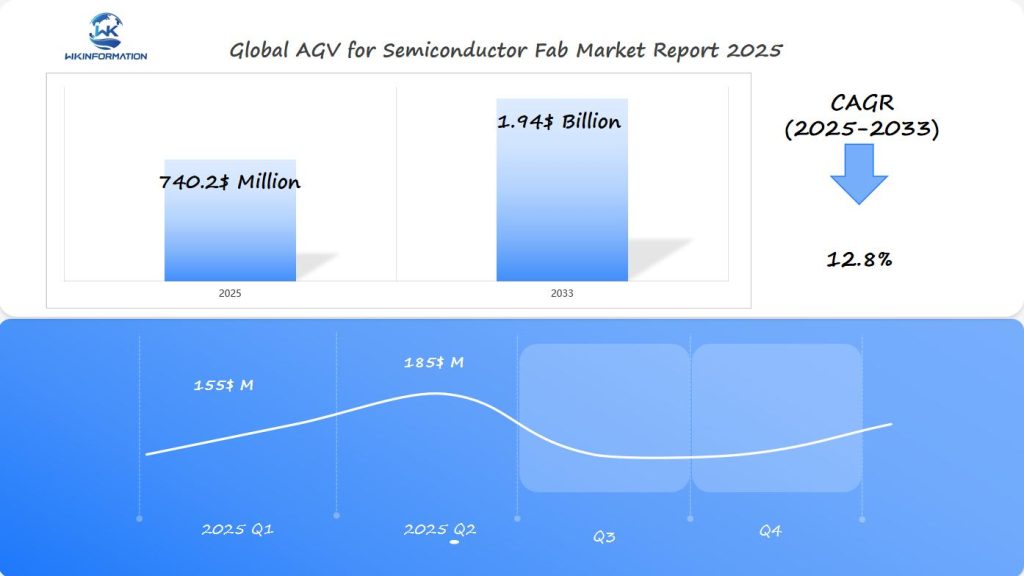

AGV for Semiconductor Fab Market Expected to Exceed $740.2 Million by 2025: Strategic Growth in the U.S., South Korea, and Japan

Discover how the AGV for Semiconductor Fab Market is experiencing rapid expansion, driven by automation needs and projected to reach $740.2 million by 2025, transforming semiconductor manufacturing.

- Last Updated:

AGV for Semiconductor Fab Market: Q1 and Q2 Trajectory in 2025

The AGV (Automated Guided Vehicle) market for Semiconductor Fabs is expected to reach $740.2 million by the end of 2025, driven by a high CAGR of 12.8% from 2025 to 2033. In Q1 2025, the market is projected to generate approximately $155 million, boosted by rising investments in semiconductor automation and fab expansion.

By Q2 2025, the market is likely to grow to around $185 million, as next-generation semiconductor facilities increase adoption of AGV systems to enhance productivity and cleanliness standards. The uneven distribution reflects phased equipment procurement and capacity planning by major fab operators. The U.S., South Korea, and Japan are key regions to observe, leading the global charge in semiconductor innovation and automation deployment.

AGV for Semiconductor Fab Market Upstream and Downstream Industry Chain Analysis

The AGV supply chain is key in the semiconductor world. It links many players who help make and use autonomous guided vehicles in advanced factories.

The semiconductor world has many important parts that affect AGV markets:

- Raw material suppliers give special parts

- AGV makers create top-notch navigation systems

- Factories use automation to make semiconductors

- Technology integrators make sure everything works smoothly

At the start of the AGV chain, we have engineering and research groups. They work on key tech like navigation, sensors, and control systems for making semiconductors better.

On the other end, we have factories that use AGV systems. They help with moving materials, cut down on human work, and make cleanrooms more efficient. Partnerships between AGV makers and factories lead to new ideas.

The AGV supply chain shows how complex relationships help advance semiconductor tech.

Things like new tech, money investments, and global factory trends shape the AGV world. Companies must keep up with new needs in engineering and automation.

Key Trends Shaping the AGV for Semiconductor Fab Market

The world of semiconductor manufacturing is changing fast thanks to new AGV technology. Advanced automated guided vehicles are making factories more precise and efficient. This is a big deal for how we make semiconductors.

New AGV systems are making a big difference in how semiconductors are made. These updates are changing what’s possible in making things automatically.

Technological Advancements in AGV Systems

Today’s AGV systems have amazing features that help a lot in making semiconductors:

- Omni-directional drive units eliminate the need for complex turns

- They can carry heavy loads, from 100 kg to 150 kg

- They can align quickly, in just 1 second

- They can position things with an accuracy of under 1mm

Integration of AI and Machine Learning

AI is making AGVs smarter in semiconductor manufacturing. Machine learning helps them find the best routes, predict when they need maintenance, and make quick decisions. This makes operations run more smoothly.

Increasing Demand for Cleanroom-Compatible AGVs

Cleanroom automation is essential for semiconductor production. Now, AGV systems are designed to maintain cleanliness. They prevent contamination and create an ideal environment for semiconductor manufacturing.

These innovative technologies are setting higher standards for semiconductor production. They demonstrate the significance of advanced AGV systems in maintaining competitiveness.

Challenges and Restrictions Affecting Market Growth

The automated guided vehicle (AGV) market for semiconductor fabrication faces big barriers. These challenges come from complex technology and economics. Manufacturers must carefully navigate these issues.

Semiconductor fab automation barriers are huge hurdles for technology integration. Companies face many challenges when thinking about AGV systems:

- Prohibitively high initial investment costs

- Technical complexity of system integration

- Intricate regulatory compliance requirements

High Initial Investment Costs

Advanced AGV systems require a significant financial investment for semiconductor manufacturers. The expenses involved include purchasing hardware, developing software, and training personnel.

Technical Complexity and Integration Issues

AGV implementation needs top-notch technical skills. It also requires meeting safety and cleanroom standards. These needs pose challenges to traditional automation methods.

| Challenge Category | Primary Obstacles | Potential Mitigation Strategies |

| Cost Barriers | High initial investment | Phased implementation, leasing options |

| Technical Complexity | System integration difficulties | Modular design, expert consultation |

| Safety Compliance | Stringent regulatory requirements | Advanced sensor technologies |

Regulatory Hurdles and Safety Concerns

Safety rules in semiconductor manufacturing are strict. Comprehensive safety systems must protect people, handle objects carefully, and keep the environment safe. This is crucial in sensitive production areas.

Geopolitical Influence on AGV for Semiconductor Fab Market Expansion

The semiconductor industry is now driven by global politics and technology. Countries are racing to lead in tech, making the AGV market a key area of competition.

Trade policies have changed the AGV market for making semiconductors. Countries see the value in making semiconductors and are investing in it.

Trade Tensions and Supply Chain Disruptions

Global tensions have revealed vulnerabilities in semiconductor supply chains. The main problems are:

- Limitations on technology transfers between countries

- Higher tariffs on semiconductor equipment

- Manufacturing ecosystems that are spread out across different regions

Government Initiatives and Subsidies

Governments are taking steps to boost domestic semiconductor making. They are investing in research and creating special zones. They also give direct subsidies for AGV and semiconductor tech.

- Substantial financial investments in research and development

- Creation of specialized economic zones

- Direct subsidies for AGV and semiconductor technologies

Regional Competition and Market Access

The AGV market for semiconductors is a key area of global tech competition. Regions are investing and forming partnerships to get ahead.

The race for semiconductor manufacturing supremacy is no longer just an economic challenge but a critical national security concern.

As trade policies change, the AGV market for semiconductor making will get more complex. Global players will need to be strategic.

Market Segmentation: Types and Variations in AGV Systems

The world of semiconductor fab automation is changing fast. New AGV types are making material handling and logistics better. Automated Guided Vehicles (AGVs) are key to making manufacturing more efficient and precise in complex settings.

Manufacturers are looking at different AGV systems to meet their needs. These solutions fall into three main types:

- Rail Guided Vehicles (RGVs)

- Autonomous Mobile Robots (AMRs)

- Hybrid AGV Solutions

Rail Guided Vehicles (RGVs)

RGV systems follow set paths, either magnetic or painted. They work best in places with clear paths and regular routes. Fabs like them for their accuracy and steady movement.

Autonomous Mobile Robots (AMRs)

AMRs are more flexible, using technology such as laser mapping and learning. They have the ability to adapt to changing environments and efficiently transport materials in intricate spaces.

Hybrid AGV Solutions

New hybrid AGV solutions mix RGV and AMR tech. They offer the best of both worlds, making them great for semiconductor automation.

| AGV Type | Navigation Method | Flexibility | Precision |

| RGV | Track-Based | Low | High |

| AMR | Dynamic Mapping | High | Moderate |

| Hybrid | Combined Approach | Very High | High |

The debate between RGV and AMR is driving new tech in semiconductor manufacturing. It’s making things more efficient and advanced.

Exploring Key Applications of AGVs in Semiconductor Fabs

Automated Guided Vehicles (AGVs) have revolutionized the semiconductor manufacturing industry. They offer unparalleled accuracy and efficiency, making them essential in the intricate process of producing semiconductors.

AGVs address significant obstacles in semiconductor production by streamlining workflows and enhancing reliability. This leads to reduced human error and improved consistency in results.

Material Handling and Transportation

AGVs are great at moving materials in semiconductor making. They handle delicate wafers and sensitive gear with great care.

- Precise navigation through complex facility layouts

- Reduction of contamination risks

- Consistent and predictable transportation routes

Cleanroom Operations

AGVs are crucial in cleanroom automation in semiconductor making. They work in super clean ISO environments. This is key for making high-quality chips.

- Compliance with ISO 3/2 environment standards

- Compatibility with SMIF pods and transport containers

- Minimized human-induced contamination

Tool-to-Tool Transfer

AGVs make semiconductor manufacturing faster and more precise. They move materials quickly and accurately between stations.

- Automated routing between manufacturing equipment

- Enhanced production line efficiency

- Reduced manual handling and potential errors

By using advanced AGV technology, semiconductor makers can reach new heights. They achieve better quality and efficiency.

Global AGV for Semiconductor Fab Market Regional Insights

The global semiconductor industry is changing fast. Automated guided vehicles (AGVs) are key in making manufacturing better in many places. Looking at the AGV markets around the world helps us understand how semiconductor fab automation works.

AGVs in semiconductor making are different in each area. Each place has its own way of using technology, affecting how much is sold and how it grows.

North American Market Overview

North America is a leader in new tech, especially in AGVs. Companies here spend a lot on the latest AGV systems. This shows their dedication to making things better with top-notch automated tools.

European Market Landscape

In Europe, making semiconductors is all about being precise and high-quality. The AGV markets here focus on working well in clean rooms and using the latest in moving things around. There’s a lot of money going into making new things happen in this area.

Asia Pacific Dynamics

The Asia Pacific is growing the fastest in AGVs for making semiconductors. Countries like South Korea, Japan, and China are big players. They’re putting a lot of money into AGV technology.

Emerging Markets

Latin America, the Middle East, and Africa are new chances in the global semiconductor world. They might not be as big yet, but they could grow a lot in the future.

- Increasing technological infrastructure

- Growing semiconductor manufacturing capabilities

- Strategic international partnerships

The differences in AGV markets show how complex and changing the global semiconductor industry is. To do well, companies need to stay flexible and keep coming up with new ideas.

U.S. Market Overview for AGVs in Semiconductor Fabs

The U.S. semiconductor industry is changing fast. Automated guided vehicles (AGVs) are key for making chips better. As making chips gets more complex, American factories are using new ways to automate.

The AGV market in semiconductors is full of new ideas and growth. Big changes are happening in how chips are made and moved around.

Market Size and Growth Projections

Experts say the AGV market in the U.S. semiconductors could grow a lot. This growth comes from:

- More need for new chip-making tech

- Higher labor costs and the need for robots

- AGV systems getting better and better

Key Players and Competitive Landscape

In the U.S., top AGV makers are working on special solutions for chip factories. They’re spending a lot on making AGVs smarter and cleaner for the factory floor.

Technological Innovation and R&D Focus

U.S. chip makers are leading in AGV tech. They’re using artificial intelligence and machine learning. This makes AGVs smarter, more flexible, and better at making chips.

The future of semiconductor manufacturing lies in the seamless integration of advanced automation technologies.

South Korea’s Position in the AGV for Semiconductor Fab Market

The South Korean semiconductor industry leads in technology, especially in AGV use for making semiconductors. Being a top maker of semiconductors, South Korea has a strong system for advanced automation in factories.

The growth of fab automation in Korea is impressive and strategic. Local makers have pushed tech forward and formed global partnerships. This has made South Korea even stronger in the market.

Domestic AGV Manufacturers and Partnerships

Top Korean tech companies are key in making advanced AGV solutions for semiconductors. They work with global partners to reach more markets.

| Manufacturer | Key Specialization | International Partners |

| Hyundai robotics | Cleanroom AGV systems | Semiconductor Equipment Manufacturers |

| LG Electronics | Advanced navigation systems | Global semiconductor firms |

| Samsung robotics | AI-powered material handling | International automation companies |

Government Support and Industry Initiatives

The South Korean government plays a crucial role in supporting the development of Automated Guided Vehicles (AGVs). It provides subsidies and research grants to promote innovation in semiconductor automation, which has positioned South Korea as a global technology leader.

“Our national strategy focuses on developing cutting-edge automation technologies that maintain Korea’s semiconductor manufacturing supremacy.” – Korean Ministry of Trade, Industry and Energy

Japan’s Market Dynamics for AGVs in Semiconductor Fabs

The Japanese semiconductor industry is a global leader in technology, especially in AGVs for making semiconductors. Japan’s history of precision engineering helps it lead in AGV innovation in semiconductor manufacturing.

Historical Context and Market Evolution

Japanese fab technology has changed a lot over the years. The country’s semiconductor makers have always been at the forefront, creating advanced AGV systems. These systems reduce human error and increase precision.

- Pioneered advanced automation techniques

- Developed cleanroom-compatible AGV solutions

- Invested heavily in robotics and precision engineering

Technological Specialization and Niche Markets

Japan is great at making ultra-precise AGV systems for specific semiconductor processes. These systems are very good at handling delicate materials without contamination.

| AGV Specialization | Market Segment | Competitive Advantage |

| Cleanroom Navigation | High-Precision Fabs | 99.99% Contamination Prevention |

| Micro-Material Handling | Advanced Chip Manufacturing | Nanometer-Level Accuracy |

Export Strategies and Global Market Influence

Japanese AGV makers have a strong presence worldwide. They focus on high-precision tech and keep innovating. This has helped them build strong partnerships and export channels.

They keep investing in research and development. This keeps Japanese semiconductor AGV tech leading globally.

Future Development Trajectory of the AGV for Semiconductor Fab Market

The semiconductor industry is on the verge of a big change. Autonomous guided vehicles (AGVs) are key to this transformation. With new tech coming fast, the AGV market is expected to grow a lot.

New technologies will change how semiconductors are made. These advancements will push the industry forward at an amazing pace.

Emerging Technologies and Their Potential Impact

- 5G connectivity enabling real-time communication between AGVs

- Artificial Intelligence for advanced route optimization

- Machine learning algorithms improving predictive maintenance

- Edge computing enhancing AGV decision-making capabilities

Market Consolidation and Strategic Partnerships

The AGV market for semiconductors is going through significant transformations. Companies are joining forces to innovate and expand. The goals of these partnerships include:

- Creating advanced AGV systems

- Lowering manufacturing expenses

- Improving technological skills

Sustainability and Green Manufacturing Initiatives

The AGV market is now focusing on being environmentally friendly. Companies want to reduce carbon emissions and make their operations more efficient.

The future of AGVs in semiconductor fabrication is not just about technological advancement, but about creating more sustainable and intelligent manufacturing ecosystems.

As the industry continues to grow, AGVs will play a crucial role. They will drive innovation, increase productivity, and support the industry’s major objectives.

Competitive Landscape and Major Players in the Market

The AGV for semiconductor fab market is very competitive. Global AGV manufacturers and semiconductor automation companies fight for the top spot. They use strategy and new technology to stay ahead.

Many big players lead the market. Each has its own strengths and tech skills in semiconductor automation:

-

Daifuku Co., Ltd. – Japan

-

Toyota Industries Corporation – Japan

-

JBT Corporation – United States

-

Kion Group – Germany

-

Mitsubishi Electric – Japan

-

Swisslog Holding AG – Switzerland

-

Bastian Solutions – United States

-

Dematic – United States

-

Murata Machinery, Ltd. – Japan

-

Lam Research – United States

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global AGV for Semiconductor Fab Market Report |

| Base Year | 2024 |

| Segment by Type | · RGV (Rail Guided Vehicle)

· AMR (Autonomous Mobile Robot) |

| Segment by Application | · 300mm Fabs

· 200mm Fabs |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The global Automated Guided Vehicle (AGV) market for semiconductors is booming. It’s expected to grow a lot, thanks to new tech and more automation. Market research insights show a bright future for the semiconductor industry.

Why Investing in Automation is Important

Investing in automation is key for semiconductor makers to stay ahead. The market is strong in places like the US, South Korea, and Japan. Companies using the latest AGV tech will see better efficiency and lower costs.

Managing Risks in the Semiconductor Market

Handling risks is important in this market. You need to think about:

- tech integration

- startup costs

- changing rules

To succeed, you need good planning, strong tech, and adaptability.

The Bright Future of Semiconductor Automation

The future looks bright for semiconductor automation. Investors and companies should watch:

- new tech

- partnerships

- innovations

By staying flexible and using the latest AGV tech, you can lead in semiconductor manufacturing.

Global AGV for Semiconductor Fab Market Report(Can Read by Free sample)–Table of Contents

Chapter 1:AGV for Semiconductor Fab Market Analysis Overview

- Competitive Forces Analysis(Porter’s Five Forces)

- Strategic Growth Assessment(Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- AGV for Semiconductor Fab Market Segmentation Overview

Chapter 2:Competitive Landscape

- GlobalAGV for Semiconductor Fab Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3:AGV for Semiconductor Fab Market Segmentation Analysis

- Key Data and Visual Insights

- Trends,Growth Rates,and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4:Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic,Demographic,and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5:AGV for Semiconductor Fab Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends,Challenges,and Opportunities

Chapter 6:Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7:AGV for Semiconductor Fab Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8:Key Findings and Recommendations

- Summary of AGV for Semiconductor Fab Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market value for AGVs in Semiconductor Fabrication by 2025?

The AGV for Semiconductor Fab market is expected to reach $740.2 million by 2025. This growth is driven by increased automation and technological advancements in semiconductor manufacturing.

How do AGVs improve semiconductor manufacturing processes?

AGVs make semiconductor manufacturing better by improving material handling and reducing human error. They also keep cleanrooms sterile and enable precise tool transfers.

What are the primary types of AGV systems used in semiconductor fabs?

The main AGV systems include Rail Guided Vehicles (RGVs), Autonomous Mobile Robots (AMRs), and hybrid AGV solutions. These combine features of both traditional navigation methods.

What challenges do manufacturers face when implementing AGV systems?

Manufacturers face challenges like high initial costs and technical complexities. They also need to ensure compatibility with existing systems and meet safety standards in cleanrooms.

Which regions are leading in AGV adoption for semiconductor fabrication?

The United States, South Korea, and Japan are leading. Each region brings unique technological innovations and strategic approaches to AGV implementation.

How are AI and machine learning impacting AGV technologies?

AI and machine learning are making AGVs better. They improve route optimization, decision-making, predictive maintenance, and navigation and handling processes.

What emerging technologies are expected to influence AGV development?

Emerging technologies such as 5G, IoT, edge computing, and advanced sensors are set to enhance AGV performance. These innovations will improve connectivity and accuracy in semiconductor manufacturing processes.

Are there specific environmental considerations for AGVs in semiconductor fabs?

Yes, AGVs must be cleanroom-compatible. They need to minimize contamination and maintain strict environmental standards for ultra-clean environments critical to semiconductor production.

How do geopolitical factors impact the AGV semiconductor market?

Geopolitical factors such as trade tensions, government initiatives, and regional competition can have a significant impact on the AGV semiconductor market. These factors can affect:

- Market access: Geopolitical issues may create barriers to entry for AGV semiconductor companies in certain regions, making it difficult for them to compete effectively.

- Supply chains: Trade tensions or government policies can disrupt supply chains, leading to delays in production and delivery of AGV semiconductors.

- Technological development: Geopolitical factors may influence the direction of technological development in the AGV semiconductor market, with countries prioritizing certain technologies over others based on their strategic interests.

What sustainability initiatives are emerging in AGV semiconductor technologies?

Manufacturers are focusing on green manufacturing. They are developing energy-efficient AGV systems, reducing waste, and implementing environmentally friendly production technologies.