Automatic Mask Production Equipment Market Set to Reach $7.5 Billion by 2025 with Innovations in Manufacturing and Healthcare in the U.S., China, and India

The Automatic Mask Production Equipment Market is experiencing rapid growth due to increasing demand for face masks and rising health awareness.

- Last Updated:

Automatic Mask Production Equipment Market Outlook for Q1 and Q2 2025

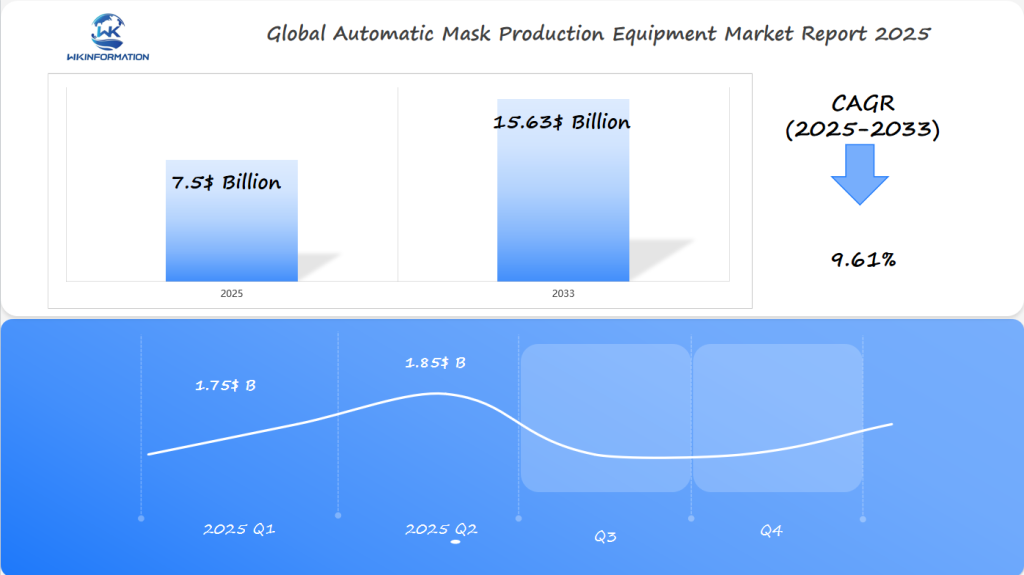

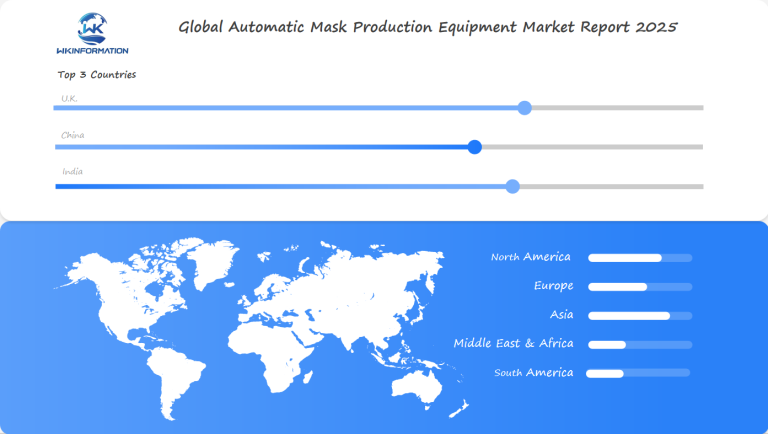

The Automatic Mask Production Equipment market is projected to reach $7.5 billion in 2025, with a CAGR of 9.61% from 2025 to 2033. In Q1 2025, the market is expected to be valued at $1.75 billion, with continued high demand for mask production systems driven by the global emphasis on health safety measures. The U.S., China, and India are key players in this market, with a strong demand for advanced, automated systems to efficiently produce masks for both domestic and international markets.

By Q2 2025, the market is forecast to grow to $1.85 billion, as further innovations in production technology and increasing industrial automation reduce costs and improve manufacturing capacity. China and India, with their large-scale manufacturing operations, will contribute significantly to market growth, while the U.S. continues to invest in production capabilities to ensure self-sufficiency in medical and protective equipment.

Analysis of the Upstream and Downstream Industry Chain for Automatic Mask Production Equipment

The automatic mask production equipment industry is a complex web of processes. Raw materials are at the heart of this chain, driving everything. Manufacturers must find top-quality materials to make mask-making equipment well.

Upstream Supply Chain Components

Key parts of the upstream supply chain include:

- Precision mechanical components

- Electronic control systems

- Advanced sensor technologies

- Specialized manufacturing metals

Importance of Distribution Channels

Distribution channels are crucial in linking makers with markets worldwide. Strategic logistics networks help equipment makers reach healthcare, industrial, and government clients well.

Challenges in the Downstream Sector

The downstream part deals with sending advanced mask-making gear to different sectors. Makers face tough market needs, like:

- Medical industry needs

- Industrial safety standards

- Personal protective gear rules

Significance of Supply Chain Strength

Supply chain strength is key, especially after global issues. Companies are putting money into strong buying plans and tech to lessen risks in making mask equipment.

Good supply chain management is key to mask equipment makers’ success in a fast-changing world market.

Rising demand for medical and industrial masks driving market growth

The demand for medical and industrial masks has skyrocketed in recent years. This surge is due to growing health concerns and stricter workplace safety rules. As a result, manufacturers are working hard to increase their production to keep up with the demand.

Several factors are driving the growth of the mask production equipment market:

- Global pandemic preparedness strategies

- Enhanced workplace safety requirements

- Growing awareness of respiratory protection

- Environmental pollution concerns

Mask production technologies are changing fast in industrial sectors. Automated manufacturing systems play a big role in meeting the needs of medical and industrial masks. These systems help manufacturers produce more while keeping quality high.

The need for medical masks is now seen in more places than just hospitals. New industries are adopting strict respiratory protection measures. This opens up new chances for companies that make mask production equipment.

The evolution of mask production technology represents a critical response to global health and safety challenges.

Companies are pouring money into research to make mask production better and cheaper. These efforts are changing how medical and industrial masks are made. They lead to faster production and better quality masks.

Challenges in automation technology and global supply chains

The automatic mask production equipment industry is facing big challenges. These challenges test the strength of manufacturers all over the world. The main problem is the technology barriers that make production hard, especially in advanced settings.

Some of the main challenges in automation technology are:

- Complex integration of sophisticated machinery

- High initial investment requirements

- Shortage of skilled technical personnel

- Rapid technological obsolescence

Supply chain disruptions have shown us how weak mask production networks can be. Global events have made it clear we need stronger and more flexible manufacturing plans. Companies must find new ways to deal with the risks of outdated technology and supply chain problems.

Adaptability becomes the cornerstone of successful automation in mask production equipment.

The pandemic made us realize how big the technology barriers in mask making are. Companies are now spending a lot on advanced automation systems. These systems can quickly meet sudden market needs. Flexible production lines are key to beating supply chain issues.

Manufacturers are tackling these problems by:

- Using modular automation technologies

- Creating cross-training programs for technical staff

- Building stronger supply chain networks

- Investing in adaptive manufacturing systems

The future needs constant innovation and smart investment in automation. We must find ways to quickly adapt to changes in the global market.

Geopolitical influences on mask production and distribution

The world of mask production is tied to complex politics. Trade rules and global laws shape who can make and sell masks. This affects the market for automatic mask making tools.

Important political factors in the mask market include:

- Diplomatic tensions between big manufacturing countries

- Trade policies that affect sharing technology

- Global health rules and standards

- Economic sanctions and rules on imports and exports

World governments see mask making as key to national security. National security has made mask making a top priority, not just an economic issue.

New markets face tough global rules to build strong mask making systems. Countries like India and Vietnam aim to grow by making masks at home. They want to cut down on relying on big manufacturers.

The mix of politics and mask making is changing fast. It’s now about new tech, following rules, and working together to stay ahead.

Segmentation analysis: Mask production capacity and equipment types

The automatic mask production equipment market is complex. It has many manufacturing capabilities and specialized machines. Market segmentation gives us key insights into production capacity and equipment types. These are what drive innovation in mask making.

Understanding production capacity

Production capacity is a key factor in understanding the market. Manufacturers fall into three main categories:

- High-volume production equipment: Makes over 100,000 masks a day

- Medium-volume production systems: Makes 50,000-100,000 masks daily

- Low-volume specialized machines: Makes 10,000-50,000 masks a day

Exploring equipment types

Equipment types also add to the market’s diversity. They offer solutions for different mask making needs:

- Fully automated production lines

- Semi-automated manufacturing systems

- Specialized machines for surgical, N95, and industrial masks

Each type of equipment meets specific market needs. This lets manufacturers choose the right machinery for their goals and tech level. The right choice in production capacity and equipment types boosts efficiency and competitive edge in the fast-changing mask production world.

Key applications in healthcare, personal protection, and industrial use

Automatic mask production equipment has changed how we make personal protective equipment. These systems are very versatile. They help make masks for healthcare, industrial safety, and personal use.

Healthcare

In healthcare, mask production equipment is very important. Medical places use advanced tech to make top-notch masks. These masks protect doctors and patients.

- Hospitals and clinics demand surgical-grade masks

- Research laboratories require specialized protective equipment

- Emergency medical services need rapid mask production capabilities

Industrial Safety

Industrial safety has improved a lot with new mask-making tech. Now, places like factories, construction sites, and chemical plants use machines to make masks. These masks must meet strict safety rules.

| Industry Sector | Mask Type | Protection Level |

| Manufacturing | Respiratory Masks | High Filtration |

| Construction | Dust Masks | Moderate Filtration |

| Chemical Processing | Chemical Resistant Masks | Maximum Protection |

Personal Protection

Masks are now used in more places than just work. People want to stay safe everywhere. This has made masks more popular for both work and personal use.

Automated mask production represents a critical technological advancement in protecting public health and workplace safety.

Regional growth trends in mask production and distribution

The automatic mask production equipment market varies greatly around the world. Different places have their own growth patterns. These are shaped by their economies and healthcare systems.

Growth trends in North America and Europe

In North America and Europe, mask production is growing steadily. The United States is at the forefront. It has the latest technology and strong networks for quick equipment setup.

Emerging growth center in Asia-Pacific

- Asia-Pacific region emerges as a critical growth center

- Developing countries invest heavily in production infrastructure

- Emerging markets accelerate automation technology adoption

In countries like India and Southeast Asia, big changes are happening. They are investing in automated systems. This is making their mask production faster and more efficient.

Factors influencing growth in different regions

What affects growth in each area includes:

- Local laws and regulations

- Healthcare system development

- Ability to innovate with technology

- Economic stability and investment opportunities

Progress in Middle Eastern and African markets

Middle Eastern and African markets are also getting better at making masks. They are adopting more advanced methods. This shows a worldwide move towards better manufacturing.

U.S. demand for automated medical mask production solutions

The U.S. market for medical mask automation has seen big changes since the pandemic. Making masks at home is now key for health care and safety. Companies are quickly buying new machines to make masks faster and not rely on other countries.

What’s driving the U.S. mask automation market?

The U.S. mask automation market is being driven by several factors, including:

- More government money for making things in the U.S.

- Need for making more masks quickly

- New tech for making masks

- Improving health care readiness

Big investments are changing the way masks are made. New tech lets us make masks faster and better. This helps us get ready for health crises quickly.

| Production Capability | Annual Capacity | Automation Level |

| Small-Scale Manufacturers | 50,000-100,000 masks/day | Partial Automation |

| Mid-Size Manufacturers | 250,000-500,000 masks/day | High Automation |

| Large Industrial Producers | 1-5 million masks/day | Full Automation |

The future of U.S. medical mask production depends on new tech and smart policies.

China's dominance in manufacturing and innovation in mask production equipment

Chinese manufacturers lead the world in making automatic mask production equipment. They have changed the game with their advanced technology. Their smart approach to making complex systems has greatly increased their share of the global market.

Chinese manufacturers stand out because of:

- Fast development in precise manufacturing

- Cost-saving production methods

- Big investments in research and development

- Ability to make lots of products

China’s success comes from many areas of mask production equipment. They use top-notch automation, precise engineering, and strict quality checks. This puts them at the top in making products all over the world.

| Manufacturing Capability | Global Market Impact |

| Automated Production Lines | 40% Market Share |

| High-Speed Equipment | 35% Global Penetration |

| Precision Engineering | 45% Technology Leadership |

Chinese makers have turned mask production into a high-tech field. They keep getting better and changing the global market.

“Innovation is the cornerstone of China’s manufacturing strategy in mask production equipment” – Industrial Manufacturing Review

India's growing healthcare sector driving demand for mask production

The Indian healthcare market is changing fast, with mask production growing a lot. This growth is key in emerging economies. New technologies and more healthcare spending are helping India make more masks.

There’s a big need for protective gear, leading to big changes in Indian factories. Important things driving this growth are:

- Expanding healthcare infrastructure

- Rising awareness of personal protection

- Government initiatives supporting domestic manufacturing

- Technological innovations in mask production

India’s strategic positioning in the global market helps makers make more masks fast. The country’s strong pharmaceutical and medical device sectors help mask production grow.

“India is transforming from a consumer to a global leader in protective medical equipment manufacturing”

India and other emerging economies are changing the mask production world. They have skilled workers, new tech, and low costs. This makes India a great place for making masks.

The Indian healthcare market is showing great strength and flexibility. It’s becoming a major player in the global protective gear world.

Innovations in mask production technology and automation systems

Technological advancements are changing the mask production world. Smart production systems are making a big difference in how masks are made. Artificial intelligence is key to making production more efficient and precise.

Some major innovations in mask production technology are:

- Advanced machine learning algorithms for real-time quality control

- Robotic automation systems with high-speed production capabilities

- Integrated AI-powered inspection mechanisms

- Adaptive manufacturing platforms that optimize production workflows

AI technologies are making manufacturers more productive than ever. Smart systems can predict when maintenance is needed, cut down on waste, and adjust production to keep quality high.

| Technology | Production Impact | Efficiency Gain |

| Machine Learning QC | Defect Detection | 95% Accuracy |

| Robotic Automation | Production Speed | 60% Increase |

| AI Workflow Optimization | Resource Management | 40% Reduction in Waste |

More manufacturers are using smart production systems with AI. These systems make mask production more flexible and responsive. These advancements are raising the bar for manufacturing precision and scalability.

Key players in the automatic mask production equipment market

The automatic mask production equipment market is very competitive. Many top companies are leading the way with new technologies. They keep investing in research to stay ahead in this fast-changing field.

Leading players:

- KYD Automatic Mask Machine Factory Ltd —— China

- Evergreen Medical Equipment Limited —— China

- Han’s Laser Technology Industry Group Co., Ltd —— China

- Shanghai Dasheng Health Products Manufacture Co., Ltd —— China

- TESTEX Testing & Certification (China) Ltd —— China

- FOTRIC —— China

- Optris —— Germany

- Southnekon —— China

- Dongguan Huitong Automatic Machinery Technology Co., Ltd —— China

- S.K.R —— China

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Automatic Mask Production Equipment Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The automatic mask production equipment market is set to grow a lot. This growth is because of the need for better health care around the world. Experts say we will see a lot of money going into new technologies for making masks.

They also think the industry will change a lot. Market research reports show big chances for making more protective gear.

Now, companies are moving towards better and more flexible ways to make masks. They are using smart technology to make masks faster and better. This helps solve big problems like making more masks and doing it well.

This makes automatic mask production very important for health care all over the world.

The future looks bright for this market, especially in Asia and other growing areas. New tech like robots and AI will change how masks are made. Big companies are also investing a lot to make things better and faster.

In the end, the market for automatic mask production is very important for health care. As health issues keep changing, makers and tech people will be key. They will help make sure we can make masks fast, well, and in big numbers all over the world.

Global Automatic Mask Production Equipment Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Automatic Mask Production Equipment Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Automatic Mask Production EquipmentMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Automatic Mask Production Equipment players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Automatic Mask Production Equipment Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Automatic Mask Production Equipment Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Automatic Mask Production Equipment Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Automatic Mask Production EquipmentMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is driving the growth of the automatic mask production equipment market?

The market is growing due to new technologies and a higher need for personal protective equipment (PPE). Global health issues, workplace safety rules, and the need for efficient mask making are also key factors.

How large is the automatic mask production equipment market expected to grow?

The market is expected to reach $7.5 billion by 2025. This shows a big increase in response to global health needs and industrial safety.

What are the key challenges in mask production equipment manufacturing?

The main challenges in manufacturing mask production equipment are:

- Technical barriers in automation

- The need for skilled workers

- Complex technology integration

- Global supply chain issues

What types of mask production equipment are available?

There are many types of mask production equipment available, including:

- Fully automated lines

- Semi-automated systems

- Machines for specific mask types and sizes

Which regions are leading in mask production equipment development?

China and the United States are leading. India is also growing fast, thanks to its healthcare sector and focus on making things at home.

Which industries use automatic mask production equipment?

Many sectors use this equipment, including healthcare, industrial, and personal protection markets.

How are technological innovations impacting mask production?

New technologies such as AI and machine learning are enhancing quality control and making production faster and more efficient.

What factors influence the global mask production equipment market?

Factors include trade policies, geopolitical relations, healthcare rules, tech advancements, and how we handle global health crises.

How do supply chains affect mask production equipment manufacturing?

Supply chains are very important. They cover getting raw materials, making products, and getting them to customers. They affect how well we can make masks.

What are the main uses of masks made by automated machines?

Masks have a wide range of applications in various fields, including:

- Healthcare: Masks are extensively used in hospitals and healthcare settings to protect medical professionals and patients from infections.

- Personal Protection: Masks are worn by individuals in public places or crowded areas to safeguard themselves from airborne particles and viruses.

- Industrial Use: Many industries require workers to wear masks as a safety measure against harmful substances, chemicals, or dust present in the workplace.

- Laboratories: Masks are essential in laboratory environments to prevent contamination and ensure the safety of researchers working with hazardous materials.