2025 Cold Room Forging Press Market Breakthrough: Unlocking a $3.68 Billion Opportunity with Advanced Manufacturing Technologies in USA, Germany, and China

Discover an in-depth analysis of the Cold Room Forging Press Market, exploring technological advancements, market dynamics, and growth potential across key regions like USA, Germany, and China. Learn how Industry 4.0 integration and innovative manufacturing solutions are shaping this sector, projected to reach $3.68 billion by 2025. Ideal for industry professionals seeking insights into market trends, competitive landscape, and emerging opportunities in cold forging technology.

- Last Updated:

Cold Room Forging Press Market Q1 and Q2 2025 Predictions

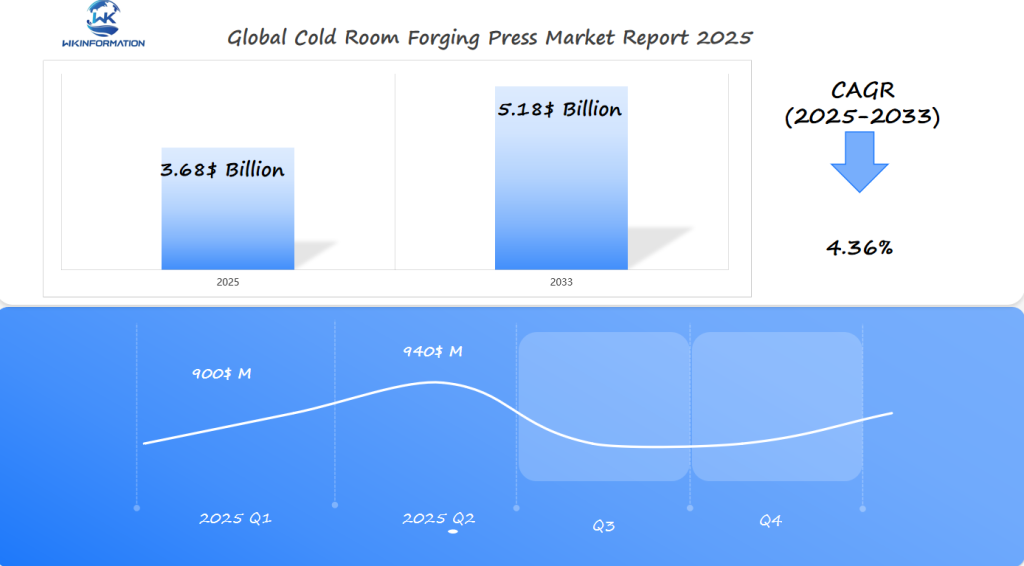

The Cold Room Forging Press market size in 2025 is USD 3.68 billion, growing at a CAGR of 4.36% from 2025 to 2033. In Q1 2025, the market is expected to generate around USD 900 million, driven by demand from industries such as automotive, aerospace, and manufacturing for high-quality forging equipment. Increased focus on efficient production methods and energy savings will also contribute to growth. By Q2 2025, the market is expected to reach about USD 940 million, with key regions like the US, Germany, and China investing in advanced cold forging technologies to enhance production capabilities and reduce costs in high-precision industries.

Key Takeaway: The cold room forging press market is expected to reach a value of $3.68 billion by 2025. This growth is driven by advanced manufacturing technologies, including innovations like automation and precision forging methods. These developments are reshaping the industry, equipping manufacturers with the necessary tools to fulfill the growing demand for lightweight and durable components in various sectors.

Understanding the Upstream and Downstream Dynamics of Cold Room Forging Presses

The cold forging process distinguishes itself by shaping metals at or near room temperature through high-pressure machinery. This method offers distinct advantages over traditional techniques like casting and machining, primarily due to the superior mechanical properties it imparts to the components. Cold-forged parts exhibit enhanced strength, precision, and surface finish, making them highly desirable in industries where these attributes are crucial.

Key Players in the Supply Chain:

1. Upstream Dynamics: Material Suppliers

Material suppliers play a pivotal role in this ecosystem. They provide essential raw materials such as carbon steel and aluminum, which are critical for achieving the desired strength-to-weight ratios in forged products.

2. Downstream Dynamics: Manufacturers

Manufacturers form the backbone of the downstream segment. These entities transform raw materials into finished products, catering to sectors like automotive and aerospace. The demand from these industries significantly influences market trends.

Applications of Cold Room Forging Presses

Cold room forging presses find extensive application across various industries:

- Automotive Industry: The need for lightweight yet robust components is paramount. Cold forging meets this demand by producing safety-critical parts like gears and fasteners with exceptional durability.

- Aerospace Sector: Here, the emphasis is on lightweight components that do not compromise on strength or reliability. Cold forging delivers precise, high-quality parts essential for aerospace applications.

The interaction between upstream material suppliers and downstream manufacturers defines the cold room forging press market’s dynamics. Understanding these interactions helps anticipate trends and influences market growth trajectories within key industries such as automotive and aerospace. As highlighted in a recent LinkedIn article, the significance of cold forging in shaping the future of metallurgy cannot be overstated.

Key Trends Shaping the Cold Room Forging Press Industry

In the ever-changing world of cold room forging presses, market trends are crucial for driving growth and innovation. One of the most significant trends is the increasing demand for lightweight components. This demand comes from industries like automotive and aerospace, where it’s essential to reduce weight without sacrificing strength. As a result, manufacturers are looking for ways to improve production efficiency and use less material.

1. Technological Advancements

Technological advancements are vital in improving the performance and capabilities of cold room forging presses. Automation and digitalization are leading the way, transforming traditional manufacturing processes. Advanced robotics and precise control systems allow manufacturers to achieve higher accuracy and consistency, greatly reducing human error. The integration of computer-aided design (CAD) systems with forging equipment enables more complex part designs, optimizing material use and minimizing waste.

2. Industry 4.0 Revolution

The rise of Industry 4.0 has brought about a revolution in the cold forging process through smart manufacturing techniques. Key elements such as the Internet of Things (IoT), machine learning, and real-time data analytics are being embraced to create more efficient production environments. These technologies enable predictive maintenance, reducing downtime by addressing potential issues before they become major problems. Additionally, smart sensors monitor every stage of the forging process, ensuring quality control and making adjustments in real-time.

The combination of market demands, technological advancements, and Industry 4.0 principles is reshaping the cold room forging press industry. It is opening doors for innovative solutions that cater to the changing needs of modern manufacturing sectors.

Overcoming Challenges in Cold Room Forging Press Technology

Adopting cold room forging press technology presents several challenges for manufacturers. Equipment costs and the limited knowledge within the industry are significant barriers. The initial investment required for advanced machinery can be substantial, deterring smaller enterprises from entering the market. Additionally, a gap in expertise often hinders effective implementation and optimization of these technologies.

Addressing these technology limitations involves proactive strategies. Collaborative research initiatives can bridge the knowledge gap by pooling resources and expertise from various stakeholders. Government support programs also play a crucial role in mitigating financial constraints, providing subsidies or incentives to encourage technological adoption.

Continuous innovation is vital for overcoming current market barriers and ensuring future growth. Emphasizing research and development helps refine existing processes and develop new solutions that enhance efficiency and reduce costs. Staying at the forefront of technological advancements not only improves competitiveness but also sets the stage for sustainable development within the Cold Room Forging Press Market.

By tackling these challenges head-on, manufacturers can unlock new opportunities and drive progress in an ever-evolving industry landscape, setting a strong foundation for expansion and success in global markets.

Geopolitical Impact on the Cold Room Forging Press Market Growth

Geopolitical factors play a crucial role in shaping the cold room forging press market, influencing the competitive landscape across key countries such as the USA, Germany, and China. Each of these nations holds significant sway in global manufacturing, and their geopolitical strategies directly affect market dynamics.

United States

With its focus on technological innovation and domestic manufacturing, the USA leverages its advanced infrastructure to maintain a competitive edge. However, trade tensions and tariff policies can impact the cost-effectiveness of imports and exports for cold-forged components.

Germany

As a leader in engineering excellence, Germany benefits from its strong industrial base and strategic location within Europe. EU trade agreements facilitate seamless exchange across borders, yet geopolitical uncertainties such as Brexit can introduce complexities in trade routes.

China

Rapid industrialization drives China’s demand for cold room forging presses. The country’s role as a manufacturing hub is reinforced by strategic investments in infrastructure. Nonetheless, international trade policies and tariffs may influence export competitiveness.

Trade policies significantly affect the export and import of cold-forged components between these regions. Tariffs, trade agreements, and regulatory standards dictate the flow of goods, impacting pricing strategies and supply chain efficiencies in the global market.

Market Segmentation: Types of Cold Room Forging Presses and Their Applications

In the world of cold room forging, market segmentation reveals different types of presses, each designed for specific uses. The two main types are mechanical and hydraulic presses, each with its own advantages.

Mechanical Presses

Applications: Widely used for high-speed production runs.

Benefits: Known for their reliability and efficiency in processes requiring consistent repeatability. Their ability to sustain high production rates makes them indispensable in industries like automotive manufacturing, where precision and speed are paramount.

Hydraulic Presses

Applications: Favoured for tasks demanding greater versatility and control over force application.

Benefits: Renowned for their precise control of pressure and position. This makes them ideal for complex forging operations where detailed component features are necessary. Hydraulic presses adapt well to various materials, including metals with varying ductility, thus enhancing their appeal across diverse sectors such as aerospace.

Each type of press has its own role in the manufacturing process, meeting the specific needs of different industries. The decision between mechanical and hydraulic presses usually depends on the requirements of the forged components, such as speed, precision, or material flexibility.

The Role of Cold Room Forging Presses in Metal Manufacturing

Cold room forging presses are crucial in metal manufacturing, improving both efficiency and product quality. These machines work by applying high pressure at or near room temperature, resulting in parts that have better mechanical properties than those made using traditional methods such as casting or machining.

Benefits of Using Cold Room Forging Presses

Here are some key advantages of using cold room forging presses:

- Increased Strength: The cold forging process enhances the strength of the metal by refining its grain structure, making it ideal for producing high-strength components.

- Enhanced Precision: It allows for the production of parts with complex shapes and tight tolerances, reducing the need for additional machining.

- Improved Surface Finish: Components often come out of the press with a smooth surface finish, minimizing post-processing requirements.

Industries That Benefit from Cold Room Forging Presses

Cold-forged components are successfully used in various industries:

- In the automotive sector, cold-forged gears and fasteners are critical due to their enhanced strength and durability, vital for safety-critical applications.

- The aerospace industry benefits from lightweight yet robust components like turbine blades and structural connectors, which are essential for fuel efficiency and performance.

- In the consumer electronics sector, cold forging technology produces small yet intricate parts necessary for compact devices.

These examples highlight how cold room forging presses have transformed metal manufacturing processes. By enabling manufacturers to produce high-quality components efficiently, these presses meet the increasing demands of modern industries for lightweight and durable materials. This progress continues to drive growth in the Cold Room Forging Press Market.

Regional Insights: Cold Room Forging Press Market Growth Across Global Regions

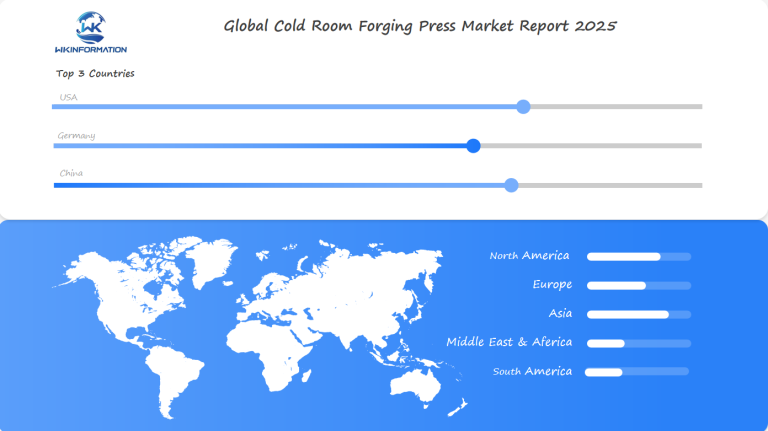

Global markets for cold room forging presses, including the USA, Germany, and China, have their own unique features that influence how they grow. The specific industrial environment and technological abilities of each region create different chances for expansion.

USA: Innovation and Leadership

- The United States continues to lead in technological innovation within the cold room forging press market. With an emphasis on advanced manufacturing technologies and robust research initiatives, American companies drive efficiency and quality improvements.

- The growing demand for lightweight components in automotive and aerospace industries fuels market expansion.

Germany: Engineering Excellence

- Germany’s strong engineering tradition underpins its leadership in developing sophisticated cold forging solutions. The country’s focus on precision engineering and automation enhances its competitiveness.

- Collaborative efforts between German firms and other European entities further bolster this region’s market standing.

China: Rapid Industrial Growth

- China’s burgeoning industrial sector propels significant demand for cold room forging presses. As a manufacturing powerhouse, China’s emphasis on cost-effective production bolsters its position as a key global player.

- The integration of Industry 4.0 principles aids in optimizing production processes, meeting both local and international demands.

These regional dynamics highlight the need for customized strategies to effectively tap into growth opportunities in each market.

The USA’s Leadership in Cold Forging and Press Technology

The United States is a leader in cold forging and press technology, thanks to its strong industrial base and dedication to research and development. Companies like Parker Hannifin Corporation and Ajax-CECO play a crucial role in driving technological advancements in the USA market. These companies are focused on improving the efficiency, accuracy, and sustainability of cold room forging presses.

Investment in Research Activities

Investment in research activities significantly contributes to the growth prospects of this sector. The emphasis on automation and smart manufacturing techniques aligns with Industry 4.0 principles, leading to increased productivity and reduced operational costs. Collaborative efforts between private industries, academic institutions, and government entities further accelerate innovation.

Promising Future for the USA Market

The USA market analysis reveals a promising future, supported by initiatives that encourage technological integration and workforce skill enhancement. The ongoing transformation towards lightweight materials and the increasing demand for high-strength components in automotive and aerospace sectors present lucrative opportunities for growth.

As the industry evolves, continued investment in research and collaborative partnerships will be crucial. Such efforts ensure that the USA maintains its leadership position, offering advanced manufacturing solutions that meet global standards.

Germany’s Contribution to Advanced Cold Forging Solutions

Germany’s manufacturing sector stands out as a leader in the development of advanced solutions for cold room forging technology. The country has a strong reputation for engineering excellence and innovation, contributing significantly to the Cold Room Forging Press Market. German manufacturers are known for their precision and quality, making them key players in this industry.

1. Technological Advancements

German companies consistently push the boundaries of cold forging technology. They invest heavily in research and development, resulting in state-of-the-art equipment that enhances efficiency and product quality.

2. Collaborations

The impact of Germany’s advancements extends across Europe through strategic partnerships and collaborations between German firms and other European companies. These collaborations foster the exchange of knowledge and technology, strengthening the entire region’s manufacturing capabilities.

3. Industry Influence

By setting high standards, Germany influences market trends across Europe. Their focus on sustainability and efficiency resonates with global demands for environmentally friendly manufacturing processes.

The combination of innovation and collaboration helps solidify Germany’s position at the forefront of the cold room forging press market. This dynamic environment not only benefits local manufacturers but also propels European markets towards greater technological achievements.

China’s Growing Demand for Cold Room Forging Presses in Manufacturing

The China market growth in cold room forging presses reflects a significant increase driven by rapid industrialization efforts. As one of the world’s largest manufacturing centers, China has positioned itself to meet the global demand for high-quality yet cost-effective forged components.

1. Industrialization and Demand

China’s relentless push towards industrialization has created a fertile ground for cold forging technologies. The automotive and aerospace sectors are particularly influential, with an increasing need for durable and lightweight components that cold forging can efficiently produce.

2. Manufacturing Hub

China’s strategic role as a manufacturing hub is underscored by its ability to deliver quality at scale. Cold room forging presses contribute to this capability by enabling more efficient production processes that meet international standards.

3. Cost-Effectiveness

By leveraging economies of scale, Chinese manufacturers offer competitive pricing without compromising on quality. This balance makes China an attractive option for global industries seeking reliable and affordable forged parts.

In essence, China’s strategic investments in manufacturing capabilities and technological advancements continue to strengthen its position in the global cold room forging press market. These developments not only cater to domestic requirements but also effectively fulfill international demands.

Innovations in Cold Room Forging Press Technology for Efficiency and Quality

In the world of cold room forging press technology, technological innovations are changing the game for manufacturers. These advancements are helping them achieve higher efficiency and uncompromising quality like never before. What’s even more exciting is that these recent developments have the potential to completely transform production cycles while still meeting strict requirements set by end-users.

Key Technological Innovations:

- Automation and Robotics: The incorporation of robotics into cold room forging presses has drastically reduced human intervention, leading to enhanced precision and repeatability in production. Automation minimizes errors, enhances safety, and streamlines the overall manufacturing process.

- Precision Forging Techniques: New methodologies in precision forging allow for the creation of complex geometries with minimal material waste. This not only reduces costs but also ensures that components meet exacting specifications required by industries such as automotive and aerospace.

- Computer-Aided Design (CAD) Integration: By integrating CAD software with forging presses, manufacturers can simulate various scenarios before actual production. This predictive capability enables the optimization of tools and processes, significantly improving both efficiency and finished product quality.

- Advanced Materials: The development of innovative alloys with superior strength-to-weight ratios is another milestone. These materials enhance performance while maintaining or even reducing weight, a critical factor in sectors like aerospace.

These technological strides are reshaping the landscape of cold room forging presses. By focusing on automation, precision, simulation, and material science, these innovations not only boost productivity but also ensure that quality standards set by end-users are consistently met. This ongoing evolution underscores the vital role of cutting-edge technology in advancing manufacturing capabilities.

Key Competitors in the Cold Room Forging Press Market

The Cold Room Forging Press Market is bustling with key players who are shaping its trajectory through strategic movements and innovative product offerings. These competitors are not only defining the market landscape but also driving technological advancements that cater to evolving industry demands.

-

Mauser Group BV – Netherlands

-

National Machinery – United States

-

Stamtec, Inc. – United States

-

Nedschroef Herentals – Belgium

-

Sijin Intelligent Forming Machinery Co. Ltd. – China

-

Zhejiang Dongrui Machinery Industrial – China

-

Zhejiang Shengtuo Machinery Co., Ltd. – China

-

Jyichyng – Taiwan

-

Zhejiang Yeswin Machinery – China

-

Sacma – Italy

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Cold Room Forging Press Market Report |

| Base Year | 2024 |

| Segment by Type | · Mobile · Fixed |

| Segment by Application | · Metal Processing · Stamping · Mold Making · Others |

| Geographies Covered | · North America(United States,Canada)

· Europe(Germany,France,UK,Italy,Russia) · Asia-Pacific(China,Japan,South Korea,Taiwan) · Southeast Asia(India) · Latin America(Mexico,Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast,company share,competitive landscape,growth factors and trends |

The Cold Room Forging Press Market is expected to grow and reach a value of $3.68 billion by 2025. This growth is driven by advancements in manufacturing technologies and the rise of Industry 4.0, which will have a significant impact on industries such as automotive and aerospace. Additionally, emerging markets, especially in regions like China, are also contributing to this growth.

Key factors driving this market include:

- Technological innovations that improve efficiency and quality

- Increasing demand for lightweight materials

- Strategic global partnerships

As these factors come into play, stakeholders can take advantage of new opportunities in this changing landscape.

Global Cold Room Forging Press Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Cold Room Forging Press Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Cold Room Forging PressMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Cold Room Forging Pressplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Cold Room Forging Press Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Cold Room Forging Press Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Cold Room Forging Press Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofCold Room Forging Press Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market size of the cold room forging press market by 2025?

The cold room forging press market is projected to reach $3.68 billion by 2025, primarily driven by advancements in manufacturing technologies.

What are the advantages of cold forging over traditional manufacturing methods?

Cold forging offers several advantages over traditional methods like casting and machining, including improved material strength, better dimensional accuracy, and reduced waste.

How do geopolitical factors influence the cold room forging press market?

Geopolitical factors affect the competitiveness of countries in the cold room forging press market, particularly in regions like the USA, Germany, and China, influencing trade policies and market dynamics.

What types of cold room forging presses are available in the market?

The market features various types of cold room forging presses, including mechanical and hydraulic presses, each tailored for specific applications in different industries.

What role does Industry 4.0 play in the cold room forging process?

Industry 4.0 is revolutionizing the cold forging process through smart manufacturing techniques that enhance automation and digitalization, leading to increased production efficiency.

What challenges do manufacturers face when adopting cold room forging press technology?

Manufacturers encounter challenges such as high equipment costs and a lack of industry knowledge. Solutions include collaborative research initiatives and government support programs to foster innovation.