$48.29 Billion Stainless Steel Pipes and Tubes Market Strengthens in 2025: India, Germany, and U.S. Lead Infrastructure and Industrial Growth

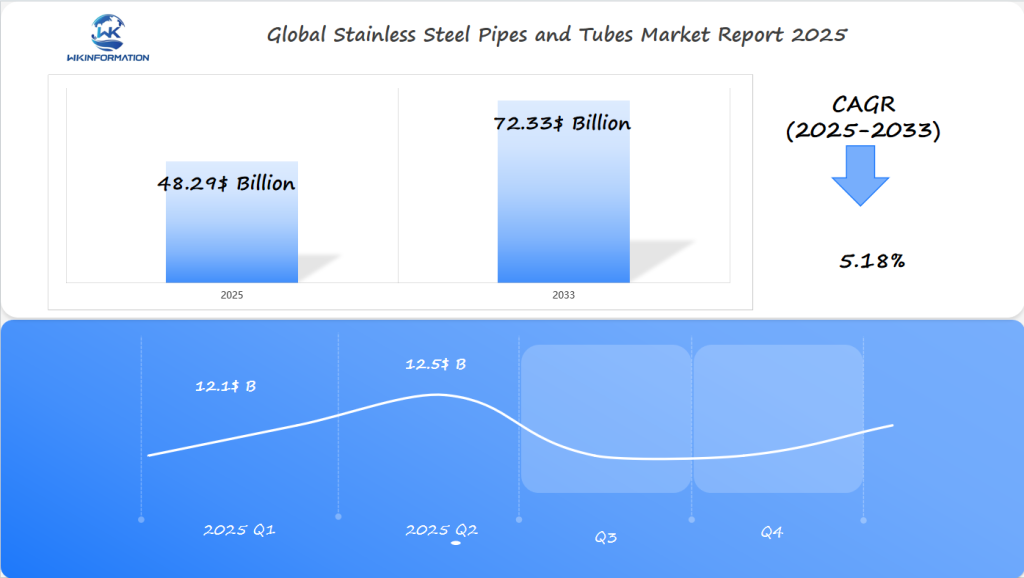

The global Stainless Steel Pipes and Tubes Market was valued at approximately $48.29 billion in 2025. Projections indicate that the market is expected to grow significantly, reaching around $72.33 billion by 2033, with a compound annual growth rate (CAGR) of 5.18% during the forecast period from 2025 to 2033. This growth is driven by increasing demand across various sectors, including construction, oil and gas, and petrochemicals, where stainless steel’s durability, corrosion resistance, and aesthetic appeal make it an essential material for piping solutions. The ongoing urbanization, infrastructure development projects, and advancements in manufacturing processes are also contributing to the robust expansion of the stainless steel pipes and tube market.

- Last Updated:

Stainless Steel Pipes and Tubes Market Q1 and Q2 2025 Forecast

The Stainless Steel Pipes and Tubes market is projected to reach $48.29 billion in 2025, with a CAGR of 5.18% from 2025 to 2033. In Q1 2025, the market is expected to generate around $12.1 billion, primarily driven by the industrial sector in India, Germany, and the U.S. Stainless steel pipes are crucial in sectors such as oil and gas, chemicals, and construction, where they are required for their durability, resistance to corrosion, and ability to withstand high-pressure environments.

By Q2 2025, the market is forecast to grow to $12.5 billion, with robust demand in energy infrastructure and water treatment industries. In India, the construction and infrastructure boom will drive significant demand for stainless steel pipes and tubes for both structural and mechanical applications, while Germany remains a key market due to its strong industrial base in automotive manufacturing and chemical processing.

Technological advancements in welding and manufacturing processes are expected to reduce production costs, making stainless steel pipes more competitive in the market and fueling further adoption in high-end applications.

Understanding the Upstream and Downstream Industry Chains for Stainless Steel Pipes and Tubes

The stainless steel supply chain is a complex web of processes. It turns raw materials into high-performance pipes and tubes. This system shows the important steps from getting raw materials to delivering the final product.

Upstream Activities: From Raw Material Extraction to Alloy Production

Upstream activities start with extracting raw materials. Key components include:

- Iron ore mining from global deposits

- Nickel extraction from mineral resources

- Chromium sourcing from specialized geological regions

- Recycling of metal scraps to support sustainable production

The manufacturing process uses advanced techniques to transform these materials. Steel mills mix iron, nickel, and chromium to create stainless steel alloys. These alloys are made for specific industries.

Downstream Segments: Connecting Manufacturers with End-User Industries

Downstream segments focus on getting the products to users. Strategic distribution channels connect manufacturers with critical industries. This includes:

- Construction and infrastructure projects

- Oil and gas exploration

- Automotive manufacturing

- Industrial equipment production

End-user industries drive demand and shape the supply chain. Their needs affect material quality and production strategies. This makes the market dynamic and responsive.

The interconnected nature of the stainless steel supply chain demonstrates the complex relationships between raw material sourcing, manufacturing processes, and market demands.

Key Trends Driving the Stainless Steel Pipes and Tubes Market: Rising Demand in Construction and Industrial Applications

The market for stainless steel pipes and tubes is growing fast. This is because of more construction projects and various uses in industries. Companies are seeing big chances as more buildings and roads are being built worldwide.

Several key market trends are changing the industry:

- Increased urbanization in developing countries

- Growing infrastructure investment

- Technological advancements in manufacturing processes

- Rising demand for corrosion-resistant materials

1. Growth of Construction Sector

Construction in new countries is making the market grow a lot. Stainless steel pipes and tubes are key in new buildings. They last longer and work better than old materials.

2. Increasing Applications in Various Industries

More uses in industries are pushing the market forward. Companies are making lighter alloys and new ways to make them. The future looks bright for stainless steel pipes and tubes in many areas.

Challenges in Stainless Steel Pipes and Tubes Manufacturing and Cost Fluctuations

The stainless steel pipes and tubes industry faces big challenges. These challenges test the strength of producers worldwide. Raw material costs are a big factor, making prices change a lot.

Manufacturing challenges affect production efficiency in many ways:

- Volatile nickel and chromium pricing

- Energy consumption expenses

- Technological infrastructure upgrades

- Environmental compliance requirements

“Successful manufacturers must adapt quickly to changing economic conditions and technological innovations,” says industry expert Mark Rodriguez.

Keeping production efficient is key for companies. They are using new technologies to make things better. This helps cut down on costs and waste.

The economic scene is tough for stainless steel pipe makers. Global trade rules, changing raw material prices, and stricter environmental laws make things hard. Companies need smart plans and new ideas to get through.

Ways to tackle these challenges include:

- Using advanced automation technologies

- Creating sustainable production methods

- Finding different sources for raw materials

- Training the workforce

Keeping up with changes and using new tech is key to staying ahead in the stainless steel market.

Geopolitical Influence on the Stainless Steel Pipes and Tubes Market

The global stainless steel pipes and tubes market sees big changes because of complex world politics. Trade policies and international relations are key in setting market rules and supply chain plans for makers all over.

Important world politics affecting the market include:

- Tariff structures affecting cross-border steel trade

- Regional economic agreements

- Political tensions between major steel-producing nations

- Infrastructure development policies

Countries like the United States, China, and India keep changing their market rules to help their steel industries. These moves change global prices, production, and who competes with whom.

| Country | Trade Policy Impact | Market Regulation Strategy |

| United States | Steel tariffs protection | Buy American initiatives |

| China | Export subsidies | State-controlled production |

| India | Import restrictions | Domestic manufacturing incentives |

New international relations change trade policies, bringing both problems and chances for stainless steel pipe makers. Companies need to be quick to adjust to fast-changing world politics to stay ahead.

Stainless Steel Pipes and Tubes Market by Type: Seamless, Welded, and Precision Tubing

The stainless steel pipes and tubes market has three main types: seamless pipes, welded tubes, and precision tubing. Each type has its own special features. They meet different needs in various industries.

Seamless Pipes

Seamless pipes are key in high-pressure and critical areas. They are made through a detailed extrusion process. This gives them strong structure and even thickness. The oil and gas, petrochemical, and power generation sectors use them a lot.

- Seamless pipes offer superior pressure resistance

- Ideal for extreme temperature applications

- Minimal structural discontinuities

Welded Tubes

Welded tubes are another big part of the market. They are made by rolling and welding stainless steel sheets. This makes them cheaper for many uses. They are used in cars, medical tools, and building structures.

| Pipe Type | Key Characteristics | Primary Applications |

| Seamless Pipes | High pressure tolerance | Oil & Gas, Petrochemical |

| Welded Tubes | Cost-effective manufacturing | Construction, Automotive |

| Precision Tubing | Tight dimensional tolerances | Medical, Instrumentation |

Precision Tubing

Precision tubing is known for its tight dimensional tolerances. It finds applications in industries such as medical and instrumentation.

Manufacturing keeps getting better for seamless pipes, welded tubes, and precision tubing. Companies are using new methods to make materials better, cheaper, and meet new needs.

Applications of Stainless Steel Pipes and Tubes in Oil & Gas, Construction, and Automotive Sectors

Stainless steel pipes and tubes are key in many industries. They are versatile and perform well in tough conditions. Their ability to resist corrosion and last long is unmatched.

Oil & Gas

In the oil and gas field, these pipes are vital. They handle extreme temperatures, high pressures, and harsh chemicals. This ensures safe and reliable energy transport.

- Offshore drilling platforms

- Subsea pipelines

- Refinery processing equipment

- Chemical transfer systems

Construction

Construction uses stainless steel pipes for strength and lasting performance. Architects and engineers choose them for:

- HVAC systems

- Architectural façades

- Structural reinforcement

- Plumbing infrastructure

Automotive

The car industry also values stainless steel tubes. They use them in exhausts, fuel lines, and other parts. This is because they are strong, yet light.

“Stainless steel pipes represent the backbone of modern industrial innovation” – Industrial Engineering Review

The future looks bright for stainless steel. Industries will keep needing materials that are strong, efficient, and green.

Global Insights into the Stainless Steel Pipes and Tubes Market

The global market for stainless steel pipes and tubes is always changing. It’s influenced by international trade and regional demand. Manufacturers and experts are watching these changes closely. They see how they affect production and use around the world.

Key regions leading the market include:

- Asia-Pacific: Dominating production with significant market share in pipes and tubes

- North America: Strong industrial applications

- Europe: High-quality manufacturing standards

- Middle East: Expanding infrastructure investments

Global market analysis shows complex trade patterns. The stainless steel pipes and tubes sector keeps growing. This is thanks to new infrastructure, industrial growth, and tech advancements.

Emerging markets are becoming critical players in the global stainless steel pipes and tubes ecosystem.

Different regions have their own demand patterns. Developed markets grow steadily, while new markets grow fast. They invest in more infrastructure. The trade flows show a complex web of production, exports, and imports.

Manufacturers are adjusting to these changes. They’re working on new ideas, keeping costs down, and making production more sustainable.

India's Expanding Infrastructure Projects and Steel Production Growth

India’s steel industry is undergoing a significant transformation, leading to increased market growth. The country’s ambitious infrastructure plans are creating new opportunities for steel production. Tata Steel, a key player in the industry, is preparing to capitalize on these emerging trends by enhancing its production capacity.

Key Areas of Investment in Infrastructure

The country’s infrastructure is receiving substantial investment across various sectors, including:

- Smart city development projects

- Transportation network expansions

- Industrial corridor developments

- Urban infrastructure modernization

Government Support for Steel Production Growth

Steel production in India is rapidly increasing to meet these new demands. The government is facilitating this growth through strategic policies and investments in infrastructure.

| Infrastructure Sector | Steel Demand Projection | Growth Potential |

| Transportation | 12.5 Million Tonnes | High |

| Urban Development | 8.3 Million Tonnes | Medium-High |

| Industrial Corridors | 6.7 Million Tonnes | Medium |

The connection between infrastructure development and steel production is strengthening India’s market. With advancements in technology and improved manufacturing processes, India is positioning itself as a major player in the global steel industry.

Germany's High-Quality Manufacturing Standards for Industrial Applications

Germany leads in making stainless steel pipes and tubes. It’s known for top-notch quality and is a top player in Europe. This is thanks to its focus on precision and meeting high standards.

The country’s factories are famous for their focus on details and new tech. They use the latest methods to make sure their products work well in many industries.

- Precise engineering tolerances

- Advanced metallurgical processes

- Rigorous quality control mechanisms

- Cutting-edge research and development

Germany’s rules for making stainless steel pipes are a world standard. These rules cover:

- Strict material selection protocols

- Comprehensive testing procedures

- Continuous product performance monitoring

Manufacturers keep investing in new tech to stay ahead globally. This drive for innovation makes Germany a top choice for high-quality stainless steel pipes. These pipes are used in many important fields like chemicals, cars, and space.

“German engineering represents the pinnacle of industrial manufacturing precision and reliability.”

People from all over the world pick German stainless steel pipes for their unmatched quality. They know these pipes are durable and perform well.

The U.S.'s Growing Demand for Corrosion-Resistant Pipes in Industrial and Energy Sectors

The United States is seeing a big increase in demand for materials that resist corrosion. Stainless steel pipes and tubes are key in the energy sector. They drive innovation and help the economy grow.

Several sectors are leading this demand:

- Oil and gas exploration

- Chemical processing plants

- Power generation facilities

- Renewable energy infrastructure

The shale gas boom has really boosted the need for pipes. Advanced corrosion-resistant materials help with extraction and transport in tough conditions.

“Stainless steel pipes represent the backbone of modern industrial infrastructure,” says industrial engineering expert Dr. Sarah Matthews.

New technologies are changing what materials are used. Companies are making pipes that last longer, cost less to maintain, and work better in harsh places.

Experts predict the stainless steel pipe market will keep growing. The United States is at the forefront in using new technologies and making things.

The Future of Stainless Steel Pipes and Tubes: Lightweight Alloys and Sustainability Innovations

The stainless steel pipes and tubes industry is changing fast. New developments in lightweight alloys and sustainable production are leading the way. Companies are working hard to create products that are better for the environment and perform well.

The Impact of Lightweight Alloys

Lightweight alloys are making a big difference in the future of stainless steel pipes and tubes. These materials are stronger and lighter, making them perfect for many industries.

- Enhanced structural integrity with reduced material weight

- Improved corrosion resistance

- Lower transportation and installation costs

- Greater energy efficiency in manufacturing

The Shift Towards Sustainable Production

Now, making products sustainably is a top priority. The industry is using new technologies to cut down on waste and keep quality high. Green manufacturing processes are leading the charge in stainless steel pipe production, with an emphasis on advanced materials and sustainability.

New research shows that future lightweight alloys could be up to 30% lighter but just as strong. This could change the game for cars, planes, and buildings.

The future of stainless steel pipes and tubes lies in balancing performance, sustainability, and innovative material engineering.

As the world looks for better, greener solutions, companies are pouring money into research. They’re working on new lightweight alloys and ways to make production more eco-friendly.

Competitive Landscape in the Stainless Steel Pipes and Tubes Market

The stainless steel pipes and tubes market is very competitive. Global manufacturers are fighting for a big share of the market. They use new ideas and smart investments to get ahead.

Market leaders:

- Marcegaglia —— Italy

- Fischer Group —— Germany

- Jiuli Group —— China

- Sandvik —— Sweden

- Tenaris —— Luxembourg

- Wujin Stainless Steel Pipe Group —— China

- Nippon Steel Corporation —— Japan

- ThyssenKrupp —— Germany

- Baosteel —— China

- ArcelorMittal —— Luxembourg

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Stainless Steel Pipes and Tube Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The market for stainless steel pipes and tubes is set to grow significantly by 2025. This growth is expected across various industrial sectors. The demand is rising rapidly, driven by major projects in countries like India, Germany, and the U.S.

Factors Influencing Growth

Several factors are contributing to this positive outlook:

- Increasing Demand: Industries such as oil & gas, construction, and automotive are expected to continue driving demand for stainless steel pipes and tubes.

- Emerging Markets: New markets are opening up, presenting opportunities for expansion and innovation.

- Technological Advancements: The introduction of new technologies and green manufacturing practices will play a crucial role in shaping the future of the market.

- Investment in Materials: Investments in new materials and alloys will bring about changes in the market dynamics.

Key Players in the Industry

Companies that prioritize sustainability and adopt advanced production techniques are likely to thrive. These organizations will differentiate themselves in the global market by offering eco-friendly solutions.

Challenges Ahead

While the prospects look promising, it’s important to acknowledge that politics and economic factors will still have an impact on the market. However, as projects become larger and requirements more intricate, the stainless steel sector is expected to continue its growth trajectory.

Conclusion

In summary, the future appears bright for stainless steel pipes and tubes. With increasing demand from various industries, emerging markets, technological advancements, and investments in materials, the market is poised for significant growth.

Global Stainless Steel Pipes and Tube Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Stainless Steel Pipes and Tube Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Stainless Steel Pipes and TubeMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Stainless Steel Pipes and Tubeplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Stainless Steel Pipes and Tube Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Stainless Steel Pipes and Tube Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Stainless Steel Pipes and Tube Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Stainless Steel Pipes and Tube Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market size for stainless steel pipes and tubes by 2025?

The market for stainless steel pipes and tubes is expected to hit $48.29 billion by 2025. This growth is mainly due to infrastructure projects in India, Germany, and the United States.

Which countries are leading the stainless steel pipes and tubes market?

India, Germany, and the United States are leading the market. They have large infrastructure projects, advanced manufacturing capabilities, and strong industrial usage.

What are the primary industries using stainless steel pipes and tubes?

The main industries using these products are:

- Oil and gas

- Construction

- Automotive

Other industries that also use stainless steel pipes and tubes include:

- Chemical processing

- Water treatment

- HVAC systems

- Power generation

What challenges do manufacturers face in the stainless steel pipes and tubes industry?

Manufacturers face many challenges. These include changes in raw material costs, energy prices, and the need for new technology. Global economic factors and strict environmental rules also affect them.

How are technological innovations impacting the stainless steel pipes and tubes market?

New technologies are making alloys lighter and stronger. They are also making production more energy-efficient and sustainable.

What types of stainless steel pipes and tubes are most common?

The most common types are seamless pipes, welded tubes, and precision tubing. Each type has its own manufacturing process and uses.

How are geopolitical factors affecting the stainless steel pipes and tubes market?

Geopolitical factors such as trade policies and tariffs have a significant impact on the market. These factors influence supply chains, pricing, and overall market dynamics.

Why are stainless steel pipes and tubes popular in industries?

Stainless steel pipes and tubes are popular in industries for several reasons:

- Corrosion resistance: They are highly resistant to corrosion, making them suitable for applications in harsh environments.

- Durability: Stainless steel is known for its durability and longevity, ensuring that the pipes and tubes can withstand heavy use without deteriorating.

- Strength: These materials have high tensile strength, allowing them to handle heavy loads and pressures.

- High-temperature resistance: Stainless steel can withstand high temperatures, making it ideal for applications involving heat.

- Versatility: They can be used in a wide range of industrial applications, including construction, manufacturing, and transportation.

Overall, the combination of these properties makes stainless steel pipes and tubes an attractive choice for various industrial needs.

How is sustainability being addressed in the stainless steel pipes and tubes industry?

The industry is working on making production more energy-efficient. They are also recycling more and looking at new materials to reduce environmental harm.

What role does India play in the global stainless steel pipes and tubes market?

India is becoming a big player in the global stainless steel pipes and tubes market. This is due to its large infrastructure projects, growing steel production, government support, and increasing market potential.