$22.2 Billion Autoclaved Lightweight Concrete Market Set for Expansion in China, India, and U.S. by 2025

Explore the expanding $22.2B Autoclaved Lightweight Concrete Market driven by sustainable construction trends, urbanization, and growing demand in China, India, and the United States.

- Last Updated:

Projected Market Insights for Autoclaved Lightweight Concrete in Q1 and Q2 of 2025

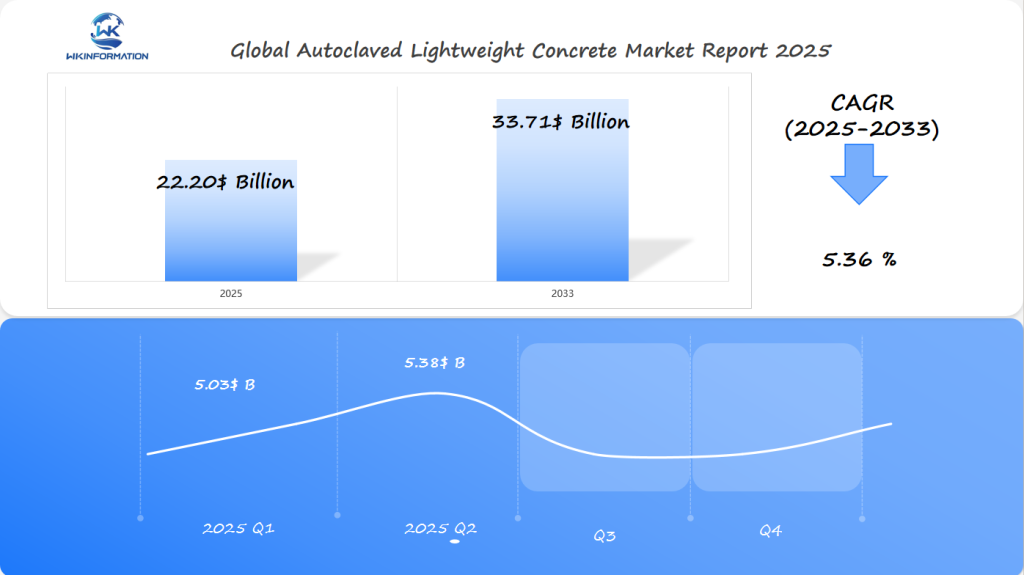

The Autoclaved Lightweight Concrete (ALC) market is forecasted to reach $22.2 billion in 2025, with a CAGR of 5.36% from 2025 to 2033.

Q1 Projections

In Q1, the market is projected to generate approximately $5.03 billion, driven by increased adoption in green building construction and lightweight structural applications.

Q2 Projections

By Q2, the market is expected to reach around $5.38 billion, as demand rises in residential, commercial, and infrastructure sectors.

Key Players

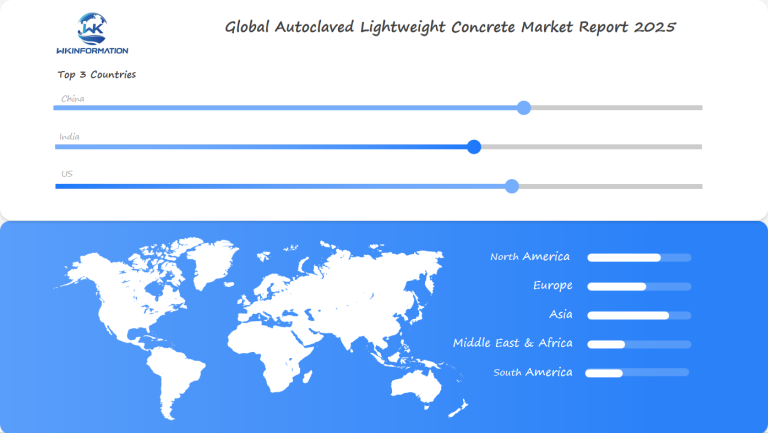

China, India, and the U.S. will be key players in this market:

- China leads with its large-scale urbanization and focus on energy-efficient buildings

- India sees increasing adoption due to cost-effective housing initiatives

- The U.S. benefits from sustainable construction regulations and advancements in material technology

With growing emphasis on environmental sustainability and seismic resistance, ALC is expected to witness steady growth across these major regions.

Understanding the Upstream and Downstream Industry Chains for Autoclaved Lightweight Concrete

The ALC supply chain is a complex network of processes. It turns raw materials into innovative construction solutions. Each stage is crucial for delivering high-performance lightweight concrete to markets worldwide.

Upstream: Sourcing Raw Materials

Raw materials are the base of autoclaved lightweight concrete production. The main components are:

- Cement as a primary binding agent

- Lime for chemical reactions

- Silica sand for structural integrity

- Aluminum powder for cellular formation

Raw Material Suppliers and Production Impact

The quality of raw materials for ALC affects production costs and product performance. Specialized suppliers offer precise mineral compositions. These are key for creating lightweight concrete with the best thermal and structural features.

Manufacturers pick suppliers who meet high standards. This ensures:

- Uniform product quality

- Reduced manufacturing variability

- Enhanced structural reliability

Distribution Channels and Market Reach

ALC distribution channels have grown to serve various construction sectors. Key areas include residential, commercial, and architectural projects. Manufacturers use different strategies to distribute:

- Direct sales to construction companies

- Specialized building material retailers

- Online procurement platforms

- Regional distribution networks

Strategic distribution ensures ALC products reach global markets efficiently. This supports sustainable construction worldwide.

Key Trends in the Autoclaved Lightweight Concrete Market

The Autoclaved Lightweight Concrete (ALC) market is changing fast. New technologies and green building practices are leading the way. These changes are making construction more modern and efficient.

New ALC technology is changing how we build. Companies are making better materials and reducing harm to the environment. This is a big step forward for construction.

Technological Advancements in ALC Production

New tech in ALC production is opening up big chances for the building world. Some key improvements include:

- Enhanced mix design optimization

- Advanced curing processes

- Precision manufacturing techniques

- Improved strength-to-weight ratios

Shift Towards Green Building Materials

Green building materials are key in today’s construction. ALC is leading the way in sustainable building. It offers big environmental benefits.

| ALC Sustainability Metrics | Performance Characteristics |

| Energy Consumption | Lower compared to traditional materials |

| Waste Generation | Zero waste during production |

| Market Growth Projection | 5.36% CAGR from 2025 to 2033 |

The ALC market is growing fast, especially in places like India and China. Infrastructure development investments are pushing for more use of these advanced materials.

The future of construction lies in sustainable, efficient, and technologically advanced materials like Autoclaved Lightweight Concrete.

Challenges in Autoclaved Lightweight Concrete Production

The Autoclaved Lightweight Concrete (ALC) industry faces many challenges. These challenges affect its growth and adoption. Companies must deal with technical, economic, and regulatory issues to succeed.

- High initial capital investment requirements for specialized manufacturing facilities

- Complex production processes demanding advanced technological infrastructure

- Limited market awareness about ALC’s performance characteristics

- Resistance from traditional construction material suppliers

Energy Consumption and Environmental Concerns

Energy efficiency is a major challenge for ALC makers. The autoclaving process requires a significant amount of thermal energy, which increases costs and raises environmental concerns.

In response, companies are actively seeking ways to reduce their energy consumption and minimize their carbon footprint.

Quality Control and Standardization Issues

Ensuring ALC quality is another big issue. Makers must meet strict performance standards to win market trust. Getting consistent quality across different places requires advanced quality systems and ongoing improvements.

Regulatory bodies are working on standards. They aim to make ALC production more reliable and consistent.

Geopolitical Influences on the Autoclaved Lightweight Concrete Market

The Autoclaved Lightweight Concrete (ALC) market is changing fast because of global politics. Trade rules and building codes in different places shape the market. They affect how ALC makers and sellers do business.

Politics around the world have a big say in the ALC market. They create complex webs of influence across various economic areas. Governments are seeing how important building materials are for growing their economies.

Trade Policies Reshaping ALC Industry Dynamics

Trading ALC around the world involves complex systems. These systems decide who can sell where and how well they can compete. Important parts include:

- Tariff structures affecting raw material costs

- Import-export regulations

- Bilateral trade agreements

- Economic sanctions impacting material supply chains

Regional Construction Regulations and Market Adaptation

Building rules greatly affect how ALC enters the market. Each area has its own building codes. Emerging markets are becoming more open to new building materials.

Countries like China, India, and the United States have their own rules for ALC. These rules look at things like:

- Structural performance standards

- Environmental sustainability requirements

- Energy efficiency guidelines

- Safety and quality control measures

Matching international trade rules with local building codes will keep shaping the ALC market worldwide.

Market Segmentation: Types and Applications of Autoclaved Lightweight Concrete

The autoclaved lightweight concrete (ALC) market is growing fast. It has many product types and uses in various construction areas. Knowing about market segments shows how versatile and important ALC is in today’s building designs.

ALC Product Types: Innovative Building Solutions

ALC comes in different types for different construction needs:

- ALC Blocks: Standard building units with exceptional thermal insulation

- ALC Panels: Lightweight structural elements for walls and facades

- ALC Lintels: Specialized load-bearing components for openings

- Specialty ALC Shapes: Customized solutions for unique architectural requirements

Comprehensive ALC Applications Across Markets

ALC is used in many market segments:

| Market Segment | Key Applications | Primary Benefits |

| Residential Construction | Wall systems, interior partitions | Energy efficiency, sound insulation |

| Commercial Buildings | Exterior cladding, fire-resistant walls | Lightweight design, quick installation |

| Industrial Facilities | Structural components, partition walls | High durability, thermal regulation |

*”ALC represents a transformative solution in modern construction, bridging performance with sustainability.”*

The market for autoclaved lightweight concrete is growing. This is because of more investments in infrastructure and green building practices. India plans to spend USD 777.73 Billion on infrastructure by 2022. ALC products are expected to see big growth in new markets.

Autoclaved Lightweight Concrete in Sustainable Construction

Autoclaved Lightweight Concrete (ALC) is changing the construction world. It offers new ways to build sustainably. This material is leading the way in green construction, with big environmental and energy-saving benefits.

ALC has amazing properties that make it a big deal in sustainable building. It gives big advantages to those who care about the environment:

- Superior thermal insulation reducing energy consumption

- Lightweight structure minimizing structural load

- Resource-efficient manufacturing process

- Significant reduction in carbon footprint

Energy Efficiency and Thermal Performance

ALC is highly efficient in saving energy due to its excellent thermal insulation properties. Buildings constructed with ALC have the potential to reduce heating and cooling energy consumption by up to 30%. The unique design of ALC allows it to trap air, which aids in maintaining temperature and minimizing heat loss.

Environmental Benefits in Construction

Using ALC in building is a big win for the environment. Its making process doesn’t waste anything and uses less energy than regular concrete. It fits well with green building standards like LEED and BREEAM.

ALC is a key innovation in lowering the construction industry’s environmental harm.

By picking ALC, builders and designers can help cut down a building’s carbon footprint. They can do this without losing any structural strength.

Global Market Overview of Autoclaved Lightweight Concrete

The global ALC market is growing fast. This is because more people want sustainable and efficient building materials. It’s expected to grow by 4.1% each year, making it a big opportunity in many places.

Regional Market Shares and Growth Projections

The ALC market is spread out across different regions. Each area has its own chance for growth. Here are the main parts of the market:

- Asia-Pacific: Dominating with approximately 40% market share

- Europe: Holding around 30% of the market

- North America: Accounting for roughly 20% market share

- Middle East and Africa: Emerging with strong growth potential

Key Players in the Global ALC Market

The ALC market has many big players. These companies are pushing the market forward with new technologies and growth plans.

| Region | Market Share | Key Characteristics |

| China | 10% | Manufacturing hub with rapid infrastructure development |

| United States | 20% | Focus on energy-efficient building standards |

| Europe | 30% | Stringent sustainability regulations |

The global ALC market forecast looks very promising. Big players like Xella Group are investing heavily, showing the market’s potential and fast pace.

China's Dominance in Autoclaved Lightweight Concrete Production

The China ALC market leads the world in making lightweight concrete. It’s a key player in the global construction materials scene. Chinese makers are pushing the limits of innovation and production.

China’s fast-growing cities need efficient building materials. So, Chinese makers have increased production. They’ve also developed new technologies for making autoclaved lightweight concrete.

Factors Driving Market Growth

- Massive infrastructure development projects

- Government support for sustainable construction

- Availability of raw materials and cost-effective labor

- Technological advancements in ALC production

The construction sector in China is driving demand for ALC. Big names like BBMG, Zhonglong, and Changtong are growing their production. They aim to meet the increasing market needs.

Export Potential and Market Dynamics

| Market Indicator | Performance |

| Global Market Share | 10% |

| Asia-Pacific Regional Dominance | 40% |

| Projected Growth Rate | 8-12% annually |

China’s ALC exports are on the rise. Makers are eyeing international markets. Their products are getting more competitive and of higher quality, drawing global interest.

The future looks bright for China’s autoclaved lightweight concrete industry. With more tech and infrastructure investments, growth is expected to continue.

India's Growing Demand for Autoclaved Lightweight Concrete

The India ALC market is booming thanks to fast urban growth and big infrastructure projects. Autoclaved lightweight concrete (ALC) is changing the game for green building.

The Indian building scene is changing fast, especially with the Housing for All by 2024 goal. ALC is a top choice for building because it meets national goals. It solves tough building problems with its special features.

Infrastructure Investment and ALC Demand

India needs a lot of money for its infrastructure, about USD 777.73 billion by 2022. The need for ALC is tied to these big plans. Builders see ALC’s value:

- Lightweight and green building material

- Reduces construction time by 30%

- Excellent thermal insulation

- Cost-effective compared to traditional materials

Market Opportunities and Challenges

Big names like Biltech Building Elements Limited and UltraTech Cement Ltd. are expanding to meet demand. AAC blocks can reduce costs by 20% on steel and concrete, making them attractive to developers.

The Asia-Pacific region, including India, is a key market for ALC due to rapid urban growth and government initiatives.

The U.S. Market's Adoption of Autoclaved Lightweight Concrete

The US ALC market is changing fast, thanks to new construction tech and green building. Autoclaved Lightweight Concrete (ALC) is becoming a top pick for building that saves energy. Architects, builders, and developers in the US are taking notice.

The way ALC is used in US construction is changing the building world. Here’s what’s happening:

- Market size estimated at USD 3.2 billion in 2024

- Expected to reach USD 5.5 billion by 2033

- Projected annual growth rate of 6.2%

Green Building Initiatives and Energy Efficiency

ALC is getting more support for green building in the US. It’s great for keeping buildings cool because it insulates well. Architects and developers are using ALC to build structures that save energy and are good for the environment.

“ALC represents a breakthrough in sustainable construction, offering unparalleled energy efficiency and environmental performance.”

Regulatory Environment and Market Trends

The US construction industry is moving towards materials that are better for the planet. ALC fits well with green building codes and rules. Big companies are growing their ALC business, focusing on tall buildings, roads, and homes.

- Increasing use in prefabricated construction

- Enhanced thermal insulation capabilities

- Compliance with environmental regulations

As the market grows, ALC will be key in making US construction more sustainable.

The Future of Autoclaved Lightweight Concrete: Innovations and Opportunities

The autoclaved lightweight concrete (ALC) industry is about to undergo significant transformations. New technologies are reshaping the construction industry, with ALC at the forefront of environmentally friendly building practices.

Technological advancements are impacting ALC in various ways:

- Advanced manufacturing processes with reduced carbon emissions

- Implementation of smart manufacturing techniques

- Improved thermal and structural performance

Emerging Technologies in Production

New ALC production methods are changing the construction world. Companies are looking into new ways to cut down on environmental impact. They’re using automated lines and finding new materials.

“The next generation of ALC will change how we build sustainably” – Construction Innovation Quarterly

Potential New Markets and Applications

The global ALC market is set to grow fast, especially in fast-growing areas. Big markets like China, India, and the US will lead in innovation and use. ALC’s flexibility means it could be used in many new ways, like:

- 3D-printed buildings

- Modular homes

- Strong buildings for earthquakes

With a 4.1% CAGR growth rate and more uses in green building, ALC is key to solving global building problems.

Competitive Landscape in the Autoclaved Lightweight Concrete Market

The ALC market has become more competitive with top players spreading out worldwide. Their success shows how important new technology is in staying ahead.

- Aercon AAC – USA

- AKG Gazbeton – Turkey

- Bauroc AS – Estonia

- Biltech Building Elements Limited – India

- Buildmate Projects Pvt. Ltd. – India

- CSR Limited – Australia

- Xella Group – Germany

- Hebel – Germany

- Ytong – Germany

- H+H International A/S – Denmark

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Autoclaved Lightweight Concrete Market Report |

| Base Year | 2024 |

| Segment by Type |

· ALC Blocks · ALC Panels · ALC Lintels · Specialty ALC Shapes |

| Segment by Application |

· Residential Construction · Commercial Buildings · Industrial Facilities |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The autoclaved lightweight concrete market demonstrates significant growth potential, driven by evolving trends in sustainable construction materials. Key factors include the increasing adoption of green building practices and stricter environmental regulations. These developments create opportunities for manufacturers to meet the rising demand for eco-friendly construction materials.

Stakeholders can leverage this growth by focusing on urbanization and infrastructure projects in emerging economies such as Asia Pacific, Latin America, and Africa. The market’s role in providing energy-efficient solutions for housing and large-scale projects underscores its importance in shaping the future of eco-friendly construction.

Global Autoclaved Lightweight Concrete Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Autoclaved Lightweight Concrete Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Vacuum Arc RemeltingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Autoclaved Lightweight Concreteplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Autoclaved Lightweight Concrete Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Autoclaved Lightweight Concrete Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Autoclaved Lightweight Concrete Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofAutoclaved Lightweight Concrete Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is Autoclaved Lightweight Concrete (ALC)?

Autoclaved Lightweight Concrete (ALC) is a sustainable building material made from a mixture of cement, lime, silica sand, and water. What sets ALC apart is its unique curing process, where it is subjected to high pressure and temperature in an autoclave.

This innovative method gives ALC several advantages over traditional concrete:

- Lightweight: ALC is significantly lighter than regular concrete, making it easier to handle and transport.

- Fire-resistant: ALC has excellent fire-resistant properties, providing added safety to buildings.

- Energy-efficient: ALC’s thermal insulation qualities help maintain comfortable indoor temperatures, reducing the need for excessive heating or cooling.

With its eco-friendly composition and superior performance characteristics, ALC is becoming increasingly popular in construction projects that prioritize sustainability and energy efficiency.

How does ALC contribute to sustainable construction?

ALC helps build green by saving energy and cutting down carbon emissions. It meets standards for green buildings like LEED and BREEAM.

Its insulation keeps buildings at a comfortable temperature. This saves on heating and cooling costs, making it eco-friendly.

What are the primary applications of Autoclaved Lightweight Concrete?

ALC is used in many buildings, homes, offices, and industrial sites. It’s great for making energy-saving walls, panels, blocks, and building parts.

Which countries are leading in ALC market growth?

China, India, and the U.S. are leading in ALC growth. They’re growing fast, building more, and choosing green building tech.

What challenges does the ALC industry currently face?

The ALC industry faces several challenges, including:

- High energy use: The production and use of ALC (Autoclaved Lightweight Concrete) requires significant energy consumption, which can impact its sustainability and cost-effectiveness.

- Quality control issues: Ensuring consistent quality in ALC production can be challenging, leading to variations in strength, durability, and other properties.

- Low awareness: There is a lack of understanding and knowledge about ALC among architects, builders, and consumers. Many people are unaware of its benefits or how to properly utilize it in construction projects.

Are there any new technologies being developed for ALC production?

Yes, there are new technologies being developed for ALC production such as improved curing methods, innovative mix designs, and the use of 3D printing. Additionally, efforts are being made to find more affordable and environmentally friendly raw materials.

How does ALC compare to traditional concrete?

ALC has several advantages over regular concrete:

- Lightweight: ALC is lighter than traditional concrete, making it easier to handle and transport.

- Better insulation: ALC provides superior insulation compared to regular concrete, helping to improve energy efficiency in buildings.

- Fire resistance: ALC offers higher fire resistance properties than traditional concrete, providing added safety.

- Environmentally friendly: ALC is more sustainable and eco-friendly compared to regular concrete, reducing its carbon footprint.

- Faster construction: ALC allows for quicker construction processes, saving time and labor costs.

What is the projected market value for Autoclaved Lightweight Concrete?

The ALC market is expected to reach $22.2 billion. China and India will be the main drivers of growth due to their construction booms and focus on sustainability.

How does ALC support green building initiatives?

ALC is environmentally friendly because it uses less energy, has a low carbon footprint, and meets green building standards. It plays a significant role in sustainable construction.

What future opportunities exist for ALC?

ALC’s future looks bright. It could be used more in modular building, 3D printing, and disaster-resistant designs. It’s also set to grow in markets seeking green solutions.