$3.87 Billion Explosive Growth in PVC Additives Market in the U.S., India, and Brazil by 2025

Explore the PVC additives market: growth trends, applications in construction and automotive, and challenges for sustainable production.

- Last Updated:

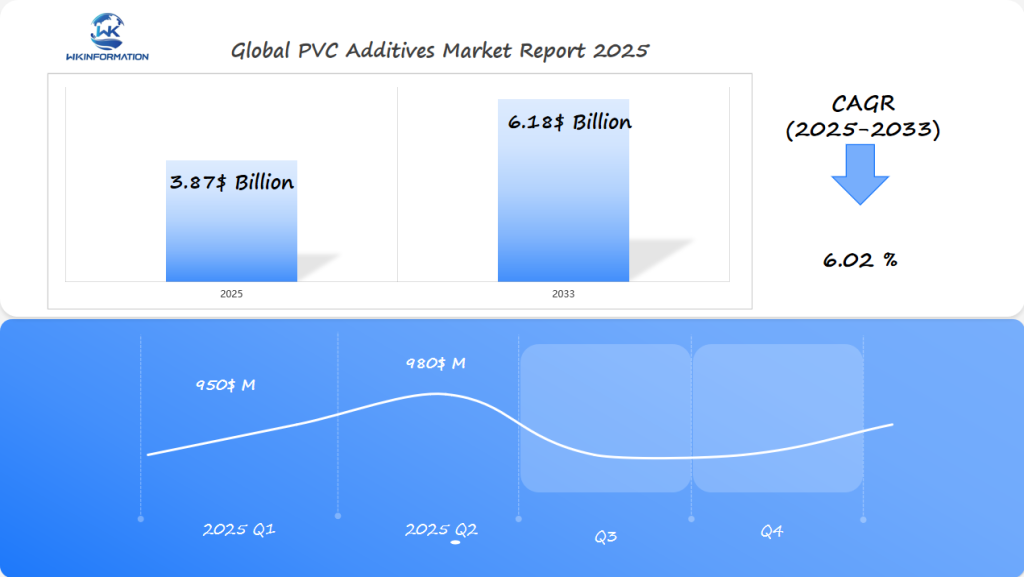

PVC Additives Market Q1 and Q2 2025 Forecast

The PVC Additives market is projected to reach $3.87 billion in 2025, with a CAGR of 6.02% from 2025 to 2033. In Q1 2025, the market is expected to generate approximately $950 million, driven by increasing demand for PVC-based products in the U.S., India, and Brazil. The growth of the construction and automotive industries is contributing to the higher consumption of PVC additives in applications like pipes, wires, and automotive interiors.

By Q2 2025, the market is forecasted to reach $980 million, supported by the continued development of sustainable PVC formulations and bio-based additives. India and Brazil are emerging as key demand markets, while the U.S. remains a significant consumer in industrial applications.

The PVC additives market is set to experience steady growth driven by the expansion of the construction, automotive, and electronics sectors, along with a growing emphasis on environmentally friendly additives.

Exploring the Upstream and Downstream Industry Chains for PVC Additives

The PVC additives supply chain consists of intricate networks spanning raw material procurement to end-user distribution. Understanding these chains reveals critical market dynamics and potential growth opportunities.

Upstream Production Process

The upstream segment relies heavily on petrochemical industries, with key raw materials including:

- Phthalic anhydride

- Alcohols and esters

- Metal compounds

- Organic stabilizers

The upstream production process involves several key stages:

- Raw material extraction and processing

- Chemical synthesis of base compounds

- Quality control and testing phases

- Storage and pre-distribution preparation

Downstream Applications and Distribution

The downstream chain encompasses multiple channels:

- Direct sales to manufacturers

- Distribution through chemical wholesalers

- Regional distributors and retailers

- Custom blending facilities

PVC additive manufacturers maintain strategic relationships with various industries, including:

- Construction material producers

- Automotive parts manufacturers

- Packaging companies

- Medical device manufacturers

Supply Chain Impact

Supply chain disruptions can have a significant impact on the PVC additives market, leading to shifts in demand and pricing. Some key effects include:

- Raw material price fluctuations affecting end-product costs

- Transportation delays influencing inventory management

- Regional availability impacting local manufacturing capabilities

- Quality control measures throughout the chain ensuring product consistency

To mitigate these risks, manufacturers are increasingly adopting vertical integration strategies, where they control multiple stages of the supply chain from production to distribution. This allows them to maintain competitive advantages and ensure steady supply flows, even in times of disruption.

Key Trends Driving the PVC Additives Market: Advancements in Plastics

The PVC additives market is experiencing rapid technological evolution due to groundbreaking innovations in plastic formulations. Smart additives are emerging as game-changers, incorporating nano-materials that enhance PVC performance and durability. These advanced formulations create self-healing properties and improved resistance to environmental factors.

Recent developments in additive technologies include:

- Bio-based plasticizers derived from renewable resources

- Heat-resistant stabilizers for high-temperature applications

- UV-protective additives with enhanced durability

- Anti-microbial compounds for medical-grade PVC

The packaging industry is driving significant market growth through its demand for high-quality solutions. Modern PVC additives enable the production of clear, flexible, and durable packaging materials that meet strict food safety requirements. These innovations address the need for extended shelf life and product protection while maintaining aesthetic appeal.

Consumer preferences are also shaping product development strategies in the PVC additives sector. Market research indicates a growing demand for:

- Eco-friendly formulations with reduced environmental impact

- Transparent materials for visible product display

- Enhanced safety features in food-contact applications

- Improved tactile properties for consumer goods

Manufacturers are responding to these preferences by developing additives that combine functionality with sustainability. The integration of smart technologies and sustainable practices reflects the industry’s adaptation to changing market demands.

Challenges in PVC Additives Production: Environmental Concerns and Regulations

Environmental concerns cast a significant shadow over PVC additives production. The manufacturing process releases volatile organic compounds (VOCs) and hazardous air pollutants, raising red flags among environmental protection agencies worldwide.

Key Environmental Issues:

- Toxic emissions during production

- Disposal challenges of PVC products

- Groundwater contamination risks

- Heavy metal content in certain additives

The regulatory landscape has grown increasingly stringent. The European Union’s REACH regulations restrict the use of specific additives, particularly phthalate plasticizers. Similar restrictions exist under California’s Proposition 65 and various Asian regulatory frameworks.

Current Regulatory Requirements:

- Maximum VOC emission limits

- Restricted use of heavy metals

- Mandatory safety documentation

- Regular environmental impact assessments

Industry leaders have developed sustainable production strategies to address these challenges. Modern facilities now implement closed-loop systems, reducing waste and emissions. Advanced filtration technologies capture harmful compounds, while water recycling systems minimize resource consumption.

Sustainable Production Innovations:

- Bio-based plasticizer alternatives

- Energy-efficient processing methods

- Waste reduction technologies

- Green chemistry principles in formulation

These environmental challenges drive continuous innovation in the PVC additives sector. Companies investing in sustainable practices gain competitive advantages through reduced regulatory risks and enhanced market perception.

Geopolitical Factors Affecting PVC Additives Demand and Production

Global political dynamics have a significant impact on the PVC additives market. Recent trade tensions between major economies have disrupted traditional supply chains, forcing manufacturers to find alternative sourcing strategies.

Key Market Impacts:

- Supply chain disruptions from regional conflicts

- Raw material price fluctuations due to political instability

- Shifting manufacturing bases to avoid trade barriers

- Currency exchange rate volatility affecting profit margins

The U.S.-China trade relationship particularly influences market dynamics. Chinese manufacturers are facing increased tariffs, which leads to:

- Higher production costs

- Reduced competitiveness in global markets

- Relocation of manufacturing facilities to Southeast Asian countries

Regional Trade Agreements Shape Market Access:

The implementation of USMCA (United States-Mexico-Canada Agreement) has created new opportunities for North American producers, while Brexit has reshaped European trade dynamics for PVC additives.

Strategic Responses by Industry Players:

In response to these geopolitical factors, industry players are adopting various strategies:

- Diversification of supplier networks

- Investment in local production facilities

- Development of regional distribution hubs

- Formation of strategic partnerships in stable markets

Political sanctions and export restrictions have pushed manufacturers to develop domestic production capabilities. Countries with stable political environments are attracting increased investment in PVC additive manufacturing facilities, creating new regional production hubs.

The emergence of new trade blocs and economic partnerships continues to reshape market access and competitive dynamics in the global PVC additives industry. These shifts influence investment decisions and long-term strategic planning for industry stakeholders.

Types of PVC Additives: Stabilizers, Plasticizers, and Flame Retardants

PVC additives transform raw polyvinyl chloride into versatile materials with enhanced properties. Each additive type serves specific functions:

1. Stabilizers

- Heat stabilizers protect PVC during processing

- UV stabilizers prevent degradation from sunlight exposure

- Antioxidants extend product lifespan by preventing oxidation

- Metal-based stabilizers (calcium-zinc, barium-zinc) offer superior heat resistance

2. Plasticizers

- Phthalate-based plasticizers increase flexibility

- Non-phthalate alternatives like DOTP meet strict safety standards

- Bio-based plasticizers offer sustainable options

- Specialty plasticizers enhance low-temperature performance

3. Flame Retardants

- Chlorinated paraffins reduce flammability

- Antimony trioxide acts as a synergist

- Phosphate-based options meet environmental regulations

- Inorganic compounds provide smoke suppression

These additives prevent PVC degradation at high temperatures, extending product life from 5 to 20+ years.

Recent innovations focus on calcium-zinc stabilizers as replacements for lead-based options, meeting global environmental standards while maintaining performance. The construction sector particularly benefits from these advances, using stabilized PVC in windows, pipes, and profiles that resist weathering and UV exposure.

Applications of PVC Additives in Construction, Automotive, and Packaging

Construction Applications

PVC additives transform construction materials through specific performance enhancements:

- Pipes and Fittings: Impact modifiers increase durability while UV stabilizers protect against sun damage

- Flooring Solutions: Plasticizers create flexible, comfortable surfaces with wear resistance

- Window Profiles: Heat stabilizers prevent warping and maintain structural integrity

Automotive Industry Integration

The automotive sector relies on PVC additives for:

- Interior Components: Flame retardants meet safety standards in dashboard materials

- Wire Harnesses: Heat stabilizers protect electrical systems

- Door Panels: Impact modifiers enhance durability while plasticizers provide flexibility

Packaging Solutions

Food and consumer goods packaging benefits from specialized additives:

- Food Contact Materials: FDA-approved stabilizers ensure safety

- Bottle Production: UV stabilizers protect contents while maintaining clarity

- Shrink Films: Plasticizers enable proper shrinkage and seal integrity

Performance Benefits

Each industry gains specific advantages:

- Construction: Extended material lifespan, weather resistance

- Automotive: Enhanced safety features, improved aesthetics

- Packaging: Better product preservation, increased shelf life

The selection of appropriate additives directly influences product performance and market success across these sectors. Manufacturers continue to develop specialized formulations to meet evolving industry requirements and safety standards.

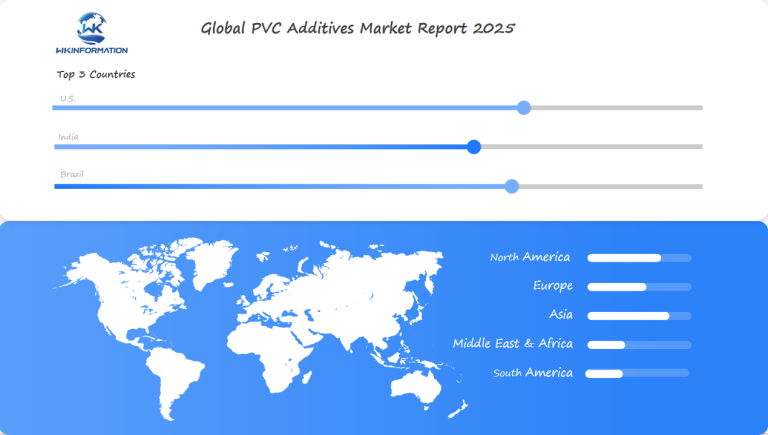

Global Insights into the PVC Additives Market

The PVC additives market displays distinct regional patterns shaped by local industrial development, regulatory frameworks, and economic conditions. The Asia Pacific holds major share, driven by rapid industrialization and urban development projects in China, Japan, and Southeast Asian nations.

Key regional market characteristics:

- North America: Advanced manufacturing capabilities, strict quality standards

- Europe: Strong focus on sustainable additives, circular economy initiatives

- Latin America: Growing construction sector, infrastructure development

- Middle East: Rising demand in pipe manufacturing, packaging industries

Market dynamics vary significantly across regions:

- Developed Markets

- Emphasis on eco-friendly formulations

- High investment in R&D

- Mature regulatory frameworks

- Emerging Markets

- Price-sensitive consumer base

- Rapid industrial growth

- Evolving environmental standards

The distribution of market share reflects regional economic strength:

Recent shifts in global trade patterns have created new opportunities in previously untapped markets, particularly in Southeast Asia and Eastern Europe. These regions show promising growth potential due to increasing manufacturing capabilities and rising domestic demand for PVC products.

U.S. PVC Additives Market: Industrial Demand and Regulatory Landscape

The U.S. PVC additives market is experiencing strong growth due to specific industrial sectors:

Key Industrial Demand Drivers:

- Construction sector demands for weather-resistant PVC window profiles

- Automotive industry’s shift toward lightweight materials

- Medical device manufacturing requirements for specialized PVC formulations

- Packaging industry’s need for food-grade additives

The U.S. regulatory framework shapes market dynamics through strict compliance requirements:

EPA Regulations:

- Clean Air Act restrictions on volatile organic compounds

- Toxic Substances Control Act oversight

- Chemical safety regulations for manufacturing processes

FDA Requirements:

- Stringent controls for food-contact materials

- Medical-grade PVC specifications

- Pharmaceutical packaging standards

The U.S. market stands out with its focus on technological innovation in the development of PVC additives. Companies are heavily investing in research and development (R&D) to create:

- Bio-based plasticizers

- Non-toxic stabilizers

- Energy-efficient processing aids

Market Response to Regulations:

- Implementation of automated quality control systems

- Development of compliance tracking software

- Investment in green chemistry initiatives

Local manufacturers are adapting their production processes to meet these regulatory requirements while still offering competitive pricing. The market shows particular strength in specialty additives used for high-performance applications, where U.S. companies are leading in technology.

India's Growing PVC Additives Market: Expansion in Construction and Automotive

India’s PVC additives market has significant growth potential due to rapid urbanization and infrastructure development. The construction industry is expanding at an astonishing annual rate, resulting in high demand for PVC products for building materials.

Key Growth Factors in India’s PVC Additives Sector

Several factors are driving the growth of India’s PVC additives sector:

1. Government Infrastructure Initiatives

Government initiatives play a crucial role in promoting infrastructure development:

- Smart Cities Mission targeting 100 cities

- Pradhan Mantri Awas Yojana housing project

- Metro rail expansions across major cities

2. Automotive Industry Development

The automotive industry is also contributing to the demand for PVC additives:

- Rising domestic vehicle production

- Electric vehicle manufacturing push

- Increased demand for PVC-based automotive components

Specific Projects Driving Demand in the Construction Industry

The construction industry’s demand for PVC additives is driven by specific projects:

- Mumbai-Ahmedabad High-Speed Rail Corridor

- Delhi-Mumbai Industrial Corridor

- Multiple airport expansion projects

Growth Projections for India’s Automotive Industry

The growth of the automotive sector is reflected in its ambitious goals:

Boosting Local Production Capabilities

Manufacturing initiatives like “Make in India” are boosting local production capabilities, reducing dependency on imports. The establishment of dedicated manufacturing clusters in Gujarat and Maharashtra strengthens the domestic supply chain for PVC additives.

Regulatory Changes Supporting Market Growth

Recent regulatory changes are supporting market growth by simplifying approval processes and standardizing quality requirements for PVC products used in construction applications. These developments align with India’s goal of becoming self-reliant in chemical manufacturing.

Brazil's PVC Additives Market: Opportunities in Infrastructure and Manufacturing

Brazil’s PVC additives market is showing strong potential for growth, driven by major infrastructure developments and expansion in manufacturing. The country’s efforts to recover economically have sparked renewed interest in construction projects, creating a significant demand for PVC products and additives.

Key Infrastructure Projects Driving Growth:

- São Paulo Metro Line 6 expansion

- Rio de Janeiro’s port modernization

- National housing program “Casa Verde e Amarela”

- Water infrastructure improvements across major cities

The Brazilian manufacturing sector is also showing an increased use of PVC additives, particularly in:

- Automotive parts production

- Agricultural equipment manufacturing

- Industrial piping systems

- Consumer goods packaging

Economic Factors Stimulating Market Growth:

- Government investments in public infrastructure: $50 billion allocated for 2023-2025

- Private sector participation through PPP models

- Rising domestic manufacturing capabilities

- Export opportunities to neighboring Latin American countries

Brazil’s strategic position as a regional manufacturing hub strengthens its PVC additives market. Local manufacturers benefit from:

- Abundant raw material resources

- Skilled labor force

- Advanced technological capabilities

- Strong domestic market demand

The country’s commitment to sustainable development has prompted manufacturers to invest in eco-friendly PVC additives, aligning with global environmental standards while maintaining competitive advantages in the regional market.

The Future of PVC Additives: Sustainability and Biodegradable Alternatives

The PVC additives industry is going through a significant change, driven by the need for sustainability and environmental awareness. Research and development efforts are now focused on finding bio-based alternatives to traditional additives made from petroleum.

Key Sustainable Innovations:

- Plant-based plasticizers derived from soybean oil and castor oil

- Natural mineral stabilizers replacing heavy metal compounds

- Biodegradable impact modifiers from renewable resources

- Recycled content integration in PVC formulations

Leading manufacturers are investing in green chemistry initiatives to develop additives that maintain performance while reducing environmental impact. These innovations include:

- Bio-based Solutions: Development of additives from agricultural waste and renewable biomass

- Smart Degradation: Engineering additives that enable controlled biodegradation

- Circular Economy: Creation of additives that enhance PVC recyclability

The market is witnessing increased adoption of:

- Non-phthalate plasticizers

- Organic-based heat stabilizers

- Eco-friendly flame retardants

- Zero-waste manufacturing processes

Research institutions are exploring novel materials like cellulose-based additives and bio-polymers that could revolutionize the industry. These developments align with global sustainability goals while meeting performance requirements for various applications.

Emerging Technologies:

- Nanotechnology integration for enhanced properties

- Smart additives responding to environmental conditions

- Hybrid organic-inorganic compounds

- Advanced recycling-compatible formulations

Competitive Landscape in the PVC Additives Industry

The PVC additives market has several key players who influence the industry through strategic innovations and their presence in the market. Here’s an overview of the main market leaders and their competitive strategies:

Key Players:

- Addivant — USA

- Arkema SA — France

- BASF SE — Germany

- Clariant AG — Switzerland

- Dow Chemical Company — USA

- Eastman Chemical Company — USA

- Evonik Industries AG — Germany

- Solvay S.A. — Belgium

- SONGWON Industrial Co. Ltd. — South Korea

- The Lubrizol Corporation — USA

Innovation Strategies

Research and Development

- Custom formulation development

- Enhanced product performance

- Cost-effective manufacturing processes

Market Expansion

- Strategic partnerships

- Regional manufacturing facilities

- Distribution network optimization

Competitive Advantages

- Patent portfolios protecting proprietary technologies

- Vertical integration of supply chains

- Investment in sustainable manufacturing practices

- Customer-centric product development

Companies are putting significant resources into digital technologies to streamline production processes and improve product quality. This shift towards digital includes using advanced data analysis for quality control and implementing automated manufacturing systems to maintain consistent product specifications.

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global PVC Additives Market Report |

| Base Year | 2024 |

| Segment by Type |

· Stabilizers · Plasticizers · Flame Retardants |

| Segment by Application |

· Construction · Automotive · Packaging · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The PVC additives market is at a crucial stage, with expected growth of $3.87 billion in the U.S., India, and Brazil by 2025. This significant growth shows how dynamic the industry is and how important it is for modern manufacturing and construction.

The PVC additives sector continues to show resilience and flexibility, with manufacturers investing in research and development to meet changing market needs. The future of the industry lies in finding a balance between performance requirements and environmental responsibility. This creates opportunities for companies that are willing to embrace sustainable innovation and expand into new markets.

Global PVC Additives Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: PVC Additives Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- PVC AdditivesMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global PVC AdditivesPlayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: PVC Additives Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: PVC Additives Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: PVC Additives Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of PVC Additives Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the significance of PVC additives in various industries?

PVC additives play a crucial role in enhancing the performance and longevity of PVC products across multiple sectors, including construction, automotive, and packaging. They improve properties such as flexibility, durability, and fire resistance, making them essential for a wide range of applications.

What are the key trends driving growth in the PVC additives market?

The PVC additives market is experiencing growth driven by advancements in plastic formulations and additive technologies. Innovations in high-quality packaging solutions and shifting consumer preferences towards sustainable products are also significant factors influencing market dynamics.

What challenges does the PVC additives industry face regarding environmental concerns?

The production of PVC additives raises several environmental issues, including pollution and waste management. Regulatory challenges aimed at reducing environmental impact have prompted the industry to adopt sustainable practices to ensure compliance and mitigate negative effects.

How do geopolitical factors influence the demand for PVC additives?

Geopolitical factors such as trade policies, tariffs, and international relations significantly affect supply chains and demand for PVC additives. Changes in these areas can lead to fluctuations in production costs and availability of raw materials, impacting the overall market landscape.

What types of PVC additives are commonly used, and what are their functions?

Common types of PVC additives include stabilizers, plasticizers, and flame retardants. Stabilizers enhance product longevity and performance by preventing degradation; plasticizers increase flexibility; while flame retardants improve safety by reducing flammability.

What are the future trends for sustainability in the PVC additives market?

The future of the PVC additives market is leaning towards sustainability with a focus on developing biodegradable alternatives. Innovations aimed at reducing environmental impact through eco-friendly practices are becoming increasingly important as industries strive to meet regulatory demands and consumer expectations.