$42.8 Billion Lithography Equipment Market Booms Across the U.S., Netherlands, and South Korea – 2025 Technology Trends & Growth

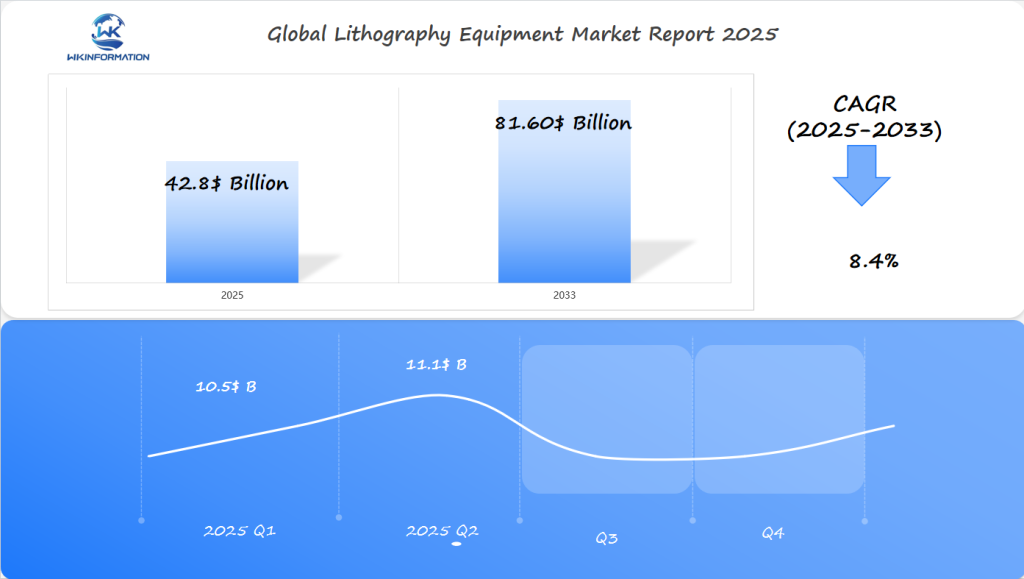

Explore the latest trends, market dynamics, and comprehensive industry analysis of the global lithography equipment market from 2025-2033. This in-depth report examines key growth drivers, including semiconductor advancements, 5G technology impact, and IoT developments. Discover regional insights, competitive landscapes, and future opportunities in this essential semiconductor manufacturing sector. Learn how EUV technology and emerging lithographic techniques are shaping the industry’s future, with market projections indicating growth from USD 42.8 billion in 2025 to USD 81.60 billion by 2033.

- Last Updated:

Lithography Equipment Market Q1 and Q2 2025 Forecast

The Lithography Equipment market is set to reach $42.8 billion in 2025, growing at a CAGR of 8.4% from 2025 to 2033. In Q1 2025, the market is expected to generate approximately $10.5 billion, driven by surging investments in advanced semiconductor manufacturing, particularly in EUV (Extreme Ultraviolet) lithography in the U.S., Netherlands, and South Korea. The push for smaller, more powerful chips is accelerating demand.

By Q2 2025, the market is forecasted to reach $11.1 billion, supported by government subsidies for semiconductor production, the expansion of fab facilities, and technological advancements in next-generation lithography. The U.S. is ramping up domestic semiconductor production, the Netherlands remains the global hub for EUV lithography machines, and South Korea continues its leadership in memory chip manufacturing.

With the rise of AI, 5G, and high-performance computing, lithography equipment manufacturers are poised for strong long-term growth, ensuring cutting-edge chip fabrication capabilities.

Understanding the Lithography Equipment Industry: Important Changes in 2025

The lithography equipment market is a complex web of technologies and processes. In 2025, the upstream industry sees big changes. These changes affect photomask production and wafer fabrication techniques.

Key developments in the industry chain include:

- Advanced photomask production technologies

- Precision improvements in wafer fabrication processes

- Enhanced semiconductor manufacturing capabilities

Innovations in Photomask Manufacturing

Photomask production has become more advanced. Manufacturers are now working on nanoscale resolution and reducing defects. They use new materials and computational methods to make more detailed semiconductor designs.

Wafer Fabrication Breakthroughs

The downstream industry is making great strides in wafer fabrication. Semiconductor makers are using new patterning techniques. These allow for smaller, more efficient chip designs.

These advancements are changing the semiconductor manufacturing world. They are making lithography equipment more precise and efficient.

“The future of semiconductor technology lies in our ability to push the boundaries of photomask and wafer fabrication techniques.” – Semiconductor Industry Expert

Technologies and Trends Shaping the Lithography Equipment Market

The lithography equipment market is at the forefront of semiconductor technology. It’s driven by new innovations that are changing the industry. These emerging technologies are pushing the limits of microchip manufacturing.

EUV lithography is a major breakthrough in making semiconductors. It allows for chips with unmatched precision and smaller sizes. This technology helps manufacturers create more powerful and efficient chips.

How Artificial Intelligence is Transforming Lithography Processes

Artificial Intelligence (AI) is revolutionizing the field of lithography, bringing about significant improvements through the use of machine learning algorithms. These algorithms are enhancing various aspects of the lithography process, including:

- Precision in chip making: AI helps achieve higher accuracy in the production of semiconductor chips, ensuring that intricate designs are reproduced with utmost precision.

- Defect detection: With the help of AI, defects in the lithography process can be identified and addressed more effectively, minimizing waste and improving overall quality.

- Production efficiency: Machine learning algorithms optimize production workflows, leading to faster turnaround times and increased productivity in lithography operations.

Multi-Beam Mask Writing: A Game-Changing Technology

Multi-beam mask writers are another big step forward. These tools make:

- Mask production faster

- Higher resolution images

- Manufacturing simpler

The mix of EUV lithography, AI, and advanced mask writing is driving the industry forward. It’s leading to new levels of innovation and performance.

Addressing Supply Chain Constraints and Manufacturing Challenges in Lithography Equipment

The lithography equipment industry has faced significant supply chain issues recently. These problems arise from global economic difficulties and the intricacies of new technologies. Semiconductor manufacturers have been severely impacted by shortages of raw materials and obstacles in production.

- Ongoing shortages of raw materials affecting the production of critical components

- Disrupted global supply networks

- Increased complexity in production for advanced semiconductor technologies

- Geopolitical tensions affecting international manufacturing ecosystems

Strategic Responses to Manufacturing Limitations

Companies are coming up with new ways to deal with these problems. They aim to make their production systems stronger and more flexible. This way, they can handle surprises in the market better.

| Strategy | Implementation Approach | Expected Outcome |

| Supplier Diversification | Expanding global supplier networks | Reduced dependency on single sources |

| Advanced Inventory Management | Implementing AI-driven forecasting tools | Improved resource allocation |

| Alternative Material Development | Researching substitute semiconductor materials | Enhanced production flexibility |

The sector of semiconductor lithography equipment is showing great flexibility. By using new technology and planning ahead, makers are overcoming tough challenges and material shortages.

How Geopolitics Shapes the Lithography Equipment Market Landscape

The global lithography equipment market is at a crossroads. It’s where technology meets international relations. Geopolitics is changing the semiconductor industry, with trade tensions and policies playing big roles.

Key geopolitical factors influencing the lithography equipment market include:

- Semiconductor technology control strategies, which are reshaping how countries manage their technological assets.

- National security considerations that drive governments to protect their technological advancements.

- Strategic technology transfer restrictions aimed at safeguarding sensitive information.

- Regional economic competition that fuels innovation and investment in the semiconductor sector.

These elements collectively shape the landscape of the lithography equipment market, influencing everything from pricing to availability and technological advancement.

Strategic Technology Rivalries

The United States, Netherlands, and China are in a fierce tech race. Regional policies help decide who gets to the market and how far they can go. Governments are taking steps to boost their own tech industries.

Lithography equipment makers face a tough geopolitical world. They must:

- Develop flexible supply chain strategies

- Create multilateral technological partnerships

- Adapt to fast-changing rules

Impact of Trade Tensions

Trade tensions are hitting the lithography equipment market hard. Geopolitics now shape who can enter the market and collaborate on tech.

The intersection of technology and international politics has transformed the lithography equipment market into a complex global chess game.

Semiconductor companies and equipment providers need to stay quick. They must keep adjusting their plans to handle the changing geopolitical scene in the lithography equipment world.

Understanding Lithography Equipment Categories and Their Impact on the Market

The lithography equipment market is always changing, with new tech leading to big steps forward in making semiconductors. Looking at the different types of equipment shows how market share and tech progress are linked.

When we compare how these technologies are used, we see big differences. Two main types stand out:

- Deep Ultraviolet (DUV) Lithography: It’s the biggest part of the market right now.

- Extreme Ultraviolet (EUV) Lithography: It’s growing fast and getting better.

Technological Capabilities and Market Dynamics

DUV lithography is key for making semiconductors, offering strong and affordable solutions. EUV lithography is more advanced and is becoming more popular for making the latest chips.

Mask aligners are very important in certain areas, like:

- Microelectromechanical Systems (MEMS) fabrication

- Optoelectronic device manufacturing

- Precision optical component production

Future Market Projections

Experts believe that EUV lithography will experience the most growth in the coming years. This demonstrates its capability to manage the intricate designs of semiconductors.

The future of lithography equipment is critical. It will contribute to the production of smaller, faster, and more efficient electronics.

Diverse Applications of Lithography Equipment Across Industries

Lithography equipment is key in many fields. It drives innovation in semiconductor making, advanced packaging, and precision engineering. This technology is changing how we make things.

Lithography equipment is very versatile. It helps make big changes in several important areas:

- Semiconductor Manufacturing: Making complex chips with super small details

- Advanced Packaging: Creating 2.5D and 3D chip stacks

- MEMS Production: Making tiny sensors for IoT and cars

- Electronics: Building fast microprocessors and memory

Semiconductor Manufacturing Innovations

In chip making, lithography is essential. It helps make tiny, powerful chips. Lithography lets us make circuits as small as nanometers.

Advanced Packaging Breakthroughs

Lithography is also key in advanced packaging. It makes it possible to stack chips in 3D. This makes devices smaller and more powerful.

MEMS Production Frontiers

Micro-Electro-Mechanical Systems (MEMS) are another area where lithography shines. These tiny devices are in smartphones, cars, and medical tools. Lithography helps make these devices with amazing accuracy.

Global Lithography Equipment Market: Growth Trends and Key Investment Areas

The global lithography equipment market is growing fast. This is thanks to new technologies and smart investments in many places. As semiconductors get better, there are big chances for investors and tech creators.

Important market trends show strong growth in new markets. Several key factors are shaping investment plans:

- Semiconductor manufacturing innovation

- Advanced chip production technologies

- Increasing demand for high-performance computing

- Next-generation electronic device development

Regional Market Projections

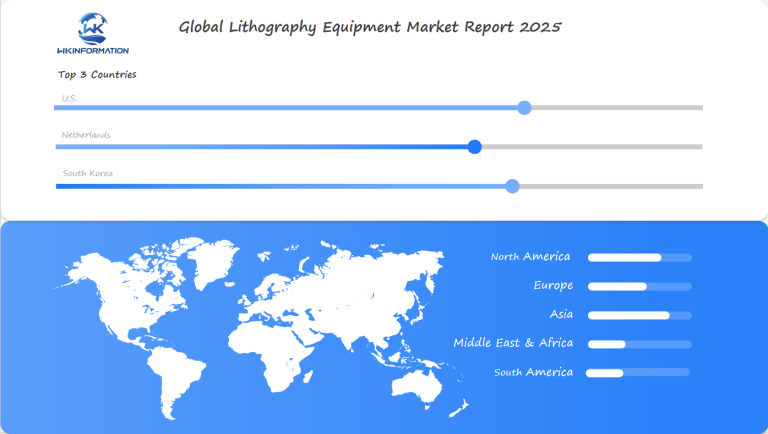

Each region has its own investment scene. European markets lead. The U.S. and Asia Pacific are becoming key places for new tech in lithography equipment.

Market values are expected to grow a lot. This big growth shows how important it is to invest in the latest lithography equipment technologies.

Emerging Investment Opportunities

New markets offer special chances for investment, especially in advanced semiconductor making. EUV lithography and new patterning methods are getting a lot of research and investment.

The future of lithography equipment lies in innovative technological solutions that push the boundaries of semiconductor manufacturing capabilities.

U.S. Leadership in Lithography Equipment: Innovation and Market Expansion

The United States is a key player in the U.S. lithography market. Companies like Applied Materials and Lam Research lead in innovation. The semiconductor ecosystem is strong thanks to partnerships between industry and academia.

- Advanced research partnerships between top universities and semiconductor companies

- Significant federal investments through initiatives like the CHIPS Act

- Cutting-edge technological developments in semiconductor manufacturing

Strategic Research and Development Landscape

North American semiconductor facilities have a strong R&D ecosystem. This supports constant technological advancements. The U.S. innovation landscape is strong thanks to strategic investments and research collaborations.

| Research Area | Key Contributors | Potential Impact |

| Advanced Lithography | MIT, Stanford University | Next-generation chip manufacturing |

| Semiconductor Materials | California Institute of Technology | Enhanced performance technologies |

| Nanotechnology | IBM Research | Miniaturization techniques |

The U.S. is committed to staying at the top in lithography equipment. This ensures the country’s leadership in this important field.

The Netherlands: A Leading Hub for Lithography Equipment Technology

The Netherlands is a global leader in semiconductor technology, thanks to ASML. This small European country has become a key place for making advanced microchips.

Several factors contribute to the Netherlands’ success in this field:

- World-leading research institutions

- Strategic government investments

- Cutting-edge EUV technology development

- Strong collaboration between academic and industry partners

ASML: Leading Global Semiconductor Innovations

ASML is the leader in semiconductor lithography, specializing in the production of photolithography systems for advanced chip manufacturing. Their expertise in EUV technology positions the Netherlands as a crucial player in the worldwide chip supply chain.

ASML continuously pushes the boundaries of technology by heavily investing in research and development of new lithography techniques. This commitment ensures that the Netherlands remains at the forefront of producing highly accurate semiconductors.

Ecosystem of Innovation

The Dutch lithography ecosystem goes beyond ASML. It includes research centers, universities, and tech companies. This teamwork leads to new discoveries and draws talent worldwide.

The Netherlands gets a lot of support for research and has a good environment for tech. This makes it a leading place for lithography equipment technology.

South Korea's Role in Driving Advanced Lithography Equipment Solutions

The South Korean semiconductor industry is leading in technology, becoming a global leader in advanced lithography equipment. Pioneers in adopting cutting-edge lithography technologies, companies like Samsung and SK Hynix are changing the semiconductor manufacturing world.

Factors contributing to South Korea’s success include:

- Substantial investments in advanced manufacturing infrastructure

- Robust government support for technological research

- Strong collaboration with global lithography equipment manufacturers

Innovation Driving Global Competitiveness

Samsung lithography is a standard for precision and technological advancement. The company’s dedication to innovation keeps South Korea competitive in the global semiconductor market.

| Company | Lithography Innovation Focus | Market Impact |

| Samsung | EUV Technology Development | Leading Global Semiconductor Manufacturing |

| SK Hynix | Advanced Memory Chip Lithography | Critical Memory Technology Advancements |

The Asia Pacific region, particularly South Korea, is expected to see the highest growth in lithography equipment by 2024. This shows South Korea’s important role in advancing semiconductor technology.

Future Prospects of Lithography Equipment: Next-Gen Technologies and Growth Drivers

The semiconductor industry is about to undergo a significant transformation. Next-generation lithography techniques are poised to revolutionize manufacturing processes. These innovative methods are crucial for advancing technology and fostering growth in various sectors.

One major development that could impact the production of lithography equipment is quantum computing. Researchers are exploring ways to leverage quantum principles to achieve greater accuracy in chip design and manufacturing processes.

Emerging Technological Frontiers

- Nanoimprint lithography promises more efficient semiconductor production

- Directed self-assembly techniques are expanding manufacturing capabilities

- Advanced optical technologies enable smaller, more complex chip designs

Nowadays, making things in a green way is very important. Companies are working on making their equipment use less energy. They want to keep making things well but also be kind to the planet.

Market Growth Projections

Experts believe the market for lithography equipment will experience significant growth. They project an annual growth rate of 8.4% from 2025 to 2033, driven by increasing demand for cutting-edge semiconductor technology.

The combination of quantum computing, sustainable manufacturing practices, and innovative lithography techniques will revolutionize the industry. This transformation will create new opportunities for advancement in semiconductor production.

Competitive Landscape: Key Lithography Equipment Manufacturers to Watch

The lithography equipment market is always changing. Top manufacturers are competing hard. They are pushing the limits of technology to stay ahead in making semiconductors with new strategies.

Here are the key players in the lithography equipment market:

- ASML Holding N.V. —— Netherlands

- Canon Inc. —— Japan

- Nikon Corporation —— Japan

- Ultratech (Veeco) —— United States

- SUSS MicroTec SE —— Germany

- EV Group (EVG) —— Austria

- Rudolph Technologies (Onto Innovation) —— United States

- Applied Materials Inc. —— United States

- KLA Corporation —— United States

- Tokyo Electron Limited —— Japan

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Lithography Equipment Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The lithography equipment market is at the center of significant changes in technology. It drives important innovations in various fields. As making semiconductors becomes more complex, technology continues to evolve rapidly. This transformation affects how we create and utilize consumer electronics and advanced systems.

Impact on AI

AI requires precise lithography to produce superior and more efficient chips. Companies such as ASML and Intel are working towards creating smaller and more intricate chips. This advancement enables the development of new technologies, including advanced learning algorithms and complex neural networks.

Influence on 5G Technology

5G technology also depends on lithography equipment. It facilitates the production of smaller, more efficient chips for improved networks. Consequently, this leads to faster and more reliable communication networks, revolutionizing global connectivity.

Economic Significance

The economic implications of these advancements are substantial. As lithography equipment fosters innovation, numerous industries will undergo significant transformations. The growth of this market indicates that technology will continue to improve, with semiconductors at the forefront.

Global Lithography Equipment Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Lithography Equipment Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Lithography Equipment Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Lithography Equipmentplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Lithography Equipment Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Lithography Equipment Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Lithography Equipment Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Lithography Equipment Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is driving the growth of the lithography equipment market?

Several factors are driving the growth of the lithography equipment market. Key drivers include advances in semiconductor technology and the demand for smaller, more efficient chips. Additionally, new technologies such as Extreme Ultraviolet (EUV) lithography also have an impact on the market.

These advancements are critical for industries such as consumer electronics, automotive, and telecommunications.

What are the key technologies transforming lithography equipment?

Key technologies include Extreme Ultraviolet (EUV) lithography and multi-beam mask writers. AI and machine learning are also transforming lithography processes. These innovations allow for the creation of smaller, more precise microchips.

They improve manufacturing efficiency and pave the way for future advancements.

How are geopolitical factors impacting the lithography equipment market?

Geopolitical tensions are reshaping the market. Trade relations between major economies are a big factor. Countries like the United States, Netherlands, and South Korea are focusing on domestic semiconductor capabilities.

They are implementing policies like the U.S. CHIPS Act and forming partnerships to stay competitive.

What are the primary applications of lithography equipment?

Lithography equipment plays a crucial role in various industries, particularly in semiconductor manufacturing and advanced packaging. Here are some key areas where lithography equipment is used:

- Semiconductor Manufacturing: Lithography equipment is essential for creating integrated circuits (ICs) used in electronic devices.

- Advanced Packaging: It is employed in advanced packaging techniques such as 2.5D and 3D chip stacking, which enhance the performance and miniaturization of electronic components.

- Micro-Electro-Mechanical Systems (MEMS) Production: Lithography is utilized in the production of MEMS devices, which are tiny mechanical systems integrated with electronics.

- Sensor Manufacturing: Lithography equipment is used to fabricate sensors for various applications, including automotive technologies and Internet of Things (IoT) devices.

These applications highlight the significance of lithography equipment in enabling technological advancements across multiple sectors.

Which countries are leading in lithography equipment technology?

The United States, the Netherlands, and South Korea are at the forefront of lithography equipment technology. Key players include:

- Applied Materials and Lam Research in the U.S.

- ASML in the Netherlands

- Samsung and SK Hynix in South Korea

What challenges are facing the lithography equipment market?

The market faces challenges like supply chain issues and raw material shortages. Companies are addressing these by diversifying suppliers and developing alternative materials. They’re also using advanced planning tools and creating flexible production systems.

What are the future prospects for lithography equipment?

The future holds potential for next-generation technologies like nanoimprint lithography. Quantum computing could also have a significant impact. The focus will be on sustainable and energy-efficient equipment.

The market will continue to drive innovations in semiconductor manufacturing and advanced electronics.

How is AI influencing lithography equipment development?

AI plays a vital role in improving lithography processes. It enhances efficiency, accuracy, and predictive maintenance. Equipment design incorporates machine learning algorithms to optimize manufacturing.

This leads to fewer mistakes and faster technological advancements in semiconductor production.

What is the projected market size for lithography equipment?

The market is expected to reach around $42.8 billion by 2025. This growth is driven by technological advancements, demand for advanced semiconductors, and expanding applications across industries.

How are emerging technologies impacting lithography equipment?

Emerging technologies like EUV lithography and advanced packaging techniques are transforming the market. They enable the production of more complex and miniaturized semiconductor components. These advancements support the development of next-generation electronic devices.