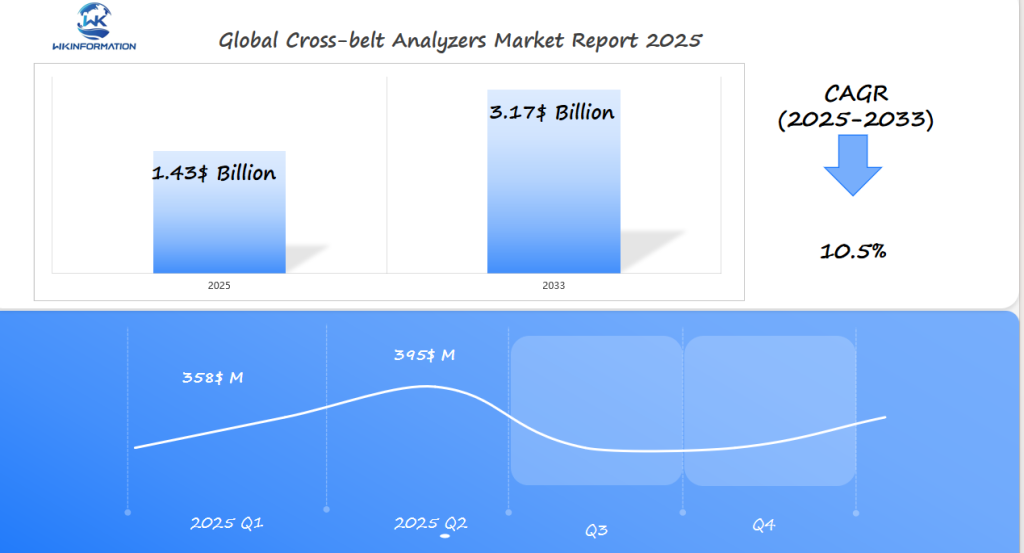

2025 Cross-belt Analyzers Market Projected at $1.43 Billion with Key Insights from the U.S., Germany, and China

Uncover the Cross-belt Analyzers Market’s growth drivers, featuring the U.S., Germany, and China.

- Last Updated:

Cross-belt Analyzers Market Forecast for Q1 and Q2 of 2025

The Cross-belt Analyzers market was valued at USD 1.43 billion in 2025, with a growth rate of 10.5% from 2025 to 2033. By Q1 2025, the market size is expected to reach approximately USD 358 million, spurred by increased demand for continuous monitoring of materials in industries like mining, recycling, and cement. By Q2 2025, the market is projected to grow to around USD 395 million, driven by the rising need for automated systems to improve operational efficiency and reduce human error.

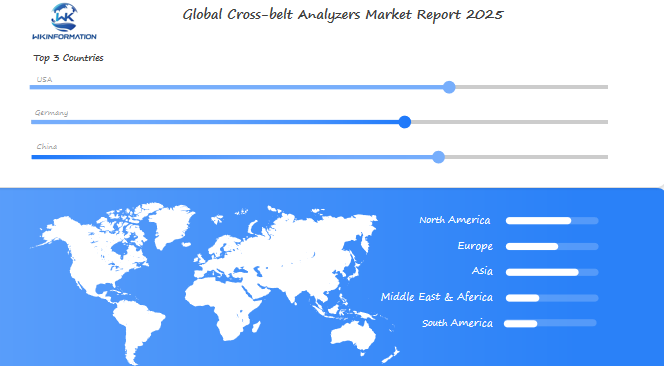

The U.S., Germany, and China are expected to be key contributors to the market’s growth, with the U.S. focusing on mining automation, Germany on manufacturing solutions, and China leading in large-scale recycling efforts.

Key Takeaways

- The global cross-belt analyzers market is projected to reach $1.43 billion by 2025, driven by technological upgrades.

- The U.S., Germany, and China are leading regional hubs for market growth and innovation.

- Industrial sectors increasingly rely on cross-belt analyzers to meet stringent quality control standards.

- Advances in material analysis technology are boosting adoption in mining and manufacturing industries.

- Market expansion hinges on regulatory compliance and regional trade policies affecting supply chains.

In-Depth Analysis of the Cross-belt Analyzers Upstream and Downstream Supply Chain

The cross-belt analyzer supply chain needs careful planning between component manufacturers, material suppliers, and assembly sites. Each step, from getting raw materials to the final test, impacts product quality and availability. Knowing these links helps businesses spot problems early and improve their work flow.

Key Suppliers and Raw Material Considerations

Operations start with raw materials for analyzers, like strong metals and precise electronics. These materials are used to make sensors, calibration tools, and structural parts. Important points include:

- Global sourcing of sensors and detectors from Asia-Pacific suppliers

- Regional partnerships for electronics supply chain stability

- Quality control during the analyzer assembly process to ensure accuracy

Downstream, distributors work with mining and manufacturing clients to set up systems on-site. Issues like semiconductor shortages have caused delays, leading companies to find more suppliers. For instance, using modular designs helps avoid relying on just one supplier.

Recently, 60% of manufacturers have started to stock up on key raw materials for analyzers to avoid halts in production. Also, new automation in the analyzer assembly process has reduced production time by up to 25% in 2024.

Keeping the cross-belt analyzer supply chain running smoothly is crucial as the need for quick data analysis grows in mining and cement production.

Current and Emerging Trends in Cross-belt Analyzers for 2025

Industries are moving towards smarter solutions. Cross-belt analyzer trends show a move towards seamless connectivity and smart systems. Real-time material analysis is now key for staying ahead. Let’s see how technology is changing these tools.

Digital Integration and AI-Enhanced Analysis Capabilities

Today’s cross-belt analyzers use industry 4.0 integration to connect machines and data. They stream data to the cloud, allowing for remote checks and quick changes. This also helps predict when maintenance is needed, cutting downtime by up to 30%.

AI in material analysis is also growing. Machine learning now analyzes data quicker, cutting time by 40%. Companies like Siemens and Thermo Fisher are adding AI to their devices. This lets systems adjust to different materials without needing manual changes.

- Real-time material analysis with IoT ensures quality at every stage.

- AI systems cut down on mistakes in mineral grading and cement making.

- Edge computing lets data be processed on-site, reducing delays.

“The mix of AI and IoT creates a loop where data boosts both analysis and equipment performance.”

These changes aren’t just for factories. Field workers use mobile apps to check cross-belt analyzer trends in real time. Whether it’s checking coal purity at a power plant or improving recycling, these tools will be vital by 2025 for both sustainability and cost control.

Identifying Key Restrictions in the Cross-belt Analyzers Market

The cross-belt analyzer market is growing, but it faces big challenges. Rules and technical issues affect how companies work. Let’s look at these problems and their effects.

Regulatory Challenges in Material Analysis

Rules for material analysis and safety around radiation are big hurdles. Systems that use nuclear power must follow strict rules. Companies need to spend on safety, training, and paperwork to stay safe.

Places using gamma-ray analyzers have to pass tough checks to keep everyone safe. This makes things more expensive but is crucial for safety.

Technical and Operational Limitations

Calibration issues and standards for equipment add to the problems. Keeping accuracy in fast production lines means constant calibration. This can slow things down.

Materials like mixed ores or recycled plastics can also make things less precise. Old equipment can’t keep up with today’s industrial equipment standards, leading to expensive updates.

“Calibration delays and regulatory audits remain top pain points for manufacturers,” notes a 2024 industry report. “Balancing speed with accuracy is a daily challenge.”

Companies are finding new ways to solve these problems. They’re making non-nuclear tools and designs that are easier to fix. Training and AI software help reduce problems caused by cross-belt analyzer limitations. Despite the challenges, the field is still moving forward.

Geopolitical Factors Affecting the Cross-belt Analyzers Market Growth

Trade policies and global supply chain disruptions are changing how cross-belt analyzers are made and sold. Companies face challenges from technology export controls and mining equipment tariffs. These issues make it hard to access international markets. Companies need flexible strategies to stay ahead.

Trade Policies and Regional Market Access Challenges

Trade tensions between big economies like the U.S. and China have made cross-belt analyzers trade policies tighter. Technology export controls on sensors and software slow down innovation. Mining equipment tariffs in places like Latin America also increase costs for makers.

- Technology export controls block key parts for new analyzer systems.

- Mining equipment tariffs make it more expensive for suppliers in rich resource areas.

- Global supply chain disruptions cause delays in getting parts, pushing back project deadlines.

“Navigating trade barriers requires proactive planning to secure market access,” states a 2024 industry report on cross-border tech trade.

Countries rich in resources like Australia and South Africa have strict export rules on minerals. This makes supply chains harder. Energy policies pushing for green practices also shape analyzer design standards. Companies must manage geopolitical risks while adapting to these changes.

The Role of Type Segmentation in the Development of Cross-belt Analyzers

The growth of cross-belt analyzers depends on the variety of cross-belt analyzer types. Each type tackles different material analysis needs, pushing innovation and specialization in various sectors. Companies keep improving these systems to meet changing needs, from mining to food production.

- Gamma-ray analyzers use radiation to measure elements like iron and sulfur in coal, favored for their depth penetration.

- X-ray analyzer technology offers speed and cost efficiency, making it a staple in cement plants and recycling facilities.

- Neutron analysis systems detect hydrogen content, critical for analyzing water or organic compounds in raw materials.

- Optical material analyzers use spectral light analysis for food quality checks and pharmaceuticals, avoiding radiation exposure.

Hybrid systems combining these technologies are gaining traction. For instance, pairing X-ray analyzer technology with optical sensors enhances accuracy in mixed-material sorting. Analysts predict gamma-ray analyzers will retain market share in mining, while neutron analysis systems see niche growth in chemical industries. As industries seek tailored solutions, the diversity of cross-belt analyzer types remains a cornerstone of sector-wide progress.

Applications of Cross-belt Analyzers Across Different Industries

Modern industries use cross-belt analyzer applications to make operations smoother and more efficient. These tools give real-time data that helps save costs and improve accuracy. Their wide use makes them key in many sectors.

Mining, Cement Production, and Emerging Application Areas

| Industry | Application | Key Advantage |

|---|---|---|

| Mining | Mining material analysis | Enhances ore sorting and cuts waste |

| Cement | Cement quality control | Maintains strict product standards |

| Coal | Coal analysis technology | Improves energy output and safety |

| Industrial Minerals | Industrial mineral processing | Optimizes raw material handling |

New industries are also using these systems. Recycling places use them to sort materials well. Chemical and pharmaceutical plants use them to keep batches consistent. For example:

- Recycling: Separates plastics from metals in waste streams

- Pharma: Monitors active ingredient ratios in real time

These tools help companies avoid expensive mistakes and meet rules. Now, many industries, from energy to construction, rely on their insights to stay ahead.

Regional Market Insights for Cross-belt Analyzers Worldwide

The global cross-belt analyzer market shows big differences in regional analysis equipment demand. North America and Europe focus on the latest mining tech. But, Asia-Pacific is leading the way in changing how industrial equipment is sold. This shows how different areas have different needs.

Material analysis regional trends show how location affects tech choices. Areas with big mining sectors spend differently than those focused on recycling or making goods.

- North America/Europe: High mining technology adoption rates and strict rules mean more demand for precise tools.

- Asia-Pacific: Fast industrial growth increases industrial equipment market distribution. China and India are at the forefront, looking for affordable analyzers.

- Latin America/Africa: Mining growth in places like Chile and South Africa boosts regional analysis equipment demand for checking ore quality.

- Europe: Rules for being green are changing what’s needed in material analysis. Now, there’s a push for eco-friendly analyzer designs.

Companies need to adjust how they sell to fit local needs. For example, areas with less tech might want simpler systems. But, places that are tech-savvy might look for analyzers with AI. Knowing these material analysis regional trends helps suppliers meet the needs of different areas.

USA Cross-belt Analyzers Market Key Drivers and Market Outlook

The US cross-belt analyzer market grows thanks to new American mining technology and material analysis innovation. Industries focus on being more efficient. They use real-time tools to meet rules and goals.

Rules about the environment and safety are making mining equipment better. This is happening all over the US.

Technological Leadership and Innovation Ecosystems

Companies and universities are working together. They create new sensors and AI systems. For example, Siemens and Colorado School of Mines are improving how ore is sorted and minerals are graded.

These partnerships help make analysis more accurate. They also make it cheaper.

- Government grants help link material analysis innovation with keeping the supply chain safe.

- Automated systems help mines work better and faster. This makes the US mineral processing industry more competitive.

“Modern industrial equipment modernization ensures US firms stay ahead in global markets.” – U.S. Mining Association, 2024

Companies that invest in American mining technology see quick returns. They make less mistakes in sampling. The US cross-belt analyzer market also grows because of US policies on mining.

These policies help the US lead in material analysis innovation.

Germany's Cross-belt Analyzers Market Trends, Opportunities, and Challenges

Germany leads in German cross-belt analyzers thanks to years of improving European material analysis technology. These systems are key in many industries worldwide. They mix old skills with new tech, making them top-notch in mining and cement making.

Engineering Excellence and Industry 4.0 Integration

- Top makers like Siemens and Endress+Hauser add IoT sensors to German cross-belt analyzers. This lets them check equipment from afar.

- Germany’s Industry 4.0 integration cuts downtime by 30% thanks to smart maintenance plans.

- Green policies encourage the use of low-pollution analyzers, meeting EU green goals.

There are chances in circular economy projects, where analyzers check recycled material quality. But, there are still big challenges. High R&D costs and training for industrial automation in Germany are big hurdles. As coal use drops, the focus turns to renewable energy tracking. Germany’s mix of old and new tech makes it a leader in this field.

China's Cross-belt Analyzers Market Key Insights and Developments

China’s cross-belt analyzers market is leading the way in innovation. Fast industrial growth has increased the need for better tools to analyze materials. This change has made Chinese mining technology more competitive worldwide.

Local companies are now making affordable equipment. This is changing how goods are supplied globally.

China’s material analysis equipment manufacturing sector has seen a 25% growth in the last five years, outpacing global averages.

Rapid Industrialization and Domestic Manufacturing Capacity

The growth of bulk material handling in China has led to better analysis systems. Companies like Sinoma and Beijing Analytical Tech are making analyzers that meet global standards. These tools help reduce waste and lower costs in coal, metals, and cement processing.

- Domestic factories now supply 60% of China’s bulk analysis needs, up from 30% in 2020.

- Government incentives prioritize eco-friendly tech, boosting demand for emissions-monitoring analyzers.

Exports through the Belt and Road Initiative are boosting Asian analyzer market growth. Buyers in Africa and Southeast Asia are adopting Chinese systems. But, there are still challenges like intellectual property disputes and uneven support in rural areas.

China is balancing cost and quality in its advancements. This makes it a leader in material analysis. Investors see great potential in this sector’s mix of tradition and technology.

Future Trends and Technological Innovations in Cross-belt Analyzers

The next era of cross-belt analyzers is here. It combines future cross-belt analyzer technology with smarter tools for industries. Innovations focus on safety, speed, and adaptability. They are changing how materials are monitored worldwide.

Breakthrough Technologies and Next-Generation Systems

- AI-powered analyzers use machine learning to analyze data faster. This reduces human error and setup time.

- Non-radioactive analyzer technology like acoustic sensors and laser spectroscopy eliminate radiation risks. This expands usability.

- Next-generation material sensing systems are now compact. They operate with less power and work in extreme conditions like mines or factories.

- Real-time data streams paired with augmented reality tools let teams act on insights instantly.

These tools also cut maintenance costs by predicting wear and tear. Material analysis innovations now integrate with autonomous machinery. This creates fully automated material handling setups.

For example, AI algorithms can adjust for varying ore grades in real time. This boosts efficiency in mining operations.

Operators now have tools that are safer, cheaper to maintain, and easier to deploy. As these systems evolve, they’ll drive down costs while raising safety standards. This makes advanced material analysis accessible even to smaller businesses.

Competitive Landscape of Cross-belt Analyzers Market Players

-

Thermo Fisher Scientific – United States

-

Malvern Panalytical – Netherlands (a subsidiary of Spectris, UK)

-

Advance Research Instruments Co. – India

-

Lyncis UAB – Lithuania

-

Pro Op Industries – Canada

-

Realtime Instruments – Australia

-

XRSciences – Australia

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Cross-belt Analyzers Market Report |

| Base Year | 2024 |

| Segment by Type | · PGNAA Technology

· PFTNA Technology · Sodern Neutron Technology |

| Segment by Application | · Cement Industry

· Minerals Industry · Coal Industry · Others |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The cross-belt analyzer market is expected to grow to $1.43 billion by 2025. This growth makes cross-belt analyzer investment a key focus. It’s driven by increased demand in mining, cement, and manufacturing.

Investors now see a chance to grow with new technologies and shifts in the economy. This is a great time to invest in the analyzer market.

Strategic Positioning for the Evolving Cross-belt Analyzer Landscape

Upgrading analyzers with AI can improve material analysis equipment ROI. Companies should partner with top manufacturers for the latest tech. The mining equipment market forecast shows big chances in the U.S. and China, thanks to big projects.

System integrators and service providers can offer custom solutions. They help connect old systems with new cross-belt analyzer investment needs. Risks like rules changes and delays can be lessened by working with many suppliers and testing new tech early.

Businesses need to be quick to adapt to trends like AI and policy changes. Making smart choices now will help succeed in this fast-changing field.

Global Cross-belt Analyzers Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Cross-belt Analyzers Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Vacuum Arc RemeltingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Cross-belt Analyzersplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Cross-belt Analyzers Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Cross-belt Analyzers Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Cross-belt Analyzers Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofCross-belt Analyzers Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are cross-belt analyzers used for?

Cross-belt analyzers are used for quality control in mining, cement, and recycling. They check the material on conveyor belts. This ensures quality and improves processes.

How do cross-belt analyzers improve operational efficiency?

They give real-time data on material composition. This allows for quick production adjustments. It reduces waste, lowers costs, and improves quality.

What are the key trends in cross-belt analyzers heading into 2025?

Trends include advanced digital technologies like IoT and AI. These improve analysis and enable predictive maintenance. There’s also a focus on compact, energy-efficient designs for various materials.

What regulatory challenges do cross-belt analyzers face?

Challenges include safety standards, especially for nuclear systems. There are also issues with emissions monitoring and environmental impacts.

How are geopolitical factors affecting the cross-belt analyzers market?

Trade tensions and export controls impact the supply chain. These factors affect technology flow and market access, creating challenges and opportunities.

What types of analysis technologies are used in cross-belt analyzers?

They use gamma-ray, X-ray, neutron activation, and optical/laser technologies. Each has its own benefits for different materials and applications.

In which industries are cross-belt analyzers making the biggest impact?

They’re making a big impact in mining, cement, coal processing, and recycling. These analyzers streamline processes, ensure quality, and save costs.

How is the competitive landscape for cross-belt analyzers evolving?

The competitive landscape is changing fast. Established brands like Thermo Fisher Scientific face new challengers from China. Companies innovate through technology and strategic moves to gain market share.

What investment opportunities exist in the cross-belt analyzers market?

Opportunities include equity, technology licensing, and service models. Investors can also look at regions with strong growth potential for strategic growth.

How do cross-belt analyzers contribute to sustainability efforts?

They improve efficiency and reduce waste, crucial for sustainability. They help industries optimize resources and minimize environmental impacts, meeting global sustainability goals.