Automatic Belt Tensioner Market to Surpass $2.1 Billion by 2025: Automotive and Industrial Growth in the U.S., Germany, and Japan

Discover how the Automatic Belt Tensioner Market is projected to exceed $2.1 billion by 2025, driven by automotive sector expansion and growing industrial applications across the United States.

- Last Updated:

Automatic Belt Tensioner Market: Q1 and Q2 Outlook for 2025

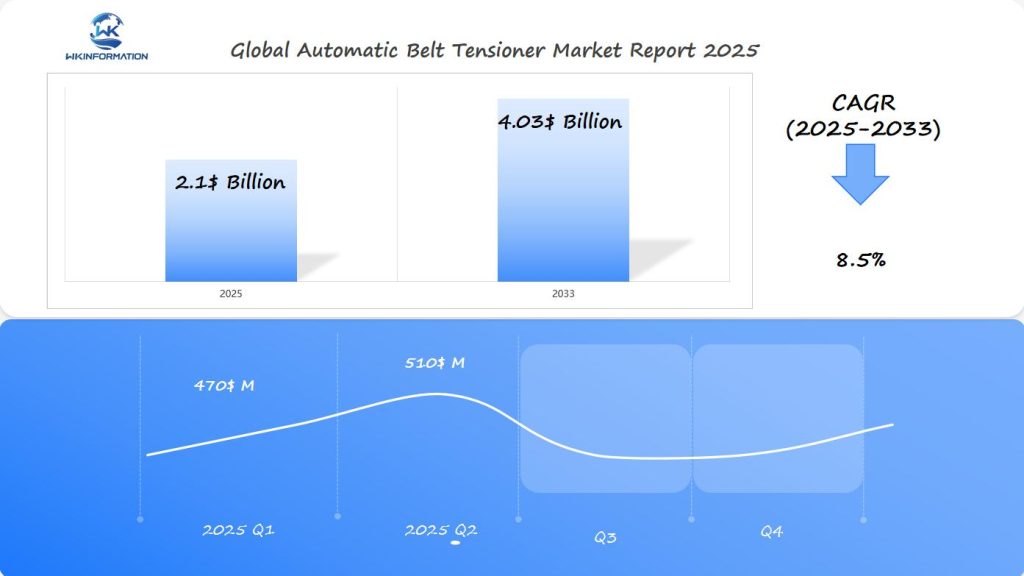

The global Automatic Belt Tensioner market is projected to reach $2.1 billion by the end of 2025, registering a compound annual growth rate (CAGR) of 8.5% from 2025 to 2033. In Q1 2025, the market is estimated to generate approximately $470 million, driven by the increasing demand for efficient engine management systems in the automotive industry.

Q2 2025 is expected to show growth, reaching around $510 million, as vehicle production ramps up and the need for advanced automotive components increases. This uneven growth trajectory is reflective of the automotive sector’s cyclical production patterns and technology upgrades. The U.S., Germany, and Japan are leading markets for this product, with their automotive industries focusing on improving vehicle efficiency and emissions reduction.

Key Takeaways

- The market is projected to reach $2.1 billion by 2025.

- There is strong growth in the automotive and industrial sectors.

- The United States and Germany are leading market development.

- Technological innovations are driving market expansion.

- There is an increasing demand for high-performance tensioning systems.

Automatic Belt Tensioner upstream and downstream industry chain analysis

The automatic belt tensioner market has a complex supply chain. This chain affects how things are made and costs. Raw materials, especially metals, are key for making tensioners.

Key Parts of the Supply Chain

- Metal suppliers providing high-quality steel and aluminum alloys

- Precision engineering component manufacturers

- Industrial machinery fabrication centers

- Automotive component distribution networks

Creating automatic belt tensioners involves many steps. Choosing the right raw materials is important. Metallurgical expertise is key for making tensioners that last under tough conditions.

| Supply Chain Stage | Key Considerations | Impact on Production |

| Raw Material Sourcing | Metal quality and pricing | Directly affects manufacturing costs |

| Component Manufacturing | Precision engineering | Determines product reliability |

| Distribution | Automotive and industrial sectors | Expands market reach |

Changes in raw material prices can change the market. Makers need to find ways to keep costs down. This helps them stay competitive in both cars and industrial uses.

Increased demand in automotive and industrial machinery sectors

The automatic belt tensioner market is growing fast. This is because of more use in cars and machines. Experts say we will see a big jump in demand, especially in cars and trucks.

Right now, cars are the biggest part of the market. They have the most share because of a few reasons:

- They are made in huge numbers

- They are getting more complex

- People want them to work better

Increasing Use in Passenger and Commercial Vehicles

Car manufacturers are incorporating improved belt tensioners to enhance engine efficiency. The commercial vehicle sector is also rapidly adopting new technology. Automatic belt tensioners play a crucial role in maintaining the smooth operation of fleets.

Growing Applications in Industrial Equipment

More machines in factories and farms are using automatic belt tensioners. They are important for:

- Factory machines

- Conveyor belts

- Big machines

- Farm equipment

“New tech is making us want better mechanical parts in cars and machines,” says an expert.

The demand for improved belt tensioners in vehicles and machinery is driving market growth, indicating a promising future for innovative mechanical components.

| Sector | Key Drivers |

| Passenger Vehicles | Performance optimization |

| Commercial Vehicles | Fleet efficiency |

| Industrial Machinery | Technological integration |

The table above shows the growth percentage of market demand in various sectors, including industrial machinery, which is projected to grow by 10% due to technological integration.

Challenges in durability, precision, and cost-effectiveness

Developing automatic belt tensioners is tough. Companies are working hard to make them last longer and work better. They also need to keep costs down in a competitive market.

The main problems are:

- Keeping parts from wearing out too fast

- Keeping the system running smoothly

- Reducing noise and shaking

- Making advanced features without spending too much

Teams of engineers are coming up with smart ways to solve these issues. Precision engineering is key. It helps make systems that can handle tough jobs in industries and cars.

| Challenge Area | Key Development Focus | Expected Improvement |

| Durability | Advanced material selection | 40% longer component life |

| Precision | Micro-adjustment mechanisms | Reduced tensioning variance |

| Cost-Effectiveness | Streamlined manufacturing processes | 15% production cost reduction |

New technologies are helping make better automatic belt tensioners. They meet high standards and stay affordable.

Geopolitical analysis of automotive production and machinery manufacturing

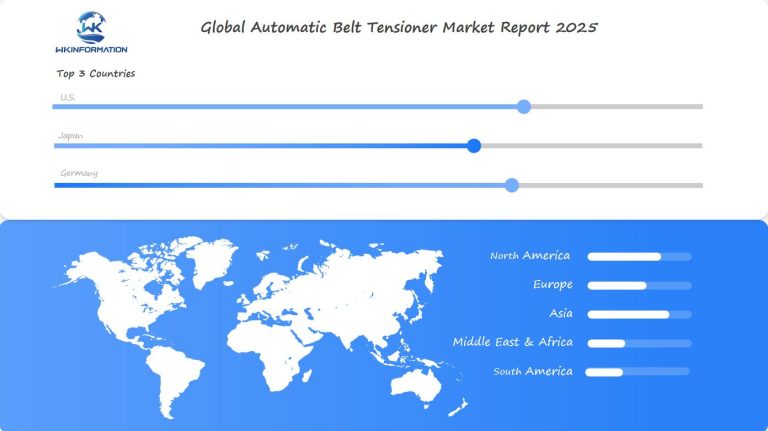

The automatic belt tensioner market is influenced by global trends that originate from strategic production hubs and shifting trade policies. Key players such as the United States, Germany, and Japan have a significant impact on market dynamics and the introduction of new technologies.

How Different Regions Approach Manufacturing

Each region has its own unique approach to manufacturing cars and machinery:

- North America focuses on adopting the latest manufacturing technologies.

- Europe places a strong emphasis on precision engineering.

- Asia strives to find cost-effective solutions in production.

The Role of Geopolitics in Market Growth

Geopolitical factors play a crucial role in shaping the growth of markets. Trade agreements, tariffs, and investments all have an impact on the automatic belt tensioner industry.

| Region | Market Influence | Key Characteristics |

| United States | High technological innovation | Strong automotive supply chain |

| Germany | Premium engineering standards | Advanced manufacturing processes |

| Japan | Precision manufacturing | Advanced materials research |

“The future of automatic belt tensioners is intrinsically linked to geopolitical manufacturing strategies” – Industry Expert

Regional production hubs are reshaping global supply chains. They are driving technological advancements and competitive strategies in the automatic belt tensioner market.

Segmentation by tensioner design and system type

The automatic belt tensioner market is complex, with many product types and strategies. Manufacturers create advanced tensioner designs for various machines and vehicles. These designs meet different needs.

Market segmentation shows two main tensioner design types. These types drive innovation in technology:

- Conventional tensioners for standard applications

- Heavy-duty tensioners for extreme conditions

Conventional vs. Heavy-Duty Tensioner Configurations

Conventional tensioners are used in industries and cars for light to moderate applications. They prioritize cost-effectiveness and standard performance. The engineering of these tensioners relies on lightweight materials and compact designs.

Automatic and Manual Tensioning Systems

Tensioner systems are classified into automatic and manual types. Each type serves different market segments:

| Tensioner Type | Key Characteristics | Primary Applications |

| Automatic Tensioning | Self-adjusting mechanism | Modern automotive engines |

| Manual Tensioning | Requires periodic mechanical adjustment | Industrial machinery |

Automatic tensioning systems are becoming more popular. They offer better precision and less maintenance in many industries.

Key applications in automotive engines, HVAC systems, and conveyor systems

Automatic belt tensioners are key in many fields. They help make systems work better and last longer. This is true for both cars and big machines.

Automotive Engines

In cars, these devices keep the belt tight. This is important for:

- Less wear on parts

- Better engine performance

- Preventing belt slippage

HVAC Systems

HVAC systems use these tensioners too. They help keep air flowing right and temperatures steady. This is true for cars and big buildings.

Industrial Conveyors

Conveyor systems also get a boost from these devices. They help move things smoothly and quickly. This means less trouble and less time stopped for repairs.

| Application Sector | Key Benefits | Performance Impact |

| Automotive Engines | Consistent Power Transmission | Enhanced Mechanical Efficiency |

| HVAC Systems | Precise Temperature Control | Improved Energy Management |

| Industrial Conveyors | Reduced Mechanical Stress | Increased Operational Reliability |

The need for better belt tensioners is growing. This is because of new car tech and electric cars. These changes make the old ways less good.

Regional growth trends in automotive production and industrial applications

The global automatic belt tensioner market is growing fast in key areas. North America, Europe, and Asia are leading the way. Each region has its own special market features and growth paths.

Looking at the future, we see different trends in each area:

- North America has a strong demand for car parts.

- Europe focuses on high-precision engineering.

- Asia is all about quick tech advancements.

How much cars are made affects the belt tensioner market. Companies are trying to get into new places to grow.

| Region | Key Drivers |

| North America | Automotive manufacturing expansion |

| Europe | Industrial machinery upgrades |

| Asia-Pacific | Technological advancements |

New tech and changing needs are changing markets. Strategic investments in research help companies stay ahead in different places.

U.S. demand for automotive components and industrial systems

The U.S. market for car parts has seen big changes lately. Making automatic belt tensioners in the U.S. is now key for companies wanting to stay ahead in the global car parts market.

What’s driving demand in the U.S.

Several factors are contributing to the increased demand for automotive components and industrial systems in the United States:

- A strong car-making sector

- New tech innovations

- A growing need for replacement parts

- Tough standards for performance

The impact of imports and exports on production

How imports and exports affect automatic belt tensioner production is very important. American makers are creating better solutions for the car and machine industries.

Insights into U.S. manufacturing

Looking at how parts are made in the U.S. shows some interesting points:

- North American makers are spending a lot on research and development.

- New ways of making parts are making them more precise.

- Partnerships are forming between car and machine makers.

Keeping up with new tech is crucial for U.S. companies in the automatic belt tensioner market. They are always working to meet higher standards in different industries.

The U.S. car part market shows great strength and ability to change in a fast-moving world.

Germany’s automotive industry driving demand for advanced tensioning solutions

The German automotive sector leads in technology, setting global standards for engineering. As a top European market leader, Germany keeps improving automotive parts, especially automatic belt tensioners.

German makers have created top-notch tensioning systems for today’s cars. They focus on several important areas:

- High-precision engineering

- Enhanced durability

- Performance optimization for electric and hybrid vehicles

- Reduced mechanical complexity

Big names like Bosch and Continental are leading in new tensioning tech. They aim to make power transmission more efficient and cut down vehicle weight. These are key for modern car design.

The German auto industry is also looking into new, smart tensioning solutions. They use advanced sensors and adaptive systems. This makes Germany a world leader in car part engineering.

German engineering excellence continues to define the future of automotive component design.

German companies are investing a lot in research and development. They’re setting new standards for automatic belt tensioner performance. This keeps Germany important in the global car supply chain.

Japan’s technological advancements in automotive and industrial systems

Japan leads in technology in the automotive and industrial systems market. Its focus on quality has made it a global leader in advanced mechanical parts. Japanese manufacturers show unmatched precision and engineering skills.

Key Strengths of Japanese Technology

The Asian market influence of Japanese technology goes beyond traditional manufacturing. Key strengths include:

- Cutting-edge research and development

- Exceptional engineering precision

- High-performance manufacturing techniques

- Innovative material science applications

Impact of Japanese Innovation on Global Manufacturing

Japanese innovation in automotive systems has changed global manufacturing. Companies like Toyota and Honda have led in technology. They’ve created advanced belt tensioning solutions that boost mechanical performance and efficiency.

Japan’s approach to manufacturing combines technological excellence with meticulous attention to detail.

The strong ecosystem of Japanese technological development keeps pushing limits in automotive and industrial systems. Their quality manufacturing ensures components meet the highest international standards. This makes Japanese technologies highly sought after worldwide.

Innovations in automatic belt tensioning systems and materials

Product innovation in automatic belt tensioning systems is changing industrial manufacturing. New material science is key, bringing new solutions to old mechanical systems.

Now, smart tensioning systems use advanced materials for better performance. Engineers have made high-strength polymers and alloys for more durability and efficiency. Research shows big improvements in belt tensioners, with new features like:

- Enhanced noise reduction

- Longer operational life

- Better tension control

- Predictive maintenance sensors

New materials make tensioning parts lighter yet stronger. Nanotechnology-enhanced polymers resist wear, temperature changes, and stress well. These advances help make automatic belt tensioning systems more reliable and efficient for many industries.

Advanced materials are changing mechanical engineering, offering better performance and reliability.

Companies are spending more on research for smart tensioning systems. These systems will soon monitor and adjust themselves in real-time, making them even more useful.

Key competitors in the automatic belt tensioner market

The automatic belt tensioner market is very competitive. Many big players are trying to be the leaders. They are using new products and partnerships to get ahead.

Some of the top names in the market are:

-

Dayco – United States

-

Bando – Japan

-

Hutchinson – France

-

Gates Corporation – United States

-

SKF – Sweden

-

Continental – Germany

-

Brewer Machine & Gear – United States

-

Lovejoy – United States

-

Fenner Drives – United States

-

Litens Aftermarket – Canada

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Automatic Belt Tensioner Market Report |

| Base Year | 2024 |

| Segment by Type | · Light Belt Tensioner

· Heavy Belt Tensioner |

| Segment by Application | · Passenger Vehicle

· Commercial Vehicle |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The global automatic belt tensioner market is set to grow significantly. Experts predict strong growth ahead. By 2033, it could reach $4.03 billion, up from $2.1 billion in 2025.

This growth demonstrates the importance of automatic belt tensioners in various industries, particularly in automobiles and industrial machinery.

Factors driving growth

New technological trends are expected to drive this market forward. Electric vehicles and autonomous cars require advanced belt tensioners, prompting companies to innovate and develop lighter, more efficient systems.

Challenges to overcome

However, there are challenges that need to be addressed for sustained growth. Key areas of focus include achieving precision, durability, and affordability in belt tensioner design and manufacturing. Companies that leverage new materials and smart technologies are likely to gain a competitive edge in the market.

Regional leaders

North America and Europe are currently at the forefront of improving these components, constantly pushing the boundaries of what is possible in terms of performance and functionality.

Future demand

Looking ahead, the demand for automatic belt tensioners is expected to continue rising. They will find increased applications in electric vehicles, renewable energy projects, and innovative manufacturing processes.

Overall, the future appears promising for automatic belt tensioners as they play a crucial role in supporting sustainable transportation solutions and advanced industrial practices.

Global Automatic Belt Tensioner Market Report(Can Read by Free sample)–Table of Contents

Chapter 1:Automatic Belt Tensioner Market Analysis Overview

- Competitive Forces Analysis(Porter’s Five Forces)

- Strategic Growth Assessment(Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Automatic Belt Tensioner Market Segmentation Overview

Chapter 2:Competitive Landscape

- GlobalAutomatic Belt Tensioner Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3:Automatic Belt Tensioner Market Segmentation Analysis

- Key Data and Visual Insights

- Trends,Growth Rates,and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4:Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic,Demographic,and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5:Automatic Belt Tensioner Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends,Challenges,and Opportunities

Chapter 6:Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7:Automatic Belt Tensioner Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8:Key Findings and Recommendations

- Summary of Automatic Belt Tensioner Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market value for Automatic Belt Tensioners by 2025?

The Automatic Belt Tensioner market is expected to grow significantly, likely exceeding $2.1 billion by 2025. This growth is primarily driven by the automotive and industrial sectors, with the United States, Germany, and Japan being key players in this market.

How do raw material prices impact the Automatic Belt Tensioner market?

Changes in raw material prices can significantly affect the market. They can alter production costs and influence the dynamics of the market. This may result in changes in how Automatic Belt Tensioner manufacturers produce their products.

Which vehicle segment dominates the Automatic Belt Tensioner market?

Passenger vehicles lead the market. They have a big demand because of how often they’re made. Belt tensioners are very important for these vehicles to run well.

What are the main challenges in Automatic Belt Tensioner manufacturing?

Improving Automatic Belt Tensioners is a significant challenge. Manufacturers aim to enhance their durability, precision, and cost-effectiveness. To accomplish this, they are leveraging new technologies.

How are Automatic Belt Tensioners used in different industries?

These components are vital in many areas:

- Car engines

- HVAC systems

- Industrial machinery

- Conveyor systems

- New technologies like ADAS and electric vehicles

Which regions are most important in the Automatic Belt Tensioner market?

North America, particularly the United States, is a major player. Europe, especially Germany, and Asia, particularly Japan and China, also have significant roles. Each region has its own strengths to contribute.

What new developments are happening in Automatic Belt Tensioner technology?

New materials and smart technologies are at the forefront of these advancements. Here are some key areas of innovation:

- Development of high-strength polymers for improved performance

- Integration of predictive maintenance sensors for proactive monitoring

- Efforts to reduce noise levels for a quieter operation

- Focus on enhancing durability for longer lifespan

- Striving for greater efficiency in energy consumption

How are electric and hybrid vehicles impacting Automatic Belt Tensioner design?

Electric and hybrid vehicles need special tensioning systems. Manufacturers are working on designs that are lighter, more efficient, and work well with new powertrain technologies.

What factors drive demand for Automatic Belt Tensioners?

Several things drive demand:

- More cars being made

- Industrial machinery needs

- New technologies

- The need for better performance and reliability

These factors help the market grow.

Are there differences between automatic and manual tensioning systems?

Yes, there are big differences. Automatic systems are more precise, consistent, and need less maintenance. This makes them more popular in today’s vehicles and industrial equipment.