Forged Aluminium Wheels Market Growth in 2025 with $10.03 Billion Opportunities Globally, Including Key Insights from the US, Germany, and China

Comprehensive analysis of the forged aluminium wheels market growth potential, focusing on key regions (US, Germany, China) and their role in automotive innovation through 2025. Explores impact of economic policies, technological advancements, and changing consumer preferences on market development. Includes detailed examination of regional market dynamics, manufacturing trends, and future growth projections.

- Last Updated:

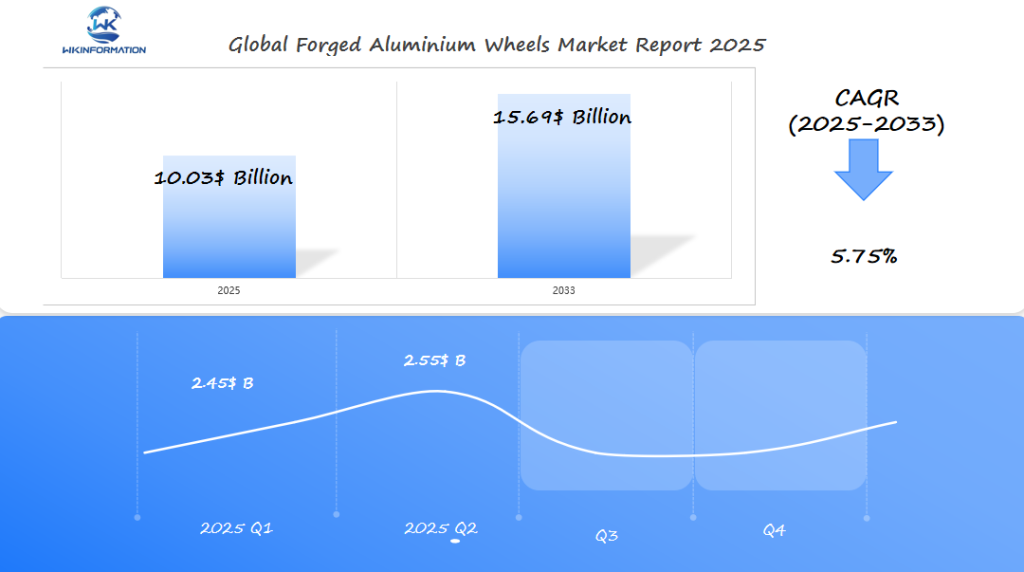

Forged Aluminium Wheels Market Forecast for Q1 and Q2 of 2025

The Forged Aluminium Wheels market was valued at USD 10.03 billion in 2025 and is expected to grow at a CAGR of 5.75% from 2025 to 2033. This growth will be driven by increasing demand for lightweight, high-performance wheels in the automotive industry, especially in countries like the US, Germany, and China.

For Q1 2025, the market is expected to reach around USD 2.45 billion, driven by strong automotive production in the US, where the demand for high-performance and energy-efficient vehicles is on the rise. Germany’s automotive industry, which is a global leader in high-end vehicle manufacturing, will further boost demand for forged aluminium wheels. In China, with its expanding automotive sector and increasing preference for lightweight materials, demand for forged wheels will also rise.

By Q2 2025, the market is projected to grow to approximately USD 2.55 billion, reflecting the continued growth of the automotive industry and the shift towards lighter, more efficient vehicles.

Analysis of the Upstream and Downstream Industry Chain in the Forged Aluminium Wheels Market

Supply Chain Analysis:

In the production of forged aluminum wheels, upstream suppliers play a crucial role. These suppliers provide the raw materials, primarily aluminum alloys, essential for forging processes. The quality and availability of these materials directly impact manufacturing efficiency and product performance. Suppliers often engage in strategic partnerships with wheel manufacturers to ensure a steady supply chain.

Manufacturing Processes:

The manufacturing process involves several stages, starting with the heating and shaping of aluminum billets under high pressure. This process enhances the strength and durability of the wheels while maintaining a lightweight profile. Advanced techniques such as automated forging and precision machining are employed to meet stringent industry standards.

Distribution Channels:

Downstream applications divide into two primary segments: Original Equipment Manufacturer (OEM) products and aftermarket sales. Major players in OEM supply include automotive giants that integrate forged wheels into new vehicle models to enhance performance metrics. Aftermarket sales focus on customization, appealing to consumers seeking unique designs or improved vehicle aesthetics.

Key Players:

Prominent companies involved in this supply chain include BBS GmbH, OZ Racing, Enkei Corporation, and Borbet GmbH. These companies leverage cutting-edge technologies and extensive distribution networks to meet growing consumer demand across both OEM and aftermarket channels.

Key Trends Shaping the Forged Aluminium Wheels Market in 2025

The increasing demand for lightweight and performance-oriented vehicles is a critical driver shaping the forged aluminum wheels market. As automotive manufacturers strive to enhance fuel efficiency and vehicle dynamics, lightweight materials become essential. Forged aluminum wheels are favored for their ability to reduce unsprung weight, improving both acceleration and handling. This trend is particularly pronounced in the electric vehicle (EV) sector, where every gram saved can extend battery range.

Emerging trends in luxury vehicles and SUVs further underscore the market’s evolution. These segments are witnessing a surge in customization, with consumers seeking unique wheel designs that reflect personal style and improve performance. The aftermarket sales of customized forged aluminum wheels cater to this demand, offering a plethora of options for discerning buyers.

Customization and performance are not just preferences—they are expectations. The market’s response includes innovative manufacturing techniques that allow for intricate designs without compromising strength or durability. As these industry trends continue to evolve, they redefine consumer expectations and drive growth within the forged aluminum wheels sector.

This dynamic landscape sets the stage for ongoing developments as manufacturers adapt to shifting demands and technological advancements in automotive design.

Challenges and Restrictions in the Forged Aluminium Wheels Market

Manufacturers in the Forged Aluminium Wheels Market face several challenges that affect production and profitability.

High Production Costs

High production costs are a major challenge, primarily due to expensive raw materials and energy-intensive manufacturing processes. These factors make it hard for smaller companies to compete on price without compromising quality.

Technological Limitations

Technological limitations are another obstacle. Producing lightweight yet durable wheels requires advanced machinery and expertise, but not all manufacturers have access to state-of-the-art technology or skilled workers. This gap in technology can slow down innovation and decrease competitiveness.

Regulatory Restrictions

Regulatory restrictions add further complexity. Environmental regulations require cleaner production methods, which makes manufacturing operations more complicated and costly. It is crucial to comply with these rules, but it can also limit flexibility in production processes and sales strategies.

Competition from Alternative Materials

Competition from other materials like carbon fiber is also a significant threat. While aluminum strikes a good balance between weight and strength, carbon fiber offers even greater weight reduction benefits, attracting specific segments focused on performance improvement.

Manufacturers must find ways to overcome these manufacturing challenges while also innovating to stay relevant in a rapidly changing market. Balancing cost, technology, and regulatory compliance will be essential for maintaining growth amidst these obstacles.

Geopolitical Factors Impacting the Forged Aluminium Wheels Market

Geopolitical influences play a critical role in the forged aluminum wheels market, primarily through their effects on trade policies and international relations. The supply chain for aluminum is particularly sensitive to changes in trade agreements and tariffs, with significant impacts observed in regions like North America and Asia-Pacific.

1. Trade Policies

In North America, recent adjustments in trade agreements have caused fluctuations in aluminum prices due to tariffs imposed on imports. This has led to increased production costs for manufacturers of forged aluminum wheels, prompting some companies to seek alternative sourcing strategies or pass costs onto consumers.

2. Asia-Pacific Dynamics

China’s dominance in aluminum production means that any shifts in its trade policies can ripple through global markets. For instance, export restrictions or increased tariffs can cause supply shortages or price hikes, affecting manufacturers’ ability to maintain competitive pricing.

Geopolitical tensions, such as conflicts or diplomatic disputes, further complicate the market landscape. These tensions can disrupt production capabilities by causing delays in raw material shipments or altering investment flows into key manufacturing regions. As a result, pricing dynamics are often volatile, challenging manufacturers to adapt quickly to maintain profitability and market share.

Market Segmentation and Type Analysis in the Forged Aluminium Wheels Industry

Understanding the market segmentation within the forged aluminum wheels industry is crucial for grasping demand distribution. Two primary segments emerge based on vehicle type: passenger cars and commercial vehicles.

1. Passenger Cars

This segment holds a significant market share, driven by the increased demand for lightweight materials that enhance fuel efficiency and performance. The rise of electric vehicles (EVs) further amplifies this need, as manufacturers seek to maximize range and efficiency.

2. Commercial Vehicles

Although smaller in comparison, this segment’s demand is growing due to the increasing preference for durable and high-performance wheels capable of handling heavy loads and long-distance travel.

In terms of product variety, several types of forged aluminum wheels cater to diverse applications:

- Standard Wheels: Typically used in everyday vehicles, offering a balance between cost and performance.

- Performance Wheels: Designed for enthusiasts and high-performance vehicles, these wheels prioritize weight reduction and strength.

- Luxury Wheels: Targeting high-end vehicles, these offer advanced customization options and aesthetic appeal.

Each type serves a specific niche within the automotive market, reflecting varied consumer preferences and vehicle specifications. These distinctions highlight the dynamic landscape of the forged aluminum wheels industry, where innovation continues to drive product development tailored to evolving market demands.

Application Analysis for Forged Aluminium Wheels in Automotive and Aerospace Sectors

Automotive Applications

Performance Vehicles

Forged aluminum wheels are widely used in high-performance vehicles due to their superior strength-to-weight ratio. By reducing overall vehicle weight, they enhance handling and acceleration, leading to a more dynamic driving experience.

Electric Vehicles (EVs)

In the EV sector, forged aluminum wheels play a crucial role in optimizing efficiency. Their lightweight nature directly contributes to an extended driving range by reducing energy consumption. Improved battery efficiency is achieved through weight reduction, allowing for better load distribution and enhanced vehicle performance.

Commercial Vehicles

For commercial vehicles, forged aluminum wheels offer several advantages that enhance operational efficiency. The reduction in overall vehicle weight increases payload capacity, allowing for more efficient transport of goods. Fuel efficiency is improved as lighter wheels contribute to lower energy consumption, which is particularly important for fleet operations.

Aerospace Applications

Commercial Aircraft

In commercial aviation, forged aluminum wheels help reduce the overall weight of aircraft, leading to improved fuel efficiency and lower operational costs. Their structural integrity enhances the performance of landing gear, providing better load distribution and resistance to stress during takeoff and landing.

Military Aircraft

For military applications, forged aluminum wheels provide significant advantages in terms of performance and durability. Their lightweight properties enhance maneuverability, allowing aircraft to execute rapid and precise movements.

Regional Overview of Growth Opportunities for Forged Aluminium Wheels Manufacturers

The global forged aluminum wheels market presents diverse growth opportunities across different regions, each with unique characteristics and potential for expansion. As demand for high-performance, lightweight, and durable wheels increases, manufacturers are adapting their strategies to capitalize on regional market dynamics.

North America

In North America, the demand for forged aluminum wheels is strongly driven by the luxury vehicle segment, where consumers seek high-quality, aesthetically appealing, and performance-enhancing wheels. A growing preference for customized wheels further contributes to market expansion, with buyers opting for personalized designs that enhance both style and functionality. Additionally, the increasing adoption of electric vehicles (EVs) in the region has led to a heightened emphasis on lightweight solutions to improve energy efficiency and driving range.

North America also benefits from advanced manufacturing capabilities, allowing for the production of high-precision forged wheels that meet industry standards. Strict quality and safety regulations further ensure that manufacturers adhere to rigorous production guidelines, reinforcing the region’s reputation for high-performance automotive components.

Europe

Europe’s premium automotive market is a key driver for the demand for high-end forged aluminum wheels. Luxury and sports car manufacturers in the region prioritize lightweight and durable wheel solutions that enhance both performance and aesthetics. The strong focus on technological innovation has led to continuous advancements in material science and production techniques, allowing manufacturers to develop next-generation wheels with improved structural integrity and aerodynamics.

Additionally, strict environmental regulations play a significant role in shaping the production landscape, with companies adopting sustainable manufacturing processes to reduce their carbon footprint. Europe’s well-established research and development infrastructure further supports market growth by fostering new product innovations and performance enhancements. Moreover, the growing aftermarket segment provides additional opportunities, as consumers seek premium forged wheels to upgrade their vehicles.

Asia-Pacific

Asia-Pacific represents the largest market share globally for forged aluminum wheels, driven by a combination of cost-competitive manufacturing and rising domestic demand. Countries such as China, Japan, and India have expanding automotive industries, with increasing production of both traditional and electric vehicles. The region’s competitive manufacturing landscape enables cost-efficient production while maintaining quality improvements to meet international standards.

As disposable incomes rise and consumer preferences shift toward premium automotive features, the demand for high-performance forged wheels continues to grow. Additionally, government initiatives promoting electric and fuel-efficient vehicles further contribute to market expansion, positioning Asia-Pacific as a crucial hub for the future of forged aluminum wheel production and innovation.

U.S. Forged Aluminium Wheels Market Insights: Driving Forces Behind Growth Potential

The United States is a major player in the forged aluminum wheels market, with promising growth opportunities driven by several key factors.

1. Rising Popularity of Electric Vehicles (EVs)

The increasing adoption of EVs in the U.S. serves as a powerful catalyst for the demand for forged aluminum wheels. These vehicles benefit from lightweight materials that enhance energy efficiency and performance, aligning perfectly with the attributes of forged aluminum wheels.

2. Focus on Fuel Efficiency and Performance

As automotive manufacturers strive to meet stringent fuel efficiency standards, the shift towards high-performance, lightweight components becomes essential. Forged aluminum wheels offer a perfect blend of strength and reduced weight, making them an attractive choice for automakers aiming to boost vehicle efficiency without compromising on performance.

3. Customization and Aftermarket Sales

The U.S. market shows a robust inclination towards vehicle customization, which fuels aftermarket sales. Consumers’ desire to personalize their vehicles with aesthetically appealing and performance-enhancing wheels contributes significantly to the market’s expansion.

4. Technological Advancements in Manufacturing

The integration of advanced manufacturing technologies, such as automation and AI-driven processes, within the U.S. automotive sector enhances production efficiency and product quality. This technological edge supports local manufacturers in meeting the growing demand for high-performance forged aluminum wheels.

5. Supportive Regulatory Environment

Government policies promoting energy-efficient vehicles create a favorable landscape for forged aluminum wheel adoption. Incentives for sustainable automotive solutions further encourage manufacturers to innovate and capitalize on this trend.

The U.S. market’s dynamic nature, coupled with its commitment to innovation and sustainability, presents lucrative opportunities for both established players and new entrants in the forged aluminum wheels sector. As the industry continues to evolve, these driving forces ensure that the U.S. remains at the forefront of this burgeoning market segment.

China's Role as a Powerhouse in Forged Aluminium Wheel Production: Opportunities & Challenges Ahead

China plays a significant role in the Forged Aluminium Wheels Market, making it a major player in global production. The country’s large manufacturing capabilities and competitive pricing strategies strengthen its position as a leader in this industry.

Factors Contributing to China’s Prominence

Several factors contribute to China’s prominence:

- Domestic Demand for EVs and Luxury Vehicles: The increase in electric vehicles (EVs) and the growing luxury vehicle market within China drives substantial demand for lightweight, high-performance wheels. This trend aligns with global shifts towards more efficient and sustainable automotive solutions.

- Strategic Production Capabilities: China’s established infrastructure allows for large-scale production, which meets both domestic needs and international demands. Its ability to produce at scale provides cost advantages that are difficult for other regions to match.

- Regional Market Growth Opportunities: As part of the Asia-Pacific region, China presents significant growth potential not only within its borders but also in surrounding markets. This regional influence supports the expansion plans of manufacturers seeking to capitalize on burgeoning automotive trends.

Challenges remain, including environmental regulations and competition from alternative materials. Yet, China’s role remains crucial in shaping the future of forged aluminum wheels, especially as it continues to innovate and adapt to changing market dynamics.

Dynamics of the Forged Aluminium Wheels Market in Germany's Automotive Industry

The German automotive industry is leading the way in technological innovation within the forged aluminium wheels market. Manufacturers in Germany are at the forefront of advancements in wheel production, with a strong emphasis on improving vehicle performance and sustainability. Here are some key areas of innovation:

1. Advanced Manufacturing Techniques

German manufacturers are known for their expertise in automation and precision engineering, which has resulted in higher production efficiency and quality.

2. Material Engineering

There is a focus on developing new aluminum alloys that provide better strength-to-weight ratios, which is essential for vehicles designed for high performance.

Future Developments & Innovations to Watch Out For in The Forged Aluminium Wheels Market

The forged aluminum wheels market is on the verge of significant technological advancements that will change traditional manufacturing processes. The main innovations expected are automation and artificial intelligence (AI), which will streamline production lines, improve precision, and reduce manufacturing time.

Emerging technologies are also set to redefine wheel design and performance. Key developments include:

- 3D printing techniques: Enabling the creation of complex wheel designs that were previously unattainable.

- Advanced materials: Incorporating innovative alloys that boost strength while maintaining lightweight properties.

- Smart wheel technology: Sensors embedded within wheels to monitor real-time performance metrics, contributing to enhanced safety and efficiency.

These trends indicate a future where forged aluminum wheels not only meet but exceed modern vehicular demands for performance and aesthetics. Leading manufacturers are likely to invest heavily in R&D, focusing on integrating these technologies into their production frameworks. This evolution in manufacturing processes promises substantial growth opportunities for the industry as it moves towards a more technologically advanced future.

Competitive Landscape and Key Players in the Forged Aluminium Wheels Market

The forged aluminum wheels market is characterized by intense competition among several major players who dominate the global landscape. These key manufacturers have established strong market positions through technological innovation, product quality, and extensive distribution networks.

-

BBS GmbH – Germany

-

OZ Racing – Italy

-

Enkei Corporation – Japan

-

Borbet GmbH – Germany

-

Ronal Group – Switzerland

-

Titan International, Inc. – USA

-

Hayes Lemmerz International, Inc. – USA

-

American Racing – USA

-

Superior Industries International, Inc. – USA

-

Vossen Wheels – USA

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Forged Aluminium Wheels Market Report |

| Base Year | 2024 |

| Segment by Type |

· Passenger Cars · Commercial Vehicles |

| Segment by Application |

· Automotive Applications · Aerospace Applications |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The forged aluminum wheels market is poised for significant expansion, projected to reach $10.03 billion by 2025. This growth is driven by increasing demand for lightweight automotive components and evolving vehicle technologies.

Global Forged Aluminium Wheels Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Forged Aluminium Wheels Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Forged Aluminium Wheels Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Forged Aluminium Wheels Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Forged Aluminium Wheels Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Forged Aluminium Wheels Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Forged Aluminium Wheels Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Forged Aluminium Wheels Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected growth of the forged aluminum wheels market by 2025?

The global forged aluminum wheels market is projected to reach $10.03 billion by 2025, primarily driven by the increasing demand for lightweight materials in vehicles.

What are the key trends shaping the forged aluminum wheels market?

Key trends include a rising demand for lightweight and performance-oriented vehicles, the emergence of luxury vehicles and SUVs, and a focus on customization and aftermarket sales.

What challenges do manufacturers face in the forged aluminum wheels market?

Manufacturers encounter challenges such as high production costs, technological limitations, regulatory restrictions impacting production processes, and competition from alternative materials.

How do geopolitical factors affect the forged aluminum wheels market?

Geopolitical factors influence trade policies that can impact aluminum supply chains, with tensions affecting production capabilities and pricing dynamics in key regions like North America and Asia-Pacific.

What are the main segments of the forged aluminum wheels market?

The market is segmented based on vehicle type into passenger cars and commercial vehicles, allowing for an understanding of demand distribution across different applications.

What innovations are expected to shape the future of the forged aluminum wheels market?

Future developments may include advancements in manufacturing processes through automation and AI, along with emerging technologies that enhance wheel design and performance improvements.