CNC Machine Market Expected to Reach $84.86 Billion by 2025: Key Drivers of Growth in the U.S., Germany, and China

Explore the dynamic CNC Machine Market, projected to reach $84.86 billion by 2025, with comprehensive insights into industry trends, technological innovations, and market developments across key regions including the U.S., Germany, and China.

- Last Updated:

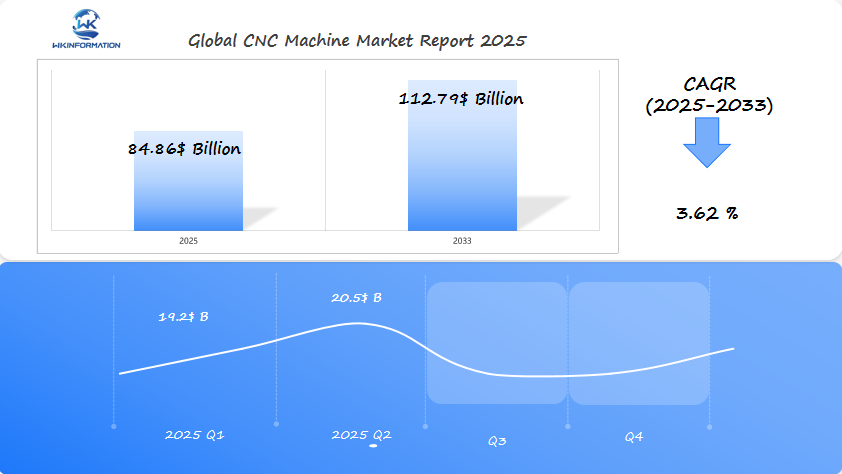

CNC Machine Market Forecast for Q1 and Q2 2025

The global CNC machine market is projected to reach $84.86 billion in 2025, with a CAGR of 3.62% through 2033. The market is expected to experience steady growth in the first half of 2025, with Q1 estimated at around $19.2 billion and Q2 showing a slight increase to approximately $20.5 billion, driven by demand across manufacturing, automotive, and aerospace industries.

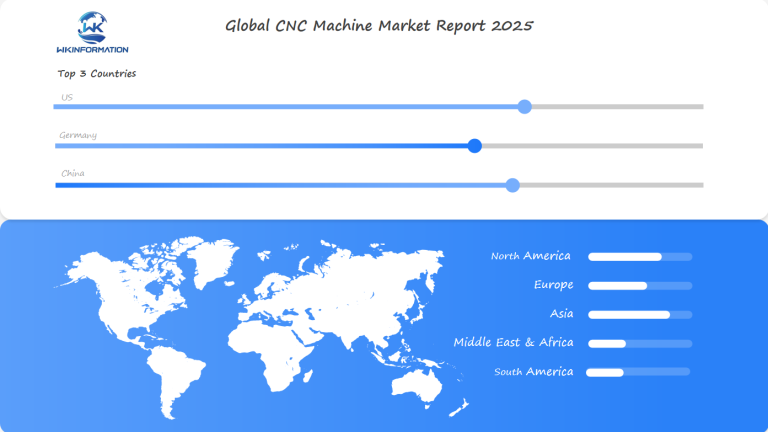

The U.S., Germany, and China are key markets for CNC machines. The U.S. remains a significant consumer, fueled by high demand in precision manufacturing, especially in aerospace and defense sectors. Germany, as a leader in industrial automation and engineering, continues to drive demand for advanced CNC machinery. China, with its large manufacturing base, plays a vital role in both production and consumption of CNC machines, making these regions crucial for understanding global CNC machine trends.

Exploring the Upstream and Downstream Factors in the CNC Machine Market

The CNC machine market is shaped by various upstream and downstream factors that influence its overall growth and dynamics. These factors can be categorized into those related to the production process (upstream) and those related to consumption and market demand (downstream).

Upstream Factors

-

Raw Material Supply

CNC machines require high-quality materials such as metals (steel, aluminum) and precision components (bearings, gears, sensors). Fluctuations in the prices or availability of these materials directly affect production costs and manufacturing timelines. -

Technological Advancements

Advances in automation, AI, and IoT have pushed the development of smarter, more efficient CNC machines. As demand for precision and automation increases, manufacturers must adapt by integrating these technologies into their machines. -

Manufacturing Process

CNC machine production involves complex, high-precision manufacturing processes. Innovations in machining, such as 5-axis machining or laser cutting, are vital for improving the efficiency and performance of CNC machines.

Downstream Factors

-

End-User Industries

The demand for CNC machines is driven by industries such as automotive, aerospace, medical devices, and electronics. For example, the automotive sector’s shift toward electric vehicles is increasing the need for specialized CNC machines that produce lighter, more complex components. -

Market Demand and Customization

Increasing demand for customization in production drives the need for flexible CNC machines capable of small-batch and on-demand manufacturing. This trend is particularly evident in industries like aerospace and medical devices, where precision and customization are crucial. -

Globalization and Emerging Markets

The expansion of manufacturing capabilities in emerging markets, especially in Asia-Pacific, has led to a rise in demand for CNC machines. Additionally, globalization has increased competition, forcing manufacturers to innovate and produce more cost-effective solutions.

Major Trends Shaping the CNC Machine Industry

The CNC machine industry is changing fast thanks to new technologies. Companies are using these innovations to make manufacturing more precise. This is happening in many different fields.

New trends in the CNC industry are changing how we make things. Artificial intelligence and machine learning are key. They help make machining smarter and more efficient.

Key Trends in the CNC Machine Industry

- Integration of AI-powered predictive maintenance systems

- Advanced robotics and automation technologies

- Real-time data analytics for enhanced productivity

New technologies are changing how we work in manufacturing. Industry 4.0 practices are making things more efficient and precise.

| Technology | Impact on CNC Machines | Market Potential |

| Machine Learning | Enhanced Predictive Maintenance | High |

| IoT Integration | Real-time Performance Monitoring | Medium-High |

| Cloud Computing | Scalable Data Management | Medium |

The digital transformation is opening up new chances for manufacturers. They can now make production better and deliver top-notch quality and precision.

Overcoming Barriers to Growth in CNC Machine Production

The CNC machine production industry is facing significant challenges to growth. These challenges require innovative solutions from within the industry. Manufacturers are confronted with complex issues that demand new technologies and improved processes.

Major Challenges in CNC Machine Production

Some major hurdles in CNC machine making are:

- High costs for new, advanced tools

- Lack of skilled workers

- Old tech becoming outdated fast

- Hard to link new tech with old systems

Strategies to Address Challenges

Top players in the field are coming up with big plans to tackle these issues. Workforce development programs are key, aiming to train CNC operators and engineers better.

Money matters are being tackled too:

- Leasing new CNC tools instead of buying

- Upgrading in steps, not all at once

- Sharing tech with others

- Getting help from government grants

Teaming up with tech partners is also a big help. Companies are working with schools and research groups. They’re making new, cheaper, and better tech solutions together.

“Innovation is the key to overcoming current manufacturing challenges” – Manufacturing Technology Insights

By fixing skill gaps, cutting costs, and pushing tech forward, CNC machines are set for growth. They’re ready to compete on a global scale.

Geopolitical Factors Affecting CNC Machine Supply Chains

Global trade tensions have changed CNC supply chains a lot in recent years. Manufacturers face complex geopolitical issues. These issues affect where they get raw materials, how they make things, and how they get them to customers.

Important geopolitical factors affecting CNC machine markets include:

- Trade restrictions between major manufacturing countries

- Technology transfer regulations

- Economic sanctions

- Regional economic partnerships

CNC machine manufacturers are getting smarter about their supply chains. They’re finding new ways to get materials and make things. This helps them avoid problems caused by market changes.

| Geopolitical Factor | Impact on CNC Supply Chains | Mitigation Strategy |

| US-China Trade Tensions | Increased tariffs on machinery components | Regional supply chain diversification |

| European Export Controls | Restricted technology transfers | Localized manufacturing investments |

| Semiconductor Shortages | Production delays | Multiple supplier agreements |

Advanced manufacturers are developing resilient strategies to navigate the complex global trade environment. By planning for possible problems and making their supply chains flexible, companies can stay ahead in the CNC machine market.

CNC Machine Market Segmentation by Type: Key Developments

The CNC machine market is always changing. New market segments and product innovations are leading the way. Manufacturers are making machines that meet specific industrial needs.

Many CNC machine types are seeing big changes:

- Milling Machines: Now have 5-axis setups for better precision

- Lathe Machines: Get better cutting accuracy with new control systems

- Grinding Machines: Use AI for predictive maintenance

- Turning Centers: Are smaller but do more

New market segments are pushing for more advanced CNC machines. Aerospace, automotive, and medical device manufacturing need better machines. These industries are driving the demand for more complex solutions.

“The future of manufacturing lies in adaptive, intelligent CNC machine technologies,” says industrial engineering expert Dr. Sarah Chen.

Product innovations are changing the game. Manufacturers are working on:

- Modular machine designs

- Better precision control systems

- More energy-efficient machines

- Smart features for connectivity

These changes show the CNC machine market is growing fast. New technologies are opening up chances in many industries.

The Role of Applications in CNC Machine Demand Growth

CNC machines have changed how we make things in many fields. The market is growing fast, with big demand from sectors looking for top tech for making things precisely.

Different industries are pushing CNC machine market growth in their own ways:

- Aerospace: Making complex parts with super accuracy

- Automotive: Creating detailed engine parts and new making systems

- Healthcare: Making special medical tools and prosthetics

- Electronics: Making tiny and detailed circuit board parts

The need for CNC machines keeps growing. Makers see how important it is to make things fast and right. New tech helps cut down on time and mistakes, making products better.

| Industry | Primary CNC Machine Applications | Market Impact |

| Aerospace | Structural component fabrication | High precision requirements |

| Automotive | Engine part manufacturing | Mass production efficiency |

| Medical | Surgical instrument production | Critical precision needs |

| Electronics | Circuit board machining | Miniaturization trends |

As tech gets better, CNC machines will help more industries grow. Companies that use the latest CNC tech will get ahead in their fields.

Regional Insights into the Global CNC Machine Market

The global CNC machine market shows big differences in technology use and growth across regions. Each area has its own special traits that influence the industry’s growth and chances.

Key regions leading the global CNC market include:

- North America: Technological innovation hub

- Europe: Advanced manufacturing standards

- Asia-Pacific: Rapid industrial expansion

- China: Emerging manufacturing powerhouse

Market analysis shows different trends in CNC machine use by region. In North America, makers focus on precision. In Asia, they aim for big production.

| Region | Market Share | Growth Rate |

| North America | 35% | 6.5% |

| Europe | 28% | 5.2% |

| Asia-Pacific | 37% | 8.3% |

The global CNC market stays strong thanks to smart investments in different areas. New tech and modern factories keep the market growing in various places.

“Regional diversity represents the true strength of the CNC machine industry” – Manufacturing Insights Report

Every region adds something special to the global CNC machine world. This creates a complex but connected market that keeps growing and innovating.

U.S. CNC Machine Market: Trends and Innovations

The US CNC market is changing American manufacturing with new technologies. These technologies bring unmatched precision and efficiency to industrial production.

Key trends driving these changes include:

- Advanced robotics integration

- Artificial intelligence optimization

- Enhanced precision manufacturing techniques

- Sustainable production methodologies

Companies are spending a lot on the latest CNC technologies to stay ahead. They’re using smart manufacturing to make production smoother and cheaper.

Important changes in American manufacturing include:

- Increased automation capabilities

- Real-time performance monitoring systems

- Sophisticated machine learning algorithms

- Modular and adaptable manufacturing platforms

“Innovation drives the future of manufacturing” – Industry Expert

Research groups and companies are working together to advance technology. This keeps the US CNC market leading in global manufacturing innovations.

Germany’s Leadership in CNC Machine Technology

The German CNC industry is a top leader in the world of making things. It’s known for its exact engineering and new ways to make things. Germany is at the top in Europe for advanced machine tech.

German makers have built a strong name by investing in new ideas. They focus on new tech innovations. This has made CNC machines much better.

- Precision engineering at the core of German manufacturing

- Substantial investments in research and development

- World-class technical education supporting industry innovation

The German CNC industry is strong because it mixes old engineering skills with new tech. Makers always try to do better. They make machines that are the best in the world.

German engineering represents the pinnacle of manufacturing innovation and precision.

What makes Germany lead in tech includes:

- Robust technical education system

- Strong collaboration between industry and academic institutions

- Continuous investment in advanced manufacturing technologies

Germany’s CNC industry has a great history of exporting and being tech-savvy. It shows why it’s a big name in making things with precision.

China’s Impact on the CNC Machine Market

The Chinese CNC market has become a game-changer in global manufacturing. It has quickly become a major force in technology and production. China has changed the world of precision machining.

Several key factors have helped China rise in the CNC machine industry:

- Massive government investment in advanced manufacturing

- Aggressive technological research and development

- Substantial workforce training programs

- Strategic focus on high-tech industrial capabilities

China’s approach has changed the global competition. Chinese makers have quickly developed advanced CNC machine tech. They are now challenging leaders from Germany and the United States.

| Market Aspect | China’s Performance | Global Impact |

| Production Volume | Increased 35% annually | Major market disruption |

| Technological Innovation | Rapid technological advancement | Increased competitive pressure |

| Cost Efficiency | Significantly lower production costs | Price-competitive offerings |

The Chinese CNC market keeps growing. Domestic makers are investing a lot in research. They are creating new technologies that meet international standards. This makes China a key player in global manufacturing.

Future Developments in the CNC Machine Industry

The CNC machine industry is on the verge of big changes. New technologies will change how we make things. This is thanks to new ways of designing and producing.

Important CNC trends are changing the way we work. They bring new ideas and tools to the table:

- Hybrid manufacturing techniques combining additive and subtractive processes

- Integration of artificial intelligence for precision machining

- Advanced materials enabling more complex manufacturing capabilities

- Sustainable production methodologies reducing environmental impact

Experts say we’re on the edge of huge tech breakthroughs. Quantum computing could change CNC machine programming. It will make machines work faster and design more complex things.

Companies are working on smart systems. These systems can adjust to new needs on their own. Smart manufacturing is the next big thing in CNC tech. It uses machine learning to improve maintenance and work better.

Being green is also a big push for new ideas. CNC machines of the future will use less energy and make less waste. They’ll also use recycled materials.

“The future of manufacturing lies in seamless integration of advanced technologies and sustainable practices.” – Manufacturing Technology Insights

The future of CNC machines will mix digital tech, new materials, and smart systems. This will lead to better, greener, and more flexible ways to make things.

Competitive Landscape in the CNC Machine Market

The CNC machine market is very competitive. It’s driven by new strategies and tech advancements. Leaders keep updating their plans to stay ahead in this fast-changing field.

- DMG MORI – Germany

- Haas Automation Inc. – US

- Okuma Corporation – Japan

- Makino Milling Machine Co. Ltd. – Japan

- JTEKT Corporation – Japan

- TRUMPF Group – Germany

- Yamazaki Mazak Corporation – Japan

- Hurco Companies Inc. – US

- GF Machining Solutions Management SA – Switzerland

- CHIRON Group SE – Germany

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global CNC Machine Market Report |

| Base Year | 2024 |

| Segment by Type |

· Milling Machines · Lathe Machines · Grinding Machines |

| Segment by Application |

· Aerospace · Automotive · Healthcare · Electronics |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The CNC machine market is growing fast in many industries. Experts predict it will reach $122.4 billion by 2031. This growth is driven by the need for better manufacturing tech, especially in aerospace, defense, and energy.

Big names like DMG MORI, FANUC CORPORATION, and Okuma Corporation are leading the way. They focus on making machines more precise and automated. Countries like China and India in Asia Pacific are also key players in this growth.

As manufacturing changes, companies need to stay flexible and creative. The CNC machine market is a place of constant innovation. It offers big chances for those ready to invest in new tech and global partnerships.

Global CNC Machine Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: CNC Machine Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Vacuum Arc RemeltingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global CNC Machineplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: CNC Machine Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: CNC Machine Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: CNC Machine Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofCNC Machine Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is driving the growth of the CNC Machine Market?

The CNC Machine Market is growing fast. This is thanks to new tech like artificial intelligence and machine learning. Also, more companies are using Industry 4.0 practices. And, there’s a big need for precise manufacturing in fields like aerospace, automotive, and electronics.

What are the main challenges in CNC machine production?

Big challenges include high start-up costs, a lack of skilled workers, and the need for constant tech updates. Also, managing complex supply chains in a fast-changing world is tough.

Which regions are leading in CNC machine technology?

Germany and the United States are at the forefront. Germany is known for its precision, while the U.S. leads in innovative manufacturing. China is also growing fast in CNC machine production and use.

How are emerging technologies impacting CNC machine manufacturing?

New tech like hybrid manufacturing and additive manufacturing is changing CNC. It’s making processes more complex, efficient, and precise.

What industries are driving demand for CNC machines?

Industries like aerospace, automotive, healthcare, electronics, and precision manufacturing need CNC machines. They need them for making complex parts.

How are geopolitical factors affecting the CNC Machine Market?

Global issues like trade tensions and tariffs are affecting CNC machine makers. They need to adapt and stay resilient in these changing times.

What are the key technological trends in CNC machine development?

Important trends include AI, machine learning, advanced sensors, and real-time monitoring. Also, Industry 4.0 and IoT are making CNC machines more connected.

Are there specific market segments showing rapid growth?

Yes, fast-growing segments include 5-axis machining centers and multi-tasking machines. Also, high-speed precision machines and specialized machines for new industries are in demand.

What role does sustainability play in CNC machine development?

Sustainability is key now. Makers are focusing on energy-saving designs, less waste, and longer-lasting machines. They’re also working on green manufacturing processes.