Ultra Thin PE Foam Tape Market to Reach $361.6 Million by 2025 with US, Japan, and Germany Driving Growth

Explore the evolving Ultra Thin PE Foam Tape market trends for 2025, focusing on industry leaders US, Japan, and Germany. This comprehensive analysis covers automotive and packaging innovations, regulatory impacts including Trump’s policies, and future market predictions. Key insights on lightweight materials, sustainability trends, and regional market dynamics provide valuable understanding for industry stakeholders.

- Last Updated:

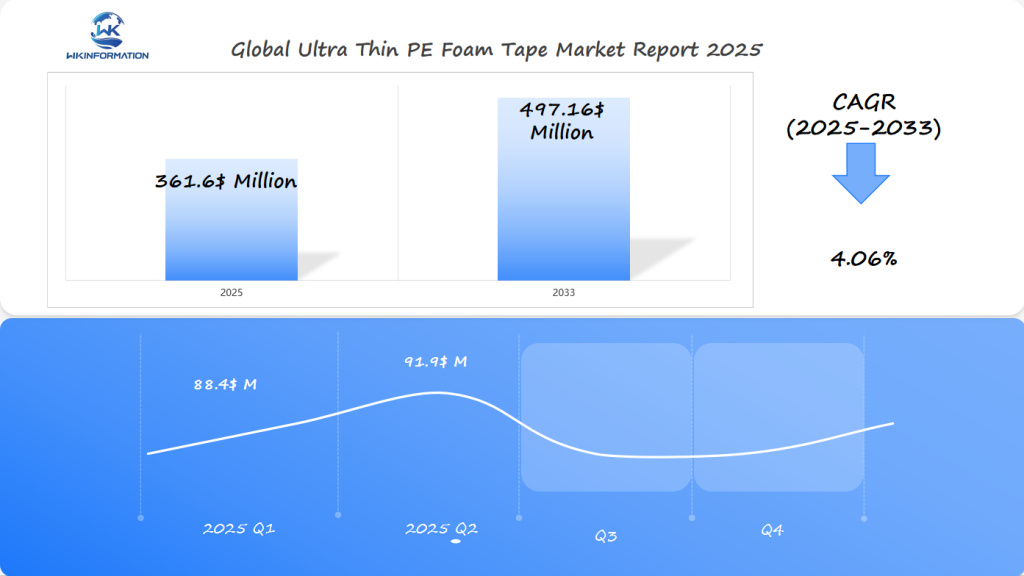

Ultra Thin PE Foam Tape Market Forecast for Q1 and Q2 of 2025

The Ultra Thin PE Foam Tape market is projected to be valued at USD 361.6 million in 2025, with a CAGR of 4.06% from 2025 to 2033. This growth is largely driven by advancements in manufacturing processes and increasing demand across key industries like automotive, electronics, and packaging, particularly in countries such as the US, Japan, and Germany.

In Q1 2025, the market is expected to reach approximately USD 88.4 million, with demand in the US leading as the automotive and electronics sectors continue to expand. Japan’s focus on advanced manufacturing technologies will drive market demand as well, particularly for precision applications in electronic components. Germany’s strong industrial base will further contribute to the growth, especially in packaging and automotive applications. By Q2 2025, the market is projected to increase to about USD 91.9 million, driven by the steady adoption of ultra-thin foam tapes in various sectors.

Understanding the Ultra Thin PE Foam Tape Market Value Chain

Exploring the supply chain analysis of the ultra-thin PE foam tape market reveals critical insights into both upstream and downstream factors.

Upstream Factors: Raw Material Suppliers

The production process begins with upstream raw material suppliers, primarily involving polyethylene manufacturers. These suppliers form the backbone of the production line, providing essential materials that ensure quality and performance in the final product.

Downstream Factors: Key Industries

In the realm of downstream applications, industries such as automotive and construction stand out prominently. In the automotive sector, ultra-thin PE foam tape plays a pivotal role in mounting fixtures, sealing joints, and bonding facades due to its lightweight properties. The construction industry leverages these tapes for energy-efficient insulation solutions, aligning with the growing emphasis on sustainable building practices.

Impact on Market Growth

The dynamics within this supply chain significantly impact market growth. Efficient coordination between suppliers and manufacturers is crucial to avoid potential bottlenecks that can disrupt production schedules. Fluctuations in raw material availability or price changes can pose challenges, affecting production costs and stability in supply.

Understanding these elements provides a comprehensive picture of how supply chain dynamics influence market trends and growth potential, highlighting areas for strategic improvement and investment within the industry.

Key Trends Fueling Expansion in the Ultra Thin PE Foam Tape Market

Market trends are crucial in shaping the ultra-thin PE foam tape industry. One major factor driving this growth is the increased demand from the automotive and construction sectors. These industries are always on the lookout for lightweight materials that can improve fuel efficiency and structural strength. Ultra-thin PE foam tape is an ideal solution because of its excellent thermal insulation properties, making it the preferred choice for manufacturers who want to reduce vehicle weight and enhance energy efficiency.

Energy efficiency regulations are also playing a significant role in promoting the use of ultra-thin PE foam tape. Governments around the world are implementing stricter standards to reduce environmental impact, which is pushing industries to adopt materials that meet these tough requirements. This shift is particularly noticeable in regions like Europe and North America, where regulatory frameworks prioritize sustainable and energy-efficient materials.

Key Drivers of Demand

The demand for ultra-thin PE foam tape is being driven by specific needs in various industries:

- Automotive Sector: The need for mounting fixtures, sealing joints, and bonding facades is steadily increasing.

- Construction Industry: The push for energy-efficient buildings is leading to a greater reliance on advanced insulation solutions.

These trends indicate that there is significant potential for growth in these industries. They also highlight the importance of innovation and adaptability in order to meet changing market demands. The focus on sustainable practices and compliance with energy regulations further reinforces the strategic direction of this market segment.

Challenges Hindering Progress in the Ultra Thin PE Foam Tape Market

Market challenges are key considerations that manufacturers must navigate to ensure the continued growth and success of the Ultra Thin PE Foam Tape Market. Here are some of the significant obstacles:

1. Fluctuation in Raw Material Prices

Fluctuation in raw material prices is a significant obstacle that directly impacts production costs. Variability in prices can erode profit margins, making it difficult for manufacturers to maintain competitive pricing without compromising on quality. This volatility often stems from broader economic factors, including supply chain disruptions and geopolitical tensions.

2. Quality Control Issues

Quality control issues also present a formidable challenge during the manufacturing process. Ensuring consistency and reliability in product performance is critical, particularly as ultra-thin PE foam tape is utilized in sensitive applications such as automotive and construction sectors. Inadequate quality control can lead to product failures, damaging brand reputation and leading to costly recalls or repairs.

Strategies to Overcome Market Challenges

To address these market challenges, manufacturers are increasingly investing in advanced production techniques and rigorous testing protocols. Here are some strategies they are implementing:

- Investing in Advanced Production Techniques: By adopting innovative manufacturing processes, companies can optimize efficiency and reduce dependency on volatile raw materials.

- Implementing Rigorous Testing Protocols: Stringent quality assurance measures throughout the production cycle help identify defects early on, ensuring only top-notch products reach customers.

- Maintaining an Agile Supply Chain Strategy: Flexibility within the supply chain allows manufacturers to swiftly respond to fluctuations in raw material availability and pricing.

By focusing on these strategies, companies aim to deliver products that meet stringent industry standards and withstand diverse application conditions.

Examining Geopolitical Factors and Trade Dynamics Impacting the Ultra Thin PE Foam Tape Market

Geopolitical factors play a significant role in shaping trade dynamics within the ultra-thin PE foam tape market. US-China tensions, for instance, have profound implications for trade flows. These tensions can lead to tariffs that increase costs for manufacturers and disrupt supply chains, necessitating strategic adjustments within the industry.

Trade agreements also significantly influence the market landscape. The United States-Mexico-Canada Agreement (USMCA) exemplifies how regional markets are affected by such treaties. This agreement not only facilitates smoother cross-border trade but also impacts import/export activities for ultra-thin PE foam tape by establishing clear regulatory standards and reducing tariffs.

Key Geopolitical and Trade Influences

- US-China Relations: Affect production costs and availability due to imposed tariffs.

- USMCA’s Influence: Enhances trade efficiency across North American borders, impacting market growth positively.

These geopolitical and trade dynamics underscore the complexities global manufacturers face in navigating regional markets. Understanding these influences is crucial for companies aiming to maintain competitive edges in an ever-evolving international environment.

Segmentation by Type in the Ultra Thin PE Foam Tape Market

Market Segmentation by Type

Single-Sided Ultra-Thin PE Foam Tape

Single-sided ultra-thin PE foam tape is the most widely used and cost-effective variant, providing basic adhesion for general-purpose applications.

Key Features:

-

Features adhesive coating on one side, making it easy to apply and remove.

-

Primarily used for basic mounting and cushioning applications, including protective padding, insulation, and sealing.

-

An affordable solution compared to double-sided and specialized variants, making it suitable for high-volume use.

Applications:

-

Packaging & Protection: Used for shock absorption and cushioning in protective packaging.

-

Furniture & Construction: Applied in lightweight mounting and insulation.

-

General Use: Suitable for temporary mounting, gap filling, and vibration damping in various industries.

Double-Sided Ultra-Thin PE Foam Tape

Double-sided ultra-thin PE foam tape is a premium segment, offering enhanced bonding capabilities due to its dual adhesive layers.

Key Features:

-

Provides superior adhesion for permanent mounting applications.

-

Stronger and more durable compared to single-sided variants, ensuring long-term stability.

-

Higher price point due to the additional adhesive layer and advanced bonding properties.

Applications:

-

Automotive Industry: Used for trim attachment, badge mounting, and dashboard assembly, where strong adhesion and vibration resistance are required.

-

Electronics & Appliances: Essential for screen assembly, panel bonding, and internal component fixation.

-

Signage & Display: Provides seamless mounting for posters, nameplates, and decorative elements.

-

Industrial Manufacturing: Used in precision bonding applications, eliminating the need for mechanical fasteners.

Special-Purpose Ultra-Thin PE Foam Tape

Special-purpose ultra-thin PE foam tape is designed for specific applications, offering enhanced properties to withstand extreme conditions.

Key Features:

-

Available in customized formulations, catering to industries with special performance requirements.

-

Offers advanced properties, such as flame retardancy, water resistance, and UV protection.

-

Positioned as a high-margin product due to its specialized nature and high-performance capabilities.

Applications:

-

Aerospace & Defense: Used in aircraft insulation and structural bonding, where fire resistance and lightweight materials are critical.

-

Medical Devices: Applied in healthcare equipment and wearable technology, requiring biocompatibility and moisture resistance.

-

Extreme Environments: Utilized in outdoor signage, industrial sealing, and marine applications, where exposure to water, heat, and chemicals is a concern.

Market Trends and Future Outlook

As industries continue to demand lighter, stronger, and more durable adhesive solutions, the ultra-thin PE foam tape market is expected to grow. The double-sided and special-purpose segments are projected to experience higher demand, particularly in electronics, automotive, and aerospace applications. Meanwhile, the single-sided segment will remain dominant in high-volume, cost-sensitive markets.

Advancements in adhesive technology, eco-friendly formulations, and smart materials will further shape the market, encouraging innovation and product diversification. Manufacturers investing in R&D and customization will have a competitive edge in this evolving landscape.

Diverse Applications Driving Demand for Ultra Thin PE Foam Tape Across Industries

The ultra-thin PE foam tape market is witnessing a surge in demand across a spectrum of application areas, reaching beyond the automotive and construction sectors. This versatile product is being increasingly utilized in electronics packaging, where its lightweight and insulating properties prove invaluable.

1. Electronics Packaging

With the ongoing trend towards miniaturization in electronic devices, ultra-thin PE foam tape offers a solution that combines space efficiency with robust protection. Its ability to provide effective cushioning without adding bulk makes it a preferred choice for manufacturers aiming to safeguard delicate components.

2. Sector Analysis

Besides electronics, other industries are recognizing the potential of ultra-thin PE foam tape. In sectors like healthcare, it serves critical roles in medical device assembly and diagnostic equipment manufacturing.

Emerging trends such as the push for more compact, efficient electronic devices are influencing application growth. As industries continue to innovate, the demand for lightweight, durable materials like ultra-thin PE foam tape is set to expand, showcasing its versatility across diverse industry uses. The adaptability and performance characteristics of this product underscore its growing importance in modern manufacturing landscapes.

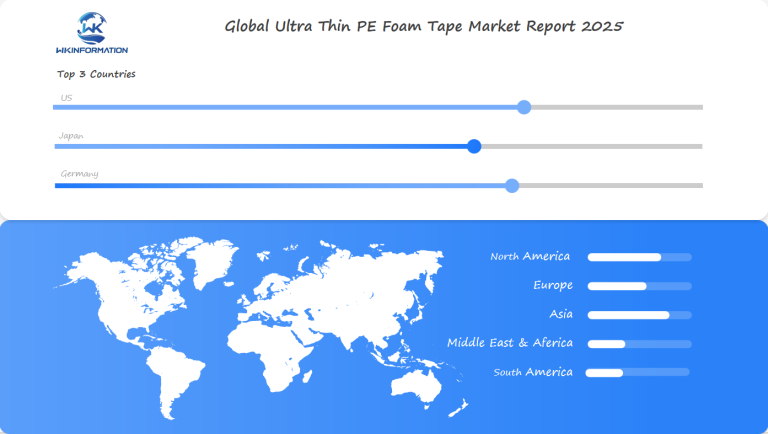

Regional Insights: Analyzing Ultra Thin PE Foam Tape Markets in Key Countries

The Ultra Thin PE Foam Tape Market is experiencing varied growth patterns across different regions, each contributing uniquely to the global market. A detailed analysis reveals significant contributions from key countries such as the United States, Japan, and Germany.

US Market Insights

The United States is anticipated to command approximately 33% of the market revenue by 2037. This dominance is largely attributed to advanced manufacturing capabilities and a strong focus on innovation. American industries have been quick to adopt ultra-thin PE foam tape for its applications in sectors like automotive and construction. The push for energy-efficient building materials continues to drive demand, aligning with regulatory standards promoting sustainability.

Japan Market Trends

In Japan, the automotive sector plays a pivotal role in shaping the demand for ultra-thin PE foam tape. Japanese manufacturers prioritize lightweight materials to enhance fuel efficiency and meet stringent emissions standards. This focus has accelerated the adoption of ultra-thin variants. Additionally, Japan’s tradition of technological innovation extends into this market segment, with ongoing research aimed at improving product performance and durability.

Germany Industry Analysis

Germany stands out due to its robust industrial base and commitment to engineering excellence. The country’s automotive industry is a primary consumer of ultra-thin PE foam tape, utilizing it for mounting fixtures, sealing joints, and other critical applications. Beyond automotive uses, Germany’s emphasis on energy efficiency in building construction has spurred demand for these lightweight tapes, supporting sustainable development goals.

These regional insights underscore the diverse factors driving growth in the Ultra Thin PE Foam Tape Market across key countries. By understanding these unique characteristics, stakeholders can tailor strategies to capitalize on region-specific opportunities while navigating potential challenges inherent in each market landscape.

US Ultra Thin PE Foam Tape Market Analysis

The US ultra-thin PE foam tape market is experiencing steady growth, driven by increasing demand across industries such as automotive, electronics, construction, and healthcare. Ultra-thin PE foam tape is valued for its lightweight, high adhesion strength, and durability, making it an essential material for bonding, cushioning, and sealing applications. With advancements in adhesive technology and material science, manufacturers are developing customized solutions to cater to industry-specific requirements, further propelling market expansion.

Several key factors are influencing the growth of the US ultra-thin PE foam tape market, including:

-

Growing Demand in Electronics & Automotive Sectors: The increasing miniaturization of electronic devices and the shift towards lightweight materials in automotive manufacturing have fueled the need for high-performance adhesive tapes.

-

Rising Adoption of Permanent Bonding Solutions: The double-sided ultra-thin PE foam tape segment is witnessing increased adoption in industries requiring long-lasting adhesion without mechanical fasteners.

-

Expansion of the Construction & Infrastructure Sector: The demand for energy-efficient and durable building materials is driving the use of foam tapes in insulation, sealing, and panel bonding applications.

-

Technological Advancements & Product Innovations: Continuous R&D investments in adhesive formulations, eco-friendly materials, and high-performance tapes are expanding product capabilities.

-

Stringent Environmental & Safety Regulations: The growing emphasis on low-VOC adhesives and fire-retardant materials is shaping the industry’s regulatory landscape, prompting manufacturers to develop sustainable and compliant solutions.

The US ultra-thin PE foam tape market is poised for continued expansion, driven by technological advancements, increasing industrial demand, and regulatory shifts toward sustainability. While challenges such as price competition and material costs persist, manufacturers focusing on innovation, customization, and eco-friendly solutions are expected to gain a competitive edge in this evolving market.

Japan Ultra Thin PE Foam Tape Market Insights

Japan’s ultra-thin PE foam tape market is characterized by high-quality manufacturing standards, advanced adhesive technologies, and strong demand from high-tech industries. With a well-established electronics, automotive, and industrial manufacturing sector, Japan serves as both a consumer and innovator in the ultra-thin PE foam tape market. The market is driven by technological advancements, sustainability initiatives, and the demand for precision bonding solutions.

Several factors contribute to the growth of ultra-thin PE foam tape in Japan:

-

Strong Electronics & Semiconductor Industry: Japan remains a global leader in electronics manufacturing, driving demand for high-performance adhesive solutions in smart devices, circuit assembly, and panel bonding.

-

Advanced Automotive Industry: With Japan being home to major automakers (Toyota, Honda, Nissan, etc.), there is a strong demand for lightweight, durable, and vibration-resistant bonding solutions.

-

High-Precision Manufacturing Standards: Japanese industries emphasize quality and reliability, leading to continuous innovation in adhesive formulations to meet strict performance requirements.

-

Rising Adoption of Eco-Friendly Adhesives: Stricter environmental regulations and corporate sustainability goals are accelerating the shift toward low-VOC and recyclable materials in adhesive tapes.

-

Expanding Applications in Robotics & Medical Devices: Japan’s leadership in robotics and healthcare technologies is driving demand for specialized ultra-thin foam tapes that offer flexibility, insulation, and medical-grade compatibility.

The Japanese ultra-thin PE foam tape market is poised for steady growth, driven by technological advancements, sustainability efforts, and demand from high-tech industries. While challenges such as cost pressures and environmental regulations exist, companies that focus on innovation, quality, and eco-friendly solutions will gain a competitive edge in this dynamic market.

Germany Ultra Thin PE Foam Tape Market Overview

Germany, as a key industrial hub in Europe, plays a significant role in the ultra-thin PE foam tape market. With its well-developed automotive, electronics, construction, and industrial manufacturing sectors, the demand for high-performance adhesive solutions continues to grow. The German market is characterized by strict quality standards, environmental regulations, and strong R&D investments, fostering innovation in eco-friendly and high-durability adhesive technologies.

The growth of the ultra-thin PE foam tape market in Germany is driven by several key factors:

-

Strong Automotive Industry: Germany is home to major automotive manufacturers (Volkswagen, BMW, Mercedes-Benz, Audi, etc.), requiring lightweight, vibration-resistant, and durable bonding solutions for interior and exterior applications.

-

Expanding Electronics & Semiconductor Sector: The rise of smart devices, IoT applications, and high-tech electronics manufacturing has increased demand for precision bonding solutions.

-

Stringent Environmental Regulations: Germany’s focus on sustainability and low-emission manufacturing is accelerating the shift toward eco-friendly adhesives with low VOC emissions.

-

Advancements in Industrial Manufacturing: The presence of leading industrial and engineering companies drives the need for high-performance and customized adhesive tapes.

-

Growth in Renewable Energy & Construction: With Germany’s push towards energy-efficient buildings and wind/solar energy infrastructure, there is increasing demand for durable, weather-resistant adhesive solutions.

Germany’s ultra-thin PE foam tape market is set for steady growth, fueled by technological advancements, sustainability regulations, and demand from high-tech industries. While challenges such as cost pressures and competition from low-cost imports persist, companies that invest in innovation, eco-friendly solutions, and high-performance adhesives will maintain a strong competitive edge in this evolving market.

Future Innovations Shaping the Evolution of Ultra Thin PE Foam Tape Technology

Advancements in adhesive technologies are propelling the ultra-thin PE foam tape market towards unprecedented heights. Researchers are actively exploring next-generation adhesives that promise enhanced product performance. These new formulations aim to improve adhesion strength, durability, and temperature resistance, making them ideal for demanding applications in the automotive and construction sectors.

Innovation is not limited to adhesive properties alone. The industry is also witnessing a shift towards sustainable practices. Manufacturers are increasingly adopting eco-friendly production techniques to align with stringent environmental regulations. This includes using recyclable materials and reducing volatile organic compound (VOC) emissions during production processes.

The demand for greener solutions is driving companies to invest in research and development, focusing on creating products that meet both performance standards and sustainability goals. Technology advancements in this segment are expected to contribute significantly to market growth, offering opportunities for businesses to differentiate themselves through innovation.

Furthermore, these technological advancements also encompass innovative production methods that enhance efficiency and product quality. As these innovations unfold, they are likely to set new benchmarks for quality and sustainability within the ultra-thin PE foam tape industry. This ongoing evolution highlights the sector’s commitment to addressing modern-day challenges while catering to emerging market needs.

Competitive Landscape: Key Players Dominating the Ultra Thin PE Foam Tape Market

In the ultra-thin PE foam tape market, several key players are setting benchmarks with their innovative approaches and extensive product portfolios. These key players include:

-

3M

-

Beiersdorf AG

-

Scapa

-

Mactac

-

Avery Dennison

-

Saint-Gobain

-

Changzhou Haotian New Material Technology

-

Vibac Group

-

YC GROUP

-

Servtek Materials Technology (Guangzhou)

Overall

.

| Report Metric | Details |

|---|---|

| Report Name | Global Ultra Thin PE Foam Tape Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Ultra Thin PE Foam Tape Market is set to experience remarkable growth, driven by significant contributions from the US, Japan, and Germany. As explored in this article, advancements in adhesive technology and sustainable practices are paving the way for future innovations.

For those seeking a deeper understanding of market dynamics and strategies employed by leading manufacturers, the Wkinformation Research report offers comprehensive insights. Engaging with this report will provide valuable perspectives into the trends, challenges, and growth opportunities within this burgeoning market.

Explore the report for an extensive analysis of how industry leaders are navigating the competitive landscape and what lies ahead for the Ultra Thin PE Foam Tape sector.

Global Ultra Thin PE Foam Tape Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Ultra Thin PE Foam Tape Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Ultra Thin PE Foam Tape Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Ultra-Thin PE Foam Tape Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Ultra Thin PE Foam Tape Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Ultra Thin PE Foam Tape Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Ultra Thin PE Foam Tape Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Ultra-Thin PE Foam Tape Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is ultra-thin PE foam tape and why is it significant?

Ultra-thin PE foam tape is a lightweight adhesive material used across various industries for applications such as insulation, bonding, and sealing. Its significance lies in its ability to provide thermal insulation and enhance energy efficiency, making it increasingly popular in sectors like automotive and construction.

What is the projected growth of the global Ultra Thin PE Foam Tape Market?

The global Ultra Thin PE Foam Tape Market is projected to reach $361.6 million by 2025, with major contributions from countries like the US, Japan, and Germany.

What are the key trends driving the expansion of the Ultra Thin PE Foam Tape Market?

Key trends fueling market expansion include rising demand for lightweight materials in the automotive and construction sectors, as well as energy efficiency regulations that encourage the adoption of ultra-thin PE foam tape.

What challenges does the Ultra Thin PE Foam Tape Market face?

The market faces several challenges including fluctuations in raw material prices that affect production costs, as well as quality control issues during manufacturing that can impact product performance and reliability.

How do geopolitical factors influence the Ultra Thin PE Foam Tape Market?

Geopolitical relations, particularly tensions between major economies like the US and China, can affect trade flows within the ultra-thin PE foam tape market. Additionally, trade agreements such as USMCA impact import/export activities for this product category.

What innovative advancements are being explored in ultra-thin PE foam tape technology?

Ongoing research efforts are focused on developing next-generation adhesive technologies to enhance product performance. The industry is also adopting sustainable practices to comply with environmental regulations, shaping future innovations in ultra-thin PE foam tape.