$2.44 Billion Advancing Additive Manufacturing Software Market in the U.S., Germany, and South Korea by 2025

Discover how the additive manufacturing software market is revolutionizing industrial production through AI integration, metal 3D printing advancements, and innovative technologies. Learn about market growth drivers, industry applications, and future trends shaping this dynamic sector, from aerospace developments to sustainable manufacturing solutions.

- Last Updated:

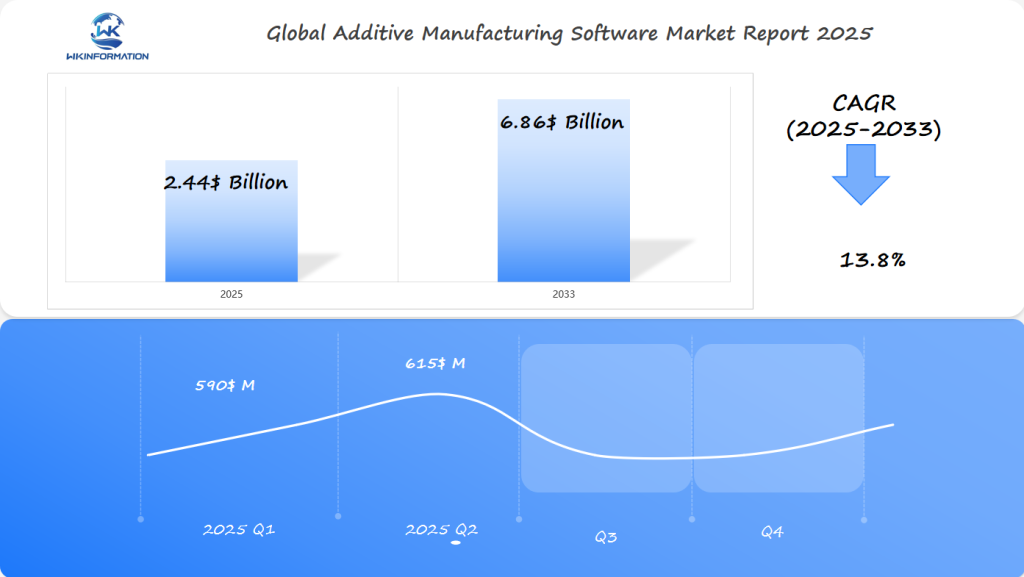

Additive Manufacturing Software Market Q1 and Q2 2025 Forecast

The Additive Manufacturing Software market is projected to reach $2.44 billion in 2025, with a CAGR of 13.8% from 2025 to 2033. In Q1 2025, the market is expected to generate approximately $590 million, driven by the growth of 3D printing technologies in industries such as automotive, aerospace, and healthcare in the U.S., Germany, and South Korea. The need for efficient design and enhanced production capabilities are key factors contributing to the market’s rapid growth.

By Q2 2025, the market is forecasted to reach $615 million, supported by innovations in generative design and the integration of AI and machine learning with additive manufacturing software. The U.S. leads in adoption of 3D printing solutions for industrial production, Germany continues to emphasize precision engineering and digital manufacturing, while South Korea expands its investment in smart factories and additive manufacturing technologies.

Understanding the Additive Manufacturing Software Industry

The additive manufacturing software industry is made up of various technologies that work together to promote innovation and efficiency in various sectors. This industry has multiple stages that contribute to its growth.

Software integration plays a crucial role in transforming traditional manufacturing methods. The initial phase of this system involves key stakeholders who facilitate the introduction of new technological advancements.

Raw Material Suppliers and Software Developers

Raw material suppliers are crucial in the additive manufacturing software chain. They offer special materials for precise 3D printing. Key traits of these suppliers include:

- Advanced polymer and metal compounds

- High-performance composite materials

- Precision-engineered substrate materials

Software developers make advanced platforms that connect material science with digital design. Their work turns complex manufacturing needs into digital plans.

End-User Industries and Applications

Different industries are quickly adopting additive manufacturing software to change how they make things. Important areas include:

- Aerospace engineering

- Medical device manufacturing

- Automotive prototyping

- Consumer electronics

Each field uses special software solutions for its unique design and production needs. This shows how versatile additive manufacturing technologies are.

Key Trends Fueling Growth in Additive Manufacturing Software

The world of additive manufacturing software is changing fast. New technologies and market shifts are driving this change. Companies are now using advanced tools to make design, production, and optimization easier.

Cloud computing is a big deal for manufacturers. It offers flexible and scalable software solutions. SaaS adoption is changing how companies use advanced design tools. This makes it easier to start and work together without big upfront costs.

Cloud-Based Solutions Reshaping Manufacturing

Modern additive manufacturing software uses cloud computing for big benefits:

- Real-time design collaboration across global teams

- Scalable computational resources

- Reduced hardware investment requirements

- Enhanced data security and backup mechanisms

“Cloud technologies are transforming manufacturing software from a static tool to a dynamic, interconnected ecosystem.” – Manufacturing Technology Insights

AI in Manufacturing: Intelligent Design Optimization

Artificial intelligence is changing additive manufacturing software. It brings advanced design capabilities. AI helps create complex shapes, predict problems, and use materials better.

Machine learning can look at thousands of designs and suggest improvements. These smart algorithms cut down on design time and make products better.

- Generative design capabilities

- Predictive maintenance predictions

- Automated quality control processes

- Enhanced topology optimization techniques

As SaaS adoption grows and AI gets better, additive manufacturing software will keep improving. It will lead to more design innovation and better operations.

Navigating Challenges in Additive Manufacturing Software Development

The world of additive manufacturing software is facing big challenges. These need new solutions. Making software work together better and standardizing it are top goals for leaders in the field.

Digital security is a major worry in today’s manufacturing world. Companies must tackle many complex problems. They need to keep their ideas and designs safe from hackers.

Standardization and Interoperability Challenges

Getting software to work together smoothly is a big problem. Some of the main issues are:

- Different file formats that don’t work with each other

- Systems that don’t communicate effectively

- Many different approaches to software development

“Interoperability is not just a technical challenge, but a strategic imperative for the future of digital manufacturing.” – Manufacturing Technology Insights

Cybersecurity Concerns in Digital Manufacturing

As manufacturing becomes more digital, so do the threats. Companies must find ways to keep their systems and ideas safe.

Here are some ways to ensure cybersecurity in digital manufacturing:

- Using strong encryption

- Setting up extra steps to log in

- Keeping an eye on systems all the time

- Implementing best cybersecurity measures

The future of additive manufacturing will be shaped by how well software works together and stays safe.

Geopolitical Factors Impacting the Additive Manufacturing Market

The world of global trade is changing fast, especially for additive manufacturing software. Geopolitical factors are key in shaping how technology develops and who gets to use it. Countries are working hard to be at the forefront of digital manufacturing innovation.

Government support is crucial for the additive manufacturing sector. Each country has its own way to boost growth and stay ahead in this tech field.

Trade Policies and International Collaboration

International partnerships are changing the additive manufacturing software market. Important points include:

- Cross-border technology transfer agreements

- Bilateral research partnerships

- Harmonization of technical standards

- Reduction of trade barriers for advanced manufacturing technologies

Regional Innovation Hubs and Government Support

Governments around the world are investing in innovation ecosystems for additive manufacturing. Their efforts include:

- Establishing dedicated research centers

- Providing financial incentives for technology startups

- Developing specialized educational programs

- Creating regulatory frameworks that encourage technological innovation

The combination of government support, international collaboration, and smart trade policies will greatly influence additive manufacturing software markets.

Types of Additive Manufacturing Software: 3D Modeling and Beyond

The world of additive manufacturing uses advanced software to turn digital designs into real objects. 3D modeling software and CAD tools are key in today’s manufacturing. They help engineers and designers create new possibilities.

Special software is changing how we design and make things. These tools offer complete solutions for creating, analyzing, and improving complex manufacturing processes.

CAD Software for Additive Manufacturing

CAD tools made for additive manufacturing have special features. They let designers:

- Create detailed 3D models

- Optimize designs for different manufacturing methods

- Test how parts will perform before making them

- Save materials by precise digital modeling

“The right CAD tools can transform complex design challenges into innovative manufacturing solutions.” – Manufacturing Technology Insights

Simulation and Process Planning Tools

Process simulation software is a big leap in additive manufacturing. It helps predict and improve print settings. This reduces mistakes and saves materials.

Modern process simulation tools have important features:

- Predict how parts will behave

- Analyze performance in real-time

- Automate workflow improvements

- Predict material performance

Using top-notch 3D modeling software and process simulation, manufacturers can achieve greater efficiency and innovation.

Applications of Additive Manufacturing Software in Various Industries

Additive manufacturing software has changed how industries make things. It lets companies design, test, and make important parts in new ways. This technology makes complex manufacturing easier and opens up new possibilities.

This software is used in many important fields. Each field uses it in different ways to solve big engineering problems:

Aerospace Manufacturing Innovations

The aerospace industry is using advanced 3D printing. Engineers make lightweight, detailed parts that help planes fly better and use less fuel. Some big achievements include:

- Lightweight structural components

- Complex turbine blade designs

- Precision-engineered aerospace parts

Medical 3D Printing Breakthroughs

Medical device making has also changed a lot. Doctors and researchers can now make custom implants and prosthetics with great accuracy. Some big steps forward are:

- Customized orthopedic implants

- Anatomical surgical models

- Personalized medical device prototyping

Automotive and Transportation Transformations

The car industry uses this software to make and test designs faster. It helps make complex parts quickly and accurately. This speeds up the making of new car parts and solutions.

Additive manufacturing represents a significant change in industrial production, allowing for greater design freedom and manufacturing flexibility than ever before.

The Global Additive Manufacturing Software Market: Growth Projections

The additive manufacturing software market is growing fast. This is thanks to new technologies and more companies using it. Experts say we can expect big growth in different parts of the world in the next few years.

Experts think the market for additive manufacturing software will grow a lot. They say it will grow at a fast rate each year. This shows how quickly this area is changing.

Market Size and CAGR Forecasts

Here are some important facts about the market:

- The global market value is expected to hit $2.44 billion by 2025.

- It’s expected to grow at a rate of about 13.8% by 2033.

- There will be a lot of money spent on research and development.

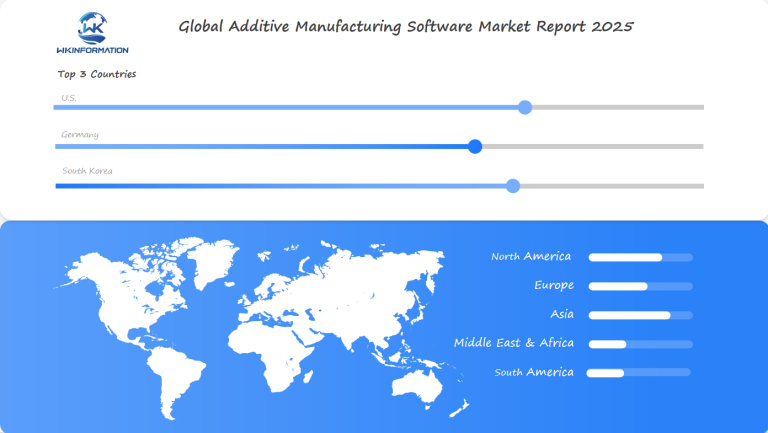

Regional Market Shares and Growth Rates

Looking at the regions, we see different growth rates. The US and Germany are leading, but Asia is catching up fast. This is because Asia is adopting new technologies quickly.

Opportunities in the U.S. Market for Additive Manufacturing Software

The United States is a key place for new ideas in additive manufacturing software. This is changing many industries in big ways. As leaders in the U.S. grow their tech, digital making is changing fast.

Startups are key in changing the world of additive manufacturing. They create new solutions for tough making problems.

Leading Software Providers and Emerging Innovations

Top names in the U.S. are making big leaps with new tech:

- Autodesk Fusion 360: Integrated design and manufacturing platform

- Solid Edge: Comprehensive software for 3D design and simulation

- PTC Creo: Advanced parametric 3D modeling solution

“Innovation in additive manufacturing software is not just about technology, but about reimagining how we design and produce complex components,” says Sarah Martinez, industry analyst at Tech Insights Research.

Industry Partnerships Driving Innovation

Working together is speeding up new tech in additive manufacturing. Partnerships between software makers, hardware makers, and research groups are making big changes.

Some big partnerships include:

- MIT-backed startup partnerships with aerospace manufacturers

- University research programs with advanced manufacturing companies

- Cross-sector technology transfer initiatives

The U.S. additive manufacturing software market is expected to grow a lot. This is thanks to ongoing innovation and smart partnerships.

Germany's Leading Role in Additive Manufacturing Software Innovations

Germany is at the forefront of digital manufacturing, thanks to its robust tech ecosystem. The country is making significant advancements in additive manufacturing software, driven by its strong emphasis on innovation. This commitment to innovation positions Germany as a global leader in transforming traditional manufacturing processes.

The Impact of Industry 4.0

Germany’s success can be attributed to its initiatives focused on Industry 4.0. These programs have revolutionized manufacturing across various sectors by integrating smart technologies and digital approaches to enhance efficiency and speed.

Industry 4.0 Initiatives and Digital Transformation

German manufacturers are embracing digital technology with ambitious plans. These plans include:

- Advanced software for production processes

- Real-time data analytics for improved manufacturing

- Seamless integration between design and production

- Intelligent automation of various manufacturing steps

Research Institutions Driving Innovation

Top research institutions play a crucial role in Germany’s manufacturing software industry. The Fraunhofer Institute and Technical Universities are at the forefront of developing next-generation manufacturing technologies.

These institutions collaborate with companies to rapidly transform innovative concepts into tangible products. This approach ensures that Germany remains a leader in digital manufacturing.

South Korea's Emerging Market for Additive Manufacturing Software

The South Korean market is quickly changing its manufacturing ways. It’s doing this by investing in additive manufacturing software. This move is making the country a top player in smart manufacturing.

Government support has been key in this change. The South Korean government has set up plans to boost digital manufacturing. They focus on key tech areas.

Strategic Government Support

South Korea is focusing on several areas for its smart manufacturing:

- Advanced research and development programs

- Funding for tech startups

- Creating innovation clusters

- Training for a specialized workforce

Integration with Smart Manufacturing Systems

South Korean manufacturers are using the latest additive manufacturing tech to improve production. They’re using advanced software to make their processes more precise and flexible.

“Our goal is to create a seamless digital manufacturing ecosystem that drives global competitiveness,” states a senior Korean manufacturing policy advisor.

South Korea’s strengths in electronics and materials science help it develop top-notch additive manufacturing software. This puts the country at the leading edge of digital manufacturing worldwide.

The Future of Additive Manufacturing: AI, Automation, and Sustainability

The world of manufacturing is changing fast thanks to new technologies. AI is making big changes in design, production, and innovation. This opens up new chances for being more efficient and creative.

New technologies are changing what’s possible in automated production. They help companies rethink old ways and make smarter systems.

Machine Learning for Design Optimization

Machine learning is changing design by looking at complex data and making better designs. These smart systems can:

- Predict how materials will perform

- Make design faster

- Create shapes that were hard to make before

Automated Workflow and Lights-Out Manufacturing

3D printing is moving towards making things without people. Lights-out manufacturing means places can run without much human help.

| Technology | Efficiency Gain | Potential Impact |

| AI Design Optimization | 35-50% | Reduced Production Time |

| Automated Workflows | 60-75% | Lower Operating Costs |

| Intelligent Monitoring | 40-55% | Enhanced Quality Control |

Sustainable Materials and Circular Economy

The future of making things includes circular economy principles. New ways to recycle and choose materials are key. They help reduce harm to the environment while keeping production high.

Sustainability is no longer an option—it’s a fundamental requirement for modern manufacturing.

Competitive Landscape: Major Players in the Additive Manufacturing Software Market

The additive manufacturing software market is always changing. Big names and new companies are competing hard. They are using new tech and teaming up to grow their market share.

Market players:

- Proto Labs Inc. —— USA

- Stratasys Ltd. —— USA

- 3D Systems Inc. —— USA

- Autodesk Inc. —— USA

- Materialise NV —— Belgium

- Siemens —— Germany

- GE Additive —— USA

- Markforged —— USA

- Hexagon —— Sweden

- Altair —— USA

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Additive Manufacturing Software Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The additive manufacturing software market is at a key moment. It’s time for everyone to see how new technologies can change how we make things. Investing in research, training, and new software is crucial for the future of making things.

As digital manufacturing grows, companies need to look ahead. They should use the latest tech like AI, cloud computing, and simulation tools. They must be ready to change and keep improving. Working together is key to making new discoveries faster.

Key Takeaways for Stakeholders

To succeed, everyone needs to work together. Software makers should create easy-to-use systems that solve real problems. Companies should also train their workers and build flexible systems that can use new tech quickly.

Preparing for the Next Wave of Innovation

The future of digital manufacturing depends on being ready for new tech. Companies that keep learning, work together, and focus on sustainable innovation will do best. They will use additive manufacturing software to make big changes in the future.

Global Additive Manufacturing Software Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Additive Manufacturing Software Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Additive Manufacturing Software Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Additive Manufacturing Softwareplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Additive Manufacturing Software Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Additive Manufacturing Software Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Additive Manufacturing Software Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Additive Manufacturing Software Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is additive manufacturing software?

Additive manufacturing software is a digital tool for 3D printing. It helps design, simulate, and optimize processes. This makes it possible to create complex parts layer by layer.

How is additive manufacturing software transforming manufacturing industries?

Additive manufacturing software is transforming the manufacturing industry in several ways:

- Precise digital designs: Additive manufacturing allows for highly accurate and detailed digital designs that can be easily created and modified using software.

- Complex shapes: With additive manufacturing, it is possible to create intricate and complex shapes that would be difficult or impossible to achieve with traditional manufacturing methods.

- Faster prototyping: The use of additive manufacturing software speeds up the prototyping process, allowing manufacturers to quickly create and test new designs.

- Reduced waste: Additive manufacturing is more efficient than traditional methods, as it only uses the material needed for each part, resulting in less waste.

- Customized production: Additive manufacturing enables manufacturers to produce customized products on-demand, without the need for large production runs.

These benefits are being realized across various industries such as aerospace, automotive, healthcare, and more.

What are the key trends in additive manufacturing software?

The key trends in additive manufacturing software include:

- Cloud-based solutions

- AI integration

- Machine learning

- Generative design

- Simulation

- Quality control

Which industries are most actively adopting additive manufacturing software?

Aerospace, automotive, healthcare, defense, and consumer electronics lead the way. They use it for making lightweight parts, custom medical devices, and complex engineering solutions.

What challenges does the additive manufacturing software market face?

Challenges include setting industry standards and improving software compatibility. There are also concerns about cybersecurity, intellectual property issues, and the need for strong security measures.

How are governments supporting additive manufacturing software development?

Governments in the U.S., Germany, and South Korea invest in additive manufacturing. They fund research, establish innovation hubs, and support technology transfer. They also create policies that help.

What role does artificial intelligence play in additive manufacturing software?

AI helps with design optimization, predictive maintenance, and process simulation. It also improves quality control, workflow management, and decision-making in manufacturing.

What are the market growth projections for additive manufacturing software?

The global market is expected to reach $2.44 billion. This growth is driven by technological advancements and increasing adoption in industries.

How is additive manufacturing software contributing to sustainability?

Additive manufacturing software contributes to sustainability in the following ways:

- Efficient use of materials: It supports sustainable manufacturing by using materials efficiently, minimizing waste, and optimizing the use of resources.

- Promotion of recycling: The software encourages recycling by enabling the design and production of products that can be easily disassembled and recycled at the end of their life cycle.

- Reduction of waste: Additive manufacturing reduces waste by creating objects layer by layer, only using the material necessary for production, and eliminating excess material typically associated with traditional manufacturing processes.

- Support for circular economy: Through advanced design capabilities, additive manufacturing software facilitates the creation of products that are compatible with circular economy principles, such as designing for longevity, repairability, and recyclability.

What types of software are used in additive manufacturing?

There are several types of software used in additive manufacturing, including:

- 3D modeling tools

- CAD platforms

- Process simulation software

- Topology optimization programs

- Specialized workflow management systems