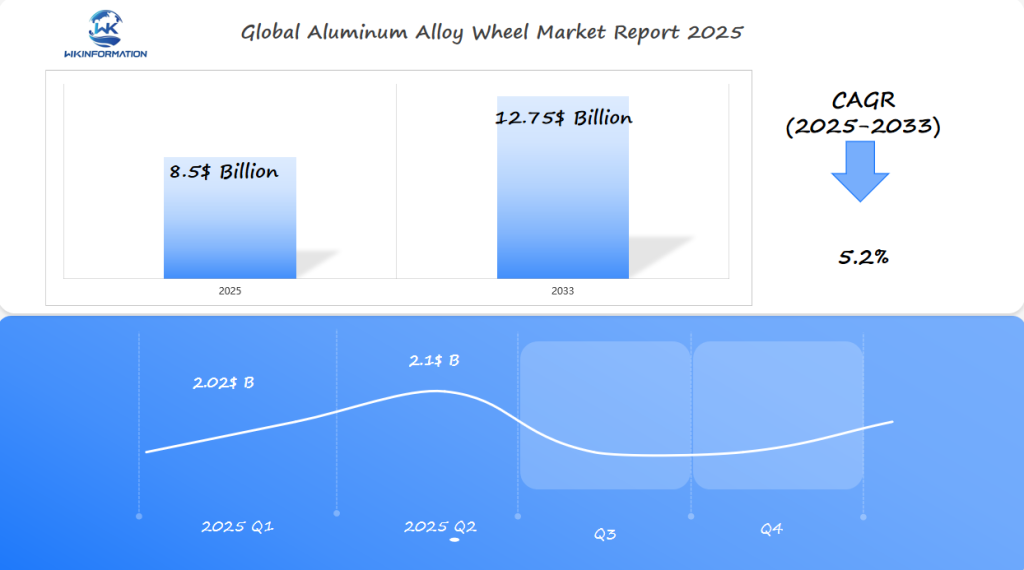

Aluminum Alloy Wheel Market Expected to Exceed $8.5 Billion by 2025: Demand Surge in the U.S., China, and India

Explore the booming Aluminum Alloy Wheel Market, projected to exceed $8.5 billion by 2025, driven by surging demand in the U.S. and China, and India.

- Last Updated:

Aluminum Alloy Wheel Market in Q1 and Q2 of 2025

The Aluminum Alloy Wheel market is estimated to reach $8.5 billion in 2025, growing at a CAGR of 5.2% during 2025–2033. Q1 revenue is forecasted around $2.02 billion, with Q2 rising to nearly $2.1 billion.

Key Factors Driving Demand

- Lightweighting trends in the automotive industry

- Improved fuel efficiency

- Aesthetic upgrades

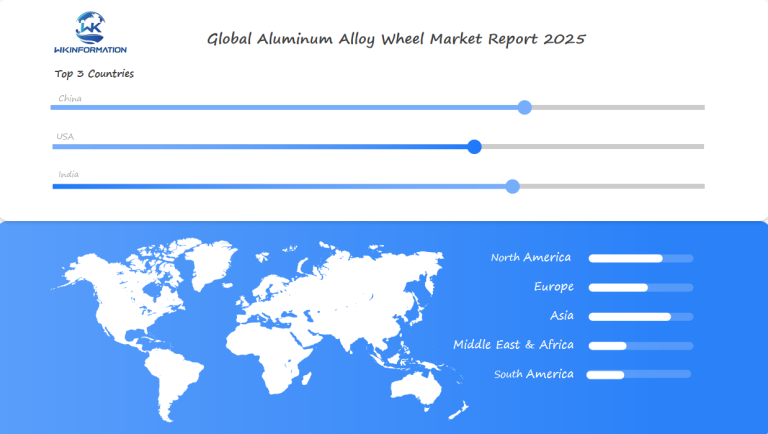

Regional Insights

- The U.S. market continues to favor alloy wheels in both OEM and aftermarket segments.

- China leads in production and export, with major manufacturers ramping up automation.

- India is experiencing fast growth in passenger vehicle customization.

Global Innovations Influencing Purchases

Innovations such as forged alloy construction, hybrid material use, and enhanced corrosion resistance are influencing purchasing decisions globally.

Upstream and Downstream Industry Chain Analysis of Aluminum Alloy Wheels

The dynamics of the aluminum alloy wheel market are significantly affected by its upstream and downstream industry chain. The upstream sector primarily involves the sourcing of raw materials and the manufacturing process, while the downstream sector deals with the distribution and application of aluminum alloy wheels.

Raw Materials and Manufacturing Process

The production of aluminum alloy wheels is a complex process that begins with the sourcing of raw materials. The primary raw materials used are aluminum alloys, which are prized for their strength, durability, and lightweight properties.

The Manufacturing Process

The manufacturing process involves several key steps:

- Melting and casting

- Forging or machining

- Surface treatment

The quality of the raw materials and the efficiency of the manufacturing process play crucial roles in determining the final product’s quality.

Impact of Raw Material Costs

The cost of raw materials is a significant factor in the pricing of aluminum alloy wheels. Manufacturers must balance the need to keep costs low with the requirement to maintain high-quality standards. Fluctuations in raw material costs can impact the final pricing of aluminum alloy wheels, making it essential for manufacturers to develop effective cost management strategies.

Strategies for Cost Management

To mitigate the impact of raw material cost fluctuations, manufacturers can adopt several strategies, including:

- Developing long-term contracts with suppliers to secure stable pricing

- Investing in research and development to improve manufacturing efficiency

- Exploring alternative raw materials or production methods

By understanding the upstream and downstream industry chain dynamics, manufacturers and consumers can better navigate the complexities of the aluminum alloy wheel market.

Trends in lightweight automotive components, performance optimization, and design innovation

The push for lighter vehicles is transforming the automotive industry, with aluminum alloy wheels playing a crucial role in this trend. As manufacturers strive to enhance fuel efficiency and vehicle performance, the demand for lightweight automotive components is on the rise.

Lightweighting in Automotive Components

Lightweighting in the automotive sector involves reducing the weight of vehicles without compromising their strength or performance. This is achieved through the use of advanced materials and innovative manufacturing techniques. Aluminum alloy wheels are a prime example of this trend, offering a significant reduction in weight compared to traditional steel wheels.

“The use of aluminum alloy wheels can improve a vehicle’s power-to-weight ratio, enhancing its overall performance and fuel efficiency,” says an industry expert. This is particularly important in today’s automotive market, where regulatory pressures and consumer demands are driving the need for more efficient and sustainable vehicles.

Design Innovations in Aluminum Alloy Wheels

Design innovations in aluminum alloy wheels are not limited to their material composition. Manufacturers are also focusing on optimizing the design of these wheels to improve their aerodynamic performance and reduce drag. This involves complex engineering and simulation techniques to create wheels that are both lightweight and aerodynamically efficient.

- Advanced casting and forging techniques allow for the creation of complex geometries that enhance the wheel’s performance.

- The use of computer-aided design (CAD) software enables precise control over the design process, ensuring that the final product meets stringent performance and safety standards.

- Innovations in surface treatment and finishing techniques improve the durability and appearance of aluminum alloy wheels.

As the automotive industry continues to evolve, the importance of lightweight automotive components, performance optimization, and design innovation will only continue to grow. Aluminum alloy wheels are at the forefront of this trend, offering a compelling combination of performance, efficiency, and design flexibility.

Regulatory factors impacting emissions and fuel efficiency standards in the automotive industry

Regulatory pressures are mounting on the automotive sector to adhere to stricter emissions standards and improve fuel efficiency. Governments worldwide are implementing policies to reduce carbon emissions and promote the use of environmentally friendly vehicles.

The impact of these regulations is multifaceted, influencing various aspects of vehicle manufacturing, from design to production. One key area affected is the choice of materials for vehicle components, including wheels.

Emissions Regulations and Fuel Efficiency Standards

Emissions regulations are becoming increasingly strict, with many countries setting ambitious goals to reduce greenhouse gas emissions. For example, the European Union aims to cut CO2 emissions from new cars by 55% by 2030 compared to 2021 levels. Similarly, the United States has reinstated tougher fuel economy standards.

These regulations create a demand for parts that can help achieve the desired fuel efficiency and emissions reductions. are one such part, offering a lightweight alternative to traditional steel wheels.

The demand for aluminum alloy wheels is expected to increase as manufacturers strive to comply with the tightening regulations. By reducing the overall weight of vehicles, aluminum alloy wheels contribute to improved fuel efficiency and lower emissions.

| Regulatory Factor | Impact on Aluminum Alloy Wheel Demand |

| Stricter Emissions Standards | Increased demand for lightweight components |

| Fuel Efficiency Standards | Higher adoption rate of aluminum alloy wheels |

| Government Incentives for Green Vehicles | Potential for increased market share for eco-friendly vehicles equipped with aluminum alloy wheels |

The table above shows how various regulatory factors can influence the demand for aluminum alloy wheels. As the automotive industry continues to adapt to these regulatory pressures, components like aluminum alloy wheels will play an increasingly vital role.

Geopolitical Impact on Global Supply Chains for Raw Materials and Manufacturing

The aluminum alloy wheel industry is dealing with a complicated situation of global supply chain disruptions caused by geopolitical instability. As a result, manufacturers are having difficulties in getting raw materials and keeping their production schedules on track.

Global Supply Chain Challenges

Geopolitical tensions and trade policies have introduced significant uncertainties into the global supply chain for aluminum alloy wheels. Tariffs and trade barriers can increase the cost of raw materials, affecting the profitability of manufacturers.

The industry is also experiencing supply chain fragmentation, where different components are sourced from various countries, complicating logistics and increasing the risk of delays.

Geopolitical Factors Affecting Aluminum Alloy Wheel Production

Several geopolitical factors are directly impacting the production of aluminum alloy wheels, including:

- Trade policies and tariffs imposed by governments

- Political instability in regions supplying critical raw materials

- Regulatory changes affecting international trade

To mitigate these risks, manufacturers are adopting strategies such as diversifying their supply chains and investing in local production capacities.

| Geopolitical Factor | Impact on Supply Chain | Mitigation Strategy |

| Trade Policies and Tariffs | Increased cost of raw materials | Diversify supply sources |

| Political Instability | Disruption in raw material supply | Invest in local production |

| Regulatory Changes | Compliance costs and potential fines | Monitor regulatory updates closely |

The geopolitical landscape is significantly influencing the global supply chains for aluminum alloy wheels. Manufacturers must remain agile and responsive to these changes to maintain their competitiveness in the market.

Type segmentation: cast, forged, and billet aluminum alloy wheels

The market for aluminum alloy wheels is primarily categorized into three types: cast, forged, and billet, based on their manufacturing processes and properties. Understanding these differences is crucial for manufacturers and consumers alike to make informed decisions.

Characteristics of Different Types of Aluminum Alloy Wheels

Each type of aluminum alloy wheel has its unique characteristics, advantages, and applications.

1. Cast Aluminum Alloy Wheels

Cast aluminum alloy wheels are produced by pouring molten aluminum into a mold. They are cost-effective and widely used in the automotive industry due to their good balance between price and performance.

2. Forged Aluminum Alloy Wheels

Forged aluminum alloy wheels are made by shaping heated aluminum alloy under high pressure, resulting in a stronger and lighter wheel compared to cast wheels. They offer superior performance and are often used in high-performance and luxury vehicles.

3. Billet Aluminum Alloy Wheels

Billet aluminum alloy wheels are crafted from a solid piece of aluminum alloy, machined to create the desired design. They offer exceptional strength, reduced weight, and a unique aesthetic appeal, making them popular among car enthusiasts.

The market share of these types varies based on factors like region, vehicle type, and consumer preferences. Generally, cast aluminum alloy wheels dominate the market due to their cost-effectiveness and widespread adoption.

The distribution of market share among these types reflects their respective advantages and the diverse needs of the automotive industry. As the industry evolves, the demand for each type is expected to shift based on technological advancements and changing consumer preferences.

Application segmentation: passenger vehicles, commercial vehicles, and racing cars

With the automotive industry’s shift towards lightweight and efficient vehicles, aluminum alloy wheels are becoming a staple in passenger vehicles, commercial vehicles, and racing cars. This trend is driven by the need for improved fuel efficiency, reduced emissions, and enhanced performance.

Use of Aluminum Alloy Wheels in Different Vehicle Types

Aluminum alloy wheels are being increasingly adopted across various vehicle segments due to their lightweight and high-performance characteristics. In passenger vehicles, these wheels improve fuel efficiency and handling. In commercial vehicles, they contribute to reduced fuel consumption and increased payload capacity. For racing cars, aluminum alloy wheels are crucial for achieving high speeds and optimal performance.

Aluminum Alloy Wheels Application Segmentation

The demand for aluminum alloy wheels is on the rise across different vehicle categories:

- In passenger vehicles, the demand is driven by consumer preferences for improved fuel efficiency and aesthetics.

- Commercial vehicles are seeing increased adoption due to the need for cost savings through reduced fuel consumption.

- Racing cars continue to drive innovation in aluminum alloy wheel technology, pushing the boundaries of performance and durability.

As the automotive industry continues to evolve, the application of aluminum alloy wheels is expected to expand further across these segments, driven by technological advancements and regulatory pressures.

Global shift toward lighter and more fuel-efficient automotive wheels

As the world moves towards more sustainable automotive solutions, the demand for lightweight wheels is on the rise. This shift is driven by the need for improved fuel efficiency, reduced emissions, and enhanced vehicle performance.

The automotive industry is undergoing a significant transformation with the adoption of advanced materials and manufacturing technologies. Aluminum alloy wheels are leading this change, providing a combination of strength, durability, and weight reduction.

Trends in Automotive Wheel Technology

Recent advancements in wheel technology have focused on reducing weight while maintaining or improving strength. Lightweight wheels not only enhance fuel efficiency but also improve vehicle handling and braking performance.

The trend towards fuel-efficient automotive wheels is driven by both regulatory requirements and consumer demand for more environmentally friendly vehicles. As a result, manufacturers are investing heavily in research and development to produce wheels that meet these demands.

The increasing demand for lightweight and fuel-efficient wheels is having a positive impact on the aluminum alloy wheel market. As manufacturers seek to reduce vehicle weight and improve performance, aluminum alloy wheels are becoming the preferred choice due to their strength, durability, and weight advantages.

The global shift towards more sustainable automotive solutions is expected to continue driving growth in the aluminum alloy wheel market. With ongoing advancements in technology and manufacturing processes, the market is poised for significant expansion in the coming years.

Key players in the industry are focusing on developing innovative products that meet the evolving needs of the automotive sector. This includes the development of new alloys and manufacturing techniques that enhance the performance and sustainability of aluminum alloy wheels.

U.S. Market Growth in Premium Automotive and Sports Car Segments

The surge in demand for premium automotive and sports cars in the U.S. is driving innovation in aluminum alloy wheels. This growth is attributed to the increasing consumer preference for high-performance and lightweight vehicles.

Premium and Sports Car Market Trends

Premium and Sports Car Market Trends

The U.S. market for premium and sports cars is witnessing a significant shift towards vehicles equipped with advanced aluminum alloy wheels. These wheels offer improved performance, fuel efficiency, and aesthetic appeal.

Demand for Aluminum Alloy Wheels in the U.S.

The demand for aluminum alloy wheels in the U.S. is driven by the growing production of premium and sports cars. Manufacturers are focusing on producing high-quality, lightweight wheels that meet the performance and safety standards of these vehicles.

The trend towards lightweight and high-performance aluminum alloy wheels is expected to continue, driven by consumer demand for improved vehicle performance and fuel efficiency.

China’s rapidly expanding automotive industry and shift toward electric vehicles

China’s automotive market is experiencing unprecedented growth, fueled by government incentives for electric vehicles. This growth is not only transforming the automotive landscape in China but also has significant implications for the global aluminum alloy wheel market.

China’s Automotive Market Trends

The Chinese automotive industry is undergoing a significant change with the growing popularity of electric vehicles (EVs). EVs are becoming increasingly popular due to their environmental benefits and lower operating costs. This trend is being fueled by government policies that support the industry, such as tax exemptions and subsidies for EV manufacturers.

The Rise of Electric Vehicles

- Environmental Benefits: EVs produce zero tailpipe emissions, reducing air pollution and greenhouse gas emissions.

- Lower Operating Costs: Electric vehicles have lower fuel and maintenance costs compared to traditional gasoline-powered cars.

As a result of this shift towards electric vehicles, there is an increasing demand for lightweight and efficient automotive components, such as aluminum alloy wheels. Aluminum alloy wheels are particularly suited for electric vehicles due to their ability to reduce overall vehicle weight, thereby enhancing efficiency and range.

India’s increasing demand for lightweight, cost-effective automotive parts

India’s automotive industry is growing, leading to a greater need for affordable, lightweight parts. This demand is driven by the requirement for fuel-efficient vehicles that are accessible to the general public.

India’s Automotive Parts Market

The automotive parts market in India is evolving rapidly, with a significant focus on lightweight materials that can enhance vehicle performance and reduce costs. Aluminum alloy wheels are gaining popularity due to their ability to provide a balance between durability and cost-effectiveness.

The shift towards lightweight automotive parts presents a substantial opportunity for aluminum alloy wheels. These wheels are not only lighter, which improves fuel efficiency, but they also offer superior strength and aesthetic appeal.

Key opportunities for aluminum alloy wheels in India include:

- Increasing demand for fuel-efficient vehicles

- Growth of the automotive aftermarket

- Rising production of electric vehicles

By capitalizing on these trends, manufacturers of aluminum alloy wheels can tap into the growing demand for lightweight, cost-effective automotive parts in India.

Future developments in sustainable alloy materials and 3D-printed wheels

The aluminum alloy wheel industry is set to make significant progress with the use of sustainable materials and new manufacturing technologies such as 3D printing. Sustainable alloy materials are being created to minimize environmental impact while still preserving the performance qualities of conventional aluminum alloys.

Sustainable Materials in Aluminum Alloy Wheels

The shift towards sustainable materials is driven by the need to minimize the ecological footprint of automotive components. Researchers are exploring new alloy compositions that are recyclable, have a lower carbon footprint, and can be produced with minimal waste.

One of the key benefits of sustainable alloy materials is their potential to reduce the overall weight of vehicles, thereby improving fuel efficiency and lowering emissions. Additionally, these materials can offer enhanced durability and performance, making them an attractive option for automotive manufacturers.

The Role of 3D Printing in Wheel Production

3D printing technology is revolutionizing the production of aluminum alloy wheels by enabling the creation of complex geometries that cannot be achieved with traditional manufacturing methods. This technology allows for the production of lightweight wheels with optimized structural integrity.

The use of 3D printing in wheel manufacturing also offers the potential for:

- Reduced material waste

- Lower energy consumption

- Customized wheels tailored to specific vehicle models or consumer preferences

These advantages open up new avenues for innovation in the industry.

Future Prospects

As the industry continues to evolve, the adoption of 3D-printed wheels is expected to grow. This growth will be driven by advancements in technology and the increasing demand for sustainable and high-performance automotive components.

Key competitors in the aluminum alloy wheel manufacturing market

Key competitors in the aluminum alloy wheel manufacturing market include a mix of global OEM and aftermarket manufacturers. These companies compete based on product quality, design, lightweight technology, and supply relationships with automakers.

- BBS – Germany

- Borbet – Germany

- ENKEI – Japan

- Maxion Wheels – United States

- Alcoa Wheels – United States

- Wanfeng Auto – China

- Lizhong Wheel Group – China

- Superior Industries – United States

- U.S. Wheel Corp. – United States

- TSW Alloy Wheels – USA

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Aluminum Alloy Wheel Report |

| Base Year | 2024 |

| Segment by Type |

· Cast · Forged · Billet Aluminum Alloy Wheels |

| Segment by Application |

· Passenger Vehicles · Commercial Vehicles · Racing Cars |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The aluminum alloy wheel market is poised for significant growth, driven by increasing demand for lightweight and fuel-efficient vehicles. Trends in lightweight automotive components, performance optimization, and design innovation are expected to continue shaping the market.

Market Conclusion and Future Prospects

The market outlook remains positive, with the U.S., China, and India emerging as key players. Regulatory factors, such as emissions and fuel efficiency standards, will continue to influence market dynamics. Technological advancements, including sustainable alloy materials and 3D-printed wheels, are expected to drive innovation.

Future Outlook

As the automotive industry continues to evolve, the aluminum alloy wheel market is likely to exceed $8.5 billion by 2025. With a growing focus on sustainability and fuel efficiency, manufacturers are expected to invest in research and development, driving further growth in the market.

Global Aluminum Alloy Wheel Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Aluminum Alloy Wheel Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Aluminum Alloy WheelMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Aluminum Alloy Wheelplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Aluminum Alloy Wheel Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Aluminum Alloy Wheel Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Aluminum Alloy Wheel Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofAluminum Alloy WheelMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is driving the growth of the Aluminum Alloy Wheel Market?

The growth is driven by increasing demand in the U.S. and China, as well as the rising need for lightweight and fuel-efficient vehicles.

How do raw material costs impact the pricing of aluminum alloy wheels?

Raw material costs significantly affect the final pricing of aluminum alloy wheels, making it crucial for manufacturers to manage these costs effectively.

What are the different types of aluminum alloy wheels?

Aluminum alloy wheels are categorized into cast, forged, and billet types, each with its unique characteristics and applications.

How do emissions regulations and fuel efficiency standards impact the demand for aluminum alloy wheels?

Stringent emissions regulations and fuel efficiency standards drive the demand for aluminum alloy wheels as they contribute to achieving these standards.

What is the trend in automotive wheel technology?

The global automotive industry is shifting towards lighter and more fuel-efficient wheels, with aluminum alloy wheels being a key aspect of this shift.

How do the premium automotive and sports car segments influence the demand for aluminum alloy wheels in the U.S. market?

The U.S. market is experiencing significant growth in the premium automotive and sports car segments, which is driving the demand for high-performance and lightweight aluminum alloy wheels.

What is the impact of China’s shift towards electric vehicles on the demand for aluminum alloy wheels?

China’s shift towards electric vehicles is expected to drive the demand for lightweight aluminum alloy wheels.

What opportunities exist for aluminum alloy wheels in India’s automotive parts market?

India’s increasing demand for lightweight and cost-effective automotive parts presents opportunities for aluminum alloy wheels.

How will future developments in sustainable alloy materials and 3D-printed wheels impact the industry?

The use of sustainable materials and 3D printing technology is expected to enhance the performance and environmental friendliness of aluminum alloy wheels, driving future growth.

What is the future outlook for the Aluminum Alloy Wheel Market?

The future of the aluminum alloy wheel market looks promising, driven by the increasing demand for lightweight and fuel-efficient vehicles, as well as advancements in technology and sustainable materials.