Fine Blanking Machine Market Growth in 2025 with $4.89 Billion Opportunities in the US, Germany, and Japan Driven by Innovation and Strategic Developments

Discover insights into the fine blanking machine market’s growth projections for 2025, focusing on technological advancements and manufacturing leadership from the US, Germany, and Japan. Learn how Trump’s economic policies impact the industry and explore key market drivers shaping this precision manufacturing sector.

- Last Updated:

Fine Blanking Machine Market Forecast for Q1 and Q2 of 2025

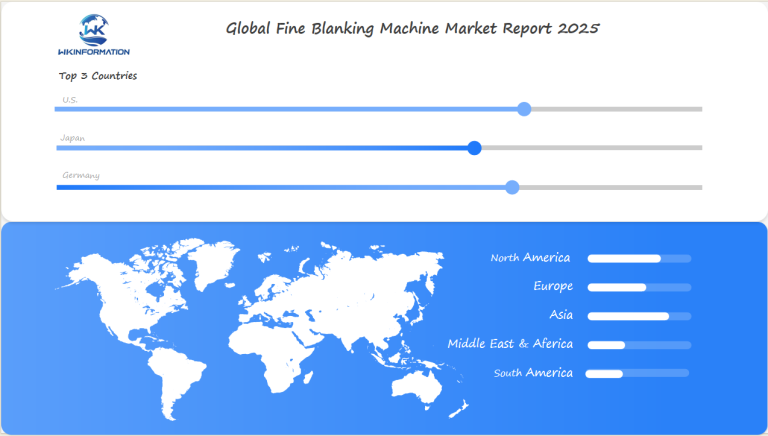

The Fine Blanking Machine market is valued at USD 4.89 billion in 2025, with an expected CAGR of 7.3% from 2025 to 2033. This growth is largely attributed to increasing demand for precision manufacturing in sectors such as automotive, aerospace, and electronics, particularly in the US, Germany, and Japan.

In Q1 2025, the market is expected to reach around USD 1.2 billion, with the US taking the lead as automotive and aerospace sectors continue to expand, requiring precise and efficient production methods. Germany’s strong industrial base and advanced manufacturing technologies will drive further growth, with companies adopting fine blanking to optimize production processes. Japan will also play a critical role, especially with its technological advancements in robotics and automation within the manufacturing industry. By Q2 2025, the market is projected to grow to about USD 1.25 billion as demand for precision manufacturing tools continues to rise in these key regions.

Analysis of the Upstream and Downstream Industry Chain in the Fine Blanking Machine Market

Examining the industry chain analysis of fine blanking machines reveals critical insights into both upstream and downstream processes.

Upstream Processes

- Material Suppliers: The foundation of the fine blanking industry rests on raw material suppliers who provide essential inputs like high-grade steel and specialty alloys. These materials are crucial for crafting durable and precise components.

- Tool Manufacturers: Tooling suppliers play a pivotal role, as they design and produce the specialized punches and dies integral to fine blanking operations. Innovations in tooling, such as galling-free punches, enhance efficiency and expand material compatibility.

Downstream Applications

The applications of fine blanking products span various downstream industries, each benefiting from its precision and quality:

- Automotive Sector: Dominates the demand for fine blanked parts due to their need for high-quality, complex components with minimal material waste.

- Aerospace Industry: Utilizes fine blanking for producing parts that require exact tolerances and reliability.

- Electronics Manufacturing: Leverages fine blanking for creating intricate components essential for modern electronic devices.

Understanding these relationships within the industry chain aids stakeholders in capitalizing on growth opportunities while navigating market dynamics effectively. This interplay between upstream suppliers and downstream applications underscores the strategic importance of innovation and quality in driving market expansion.

Key Trends Influencing the Fine Blanking Machine Market's Growth and Evolution in 2025

The fine blanking machine market is being reshaped by several key trends that are driving its growth and evolution.

1. Technological Innovations

Advances in fine blanking technology are at the forefront, with developments such as galling-free punches enhancing the process’s efficiency. These innovations enable the handling of challenging materials like titanium, expanding application possibilities across sectors. The galling and friction behavior improvements are particularly noteworthy.

2. Sustainability in Manufacturing

A shift towards environmentally sustainable manufacturing processes is gaining momentum. Fine blanking’s ability to produce complex shapes with minimal material waste aligns with industry-wide sustainability goals. This trend is particularly crucial as businesses seek to reduce their environmental footprint while maintaining production quality.

3. Demand for High-Quality Parts

As industries such as automotive, aerospace, and electronics prioritize high-quality components, the demand for fine blanking machines continues to rise. This process offers precise tolerances and smooth edges, meeting the stringent requirements for modern manufacturing standards.

These trends underscore the market’s dynamic nature and its adaptability to evolving industrial demands. The ongoing focus on technological innovations and sustainability positions the fine blanking machine market for significant growth through 2025.

Challenges and Restrictions Facing the Fine Blanking Machine Market in 2025

The fine blanking machine industry faces significant challenges as it aims for growth by 2025. These challenges include regulatory hurdles, competition from alternative manufacturing processes, and the need for strategic planning and investment in research and development.

Regulatory Challenges

Stricter environmental and safety regulations can increase compliance costs, potentially slowing down market expansion. Manufacturers must navigate complex legal landscapes, particularly in regions with stringent standards, to ensure that their processes adhere to evolving rules. This is where understanding the Canadian Critical Minerals Strategy could provide valuable insights, as it outlines the regulatory landscape for critical minerals which are often used in manufacturing processes.

Competition from Alternative Manufacturing Processes

Technologies such as laser cutting and CNC machining offer flexibility and precision, often at a lower cost for certain applications. These alternatives can deter potential clients from adopting fine blanking solutions, especially when budget constraints are a factor. The pressure is on fine blanking manufacturers to continually innovate and demonstrate superior value propositions.

Strategic Planning and Investment

Addressing these challenges requires strategic planning and investment in research and development. Companies must focus on improving efficiency, reducing costs, and enhancing product capabilities to stay competitive. Embracing technological advancements while maintaining regulatory compliance will be key to overcoming these industry hurdles and sustaining growth in the fine blanking machine market.

Geopolitical Factors Shaping the Fine Blanking Machine Market's Global Landscape

The fine blanking machine market is significantly influenced by geopolitical factors, which shape its global dynamics and accessibility. International trade agreements play a pivotal role in determining market conditions. These agreements can either facilitate or hinder the flow of goods, impacting the supply chain and pricing strategies for fine blanking machines.

1. Trade Policies

Favorable trade policies can reduce tariffs and barriers, making it easier for manufacturers to source materials and distribute products across borders. For instance, agreements such as the United States-Mexico-Canada Agreement (USMCA) have streamlined trade relations in North America, potentially boosting market opportunities there. Conversely, trade tensions or sanctions can restrict access to critical markets or raw materials, complicating operations for businesses involved in fine blanking production.

2. Regional Political Stability

The political climate of a region also affects market accessibility. Countries with stable governments are more attractive to investors, ensuring a reliable business environment for machinery production and sales. Unrest or political instability can deter investment and disrupt production schedules, leading to delays and increased costs.

Geopolitical influences remain a crucial consideration for industry players seeking to navigate the complexities of the global market, underscoring the importance of strategic planning in response to these evolving dynamics.

Detailed Market Segmentation and Type Analysis in the Fine Blanking Machine Industry

The fine blanking machine industry is divided into several key segments, each catering to different manufacturing needs and production environments. Segmentation is typically based on factors such as machine type, component material, and automation level. Machines are generally categorized into manual, semi-automatic, and fully automatic systems, with fully automatic machines gaining significant traction in industries requiring high precision and productivity.

In terms of component materials, fine blanking machines are used for working with steel, aluminum, and other metals, with specific machines tailored for different material properties and thicknesses. Type analysis reveals that hydraulic presses are the most commonly used machines in the fine blanking process, owing to their ability to apply consistent force across varying sheet metal thicknesses. Additionally, the advent of hybrid fine blanking machines—integrating mechanical and hydraulic systems—has further broadened the scope of applications and market growth opportunities in the industry.

Application Analysis for Fine Blanking Machines in Key Sectors such as Automotive and Aerospace

Fine blanking machines play a crucial role in the automotive and aerospace sectors, where precision and efficiency are paramount. In the automotive industry, these machines are primarily used for producing critical components such as gears, brake parts, and housings that demand high levels of precision and surface finish. Their ability to create components with minimal post-processing requirements makes them a preferred choice for automotive manufacturers seeking cost-effective and scalable production methods.

In aerospace, fine blanking machines are employed to produce intricate, high-strength parts, including structural components, brackets, and connectors that must meet strict industry standards. The ability to achieve tight tolerances and high-quality finishes makes fine blanking essential for ensuring the performance and safety of aerospace applications. Furthermore, the demand for lightweight and durable parts in both industries has spurred the continued adoption of advanced fine blanking technologies to meet these evolving material requirements.

Regional Overview of the Global Fine Blanking Machine Market, Highlighting Growth Areas

The global fine blanking machine market exhibits a diverse regional landscape, with distinct growth patterns driven by regional manufacturing capabilities, technological advancements, and industry demand. Among the key regions, Asia-Pacific, North America, and Europe stand out as significant contributors to market growth, each with unique drivers and challenges.

Asia-Pacific is currently the largest and fastest-growing market for fine blanking machines. The region’s robust manufacturing base, especially in China, Japan, and South Korea, is a major factor in driving market expansion. With the automotive, electronics, and industrial machinery sectors seeing continuous growth, the demand for precision-machined parts has led to increased adoption of fine blanking technology. Additionally, the rising trend of automation and technological upgrades within manufacturing industries has spurred the need for more advanced fine blanking machines. This growth is further supported by the ongoing industrialization and the shift towards electric vehicles (EVs), which require high-precision components.

North America, particularly the United States, holds a significant share of the fine blanking machine market. The region is home to several automotive giants and aerospace manufacturers that demand precision-engineered components for their operations. As industries push for higher quality and more efficient production processes, the adoption of fine blanking machines has risen. Additionally, the presence of advanced manufacturing technologies and the adoption of Industry 4.0 in the region have led to an increased demand for automated and high-precision fine blanking systems. The growing trend of reshoring manufacturing activities also contributes to the region’s market growth.

Europe also represents a mature market with stable growth prospects, particularly in countries like Germany, Italy, and the United Kingdom, which have strong automotive and industrial sectors. In Europe, fine blanking machines are in high demand for manufacturing components for automotive, aerospace, and medical applications. The market is driven by stringent quality control requirements and the need for precise, cost-effective manufacturing. Moreover, the ongoing push for sustainability and green manufacturing practices has led European manufacturers to adopt more energy-efficient fine blanking machines to meet environmental standards.

U.S. Fine Blanking Machine Market Analysis, Focusing on Key Drivers and Trends

The U.S. fine blanking machine market is growing due to key factors like strong demand from industries such as automotive, aerospace, and industrial machinery. These sectors require high-precision components, which fine blanking machines excel at producing.

Key Drivers:

-

Strong Automotive and Aerospace Demand

The automotive and aerospace sectors are major drivers of the fine blanking machine market in the U.S. These industries rely on fine blanking technology for precision parts such as gears, brake components, and aircraft brackets. -

Technological Advancements

Automation and smart manufacturing technologies are becoming more common in U.S. factories. Fine blanking machines are being upgraded with automation to improve efficiency and reduce production costs. -

Growing Need for Precision Parts

As industries like electronics, medical devices, and machinery demand high-quality parts, fine blanking machines are increasingly used to produce components with exact specifications. -

Reshoring Manufacturing

The trend of reshoring manufacturing to the U.S. is also boosting the market. As companies bring production back home, they require fine blanking machines to meet their manufacturing needs.

Key Trends:

-

Hybrid Machines

Hybrid fine blanking machines, combining hydraulic and mechanical systems, are becoming more popular. These machines offer improved efficiency and precision, making them ideal for various manufacturing needs. -

Focus on Sustainability

There is a growing emphasis on energy-efficient fine blanking machines. Manufacturers are looking for machines that reduce energy consumption and minimize waste. -

Smart Manufacturing Integration

Fine blanking machines are increasingly integrated with smart manufacturing technologies like IoT and real-time monitoring systems, helping manufacturers optimize performance and reduce downtime.

Opportunities and Growth Potential in the Fine Blanking Machine Market in Japan

Japan’s innovation landscape plays a crucial role in the fine blanking machine market. Known for its technological expertise, Japan is leading the way in developing advanced solutions that improve accuracy and efficiency in machinery. This environment creates significant growth potential, attracting investments from both domestic and international stakeholders.

Strategic Positioning of Japanese Firms

Japanese companies are strategically positioning themselves to take advantage of these opportunities. They are actively involved in research and development to push the limits of what can be achieved with fine blanking technology. Notable advancements include automation integration and improved tooling materials, which enhance production capabilities and lower operational costs.

Impact on Global Market

These strategic initiatives not only strengthen Japan’s competitive advantage but also set a standard for quality and innovation in the global market. As a result, Japan is becoming a key player in shaping the future direction of the fine blanking industry, providing significant opportunities for growth and technological advancements.

Insights into the Fine Blanking Machine Market in Germany, Examining Local Dynamics

Germany is a leader in precision machinery production, which has a significant impact on the fine blanking machine market. With its strong industrial base, Germany’s expertise in engineering and manufacturing has made it a global leader in creating high-quality, dependable machinery.

1. Precision Machinery Leadership

Germany’s reputation for precision extends to the fine blanking sector, where German manufacturers have pioneered advanced processes and technologies. This leadership is a testament to the country’s commitment to innovation and quality, ensuring that German-produced machines meet exacting standards.

2. Manufacturing Standards Influence

The adoption of fine blanking technology within Germany is heavily influenced by stringent manufacturing standards. German industry demands tools that provide superior performance with minimal waste. These standards drive local companies to continuously enhance their machinery, aligning with both national and international expectations.

The combination of expertise in precision machinery and strict standards not only strengthens Germany’s position in the global market but also encourages ongoing improvement and adoption in the fine blanking industry.

Future Developments and Technological Innovations in the Fine Blanking Machine Market

The fine blanking machine market is on the verge of significant technological innovations and future developments that promise to reshape the industry’s landscape. Automation integration stands at the forefront, with advancements expected to streamline processes, enhance precision, and reduce manual intervention. This shift towards automation not only improves efficiency but also aligns with industry demands for higher throughput and reliability.

Emerging Trends in the Industry

Predictions indicate several emerging trends poised to shape future industry dynamics:

- AI-driven quality control: Leveraging artificial intelligence for real-time monitoring and quality assurance could revolutionize how defects are detected and rectified.

- Sustainable manufacturing technologies: As environmental concerns rise, innovations focusing on reducing energy consumption and waste will gain traction. Efforts in developing eco-friendly materials and processes are likely to dominate future engineering goals.

- Advanced material processing: The ability to handle a broader range of materials, including high-strength alloys and composites, expands the applicability of fine blanking across various sectors.

These future-oriented developments signal a transformative era for the fine blanking machine market. As companies invest in research and development to stay ahead, these technological advancements are set to drive growth, efficiency, and sustainability throughout the industry.

Competitive Landscape of the Fine Blanking Machine Market, Key Players, and Market Share Analysis

The fine blanking machine market is highly competitive, with many companies working hard to increase their market presence through strategic investments and innovations.

Key Players:

- Aida Engineering – Japan

- Feintool – Switzerland

- Schuler – Germany

- Komatsu – Japan

- LVD Company – Belgium

- Bruderer – Switzerland

- BLM Group – Italy

- Euromac – France

- Amada – Japan

- Nisshinbo Mechatronics – Japan

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Fine Blanking Machine Market Report |

| Base Year | 2024 |

| Segment by Type |

· Manual · Semi-automatic · Fully Automatic Systems |

| Segment by Application |

· Automotive · Aerospace · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Fine Blanking Machine Market is experiencing significant growth, driven by ongoing innovations and strategic advancements. By 2025, the market is expected to reach a value of $4.89 billion, with strong demand coming from the U.S., Germany, and Japan. This growth can be attributed to technological advancements, increased use in industries such as automotive and aerospace, and a focus on precision manufacturing.

- The anticipated growth suggests a positive future outlook with an evolving emphasis on quality and sustainability.

- Strategic investments in research and development are pushing this market into new areas of innovation.

For those looking for more information about the factors influencing this industry, the complete Wkinformation Research report offers detailed analysis and data. This resource will provide a better understanding of the trends shaping the future of the fine blanking machine market.

Global Fine Blanking Machine Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Fine Blanking Machine Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Fine Blanking Machine Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Fine Blanking Machine players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Fine Blanking Machine Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Fine Blanking Machine Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Fine Blanking Machine Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Fine Blanking Machine Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market value of the fine blanking machine market by 2025?

The fine blanking machine market is projected to reach an estimated value of $4.89 billion by 2025, indicating significant growth opportunities driven by innovation and strategic developments.

What are the key trends influencing the growth of the fine blanking machine market?

Key trends influencing the fine blanking machine market include technological innovations such as galling-free punches, a shift towards environmentally sustainable manufacturing processes, and an increasing demand for high-quality parts.

What challenges does the fine blanking machine market face in 2025?

The fine blanking machine market faces several challenges, including regulatory hurdles that may restrict growth and competition from alternative manufacturing processes that could impact market share.

How do geopolitical factors affect the fine blanking machine market globally?

Geopolitical factors such as international trade agreements and regional political stability significantly shape the global landscape of the fine blanking machine market, influencing accessibility and market dynamics.

What opportunities exist for growth in Japan’s fine blanking machine market?

Japan presents numerous opportunities for growth in the fine blanking machine market due to its strong innovation landscape and strategic developments by local firms that enhance competitive positioning.

Who are the key players in the fine blanking machine market and what strategies are they employing?

Major companies involved in fine blanking machinery production focus on R&D investments and employ various competitive strategies to strengthen their positions in the market.