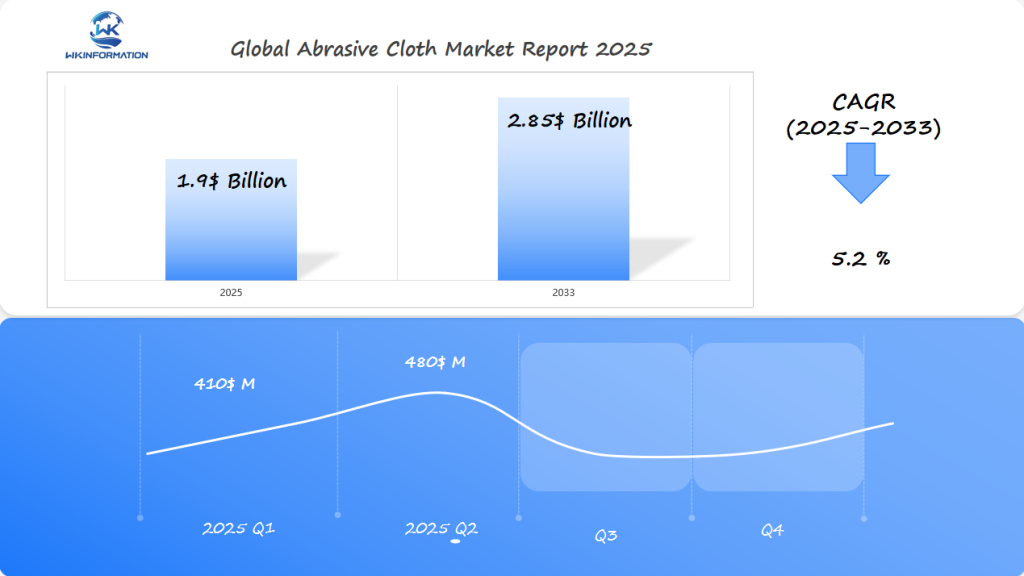

Abrasive Cloth Market to Surpass $1.9 Billion Globally by 2025: Industrial Polishing and Finishing Demand Surges in China, Mexico, and Turkey

The Abrasive Cloth Market experiences robust growth driven by rising demand in automotive, metalworking, and woodworking sectors. Key players include 3M and Saint-Gobain leading innovation.

- Last Updated:

Abrasive Cloth Market Performance in Q1 and Q2 of 2025

The global Abrasive Cloth market is expected to reach $1.9 billion in 2025, supported by a CAGR of 5.2% from 2025 to 2033. The market showed steady activity in Q1, estimated at $410 million, while Q2 is projected to reach $480 million, reflecting increased demand from metal finishing, woodworking, and automotive refurbishing sectors. Seasonal industrial output in Q2 typically pushes procurement cycles upward.

Key Takeaways

- The global abrasive cloth market is expected to reach $1.9 billion by 2025.

- There is a growing demand in various manufacturing industries.

- Technological advancements are contributing to the growth of the market.

- Asia-Pacific and North America are the main regions driving market growth.

- There is a greater emphasis on precision finishing technologies.

Analysis of the Upstream and Downstream Industry Chain in the Abrasive Cloth Market

The abrasive cloth market is a complex system of parts that drive innovation and quality. Knowing the industry chain helps us understand how the market works and adds value.

Raw material suppliers are key in making abrasive cloth. They get and give out special minerals and synthetic stuff needed for top-notch abrasive products.

Key Raw Material Suppliers and Sources

- Mineral-based suppliers providing

- Synthetic abrasive manufacturers producing

- Advanced material producers creating zirconia alumina compounds

Manufacturing Processes in Abrasive Cloth Production

Making abrasive cloths involves advanced methods that turn raw materials into precise tools. These steps include getting ready the materials, bonding them, and applying coatings.

| Manufacturing Stage | Key Process | Primary Technique |

| Material Selection | Abrasive Grain Identification | Mineral and Synthetic Evaluation |

| Substrate Preparation | Cloth Base Treatment | Resin Impregnation |

| Coating Application | Abrasive Grain Bonding | Precision Layering |

Distribution Channels and End-User Industries

Distribution for abrasive cloths goes through many channels, linking makers with various sectors. Key end-user industries include metal fabrication, automotive manufacturing, woodworking, and electronics.

- Industrial supply distributors

- Direct manufacturer sales

- Specialized technical equipment retailers

The complex ties between suppliers, makers, and users make the abrasive cloth market dynamic and adaptable.

Trends include expansion in precision finishing and robotic grinding

The abrasive cloth market is undergoing significant transformations due to advancements in precision finishing and robotic grinding technologies. Businesses are swiftly embracing innovative techniques that surpass traditional methods of surface treatment.

New trends in precision finishing

These emerging trends in precision finishing are revolutionizing manufacturing processes within factories. They empower manufacturers to achieve unprecedented levels of smoothness and accuracy in surface finishes. Notable developments include:

- Micro-scale surface modification capabilities

- Enhanced abrasive applications for intricate shapes

- Improved material removal rates

- Reduced surface roughness

Advancements in Precision Finishing Techniques

New precision finishing tech is changing making things by making surfaces super smooth and using less material. Robotic grinding systems now use smart sensors and control systems. These help make abrasive work better in many industries.

| Technology | Performance Metrics | Industry Application |

| Automated Precision Grinding | 99.5% Surface Accuracy | Aerospace |

| Robotic Abrasive Processing | 40% Faster Processing | Automotive |

| Nano-Scale Surface Treatment | 0.1μm Roughness | Electronics |

Integration of Robotic Systems in Abrasive Applications

Robotic grinding systems are getting smarter, making it possible to get unprecedented precision in finishing surfaces. These systems use AI and machine learning to make abrasive cloth work better in tough factory settings.

- Real-time surface monitoring

- Adaptive grinding strategies

- Predictive maintenance capabilities

Challenges in the Abrasive Cloth Industry: Emission Rules and Health Concerns

The abrasive cloth industry is facing significant challenges due to strict environmental regulations and health concerns. Companies in this industry must navigate tough emission rules while also ensuring the safety of their workers.

Impact of Emission Rules

Emission rules are becoming increasingly stringent, which means that companies will need to find new and innovative ways to manage dust in their factories. These regulations are put in place to protect both the health of workers and the environment.

As a result, businesses in the abrasive cloth sector will have to invest in cleaner technologies and implement effective dust control measures. Failure to comply with these rules could lead to penalties and damage to their reputation.

Importance of Worker Safety

In addition to meeting emission requirements, companies must also prioritize the well-being of their employees. Prolonged exposure to abrasive dust can have serious health implications for workers, including respiratory issues and other occupational diseases.

To address these concerns, employers should:

- Provide proper personal protective equipment (PPE) such as masks and respirators

- Implement regular health check-ups for employees

- Conduct training programs on safe handling practices

By taking proactive steps towards worker safety, companies can create a healthier workplace environment and reduce the risk of accidents or illnesses caused by dust exposure.

Environmental Regulations Impacting Abrasive Cloth Production

Big challenges in making abrasive cloth include:

- Lowering dust in the air

- Using better filters

- Creating dust-catching tech

Companies must spend on advanced dust control to meet strict standards. Managing emissions well is now key to staying ahead.

Occupational Health and Safety Considerations

To manage dust, companies need strong safety plans. They should give workers special gear and check their health often.

| Health Risk | Potential Impact | Mitigation Strategy |

| Respiratory Issues | Lung inflammation | Advanced respirator systems |

| Skin Exposure | Dermatological problems | Personal protective equipment |

| Long-term Exposure | Chronic health conditions | Regular medical monitoring |

To effectively manage dust, companies must implement robust safety plans that include the following:

- Advanced respirator systems: These systems are designed to provide optimal protection against respiratory issues caused by dust exposure.

- Personal protective equipment (PPE): This includes specialized gear such as gloves, masks, and protective clothing to prevent skin exposure to harmful substances.

- Regular medical monitoring: Companies should conduct routine health check-ups for employees to identify any potential long-term health conditions resulting from dust exposure.

Geopolitical impacts on manufacturing outsourcing and tariff structures

The global abrasive cloth market is changing fast because of world politics. Companies are now thinking hard about where to make their products. This is because the world trade scene is getting more unstable.

How businesses make things is changing because of global shifts. Countries are looking at their place in the world’s supply chains. Companies are checking out different places to make their products.

Global Trade Dynamics Reshaping Production

Factors influencing where companies produce their goods include:

- Changing tariffs between major nations

- Global political events impacting trade routes

- Variations in production costs across regions

- Technological requirements for manufacturing

Trade Policy Impact on Abrasive Cloth Market

New trade rules have changed how tariffs work. This has made things tough and also opened up chances for makers of abrasive cloth. Companies need to be flexible and strong in their supply chains because of these rules.

| Region | Manufacturing Outsourcing Trend | Tariff Impact |

| North America | Nearshoring increase | Moderate protectionist policies |

| Asia-Pacific | Continued manufacturing hub | Competitive trade incentives |

| Europe | Diversification of supply chains | Strict regulatory environment |

The future of global trade in abrasive cloth markets will depend on manufacturers’ ability to navigate complex geopolitical landscapes while maintaining competitive pricing and quality standards.

Abrasive Cloth Market Segmentation by Type: Aluminum Oxide, Silicon Carbide, Zirconia Alumina, Garnet Cloth

The abrasive cloth market has many types, each with its own benefits and uses. Knowing about aluminum oxide, silicon carbide, zirconia alumina, and garnet cloth helps us understand the market better.

Each abrasive material has its own strengths in finishing surfaces and processing materials. People choose these materials based on what they need.

Aluminum Oxide: Versatile Abrasive Material

Aluminum oxide is a key abrasive material used in many industries. It’s durable and affordable, making it great for metal and wood work, and preparing surfaces.

- Excellent for ferrous metal processing

- High resistance to wear

- Economical performance profile

Silicon Carbide: Precision Grinding Champion

Silicon carbide is excellent for precise grinding. It works well with non-ferrous metals, ceramics, and composites.

Zirconia Alumina: High-Performance Abrasive Solution

Zirconia alumina is very hard and can handle high temperatures. It’s perfect for removing a lot of material and for tough surface finishes.

Garnet Cloth: Specialized Surface Treatment

Garnet cloth is great for wood and marine work. It’s made from natural minerals, which are gentle but effective.

As industries grow, these abrasive materials keep improving. They meet new challenges in manufacturing.

Abrasive Cloth market segmentation by application: metal fabrication, woodworking, automotive, electronics

The abrasive cloth market covers many high-performance industries. Each one has its own needs and special requirements. These materials are key in surface finishing and processing, from metal fabrication to electronics.

- Metal fabrication: Precision surface preparation and finishing of metal components

- Woodworking: Smoothing and refining wooden surfaces for furniture and construction

- Automotive applications: Preparing and finishing automotive parts and body panels

- Electronics industry: Delicate surface treatment for sensitive electronic components

Metal Fabrication Requirements

Metal fabrication needs abrasive cloths that can handle tough materials. These cloths are made to be durable and cut well. Zirconia and aluminum oxide-based materials work great in metal surface preparation.

Specialized Industrial Applications

Every industry has its own needs for abrasive cloths:

- Woodworking: needs soft, flexible materials to avoid damage.

- Automotive manufacturing: looks for cloths that work well on different metals.

- Electronics industry: needs fine, precise cloths to protect delicate parts.

Precision and adaptability define the modern abrasive cloth market across diverse industrial applications.

Global Footprint of the Abrasive Cloth Market

The global market for abrasive cloth has seen big changes. It now has a complex mix of growth and competition. Companies and experts see huge growth in many places.

Looking at the global market, we find important facts about how regions perform:

- North America leads with its advanced tech

- Asia-Pacific grows fast with big potential

- European markets keep innovating steadily

- New markets in emerging economies offer chances

Regional Market Sizes and Growth Trajectories

Every region has its own special traits in the market. Market sizes differ a lot. Growth rates vary based on industrial needs and new tech.

Competitive Landscape Dynamics

Big players in the market are changing how things work globally. They focus on making special products for certain uses. This helps them stand out.

Regional growth patterns show a complex mix. Tech innovation, making skills, and demand come together. This creates special chances for makers of abrasive cloth.

Being able to adapt to new tech and understanding local markets is key for lasting success in this changing global market.

China's Role in the Global Abrasive Cloth Market: Large-Scale Manufacturing and Tool Exports

China has become a key player in global abrasive cloth production, reshaping the way we manufacture and trade tools. Chinese producers have significantly influenced tool exports across various industries.

Factors Behind China’s Success in Abrasive Cloth Production

China’s success in producing abrasive cloth can be attributed to several strengths:

- Massive production capacity: China has the ability to produce large quantities of abrasive cloth, meeting the demands of both domestic and international markets.

- Cost-effective manufacturing processes: Chinese manufacturers have implemented efficient production methods that help keep costs low, making their products competitive in pricing.

- Advanced technological integration: The use of modern technology in the manufacturing process has improved the quality and consistency of abrasive cloth produced in China.

- Robust export infrastructure: China has well-developed transportation and logistics systems that facilitate smooth export operations, ensuring timely delivery of products to global markets.

Dominance in Global Manufacturing

China is known for its large-scale manufacturing in the abrasive cloth industry. They use the latest production methods to make high-quality tools at good prices. Chinese manufacturers have become top players in tool exports, taking a big share of the global market.

Market Impact and Global Dynamics

Chinese manufacturers’ influence goes beyond just making lots of tools. Their smart pricing, new technologies, and efficient supply chains make others rethink their strategies. Tool exports from China are pushing traditional manufacturing centers to change.

But, there are still challenges. Like keeping quality high and investing in new tech. Yet, China is still focused on staying ahead in the abrasive cloth market.

Mexico Abrasive Cloth market: cost-effective finishing hubs for U.S. OEMs

The Mexico market is key for cost-effective finishing, especially for U.S. OEMs. Its close location to the U.S. and strong trade setup make it a top spot in the abrasive cloth world.

More and more, companies see the value in making things in Mexico. The country has many good points:

- Significantly lower labor costs

- Proximity to U.S. manufacturing centers

- Established industrial infrastructure

- Favorable trade agreements

North American Supply Chain Dynamics

U.S. OEMs use Mexico’s manufacturing skills to improve their supply chains. The finishing work done in Mexico gives them a significant advantage globally.

There are significant opportunities for manufacturers of abrasive cloth:

- Expanding production capabilities

- Developing specialized finishing techniques

- Investing in advanced manufacturing technologies

Challenges in the Mexican Abrasive Cloth Market

Despite its positive prospects, manufacturers encounter certain obstacles. Quality control, worker training, and maintaining competitive prices are significant challenges in Mexico.

Turkey Abrasive Cloth market: regional metal and furniture industries

The Turkey market is a key place for making abrasive cloth. It sits between European and Middle Eastern manufacturing areas. Metal and furniture making need special abrasive materials a lot.

Turkey is great for making abrasive cloth because of:

- Its location between Europe and Asia

- Strong industrial setup

- Workers skilled in making things precisely

- Lower production costs

Manufacturing Hub Dynamics

The metal industries in Turkey are improving. They require high-quality abrasive cloths for precise finishes and surface work. Additionally, furniture manufacturers are seeking superior abrasive solutions for both wood and metal applications.

Growth Prospects and Market Opportunities

Turkish makers of abrasive cloth are getting better by using advanced production technologies. They see a lot of growth ahead. This is because of more exports and growth in the country’s industries.

Signs show Turkey’s metal and furniture making will keep growing. This makes Turkey a big name in the global abrasive cloth market.

Future direction includes nanostructured abrasives and eco-friendly binders

The abrasive cloth industry is about to undergo a significant transformation, driven by new technologies and a strong emphasis on sustainability. Leading this change are nanostructured abrasives, which promise unparalleled precision and performance.

In addition to this, companies are actively developing eco-friendly binders. These innovative binders aim to reduce environmental impact while maintaining high standards of quality. This initiative marks a significant advancement towards more environmentally friendly manufacturing practices.

Emerging Technologies in Abrasive Cloth Production

- Advanced nanostructured abrasive materials with enhanced durability

- Precision-engineered surface technologies

- Reduced material waste during manufacturing

Nanotechnology is making a huge difference in abrasive cloth. It allows for tiny changes that boost performance. Scientists are looking into new ways to make products better and kinder to the planet.

Sustainability Trends Driving Product Development

| Technology | Environmental Impact | Performance Improvement |

| Nanostructured Abrasives | Reduced Material Consumption | Higher Precision |

| Eco-Friendly Binders | Lower Carbon Footprint | Enhanced Durability |

Companies are investing heavily in research to develop better abrasive cloths. Their goal is to comply with stringent environmental regulations while enhancing performance across various industries.

Competitive overview of leading and niche abrasive suppliers

Key players in the abrasive cloth market are focusing on developing high-performance, long-lasting materials to meet the needs of precision surface finishing across industries like metalworking, automotive, and woodworking. They are expanding into emerging markets such as Southeast Asia and Latin America, where industrial manufacturing and infrastructure development are driving demand. Strategic investments in automation and partnerships with tool and machinery manufacturers are enabling these companies to improve product efficiency and expand their global market share.

Key players:

-

XuChang SanShun Abrasive Materials Co., Ltd. (China)

-

3M (USA)

-

Saint-Gobain Abrasives (France)

-

Mirka (Finland)

-

Klingspor (Germany)

-

Pferd (Germany)

-

Norton Abrasives (Saint-Gobain) (France)

-

VSM Abrasives (Germany)

-

Hermes Schleifmittel (Germany)

-

Indasa (Portugal)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Abrasive Cloth Market Report |

| Base Year | 2024 |

| Segment by Type |

· Aluminum Oxide · Silicon Carbide · Zirconia Alumina · Garnet Cloth |

|

Segment by Application |

· Metal Fabrication · Woodworking · Automotive · Electronics |

|

Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Abrasive Cloth Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Abrasive Cloth Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Abrasive Cloth Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Abrasive Cloth Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Abrasive Cloth Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Abrasive Cloth Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Abrasive Cloth Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Abrasive Cloth Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is driving the growth of the abrasive cloth market?

The abrasive cloth market is growing fast. This is because more people need these products for polishing and finishing. They are used in metal work, cars, wood, and electronics.

What are the key materials used in abrasive cloths?

The main materials used in abrasive cloths are:

- Aluminum oxide

- Silicon carbide

- Zirconia alumina

- Garnet cloth

Each of these materials has special properties that make them suitable for different applications.

How are environmental regulations affecting the abrasive cloth market?

Environmental regulations are causing changes in the market. They promote cleaner production methods and encourage the use of products that have lower pollution levels.

What emerging technologies are changing the abrasive cloth industry?

New technologies such as nanoabrasives, green binders, and robots for grinding are making their way into the industry. These advancements are improving products and making them more accurate.

Which regions are significant in the global abrasive cloth market?

Important areas are North America, Europe, and Asia-Pacific. China is a big maker and seller, and Mexico is a cost-effective place for production.

Which industries primarily use abrasive cloths?

The main users of abrasive cloths include:

- Metal manufacturers

- Woodworkers

- Automobile manufacturers

- Electronics industry

- Precision engineering

Each of these industries requires specific types of abrasive cloths to meet their unique needs.

What challenges does the abrasive cloth market face?

The market faces issues like green rules, health worries, trade problems, and the need for new products. These are due to changing manufacturing needs.

Who are the major players in the abrasive cloth market?

The leading companies in the abrasive cloth market are 3M, Saint-Gobain, and Klingspor. In addition to these big names, there are also several smaller and newer companies that are focusing on specific areas within the industry.

What are the sustainability trends in abrasive cloth production?

Trends include making products with green binders, cutting down environmental harm, and making production better. The goal is to make products that are good for the planet.

How is technology changing abrasive cloth manufacturing?

New tech brings better finishing, robots, nano materials, and digital making. These changes make products better and more precise.