Overrunning Alternator Pulley Market to Reach $425 Million by 2025: Automotive Demand in the U.S., Germany, and Japan

Explore the comprehensive analysis of the 2025 Overrunning Alternator Pulley Market, focusing on fuel efficiency, engine protection, and sustainability in automotive technology. This in-depth examination covers market growth projections, technological advancements, and the increasing importance of OAPs and OADs in modern vehicles, making it essential reading for industry professionals and stakeholders interested in automotive innovation and market trends.

- Last Updated:

Overrunning Alternator Pulley Market Outlook for Q1 and Q2 2025

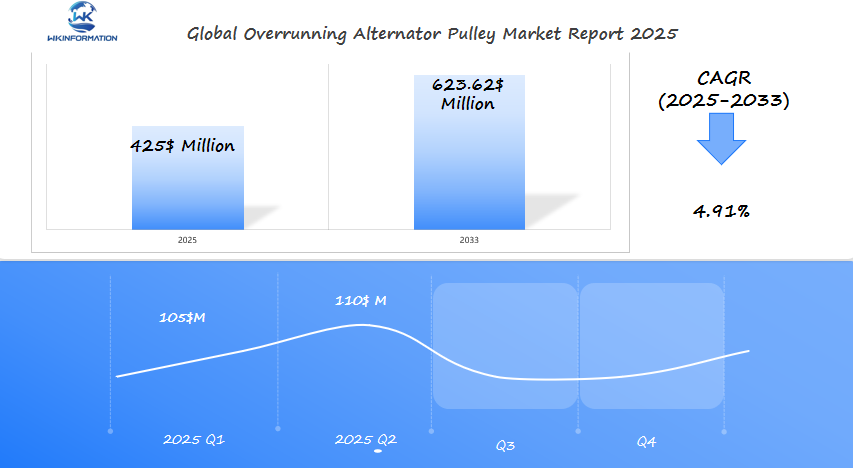

The Overrunning Alternator Pulley market is projected to reach $425 million in 2025, with a CAGR of 4.91% from 2025 to 2033. In Q1 2025, the market is expected to be valued at $105 million, driven by the ongoing demand for advanced automotive components in the U.S., Germany, and Japan. Overrunning alternator pulleys play a crucial role in improving the fuel efficiency and performance of automotive electrical systems.

By Q2 2025, the market is expected to grow to $110 million, with Japan and Germany continuing to be key drivers due to their strong automotive manufacturing sectors. The U.S. market is also growing, fueled by increased production of energy-efficient vehicles. Technological improvements in pulley designs, reducing noise and wear, will further support market growth.

Key Takeaways

- Growing automotive demand in the U.S., Germany, and Japan drives market growth.

- Increasing need for efficient alternator systems fuels market expansion.

- Advancements in automotive technology contribute to market development.

- Market forecast indicates a promising outlook by 2025.

- Rising demand for high-performance alternator pulleys.

Overrunning Alternator Pulley upstream and downstream industry chain analysis

Understanding the industry chain analysis of Overrunning Alternator Pulley is crucial for stakeholders. The production of Overrunning Alternator Pulleys involves a complex process that relies heavily on the upstream industry chain.

Upstream industry chain analysis

The upstream industry chain analysis involves examining the raw materials used in the production of Overrunning Alternator Pulleys. Raw material sourcing and supplier dynamics play a critical role in determining the quality and cost of the final product.

Raw material sourcing and supplier dynamics

The quality of raw materials used in the production of Overrunning Alternator Pulleys significantly impacts the performance and durability of the final product. Suppliers of raw materials, such as steel and aluminum, must be carefully selected to ensure a stable supply chain.

The dynamics of supplier relationships also influence the cost of raw materials. Strong relationships with suppliers can lead to better pricing and more reliable deliveries.

By understanding the upstream industry chain analysis, manufacturers can better navigate the complexities of raw material sourcing and supplier dynamics, ultimately leading to improved product quality and reduced costs.

Automotive industry growth driving demand for overrunning pulleys

The growth of the automotive industry is significantly influencing the demand for overrunning alternator pulleys. As the industry continues to evolve, trends in automotive production are playing a crucial role in shaping the demand for these pulleys.

Trends in automotive production and their impact on pulley demand

One of the significant trends in automotive production is the shift towards electric and hybrid vehicles. This shift is driven by increasing consumer demand for fuel-efficient and environmentally friendly vehicles. As a result, manufacturers are adapting their production lines to meet this new demand, which in turn affects the demand for overrunning alternator pulleys.

The role of overrunning alternator pulleys in modern vehicles

Overrunning alternator pulleys are critical components in modern vehicles, particularly in alternator systems. They help in reducing belt tension and improving the overall efficiency of the alternator. With the increasing production of electric and hybrid vehicles, the demand for these pulleys is expected to rise.

Other factors influencing pulley demand

The trend towards more complex automotive systems, including advanced alternator systems, is also driving the demand for high-quality overrunning pulleys. Manufacturers are focusing on producing pulleys that can withstand the stresses of modern automotive systems, leading to innovations in pulley design and materials.

| Trend | Impact on Pulley Demand |

| Shift to electric and hybrid vehicles | Increased demand for overrunning alternator pulleys |

| Advancements in automotive systems | Higher demand for high-quality pulleys |

| Increasing production in emerging markets | Growing demand for pulleys in new markets |

As the automotive industry continues to grow, understanding these trends and their impact on the demand for overrunning alternator pulleys is crucial for manufacturers. By adapting to these trends, manufacturers can ensure they meet the evolving needs of the industry.

Challenges in pulley design, manufacturing, and market competition

The design and manufacturing of Overrunning Alternator Pulleys pose significant challenges due to technological and material constraints.

One of the primary challenges in pulley design is ensuring that the product can withstand the stresses and strains of continuous operation. This requires careful consideration of factors such as material selection, design geometry, and manufacturing processes.

Design and manufacturing challenges

Manufacturing Overrunning Alternator Pulleys involves several complex processes, including machining, assembly, and testing. Each of these processes presents its own set of challenges, from maintaining precise tolerances to ensuring the quality of the final product.

To overcome these challenges, manufacturers must invest in advanced technologies and techniques, such as computer-aided design (CAD) software and precision machining tools.

Technological and material challenges

The choice of materials for Overrunning Alternator Pulleys is critical, as it directly affects the product’s performance, durability, and cost. Materials must be carefully selected to balance these competing factors.

Technological advancements, such as the development of new materials and manufacturing processes, can also play a crucial role in addressing the challenges faced by pulley manufacturers.

The market for Overrunning Alternator Pulleys is highly competitive, with numerous players competing for market share. To remain competitive, companies must focus on innovation, quality, and customer service.

By investing in research and development, improving manufacturing processes, and providing excellent customer support, companies can differentiate themselves and succeed in this challenging market.

Geopolitical Analysis of Automotive Manufacturing Trends and Supply Chains

The automotive industry’s supply chain is heavily influenced by geopolitical tensions and trade agreements. As the global landscape continues to evolve, understanding these geopolitical factors becomes increasingly important for companies operating within the automotive sector.

Geopolitical analysis involves examining the complex interplay of political, economic, and social factors that impact the automotive manufacturing industry. This includes analyzing trade policies, tariffs, and other regulatory measures that can affect the flow of goods and materials across borders.

Regional automotive manufacturing trends

Regional trends in automotive manufacturing are shaped by a combination of local market conditions, government policies, and global economic factors. For instance, the rise of electric vehicles in certain regions is driven by government incentives and investments in charging infrastructure.

In regions with significant automotive manufacturing hubs, such as North America, Europe, and Asia, trends vary based on local consumer demand, regulatory environments, and the presence of key industry players. Understanding these regional trends is crucial for manufacturers looking to optimize their supply chains and stay competitive.

| Region | Key Trends | Impact on Supply Chain |

| North America | Rise of electric and hybrid vehicles, increased focus on autonomous driving | Greater demand for advanced battery technologies and components |

| Europe | Stringent emissions regulations, growth of electric vehicle adoption | Need for compliance with strict environmental standards,increaseddemandforEVcomponents |

| Asia | Rapidexpansionofautomotivemanufacturingcapacity,growthinemergingmarkets | Opportunitiesforsupplierstotier1andtier2manufacturers,increasedcompetition |

The geopolitical landscape continues to shape the automotive manufacturing industry, influencing everything from supply chain logistics to the competitive dynamics among manufacturers. As the industry evolves, companies that effectively navigate these geopolitical factors will be better positioned for success.

Segmentation by pulley design, size, and material type

The Overrunning Alternator Pulley market is diverse, with various designs, sizes, and materials being utilized. Understanding the different segments is crucial for manufacturers to cater to diverse customer needs and stay competitive.

Pulley design variations and their applications

Pulley design plays a significant role in determining the efficiency and effectiveness of the alternator system. Different designs are suited for various applications, such as high-performance vehicles or standard passenger cars. For instance, a one-way clutch pulley design is often used in high-performance vehicles to improve alternator efficiency.

The design variations also impact the overall system reliability and durability. Manufacturers must consider factors such as friction reduction, noise minimization, and heat dissipation when designing pulleys.

Material types used in pulley manufacturing

The choice of material for pulley manufacturing is critical, as it affects the pulley’s performance, durability, and cost. Common materials used include aluminum, steel, and various composite materials.

| Material Type | Characteristics | Applications |

| Aluminum | Lightweight, corrosion-resistant | High-performance vehicles |

| Steel | High strength, durability | Heavy-duty applications |

| Composite Materials | High strength-to-weight ratio, corrosion-resistant | Specialized applications |

By understanding the different material types and their characteristics, manufacturers can select the most suitable material for their pulley designs, ensuring optimal performance and customer satisfaction.

Key applications in automotive alternators, energy recovery, and vehicle efficiency

Overrunning Alternator Pulleys play a vital role in modern automotive alternators, enabling efficient energy recovery and improved vehicle performance.

The use of Overrunning Alternator Pulleys in automotive alternators has become increasingly important as the demand for fuel-efficient vehicles continues to grow. These pulleys help to optimize alternator performance, reduce energy losses, and promote overall vehicle efficiency.

Role of Overrunning Alternator Pulleys in automotive alternators

Overrunning Alternator Pulleys are designed to decouple the alternator from the engine’s crankshaft during certain operating conditions, allowing the alternator to freewheel and reduce the load on the engine. This results in improved fuel efficiency and reduced emissions.

The benefits of using Overrunning Alternator Pulleys in automotive alternators include:

- Improved fuel efficiency

- Reduced emissions

- Increased alternator lifespan

- Enhanced overall vehicle performance

A comparison of traditional alternator pulleys and Overrunning Alternator Pulleys is shown in the table below:

| Pulley Type | Fuel Efficiency | Emissions | Alternator Lifespan |

| Traditional Alternator Pulley | Lower | Higher | Shorter |

| Overrunning Alternator Pulley | Higher | Lower | Longer |

Regional growth patterns and demand in automotive markets

The demand for Overrunning Alternator Pulleys varies significantly across regions, driven by local automotive manufacturing trends. Different regions exhibit unique growth patterns in their automotive markets, influencing the demand for these pulleys.

Regional demand analysis is crucial for manufacturers to identify opportunities and challenges in various markets. By understanding the regional growth patterns, manufacturers can tailor their production and distribution strategies to meet the specific needs of each market.

Regional demand analysis

Regional demand for Overrunning Alternator Pulleys is influenced by factors such as local automotive production, consumer preferences, and regulatory environments. For instance, regions with a high demand for fuel-efficient vehicles may drive the demand for advanced alternator pulleys.

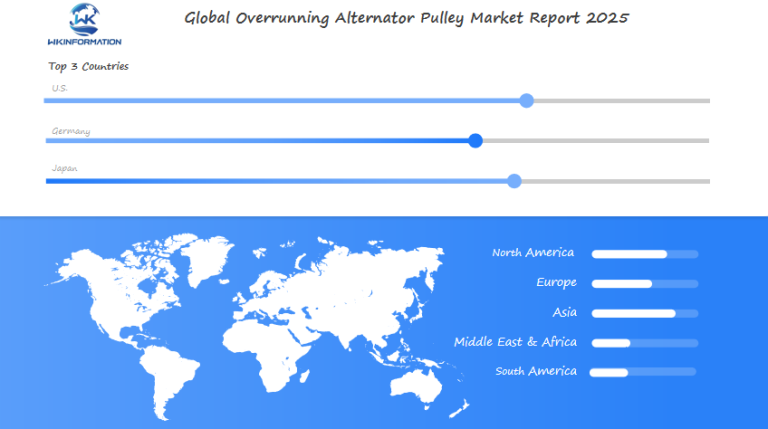

In regions with a strong automotive manufacturing presence, such as the United States, Germany, and Japan, the demand for Overrunning Alternator Pulleys is likely to be higher due to the presence of major automotive manufacturers.

By analyzing regional demand patterns, manufacturers can identify emerging trends and opportunities in the automotive market. This enables them to make informed decisions about production, investment, and market expansion.

U.S. automotive industry’s focus on fuel efficiency and alternator systems

The U.S. automotive industry is driving innovations in alternator systems with its focus on fuel efficiency. As the industry continues to prioritize fuel efficiency, the demand for advanced alternator systems is increasing.

Impact of fuel efficiency standards on alternator systems

Fuel efficiency standards have a significant impact on alternator systems. With stricter regulations in place, manufacturers are seeking ways to improve the efficiency of their alternator systems.

One approach to achieving this is by using Overrunning Alternator Pulleys (OAPs), which are essential in minimizing energy losses and enhancing overall system efficiency.

Impact of fuel efficiency standards on alternator systems

Fuel efficiency standards have a direct impact on the design and functionality of alternator systems. As manufacturers strive to meet these standards, they are turning to innovative solutions like OAPs to improve efficiency and reduce energy losses.

A detailed analysis of the U.S. automotive industry’s focus on fuel efficiency reveals a growing trend towards more efficient alternator systems. The use of OAPs is becoming increasingly popular as manufacturers look for ways to improve fuel efficiency and reduce emissions.

| Alternator System Component Impact on Fuel Efficiency Overrunning Alternator Pulley (OAP) | Reduces energy losses, improves overall system efficiency |

| Alternator Belt | Improves power transmission, reduces wear and tear |

| Tensioner | Maintains optimal belt tension, reduces energy losses |

The U.S. automotive industry’s focus on fuel efficiency is driving the demand for advanced alternator systems, including OAPs. As the industry continues to evolve, we can expect to see even more innovative solutions emerge.

Germany's leadership in automotive engineering and electric vehicle adoption

Germany, known for its expertise in automotive engineering, is making significant progress in electric vehicle adoption. The country’s robust automotive industry is driving innovation, focusing on advanced technologies that enhance vehicle efficiency and minimize environmental impact.

Advancements through collaboration

Germany’s advancements in automotive engineering are characterized by a strong emphasis on research and development. The country is home to numerous world-renowned automotive manufacturers and research institutions, which collaborate to drive innovation in electric vehicle technology.

Advancements in Automotive Engineering

Germany’s automotive engineering sector is driving advancements in electric vehicle technology, including improvements in battery technology, electric motors, and charging infrastructure. These advancements are crucial for the widespread adoption of electric vehicles.

Some of the key developments in Germany’s automotive engineering sector include:

- Advances in battery technology, enabling longer driving ranges and faster charging times.

- Innovations in electric motor design, resulting in more efficient and powerful motors.

- Improvements in charging infrastructure, making it easier for consumers to charge their vehicles on the go.

Germany automotive engineering

Germany’s leadership in automotive engineering is also driven by its strong vocational training programs and research institutions. These programs help to develop the skills and expertise needed to drive innovation in the automotive sector.

As the world continues to shift towards electric vehicles, Germany is well-positioned to remain a leader in the automotive industry. The country’s commitment to innovation and quality is expected to drive further advancements in electric vehicle technology.

Japan’s role in hybrid and electric vehicle technology integration

Japan has been a leader in hybrid and electric vehicle technology, setting an example for the global automotive industry. The country’s dedication to innovation has led to significant progress in this area, including the development of Overrunning Alternator Pulleys.

Japan’s automotive industry has played a crucial role in bringing hybrid and electric vehicle technology together. Japanese manufacturers, with their strong emphasis on research and development, have been pioneers in introducing new technologies that enhance vehicle efficiency and minimize harm to the environment.

Japan’s advancements in hybrid and electric vehicle technology

One of the key areas where Japan has made significant contributions is in the development of hybrid vehicles. Japanese automakers have been instrumental in popularizing hybrid technology, with models such as the Toyota Prius becoming synonymous with fuel efficiency. The success of these models has encouraged other manufacturers to follow suit, leading to a wider adoption of hybrid technology globally.

In addition to hybrid vehicles, Japan has also been a leader in the development of electric vehicle technology. Japanese companies have been investing heavily in the research and development of electric vehicles, with a focus on improving battery technology and reducing production costs. This has led to the introduction of a range of electric vehicles that offer improved performance and range.

The integration of hybrid and electric vehicle technology has also had an impact on the development of Overrunning Alternator Pulleys. As vehicles become more efficient and environmentally friendly, the demand for components that can support these technologies is increasing. Overrunning Alternator Pulleys play a critical role in this context, as they help to improve the efficiency of alternator systems and reduce wear on engine components.

| Technology | Impact on Vehicle Efficiency | Environmental Benefits |

| Hybrid Technology | Improved fuel efficiency | Reduced emissions |

| Electric Vehicle Technology | Zero tailpipe emissions | Reduced dependence on fossil fuels |

Technological advancements in pulley systems and their impact on vehicle efficiency

Pulley systems have undergone significant changes in recent years, driven by the need for improved vehicle efficiency. The increasing demand for fuel-efficient vehicles has led to innovations in pulley design and materials, resulting in better performance and lower energy consumption.

Innovations in Pulley System Design and Materials

One of the key areas of innovation in pulley systems is the development of advanced materials and designs. For instance, the use of lightweight materials such as aluminum and titanium has enabled the creation of pulleys that are not only stronger but also lighter, contributing to overall vehicle weight reduction and improved fuel efficiency.

Another significant innovation is the development of one-way clutch technology in Overrunning Alternator Pulleys (OAPs). This technology allows the alternator to freewheel when the engine is under high load, reducing the load on the engine and resulting in improved fuel efficiency and reduced emissions.

The design of modern pulley systems also incorporates advanced technologies such as precision engineering and computer-aided design (CAD). These technologies enable the creation of complex pulley designs that are optimized for specific applications, leading to improved performance and efficiency.

Impact on Vehicle Efficiency

The technological advancements in pulley systems have a direct impact on vehicle efficiency. By reducing energy consumption and improving performance, these innovations contribute to a more sustainable and environmentally friendly automotive industry.

- Improved fuel efficiency

- Reduced emissions

- Enhanced performance

As the demand for fuel-efficient vehicles continues to grow, the importance of technological advancements in pulley systems will only continue to increase. As manufacturers strive to meet increasingly stringent emissions regulations, innovations in pulley design and materials will play a critical role in shaping the future of the automotive industry.

Leading players in the overrunning alternator pulley market

- SKF — Gothenburg, Sweden

- Schaeffler — Herzogenaurach, Germany

- Continental — Hanover, Germany

- Ferdinand Bilstein — Ennepetal, Germany

- NEW VIS SRL — Milan, Italy

- Dayco — Troy, USA

- Gates — Denver, USA

- GMB — Yokohama, Japan

- Gaido — Turin, Italy

- Kamoka — Bucharest, Romania

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Overrunning Alternator Pulley Market Report |

| Base Year | 2024 |

| Segment by Type | · Cast Iron

· Aluminium Alloy · Others |

| Segment by Application | · OEM

· Aftermarket |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Overrunning Alternator Pulley market is about to experience significant growth, driven by increasing demand from the automotive sector in the U.S., Germany, and Japan. As technological advancements continue to shape the industry, the future outlook for this market is promising.

Emerging Trends and Opportunities

The automotive industry is currently prioritizing fuel efficiency and alternator systems. In this competitive landscape, companies that adapt to changing trends and customer needs are more likely to succeed. One key area that will significantly impact the market’s future is the innovation of pulley system design and materials.

As the market continues to evolve, leading players are expected to drive growth through strategic innovations and expansions. The Overrunning Alternator Pulley market has a promising future ahead, with potential opportunities for growth and development in the years to come.

Global Overrunning Alternator Pulley Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Overrunning Alternator Pulley Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Overrunning Alternator PulleyMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Overrunning Alternator Pulleyplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Overrunning Alternator Pulley Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Overrunning Alternator Pulley Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Overrunning Alternator Pulley Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofOverrunning Alternator PulleyMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is an Overrunning Alternator Pulley?

An Overrunning Alternator Pulley is a component used in automotive alternators to improve efficiency and reduce wear on the alternator belt.

What is the expected growth of the Overrunning Alternator Pulley market by 2025?

The Overrunning Alternator Pulley market is expected to reach $425 million by 2025, driven by increasing automotive demand in the U.S., Germany, and Japan.

What factors influence the demand for Overrunning Alternator Pulleys?

The demand for Overrunning Alternator Pulleys is influenced by trends in automotive production, such as the shift towards electric and hybrid vehicles, as well as regional automotive manufacturing trends.

What are the challenges in designing and manufacturing Overrunning Alternator Pulleys?

The design and manufacturing of Overrunning Alternator Pulleys pose several challenges, including technological and material constraints, as well as intense market competition.

How do geopolitical factors impact the Overrunning Alternator Pulley market?

Geopolitical factors significantly influence automotive manufacturing trends and supply chains, affecting the demand for Overrunning Alternator Pulleys and the overall market landscape.

What are the key applications of Overrunning Alternator Pulleys?

Overrunning Alternator Pulleys play a critical role in automotive alternators, contributing to energy recovery and vehicle efficiency.

How do regional growth patterns affect the demand for Overrunning Alternator Pulleys?

The demand for Overrunning Alternator Pulleys varies across different regions, influenced by local automotive markets and manufacturing trends.

How do fuel efficiency standards affect alternator systems?

The U.S. automotive industry’s focus on improving fuel efficiency has a direct impact on the design and functionality of alternator systems, including the use of Overrunning Alternator Pulleys.

How is Germany contributing to the development of Overrunning Alternator Pulleys?

Germany’s leadership in automotive engineering and electric vehicle adoption is driving the development of advanced technologies, including those related to Overrunning Alternator Pulleys.

What role is Japan playing in the development of hybrid and electric vehicle technology?

Japan has been a pioneer in hybrid and electric vehicle technology, with significant advancements in integrating these technologies into vehicles. One such advancement is the development of Overrunning Alternator Pulleys, which play a crucial role in improving the efficiency of these vehicles.