Laboratory Furnace Market Expected to Reach $380.7 Million by 2025 with Advancements in Research and Manufacturing in the U.S., Germany, and Japan

The laboratory furnace market is experiencing consistent growth due to increasing research and development activities across various industries. This market is driven by the need for precise temperature control in experiments, material testing, and quality control processes within the pharmaceutical, biotechnology, and materials science sectors.

- Last Updated:

Laboratory Furnace Market Outlook for Q1 and Q2 2025

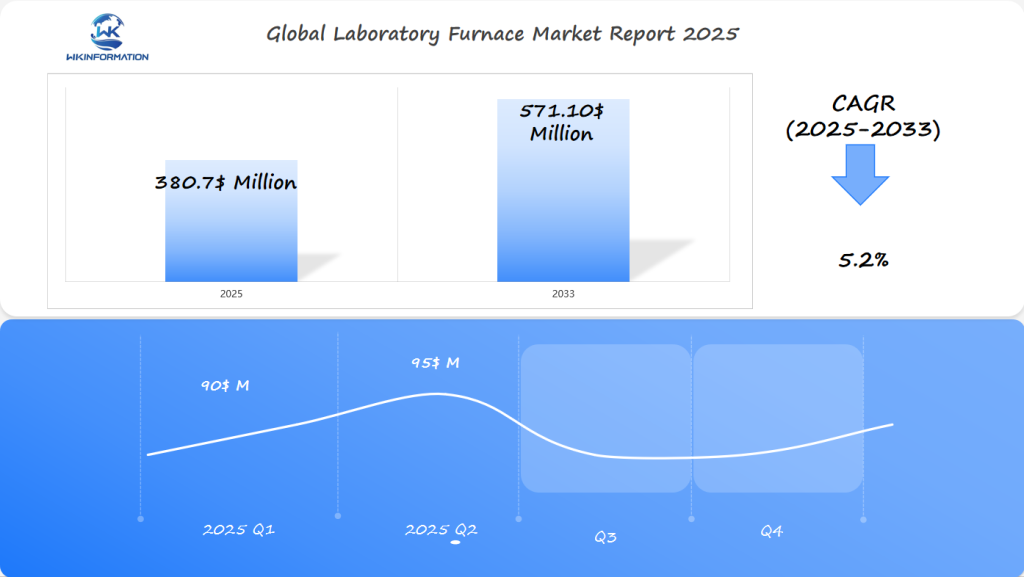

The Laboratory Furnace market is expected to reach $380.7 million in 2025, with a CAGR of 5.2% from 2025 to 2033. In Q1 2025, the market is projected to be valued at $90 million, driven by steady demand from sectors such as materials testing, electronics manufacturing, and academic research in the U.S., Germany, and Japan. Laboratory furnaces are essential for a range of high-temperature processes in research and industrial applications, and advancements in furnace technology continue to enhance their performance and efficiency.

By Q2 2025, the market is expected to grow to $95 million, with Germany and Japan being key contributors due to their strong emphasis on high-precision industrial and research technologies. The U.S. market will continue to see growth from sectors such as the automotive and aerospace industries, where high-temperature testing is critical. Increasing investment in advanced material sciences and research technologies will further drive demand.

Laboratory Furnace Upstream and Downstream Industry Chain Analysis

The laboratory furnace market is a complex web of industries. Raw materials are key to the quality and performance of furnaces.

Upstream Industry Components

Upstream industry components include:

- High-grade metal alloys

- Ceramic insulation materials

- Advanced heating elements

- Precision control systems

Downstream industries use laboratory furnaces in many areas. This creates a strong supply chain. Research labs, materials science labs, and manufacturing facilities need these systems for innovation.

“The intricate relationship between upstream suppliers and downstream users defines the laboratory furnace market’s dynamic landscape.” – Manufacturing Technology Research Institute

Key Downstream Applications

Key downstream applications include:

- Advanced materials research

- Semiconductor manufacturing

- Pharmaceutical development

- Metallurgical testing

The supply chain for laboratory furnaces needs careful engineering. Manufacturers must find the right parts to work well in different places.

Strategic partnerships between raw material suppliers and end-users lead to better furnace designs and functions.

Technological advancements driving demand for laboratory furnaces

The world of laboratory furnaces is changing fast thanks to new tech. Now, we need furnaces that are super precise and efficient. This is key for scientists and engineers who need top-notch heating tools.

Some big changes in laboratory furnaces include:

- Advanced temperature control systems with microprocessor-based controllers

- Smart automation for steady results

- Better heat distribution with new heating element designs

- Real-time monitoring and digital data logging

Today’s furnaces use smart sensors for exact control. This lets scientists keep temperatures stable to just a fraction of a degree. This is vital for precise experiments and testing materials.

Energy saving is also a big deal now. Makers are making furnaces that lose less heat and use less power. These changes cut costs and help the environment too.

Technological breakthroughs are turning laboratory furnaces into smart, data-rich tools for research.

New materials, digital tech, and engineering are making furnaces do more. This opens up new chances in science and industry.

Challenges in energy consumption, precision, and material handling

Laboratory furnaces face big challenges that affect their performance and efficiency. Saving energy is a top priority for researchers and makers. They want to cut costs and lessen harm to the environment.

Handling materials is a big problem in laboratory furnace tech. Scientists must deal with tough needs for exact temperature control and careful sample care. The complex nature of material handling needs smart solutions to avoid contamination and boost experiment accuracy.

- Temperature precision requires advanced thermal control mechanisms

- Energy consumption limits long-duration research experiments

- Material integrity depends on consistent heating environments

Today’s laboratory furnace challenges touch on many technical areas. Makers are working on new ways to tackle these big issues with advanced engineering.

| Challenge Category | Current Impact | Potential Solutions |

| Energy Efficiency | High operational costs | Improved thermal insulation |

| Temperature Precision | Experimental variability | Advanced sensor technologies |

| Material Handling | Sample contamination risks | Specialized containment systems |

Research places keep investing in the latest furnace tech to tackle these key issues. By focusing on saving energy, improving temperature control, and advanced material handling, makers are expanding what scientific equipment can do.

Geopolitical factors affecting global laboratory furnace production and trade

The global trade of laboratory furnaces is shaped by complex geopolitical factors. These factors impact how international markets work. Governments and regulatory bodies play a big role in setting the stage for laboratory equipment production and distribution.

Key geopolitical influences on the laboratory furnace market

Key geopolitical influences on the laboratory furnace market include:

- Trade regulations that restrict or enable cross-border equipment transfers

- International sanctions affecting technology exchange

- Research collaboration agreements between nations

- Export control policies for specialized scientific equipment

Emerging economies are changing the international market for laboratory furnaces. They do this through strategic investments in research infrastructure. Technological capabilities are a big driver of geopolitical positioning. Nations compete to lead in advanced manufacturing technologies.

Now, sophisticated trade regulations require manufacturers to navigate complex compliance frameworks. Countries like the United States, Germany, and Japan have strict policies. These policies directly affect global trade of laboratory furnaces, offering both challenges and opportunities for manufacturers.

“Geopolitical dynamics are transforming the laboratory equipment market faster than ever before” – Global Scientific Equipment Report, 2023

The global trade is interconnected, meaning political relationships, economic policies, and technological restrictions keep changing the laboratory furnace production landscape. Manufacturers need to stay agile and responsive to these changing geopolitical environments.

Segmentation analysis: Furnace types and temperature ranges

The laboratory furnace market is complex, with many product categories and temperature ranges. Researchers and manufacturers use different furnace types for their needs.

Diverse furnace types are key in advanced research and manufacturing. The main types of laboratory furnaces are:

- Muffle Furnaces: Ideal for high-temperature material testing

- Tube Furnaces: Perfect for precise chemical reactions

- Vacuum Furnaces: Essential for sensitive material processing

- Box Furnaces: Versatile for multiple research applications

Temperature ranges greatly affect furnace functionality and research capabilities. Scientists choose furnace types based on specific temperature needs:

| Furnace Type | Temperature Range | Primary Applications |

| Low-Temperature Furnaces | 50-500°C | Biological research, pharmaceutical testing |

| Mid-Temperature Furnaces | 500-1000°C | Materials science, ceramic processing |

| High-Temperature Furnaces | 1000-1800°C | Metallurgy, semiconductor manufacturing |

Market segmentation shows unique opportunities for specialized furnace technologies. Manufacturers keep developing new solutions to meet emerging research challenges in different scientific fields.

Key applications in research, materials testing, and manufacturing processes

Laboratory furnaces are vital in many fields. They help scientists and engineers in their work. These devices let them study materials, create new technologies, and make production better.

These furnaces are used in many ways:

- Materials Science: They help researchers understand how materials change at high temperatures.

- Electronics Manufacturing: They are key for making semiconductors and microchips.

- Pharmaceutical Research: They aid in drug development and chemical synthesis.

- Ceramics and Metallurgy: They are essential for studying material changes and creating new materials.

Materials testing needs precise temperature control. Modern furnaces can reach up to 1,800°C. This lets researchers study materials in detail.

Manufacturing also relies on these furnaces. They help test product quality, material strength, and new technologies. This is important in aerospace, automotive, and renewable energy.

Laboratory furnaces are a key link between scientific research and industrial innovation.

Regional growth trends in laboratory furnace markets

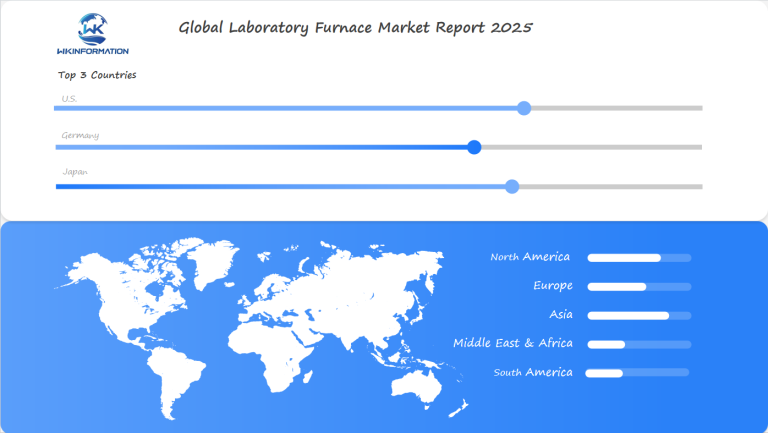

The global laboratory furnace market is growing fast in different parts of the world. East Asia is leading the way, thanks to its fast industrial growth in fields like pharmaceuticals, metallurgy, and research. This growth is fueled by remarkable trends.

Unique market traits by region

Each region has its own unique traits in the market:

- North America is known for its high-precision equipment.

- East Asia quickly adopts new technologies.

- European markets focus on specialized research.

Key industries in each region

Different industries play big roles in each region:

- Germany focuses on pharmaceutical and biotechnology research.

- Japan is all about high-temperature furnaces for semiconductors.

These areas help grow the market and bring in new technologies.

Growth potential in emerging markets

Emerging markets like India are also growing fast, with a 4.9% CAGR expected. Research centers and manufacturing are investing in new furnace technologies. This shows great promise for these markets in the future.

U.S. Market Demand for High-Precision Furnaces in Research Institutions

The U.S. market for high-precision furnaces has grown a lot lately. This growth comes from more money for research and new tech in labs. These furnaces are key for top science work in many fields.

Factors Driving Growth

- More money for research from the government

- More complex materials science tests

- Need for better temperature control

- New tech in research

There’s a big push for better furnace tech in the U.S. Labs want furnaces that:

- Keep temperature even

- Manage heat well

- Have smart control systems

- Work with many research tasks

| Research Sector | Furnace Demand | Primary Applications |

| Materials Science | 45% | Ceramic and metal research |

| Chemistry | 25% | Synthesis and compound analysis |

| Engineering | 20% | Semiconductor development |

| Physics | 10% | Quantum material studies |

Companies are making these furnaces better to meet lab needs. These new furnaces let scientists do more detailed and reliable tests.

The future of scientific discovery is closely tied to the continued evolution of laboratory furnace technologies.

Research institutions are leading the way in making these furnaces better in the U.S. market.

Germany's role in advanced manufacturing technologies and furnace production

Germany is a leader in advanced manufacturing, particularly in the field of laboratory furnaces. The country is renowned for its precision engineering and innovative design, making it a key player in industrial manufacturing on a global scale.

How Germany is Shaping Furnace Production with Industry 4.0

The German manufacturing sector is leveraging Industry 4.0 to revolutionize furnace production. This technological shift encompasses:

- Intelligent automation systems

- Real-time data monitoring

- Advanced material handling technologies

- Integrated quality control mechanisms

The European Impact: Germany’s Dominance in Laboratory Furnace Technology

In the European market, Germany’s impact on laboratory furnace technology is unmistakable. Companies such as ONEJOON exemplify Germany’s expertise in crafting high-quality thermal processing equipment.

| Technology Aspect | German Manufacturing Strength |

| Precision Engineering | Highest global standards |

| Energy Efficiency | Up to 75% optimization |

| Temperature Range | 200°C to 3,000°C |

Customized Solutions: How German Manufacturers are Meeting Complex Needs

German manufacturers are utilizing cutting-edge technology to develop customized furnace solutions. These tailored solutions address the requirements of intricate research and industrial applications, ensuring that Germany remains at the forefront of laboratory furnace production in Europe.

Japan's Focus on High-Temperature Furnaces for Semiconductor and Electronics Industries

Japan is a global leader in high-temperature furnaces, which are essential for manufacturing semiconductors and electronics. The country’s emphasis on precision and innovation has established it as a key player in advanced manufacturing.

Strengths of Japan’s Semiconductor Industry

Japan’s semiconductor industry is known for:

- Cutting-edge high-temperature furnace design

- Exceptional materials processing capabilities

- Rigorous quality control standards

- Continuous technological research

Japanese manufacturers have developed specialized high-temperature furnaces capable of withstanding extreme heat while delivering unparalleled precision in electronics production. These furnaces enable the creation of semiconductors with minuscule tolerances, fulfilling the global demand for smaller and more powerful devices.

Applications of Advanced Furnace Technology in Japan

The semiconductor industry in Japan leverages advanced furnace technology to:

- Produce ultra-pure semiconductor materials

- Fabricate intricate integrated circuits

- Improve product performance

- Minimize manufacturing defects

Japan’s leadership in high-temperature furnace technology for the semiconductor and electronics sectors is sustained by its technological expertise and dedication to innovation.

Innovations in energy-efficient furnace designs and their market impact

The furnace industry is changing fast, moving towards energy-saving designs. These changes are making manufacturing more sustainable. New green technologies are making a big difference, helping companies use less energy and harm the environment less.

Some of the main changes include:

- Advanced thermal insulation materials that minimize heat loss

- Smart control systems with real-time energy monitoring

- Precision heating elements that optimize power consumption

- Waste heat recovery mechanisms

Researchers and makers are working together to create better, greener ways to make things. The global industrial furnace market is expected to grow a lot because of these new technologies.

There’s a big push to use less energy and protect the environment. Companies that use green tech are getting ahead. They save money and meet tough environmental rules.

Competitive landscape in the laboratory furnace market

The laboratory furnace market is very competitive. Many key players are trying to get ahead. They use smart strategies to grab a big share of the market.

Key players:

- Thermo Fisher Scientific —— United States

- CARBOLITE GERO —— United Kingdom

- Nabertherm GmbH —— Germany

- C M Furnaces Inc. —— United States

- Across International —— United States

- Yamato Scientific Co., Ltd —— Japan

- BIO BASE —— China

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Laboratory Furnace Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The laboratory furnace market is set for big growth. A strong market forecast shows it will expand a lot in the next years. New technologies and more research investments are leading to big changes in many fields.

Growth in key regions

Places like the United States, Germany, and Japan are seeing a lot of growth. This is because of advanced manufacturing and scientific research. These areas need better thermal processing equipment.

Challenges to overcome

There are still challenges to overcome:

- Using less energy

- Making things more precise

- Creating greener furnaces that meet strict environmental rules

Opportunities for growth

Asia-Pacific markets are growing, and North America’s research is getting better. This will help the market grow even more. Smart technologies, artificial intelligence, and new materials will change how furnaces work.

Experts think there will be more money spent on top-notch laboratory furnaces. They predict a high growth rate. As industries need better thermal processing, makers must keep innovating and using less energy.

Global Laboratory Furnace Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Laboratory Furnace Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Laboratory FurnaceMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Laboratory Furnaceplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Laboratory Furnace Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Laboratory Furnace Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Laboratory Furnace Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofLaboratory FurnaceMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market value for laboratory furnaces by 2025?

The market for laboratory furnaces is set to hit $380.7 million by 2025. This growth is driven by new research and manufacturing technology.

What types of laboratory furnaces are commonly used in research and industry?

You’ll find muffle, tube, and vacuum furnaces in labs and factories. Each is made for different temperatures and tasks.

How are technological advancements impacting laboratory furnace design?

New technology brings better temperature control, energy use, and automation. This means more precise and advanced research tools.

Which industries primarily use laboratory furnaces?

Laboratory furnaces are mainly used in the following industries:

- Materials science

- Pharmaceuticals

- Electronics

- Ceramics

- Semiconductors

Each of these industries requires specific furnace technology to meet their unique needs.

What are the main challenges in laboratory furnace technology?

The main challenges in laboratory furnace technology are:

- Reducing energy consumption

- Achieving specific high temperatures accurately

- Improving material handling capabilities

How do regional markets differ in laboratory furnace production?

The U.S. focuses on precise research furnaces, Germany leads in advanced manufacturing, and Japan excels in high-temperature furnaces for semiconductors.

What factors are driving growth in the laboratory furnace market?

Growth comes from more research funding, new tech, wider industrial use, and demand for energy-saving designs.

Are there emerging trends in laboratory furnace sustainability?

Yes, manufacturers are producing more environmentally friendly furnaces. Their goal is to comply with environmental regulations and reduce expenses by consuming less energy.

How do geopolitical factors impact the laboratory furnace market?

Political elements such as trade regulations, international alliances, and domestic policies play a significant role in shaping the laboratory furnace market. These factors influence various aspects of the industry, including:

- Manufacturing: Geopolitical factors can affect the production processes and resources used in manufacturing furnaces.

- Sales: Trade rules and global partnerships can impact the distribution and sales channels for laboratory furnaces.

- Usage: Local policies may dictate how furnaces are utilized in specific regions or industries.

What temperature ranges are typical for laboratory furnaces?

Furnaces can reach from room temperature to 1800°C. This depends on the task at hand.