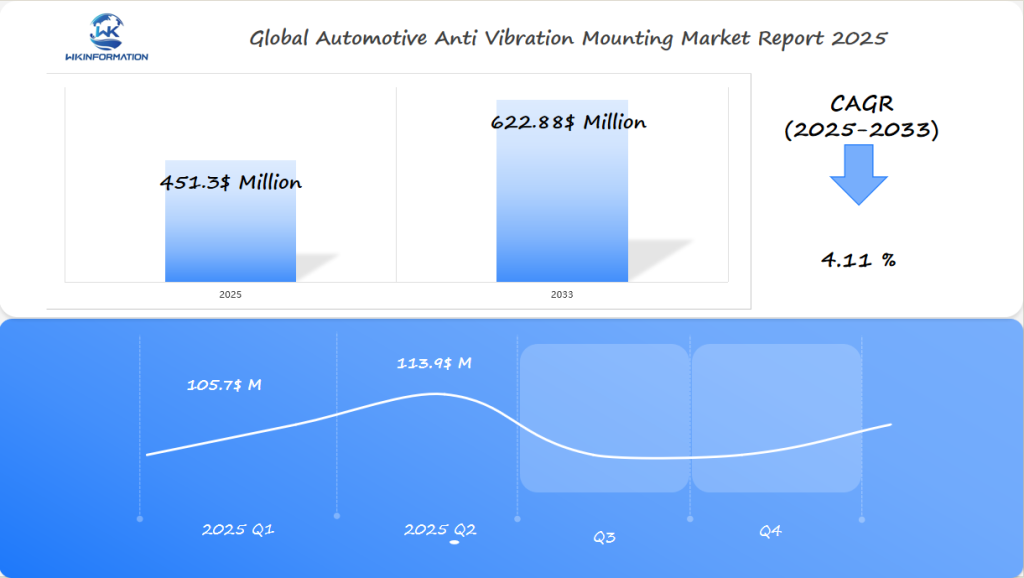

Automotive Anti Vibration Mounting Market Set to Reach $451.3 Million Globally by 2025: Enhancing Vehicle Performance in the U.S., Japan, and Mexico

Discover key insights into the Automotive Anti Vibration Mounting Market as it expands globally, driven by rising demand for enhanced vehicle comfort and noise reduction.

- Last Updated:

Automotive Anti Vibration Mounting Market Q1 and Q2 2025 Outlook with Key Regional Focus

The Automotive Anti Vibration Mounting market is projected to reach $451.3 million in 2025, supported by a moderate CAGR of 4.11%. In Q1, the market size is estimated at $105.7 million, fueled by ongoing demand in the U.S. automotive sector and supply chain stabilization post-pandemic. By Q2, the market grows to around $113.9 million, boosted by new model launches and enhanced vehicle comfort requirements in Japan and Mexico.

These countries are critical for studying evolving automotive manufacturing trends and regulatory impacts on vibration control technologies. Innovations in materials and mounting designs to reduce noise and increase durability are expected to play a key role in market expansion. Additionally, rising consumer expectations for smoother ride experiences are driving OEMs to invest in improved anti-vibration solutions. Regional trade agreements and tariff adjustments will also influence supply dynamics throughout the year.

Key Takeaways

- Projected market value of $451.3 million by 2025

- Growing emphasis on vehicle performance enhancement

- Technological advancements in vibration control systems

- Increasing demand from passenger and commercial vehicle segments

- Strong investment in research and development

Examining upstream and downstream industry chain in anti vibration mountings

The automotive anti vibration mounting industry is a complex web of suppliers and manufacturers. Upstream suppliers are key, providing raw materials that affect the quality and performance of vibration control parts.

Key upstream suppliers

Key upstream suppliers focus on materials essential for making anti vibration mounts:

- Rubber compound manufacturers

- Synthetic elastomer producers

- Metal fabrication specialists

- Chemical engineering companies

Downstream manufacturers turn these raw materials into advanced anti vibration mounts for cars. Their skills in engineering make the mounts effective in reducing noise, vibration, and harshness (NVH).

| Supply Chain Stage | Key Responsibilities | Primary Materials |

| Upstream Suppliers | Material Development | Synthetic Rubber, Metal Alloys |

| Component Manufacturers | Design and Fabrication | Precision Engineered Mounting Systems |

| Downstream Manufacturers | Vehicle Integration | Complete Anti Vibration Solutions |

The industry chain works together to make high-performance anti vibration mounts. Technological innovation and material science advancements keep improving car vibration control systems.

Trends Improving Vehicle NVH (Noise, Vibration, Harshness) Control

The car industry is always getting better at controlling NVH. This means making cars quieter and more comfortable. Today’s cars have complex systems and new engines that make noise and vibrations worse.

New materials are changing how cars handle NVH. Car makers are using new ways to cut down on vibrations and noise:

- Advanced composite materials with enhanced damping properties

- Precision-engineered mounting systems

- Active noise cancellation technologies

- Smart vibration isolation techniques

Car engineers are trying many ways to make cars more comfortable. Adaptive mounting systems use smart materials that adjust to the road. This makes cars quieter than ever before.

Some big steps in NVH control include:

- Electromagnetic suspension technologies

- Customized rubber compound developments

- Computer-aided design for vibration mitigation

- Integration of sensor-based feedback mechanisms

These new technologies are key to making cars quieter and smoother. They help meet what people want in their cars, whether it’s a family car, a truck, or an electric vehicle.

Market restrictions related to safety and material standards

The automotive anti-vibration mounting industry is facing big challenges. Safety standards and material regulations are getting stricter. Governments around the world are setting tough environmental and performance rules.

These rules are changing how products are made and developed.

Key market restrictions impacting the industry include:

- Stringent environmental compliance requirements

- Enhanced material safety standards

- Reduced carbon footprint mandates

- Increased testing and certification protocols

Industry compliance is now a top priority for manufacturers. They must deal with complex rules that require new ideas in material science and engineering.

| Regulation Type | Primary Focus | Industry Impact |

| Environmental Regulations | Sustainable Materials | Driving Research in Eco-Friendly Alternatives |

| Safety Standards | Performance Reliability | Increased Testing Requirements |

| Material Regulations | Chemical Composition | Restricted Use of Harmful Substances |

Companies are spending a lot on research and development to keep up with safety standards. The push for sustainable and high-performance materials is changing the market. It’s opening up chances for new solutions that meet rules and improve engineering.

The ongoing changes in material rules are pushing manufacturers to create advanced mounting technologies. These technologies must meet strict compliance rules while keeping vehicles running well.

Geopolitical influences on automotive component supply chains

The automotive industry is facing big challenges in global trade and getting parts. Supply chain problems have changed how makers get important parts like anti-vibration mountings.

Geopolitical tensions are a big deal in car part supply networks. Important areas are changing how they make things and trade, making it hard to get parts.

Key players in the automotive component market

- Asia-Pacific dominates the automotive component market

- China, India, and Japan lead regional production capabilities

- Emerging trade policies reshape global manufacturing strategies

Now, making parts involves complex international deals. The car world needs strong supply chains that can handle political issues.

Companies are looking for localized supply chain solutions to deal with global trade risks. This way, they can be more flexible and not rely too much on one place.

The future of getting car parts will likely be more diverse and strong. It will balance being cost-effective with managing risks well.

Types of Rubber, Hydraulic, and Pneumatic Mountings

The automotive industry uses rubber, hydraulic, and pneumatic mountings to combat vehicle vibration. These mountings help enhance vehicle performance. Each type has unique characteristics to address various engineering challenges in modern cars.

1. Rubber Mountings: Economical and Versatile

Rubber mountings are the oldest and most common method of controlling vibration. They are inexpensive and effective at reducing noise and absorbing shocks. Rubber mountings work well in small cars and standard passenger vehicles where cost and basic performance are important factors.

2. Hydraulic Mountings: Advanced Dynamic Performance

Hydraulic mountings employ fluid technology to better dampen vibrations. They adapt to different driving conditions, resulting in smoother and quieter rides. These mountings are typically found in cars that prioritize high performance and luxury.

3. Pneumatic Mountings: Precision Vibration Control

Pneumatic mountings represent the latest advancement in vibration control technology. They utilize compressed air to adjust stiffness in real-time, providing vehicles with improved maneuverability. Electric cars and high-end vehicles often incorporate these cutting-edge mountings.

Automakers select the appropriate mounting type based on the car’s design, desired performance characteristics, and target audience. The combination of rubber, hydraulic, and pneumatic mountings reflects the automotive industry’s commitment to creating more comfortable and efficient vehicles.

Application analysis in passenger cars, commercial vehicles, and EVs

The car industry is changing fast with new anti-vibration mounting tech. Passenger cars need special engineering to cut down road vibes and make driving smoother. Car makers are working on advanced rubber and hydraulic mounts to lessen noise and boost car performance.

Challenges in Commercial Vehicles

Commercial vehicles face special challenges with anti-vibration solutions. Big trucks and transport vehicles need strong mounts that can handle tough conditions and constant use. These mounts must manage:

- High-frequency vibrations from the engine

- Constant load-bearing needs

- Durability in harsh environments

Cutting-Edge Solutions for Electric Vehicles

EV anti-vibration solutions are the most cutting-edge in car engineering. Electric cars vibrate differently than gas cars, needing special mounts. Since EVs are quiet, it’s key to control vibrations well.

| Vehicle Type | Mounting Technology Focus | Key Performance Objectives |

| Passenger Cars | Precision Rubber Mountings | Comfort and Noise Reduction |

| Commercial Vehicles | Heavy-Duty Hydraulic Systems | Durability and Load Management |

| Electric Vehicles | Advanced Adaptive Mountings | Vibration Isolation and NVH Control |

Car makers are putting a lot into R&D for intelligent mounting systems. These systems aim to adjust to different driving situations and car types.

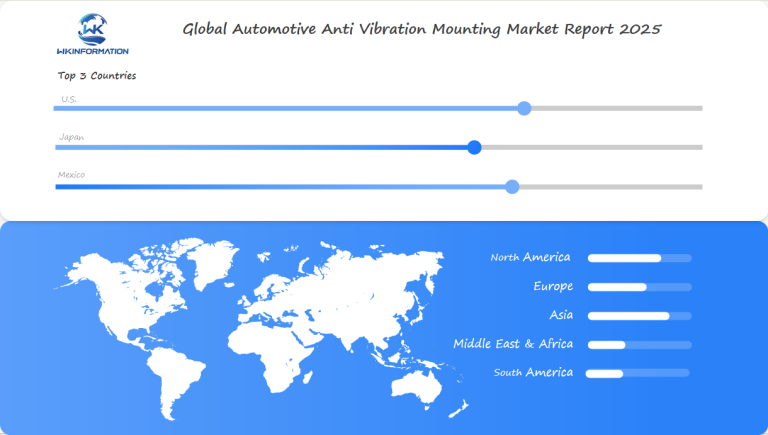

Regional insights on automotive anti vibration mounting demand

The global market for automotive anti vibration mounting shows interesting trends by region. North America is leading, thanks to its strong car industry. This region’s demand is growing fast, thanks to new tech and more electric cars.

Looking at the market, we see different things in each area:

- North America is ahead with its advanced factories

- Europe is known for its tech use

- Asia-Pacific is growing fast

In the automotive components market, demand changes a lot. The Asia-Pacific area is growing fast, with China and India playing big roles.

In Europe, demand is for top-notch and green solutions. The strict car engineering rules push for better vibration control tech.

| Region | Market Growth | Key Drivers |

| North America | High | EV Manufacturing |

| Europe | Steady | Advanced Engineering |

| Asia-Pacific | Rapid | Emerging Markets |

The world of automotive anti vibration mounting is changing fast. Regional plans are key for future tech progress.

U.S. automotive NVH regulations driving market expansion

The U.S. auto industry is changing fast because of strict NVH standards. These rules are making the anti-vibration mounting market grow. They’re pushing makers to create better solutions for quieter and more comfortable cars.

What’s making the market grow for anti-vibration mounts in cars include:

- More people wanting quieter car interiors

- Tough federal rules on noise and vibration

- Better safety needs

- More focus on making passengers comfortable

The National Highway Traffic Safety Administration (NHTSA) has set strict NVH standards. These rules make car makers use new vibration control tech. They need to make mounts that cut down on noise, vibration, and harshness in cars.

These U.S. rules are doing more than just making cars meet standards. They’re also driving tech progress in materials, design, and making things. Rubber, hydraulic, and pneumatic mounts are getting better to meet new high standards.

Car makers are now seeing anti-vibration mounts as key parts of car design. They know how important they are for the car’s performance and how comfy it is for passengers.

Japan's Advanced Innovations in Mounting Technology

Japanese technology is at the forefront of car anti-vibration mounting solutions. The country’s engineers continuously strive to push boundaries, developing high-quality mounting solutions that enhance both vehicle performance and safety.

Major Breakthroughs in Japanese Mounting Tech

Some significant advancements in Japanese mounting technology include:

- Precision-engineered rubber compounds with improved durability

- Intelligent systems for dampening vibrations

- Mounting technologies utilizing nano-materials

- Mechanisms for adaptive suspension

Leading Companies in Mounting Tech Innovation

Companies such as Toyota and Honda are at the forefront of innovation in mounting technology. Their teams are dedicated to creating vehicles that are quieter, smoother, and more efficient.

The Japanese Approach to Mounting Technology

The Japanese method combines the use of smart materials with advanced engineering techniques. These processes result in increased comfort for passengers, fuel savings, and overall performance improvements.

Collaborative Efforts for Global Standards

The Japan Automotive Research Institute collaborates with manufacturers to develop new mounting technologies. Their objective is to establish worldwide benchmarks for vehicle performance and safety.

Mexico's growing automotive parts manufacturing industry

Mexico is now a key player in the automotive world. It has changed its manufacturing scene a lot. Its good location and lower costs make it a big spot for car parts.

What’s driving the growth of Mexico’s automotive parts manufacturing?

The following factors are contributing to the growth of Mexico’s car parts industry:

- Being close to the US car market

- Lower labor costs than other places

- A skilled technical workforce

- Strong support for industrial growth

Mexico is really good at making anti-vibration mounts. Its makers have top skills that meet world car standards. This has brought in more money and partnerships from abroad.

Mexico’s role in the car parts world is getting stronger. It keeps getting better at making things and using new tech. This means Mexican makers will be more important in the global car parts market.

Future development in smart and adaptive vibration mountings

The automotive world is changing fast with smart mountings technology. This new tech is changing how cars handle vibrations and perform better. It opens up new chances for better car dynamics.

New trends in car engineering are leading to big changes in vibration control. Now, smart mountings use advanced sensors to adjust to the car’s changing needs. This means cars can perform better in real time.

- Intelligent material compositions that adapt to temperature and stress

- Integrated sensor networks for continuous performance monitoring

- Self-adjusting damping capabilities

- Predictive maintenance potential

Scientists are working on cutting-edge materials that can change their structure quickly. These smart mountings can spot tiny changes in how a car moves. They can then adjust to reduce stress and improve performance.

New tech is making mountings that not only soak up vibrations but also give detailed info on car performance. This could lead to cars lasting longer, needing less maintenance, and giving better rides.

The mix of adaptive tech and new materials is set to change car engineering. Smart mountings will be key in designing cars of the future.

Competitive market analysis of leading suppliers

The automotive anti-vibration mounting market is very competitive. Global players are always coming up with new ideas to stay ahead. They aim to grab key market spots and boost their standing.

Leading companies have their own ways to compete:

- They focus on new technology to lead the market.

- Having a strong presence worldwide is key.

- They invest a lot in research and development.

- Creating products that meet specific needs is important.

Key Players:

-

Trelleborg AB – Sweden

-

Hutchinson SA – France

-

Lord Corporation – USA

-

Parker Hannifin – USA

-

Freudenberg Group – Germany

-

Vibracoustic – Germany

-

Mubea – Germany

-

ContiTech – Germany

-

SKF – Sweden

-

Dana Incorporated – USA

What makes the market competitive?

- New material technologies play a big role.

- Keeping production costs low is crucial.

- Having a strong global network helps.

- Meeting quality standards is essential.

New players are shaking things up by introducing fresh designs and cheaper ways to make products. This keeps the competition fierce, pushing everyone to innovate and make better products.

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Automotive Anti Vibration Mounting Market Report |

| Base Year | 2024 |

| Segment by Type |

· Rubber Mountings · Hydraulic Mountings · Pneumatic Mountings |

| Segment by Application |

· Passenger Cars · Commercial Vehicles · Electric Vehicles |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The automotive anti-vibration mounting industry is set for big growth. Market forecasts show strong expansion in the next few years. New technologies and more car production are driving this growth worldwide.

Looking ahead, electric vehicle (EV) platforms and new car tech are key areas of focus. Research shows that light, flexible mounting systems will be essential for future cars. Companies like Bridgestone, Continental, and Sumitomo Rubber are pouring money into R&D for better vibration control.

There’s a big push for better car comfort and less mechanical stress. This is driving the need for advanced anti-vibration mounting tech. The market is expected to grow a lot in Asia-Pacific and North America, where car making is booming.

Investments in material science and engineering will shape the future of car mounts. As car makers focus on better performance, safety, and comfort, we can expect more innovation. The outlook is positive, with more advanced mounts being used in different car types.

Global Automotive Anti Vibration Mounting Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Automotive Anti Vibration Mounting Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Automotive Anti Vibration Mounting Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Automotive Anti Vibration Mounting Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Automotive Anti Vibration Mounting Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Automotive Anti Vibration Mounting Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Automotive Anti Vibration Mounting Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Automotive Anti Vibration MountingMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market value for automotive anti-vibration mountings by 2025?

The market for automotive anti-vibration mountings is set to hit $451.3 million by 2025. This growth is fueled by a need for better vehicle performance and comfort.

How do anti-vibration mountings impact vehicle performance?

These mountings are key in controlling noise, vibration, and harshness (NVH). They improve ride quality by cutting down vibrations and noise between parts and the chassis.

What types of anti-vibration mountings are commonly used?

The market mainly uses rubber, hydraulic, and pneumatic mountings. Each type has its own strengths for different vehicle needs and performance levels.

How are electric vehicles changing anti-vibration mounting technology?

Electric vehicles need special mounts because of their quiet engines. This has led to new, advanced mounting technologies that handle the unique vibrations of electric powertrains.

Which regions are leading in anti-vibration mounting manufacturing?

The Asia-Pacific region is at the forefront of manufacturing. Countries such as Japan and China are leading the way with their advanced technology and manufacturing expertise.

How are regulatory standards affecting anti-vibration mounting development?

Strict safety and environmental regulations are driving the demand for more sustainable and innovative materials in the development of anti-vibration mountings. This shift is necessary to comply with the industry’s stringent standards.

What are the key challenges in the automotive anti-vibration mounting industry?

The main challenges include:

- Keeping up with safety standards

- Finding materials for extreme conditions

- Creating cost-effective solutions

All of these challenges are focused on improving vehicle performance.

How are smart technologies impacting anti-vibration mounting design?

New tech like sensor-integrated mountings and adaptive materials are changing the game. They allow for better responses to changing vehicle conditions, potentially changing how we control vibrations.

What factors drive innovation in anti-vibration mounting technology?

The main drivers are consumer demand for quieter rides, advancements in materials science, and the need for better comfort. These are pushing the field forward.

How do anti-vibration mountings differ across vehicle types?

Different types of vehicles need their own special mounts. This is because of their unique weights, performance, and vibration needs.