PMMA Coated Separator Market to Hit $1.19 Billion by 2025: Battery and Energy Storage Growth in the U.S., China, and Japan

Discover how the PMMA Coated Separator Market is projected to reach $1.19 billion by 2025, driven by growing demand in battery technology and energy storage solutions across industries.

- Last Updated:

PMMA Coated Separator Market: Q1 and Q2 Outlook for 2025

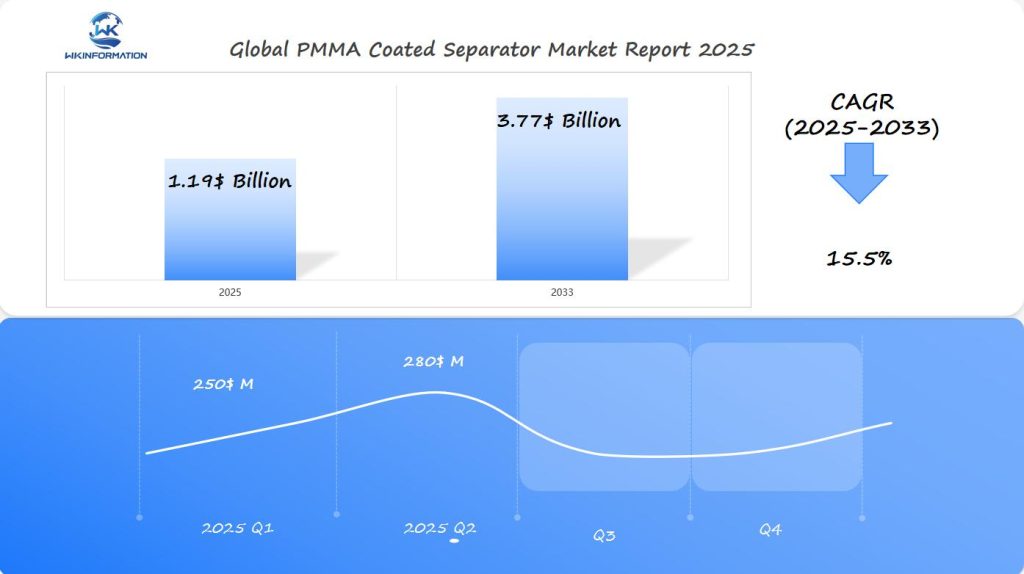

The PMMA Coated Separator market is projected to reach $1.19 billion by the end of 2025, with a strong CAGR of 15.5% from 2025 to 2033. In Q1 2025, the market is estimated to generate around $250 million, primarily driven by the growing demand for advanced battery technologies in electric vehicles (EVs) and energy storage solutions.

By Q2 2025, the market is expected to expand to $280 million, fueled by the increasing adoption of PMMA coated separators in high-performance batteries. This uneven growth reflects the accelerating pace of EV production and global shifts toward renewable energy. The U.S., China, and Japan are pivotal in shaping this market, with these countries leading the charge in EV adoption and battery technology innovations.

Key Takeaways

- PMMA coated separator market expected to reach $1.19 billion by 2025

- Significant growth in battery technology innovations

- U.S., China, and Japan driving energy storage market developments

- Increased focus on electric vehicle and renewable energy applications

- Technological advancements improving battery performance and efficiency

PMMA Coated Separator upstream and downstream industry chain analysis

The PMMA coated separator industry is made up of various components that contribute to the advancement of energy storage technology. Understanding the industry chain allows us to gain insights into the functioning of the market and potential areas for growth.

Raw Materials Landscape

PMMA coated separators start with top-notch raw materials. The main ones are:

- Polymethyl methacrylate (PMMA) base materials

- Specialty polymer films

- Advanced coating compounds

- Precision-grade chemical additives

Manufacturing Process Insights

Turning these raw materials into top-notch separators is a detailed process. It includes:

- Material selection and preparation

- Precision coating techniques

- Quality control and performance testing

- Final product optimization

Market Interconnections

The PMMA coated separator industry has deep connections between its parts. Manufacturers work hand in hand with raw material suppliers, battery tech firms, and end-users. This teamwork drives innovation and better performance.

Partnerships between material scientists, battery makers, and tech innovators are changing the energy storage scene. This creates a fast-moving and changing market.

Increasing demand for high-performance separators in lithium-ion batteries

The world is changing fast, with a big push towards better energy storage. High-performance separators are key in lithium-ion batteries. They help make electric cars and gadgets better.

Companies are working hard to make these separators better. They want to improve how batteries work and stay safe. The benefits of these advanced separators include:

- Improved thermal stability

- Enhanced electrical insulation

- Increased battery life cycle

- Better safety mechanisms

Performance Characteristics of Advanced Separators

Electric cars are pushing the limits of what separators can do. Scientists are creating new materials. These materials can handle very high temperatures and protect batteries from failing.

| Separator Type | Thermal Stability | Cost Efficiency | Application |

| PMMA Coated | High | Moderate | Electric Vehicles |

| Ceramic Coated | Very High | High | Advanced Electronics |

| Polyolefin | Standard | Low | Consumer Devices |

The need for better separators in lithium-ion batteries is growing fast. As electric cars become more common, these separators will be key. They will help shape the future of how we travel and use energy.

Challenges in material cost, efficiency, and manufacturing processes

The PMMA coated separator market faces big challenges that affect its growth and tech progress. High material costs are a major hurdle for makers aiming for top-notch battery separators. These costs put a lot of pressure on how they make and sell their products.

Here are some key areas where challenges exist:

- Lowering material costs with new coating methods

- Boosting efficiency with precise engineering

- Finding cheaper ways to make separators

- Reducing waste in the making process

Manufacturing Efficiency Strategies

Battery tech firms are investing heavily in improving their manufacturing processes. Their goal is to streamline production while maintaining high-quality separators. Technological innovations play a crucial role in addressing these efficiency challenges.

Here are some of the strategies they’re implementing:

- Advanced automation: By incorporating automated systems into their production lines, battery manufacturers can increase efficiency and reduce human error.

- More accurate coating technology: Developing precise coating techniques ensures that separators are uniformly coated, leading to better performance.

- Cost-effective materials: Exploring alternative materials that are cheaper yet still meet quality standards can help reduce overall production costs.

These initiatives aim to tackle manufacturing issues and minimize expenses associated with PMMA coated separators.

Economic Considerations

The economics of making separators need constant changes. Makers have to weigh material costs against performance needs, leading to a mix of tech and money hurdles.

Geopolitical analysis of energy storage and electric vehicle trends

The world of energy storage and electric vehicles is changing fast. This change is driven by complex global politics. Governments around the world are racing to lead in clean energy, creating a competitive field that affects the PMMA coated separator market.

Here are some key geopolitical factors influencing the trends in energy storage and electric vehicles:

- National security considerations around critical mineral supply chains

- International collaboration on electric vehicle infrastructure

- Renewable energy investment strategies

- Carbon emission reduction commitments

Strategic Policy Frameworks

Different regions have their own electric vehicle plans to boost the market:

- The U.S. offers big incentives for making batteries at home.

- The European Union has strict rules on emissions.

- China leads in electric cars with big investments from the government.

Looking at the big picture, energy storage trends are linked to new tech and economic strategy. Countries see advanced batteries as a key to both saving the planet and growing their economy in the green sector.

Segmentation by separator material and performance criteria

The PMMA coated separator market is key in advanced energy storage. It focuses on making special separators. These meet tough standards and improve battery performance and safety.

Key Separator Material Classifications

There are several main types of separators:

- Polyethylene-based separators: Great for high-temperature use

- Polypropylene composite separators: Have better mechanical strength

- Ceramic-coated separators: Stay stable in heat

- PMMA hybrid separators: Improve electrical insulation

Performance Evaluation Metrics

Standards set key criteria for separator quality:

- Thermal stability

- Mechanical strength

- Electrical resistance

- Porosity

- Chemical compatibility

Top manufacturers keep improving their separators. They aim to meet the high needs of electric vehicles and renewable energy.

Key applications in lithium-ion batteries, EVs, and renewable energy storage

PMMA coated separators are changing the game in energy storage. They are key in making lithium-ion batteries better for electric vehicles, storing energy for the grid, and powering portable devices.

Electric Vehicle Battery Performance

In electric vehicles, PMMA coated separators make batteries work better and last longer. They tackle big problems in EV battery design by:

- Lowering the risk of internal shorts

- Boosting thermal stability

- Extending battery life

Renewable Energy Storage Solutions

PMMA coated separators also help with renewable energy storage. They make it easier to store energy from the sun and wind, making it more reliable and efficient.

| Application Area | Key Benefits | Performance Improvement |

| Electric Vehicles | Enhanced Safety | Up to 20% longer battery life |

| Grid Storage | Increased Reliability | 15% improved energy retention |

| Portable Electronics | Better Thermal Management | 10% reduced heat generation |

Emerging Technology Integration

PMMA coated separators are not just for today’s tech. They’re being considered for next-generation energy storage systems, including new electric vehicles and large renewable energy projects.

Regional growth in energy storage and electric vehicle sectors

The global energy storage sector is changing fast. New markets are leading to big advances in battery tech. This is changing how electric vehicles are developed around the world.

Each region is moving forward in its own way in the energy storage field:

- North America is at the forefront of tech innovation

- Asia-Pacific is the leader in making products

- Europe is focusing on green infrastructure

Market Dynamics Across Continents

Different parts of the world are showing unique chances for PMMA coated separator makers. Each area has its own way of investing and using tech.

Emerging Market Opportunities

Fast-growing regions are boosting their energy storage. Strategic investments in batteries are opening up new chances for growth. This is especially true in countries aiming for a green energy future.

The future of energy storage depends on understanding local tech systems and creating new solutions.

U.S. push for electric vehicles driving demand for advanced separators

The U.S. electric vehicle market is growing fast. This growth is creating a big need for advanced separators in battery production. Federal and state policies are helping make electric cars more common, boosting innovation in battery tech.

Investments in advanced battery separator technologies are key. The U.S. government is offering incentives to help make batteries in the U.S. They know how important good separators are for electric cars.

Strategic Market Developments

- Increased federal funding for battery research and development

- Tax credits for electric vehicle manufacturers

- Expansion of domestic battery production facilities

Companies are working hard to keep up with the demand for better separators. They’re focusing on making separators that work better and last longer. This is changing the U.S. electric car supply chain a lot.

The future of electric mobility depends on breakthrough separator technologies that enhance battery performance and reliability.

| Market Segment | Key Impact |

| Electric Vehicle Separators | Enhanced Battery Efficiency |

| Domestic Battery Production | Job Creation and Innovation |

The U.S. electric vehicle market is going through a big change. This change is making the U.S. a leader in battery innovation. Domestic manufacturers are at the center of this exciting shift.

China’s rapid EV adoption fueling separator market growth

The China EV market is a key driver of global separator market growth. China leads in electric vehicle production and battery tech thanks to government support and innovation.

China’s focus on making separators at home has changed the industry. Key points include:

- Big investments in making battery separators

- Strong national policies for electric cars

- Big efforts in new separator tech

Economic and Technological Drivers

The Chinese government has launched big programs to grow the EV market. These efforts have built a strong support system for separators, with many local makers increasing production.

Chinese tech in PMMA-coated separators is really advanced. They’re making separators that make batteries work better, safer, and last longer.

Market Competitive Landscape

Chinese companies are rapidly emerging as major competitors in separator production. They are recognized for their innovative approach and cost-effective solutions, which have positioned them as leaders in the global battery separator market.

China’s drive for electric vehicle technology is reshaping the global energy storage landscape.

Japan’s leadership in energy storage technologies and battery efficiency

Japan is a global leader in energy storage technologies. It has made significant progress in battery efficiency and separator technology, positioning itself as a key player in the global energy storage market.

Japanese companies leading the way

Japanese companies are at the forefront of separator technology, which plays a crucial role in enhancing battery performance. By developing advanced separators, these companies are able to create batteries that not only have higher energy densities but also possess improved safety features.

Collaboration with research groups

To further enhance their capabilities, Japanese companies actively collaborate with leading research institutions and academic organizations. This partnership allows them to stay updated with the latest advancements in energy storage and incorporate innovative solutions into their battery designs.

Key Innovations in Battery Technology

- Advanced PMMA-coated separators with improved thermal stability

- Nano-engineered materials for enhanced battery efficiency

- High-performance lithium-ion battery designs

Japan’s work in energy storage is key to new battery tech. They focus on making separators that work well in tough conditions.

“Japan continues to lead the world in battery technology innovation, setting new standards for energy storage efficiency.” – Energy Research Institute

Strategic Research and Development

Top Japanese companies spend a lot on research to make batteries better. They aim to:

- Make energy storage solutions smaller and more powerful

- Lower production costs

- Improve battery safety

Japan’s dedication to separator technology shows its important role in energy storage and electric vehicles.

Future trends in separator materials and battery technologies

The world of battery technology is changing fast. New separator materials are key to better energy storage. Scientists are working on next-generation batteries to improve performance.

New battery tech trends are changing how we store energy. New separator materials are being developed. They have exciting features like better thermal stability and ion conductivity.

- Enhanced thermal stability

- Improved ion conductivity

- Increased mechanical strength

- Advanced composite structures

Emerging Separator Technologies

Researchers are working on advanced separator materials. They aim to make batteries work better in tough conditions. Ceramic-coated and polymer composites are getting a lot of attention.

Material Innovation Strategies

Scientists are pushing the limits of battery materials. They’re trying new things like nano-ceramic separators and multi-layer composites. They’re also looking into self-healing and temperature-sensitive materials.

These new technologies could change how we store energy. They aim to solve big problems in battery performance and safety.

The future of battery technology lies in developing separator materials that can unlock unprecedented levels of efficiency and safety.

Leading competitors in the PMMA-coated separator market

The PMMA-coated separator market is very competitive. Top manufacturers are always trying to be the best. They work hard to make their products stand out and get more market share.

Some big names in the PMMA-coated separator world are really important. They are known for their special ways of making products and how they position themselves in the market.

-

Yunnan Energy New Material Co., Ltd. – China

-

Putailai New Energy Technology Co., Ltd. – China

-

Yingbolai Technology – China

-

BoSheng Advanced Materials – China

-

Gellec New Energy – China

-

Shanghai Energy Materials – China

-

Tianjin New Energy – China

-

Anhui Advanced Materials – China

-

Jiangsu New Energy Development Co., Ltd. – China

-

Hubei Energy New Material Co., Ltd. – China

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global PMMA Coated Separator Market Report |

| Base Year | 2024 |

| Segment by Type | · Single Sided Coated

· Double Sided Coated |

| Segment by Application | · Consumer Batteries

· Power Batteries |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The PMMA coated separator market is set to grow a lot in the next few years. This growth comes from more electric vehicles and energy storage tech. Experts say the market will see big growth in the US, China, and Japan.

But, the market faces challenges like changing material costs and complex making processes. To tackle these, companies are investing in new research and tech. Breakthroughs in battery materials will shape the market’s future.

Big names in battery tech are making key investments to boost growth. The rise in renewable energy and electric cars will open up new chances for PMMA separator makers. The market is expected to grow at a steady rate, showing its strong potential.

Top players are working to make their products better, cheaper, and more eco-friendly. They aim to stay ahead by improving their battery separators. This will help them meet the changing needs of the industry.

Global PMMA Coated Separator Market Report(Can Read by Free sample)–Table of Contents

Chapter 1:PMMA Coated Separator Market Analysis Overview

- Competitive Forces Analysis(Porter’s Five Forces)

- Strategic Growth Assessment(Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- PMMA Coated Separator Market Segmentation Overview

Chapter 2:Competitive Landscape

- GlobalPMMA Coated Separator Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3:PMMA Coated Separator Market Segmentation Analysis

- Key Data and Visual Insights

- Trends,Growth Rates,and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4:Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic,Demographic,and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5:PMMA Coated Separator Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends,Challenges,and Opportunities

Chapter 6:Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7:PMMA Coated Separator Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8:Key Findings and Recommendations

- Summary of PMMA Coated Separator Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is a PMMA Coated Separator?

A PMMA Coated Separator is a special material for lithium-ion batteries. It boosts battery safety, thermal stability, and efficiency. The coating protects the battery’s components and improves its performance.

Why is the PMMA Coated Separator Market projected to reach $1.19 billion by 2025?

The market is growing fast because of the need for better battery tech. This is especially true for electric cars, gadgets, and green energy storage. Advances in tech, green energy support, and the shift to electric vehicles are driving this growth.

What are the primary applications of PMMA Coated Separators?

PMMA Coated Separators are crucial components in lithium-ion batteries used for various applications such as:

- Electric vehicles (EVs)

- Consumer electronics (gadgets)

- Renewable energy systems (green energy)

These separators play a vital role in enhancing the performance and safety of batteries, making them more efficient and durable across multiple industries.

How do PMMA Coated Separators improve battery performance?

PMMA Coated Separators enhance battery performance in several ways:

- Thermal Stability: They help batteries withstand high temperatures without degrading.

- Safety: The coating prevents short circuits, reducing the risk of fires or explosions.

- Strength: PMMA adds durability to the separators, making them less prone to damage.

- Ion Flow: The special coating promotes better movement of ions, leading to improved efficiency.

These features combined result in safer, more efficient, and longer-lasting batteries.

Which countries are leading in PMMA Coated Separator technology?

The U.S., China, and Japan lead in PMMA Coated Separator tech. They drive innovation with policies, research, and strong electric car and battery industries.

What challenges does the PMMA Coated Separator Market face?

Challenges include high costs, complex manufacturing processes, technological obstacles, and the need for constant innovation. To address these challenges, manufacturers are focusing on research and development efforts.

What are the future trends in PMMA Coated Separator technology?

Future trends include better coatings, new materials, and improved performance. The aim is to make battery separators more efficient, safe, and eco-friendly.

How is the electric vehicle industry influencing the PMMA Coated Separator Market?

The rapid growth of the electric car market is driving up demand for PMMA Coated Separators. As EV manufacturers strive for improved batteries, the requirement for advanced separators significantly increases.

What role do government policies play in the PMMA Coated Separator Market?

Government support for clean energy, EVs, and battery technology is crucial for the growth of the market. Incentives, funding, and regulations are helping to accelerate the adoption of new separator technologies.

Are there emerging markets for PMMA Coated Separators?

Yes, new markets include green energy storage, grid solutions, telecom, aerospace, and advanced gadgets. As battery technology advances, new uses for PMMA Coated Separators keep appearing.