$1.21 Billion Shipbuilding Cables Market Sets Sail in 2025: Norway, China, and U.S. Power Maritime Growth

Discover the $1.21 billion Shipbuilding Cables Market in 2025, as Norway, China, and the U.S. power the maritime industry.

- Last Updated:

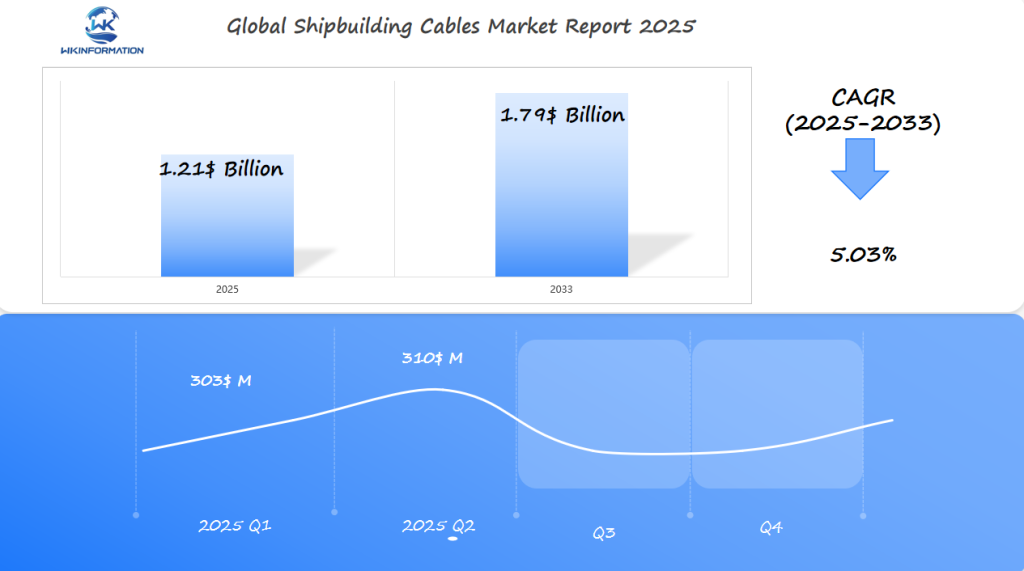

Shipbuilding Cables Market Q1 and Q2 2025 Forecast

The Shipbuilding Cables market is projected to reach $1.21 billion in 2025, with a CAGR of 5.03% from 2025 to 2033. In Q1 2025, the market is expected to generate approximately $303 million, with significant demand from Norway, China, and the U.S., driven by the growing global focus on maritime safety, environmental regulations, and the expansion of naval fleets. Shipbuilding cables are crucial for ensuring the power transmission and safety systems of vessels, with increasing emphasis on eco-friendly and energy-efficient ship designs.

By Q2 2025, the market is forecast to reach $310 million, with China continuing to lead in shipbuilding production and Norway focusing on marine sustainability and the construction of eco-friendly vessels. The U.S. will continue to invest in naval defense and offshore industries, further boosting demand for specialized cables designed for harsh marine environments.

Understanding the Upstream and Downstream Processes in Shipbuilding Cables

The maritime supply chain for shipbuilding cables starts with raw materials. These materials include copper, insulation polymers, and special coatings, which are supplied by countries like Chile and South Korea to various parts of the world.

From Raw Materials to Manufacturing

Once the raw materials are sourced, they make their way to manufacturing hubs located in China and Germany. Here, companies such as Prysmian and TE Connectivity take these basic components and transform them into finished cables ready for use.

Integration into Shipbuilding

After the manufacturing process is complete, the cables find their way to shipyards situated in Norway, Japan, and the United States. It is at these locations that the cables are integrated into the electrical systems of ships, ensuring seamless functionality on board.

Importance of Quality Control

Quality control plays a vital role at each stage of this process:

- Upstream: Material purity testing

- Manufacturing:耐压试验 (Dielectric testing)

- Downstream: Vessel system integration

| Stage | Key Players | Impact |

| Upstream | Miners, chemical producers | Cost fluctuations, material availability |

| Manufacturing | Cable producers | Production efficiency |

| Downstream | Shipbuilders, navies | Final product performance |

The Significance of Efficient Industry Chains

Efficient industry chains are crucial for ensuring timely delivery of cables. These chains must adhere to maritime safety standards, as any delay in the process can disrupt the entire maritime supply chain.

This highlights the significance of strong partnerships with suppliers. The performance of the entire system directly impacts the speed at which ships are constructed and their overall effectiveness at sea.

Key Trends Driving the Shipbuilding Cables Market: Electrification and Maritime Expansion

Electrification is changing the maritime world, making advanced cables more needed. Today’s ships use power systems that cut down on emissions and boost efficiency. Leaders like ABB and General Cable are at the forefront with new energy distribution solutions.

Two big trends are driving growth: electrification and maritime expansion. Electrification brings hybrid propulsion and energy-saving designs. Maritime expansion is about more global trade and bigger ships.

Key drivers include:

- Electrification: Hybrid power systems, battery integration

- Maritime expansion: Growing cargo demand, offshore exploration

A table shows how these trends meet:

| Trend | Market Impact |

| Electrification | Lower emissions, quieter operations |

| Maritime Expansion | Increased cable durability requirements |

As ships get bigger and more complex, cables need to handle more voltage and tough conditions. These trends keep the market lively, mixing green goals with tech advancements.

Challenges in Shipbuilding Cable Production and Regulatory Compliance

Creating shipbuilding cables needs great care to meet tough sea requirements. come from issues like saltwater damage and extreme temperatures. It’s hard to mix light materials with strength. Also, advanced insulation and tests add to the cost.

Some of the key challenges include:

- Material innovation: Finding materials that last decades in the ocean

- Testing standards: Making sure cables pass fire, vibration, and pressure tests

- Global demand: Growing production without losing quality

Following compliance regulations like the International Electrotechnical Commission (IEC) 60092 standards is key. Companies must also keep up with new fire safety rules from the International Maritime Organization (IMO). Even small mistakes can hold up ship approvals.

Yet, companies like General Cable and Prysmian Group are using AI for quality checks. They use automation to improve and follow compliance regulations. This mix of new tech and strict rules helps them overcome cable production challenges and grow sustainably.

Geopolitical Influence on the Shipbuilding Cables Market

Global power dynamics shape the shipbuilding cables industry in unexpected ways. Trade policies and diplomatic relations directly affect geopolitical influence over supply chains and raw material availability. For example:

- U.S. tariffs on Chinese imports disrupt copper sourcing for cable manufacturers.

- EU sanctions impact Russian naval projects relying on European cable tech.

- Norway’s partnerships with Asian markets secure competitive pricing advantages.

Market volatility rises when conflicts delay projects or shift production locations. The market impact of these shifts is clear: companies like Prysmian and TE Connectivity now diversify factories across multiple countries to mitigate risks. Recent data shows 18% of 2024 cable delays stem from export restrictions tied to regional tensions.

Nations prioritizing self-sufficiency invest in domestic cable R&D. This creates opportunities for U.S. firms like General Cable while pressuring smaller suppliers to form alliances. Balancing geopolitical risks with market demands remains critical as maritime electrification expands.

Shipbuilding Cables Market by Type: Power, Data, and Communication Cables

Shipbuilders use three main cable types: power cables, data cables, and communication cables. Each type has a special role in maritime operations. Let’s explore their functions:

- Power cables carry high-voltage energy for propulsion and equipment.

- Data cables manage navigation and control signals for systems like sonar and radar.

- Communication cables provide voice and internet for crew and safety.

| Power cables | High insulation, heat resistance | Electric motors, energy distribution |

| Data cables | Low signal loss, EMI shielding | Navigation systems, autopilot |

| Communication cables | Fiber optics, durability | Global satellite links, emergency comms |

Companies like General Cable and Prysmian make these cables for harsh marine conditions. As ships get smarter, data cables need to carry more data. Power cables must handle more power in hybrid vessels. Each cable type is crucial for modern maritime tech.

Applications of Shipbuilding Cables in Naval, Commercial, and Luxury Marine Vessels

Shipbuilding cables are key for powering and connecting systems in various vessels. They play a crucial role in ensuring the smooth operation of different types of marine vehicles.

Naval Applications

In naval applications, shipbuilding cables are used to ensure reliable communication and propulsion in submarines and warships. These cables must be able to withstand extreme conditions such as saltwater exposure and shock.

- Armored power cables: These cables are designed with additional protection to resist damage from external forces.

- High-flex data cables: These cables are built to be flexible and durable, allowing for easy movement and bending without compromising performance.

- Low-smoke, zero-halogen cables: These cables are manufactured using materials that produce minimal smoke and no halogen gases when burned, ensuring safety in case of fire.

Commercial Vessels

For commercial vessels, shipbuilding cables are used to manage cargo operations and navigation. They play a vital role in supporting global trade by facilitating the efficient movement of goods across oceans.

- High-flex data cables: These cables are built to be flexible and durable, allowing for easy movement and bending without compromising performance.

- Lightweight materials: Innovations such as lightweight materials used in cable construction help reduce fuel costs for commercial vessels.

Luxury Marine Yachts

Luxury marine yachts utilize shipbuilding cables that are sleek and high-performance. These cables are specifically designed to meet the aesthetic requirements of luxury vessels while also providing reliable functionality.

- Low-smoke, zero-halogen cables: These cables are manufactured using materials that produce minimal smoke and no halogen gases when burned, ensuring safety in case of fire.

- Discreet yet robust cables: The use of discreetly placed but strong cables supports high-end technology on luxury yachts without compromising the overall design aesthetic.

Modern advancements like fiber optics enhance naval applications by enabling real-time data transmission. In commercial vessels, lightweight materials contribute to fuel efficiency. For luxury marine vessels, the integration of discreet yet durable cables allows for the seamless incorporation of advanced technologies without detracting from the vessel’s visual appeal.

Global Insights into the Shipbuilding Cables Market

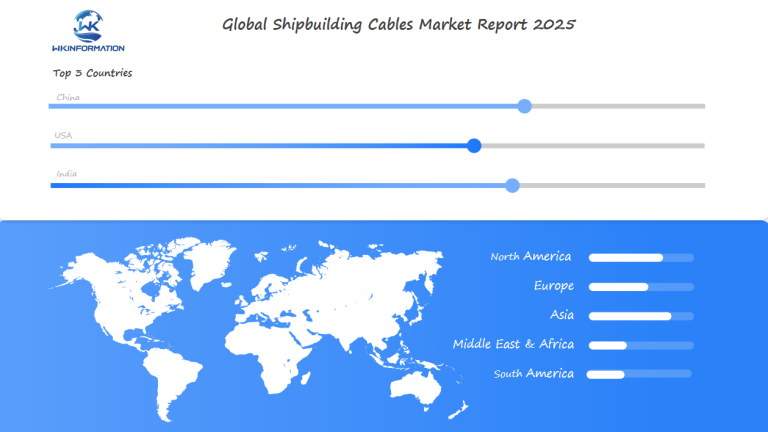

Global market insights show big changes in shipbuilding trends. Asia-Pacific is leading with fast growth in commercial vessels. Europe is pushing for green naval tech. The Americas are innovating in energy-saving cables for offshore projects.

| Region | Growth Driver | Market Focus |

| Asia-Pacific | Commercial shipping expansion | Cost-effective cable solutions |

| Europe | Environmental regulations | Low-emission materials |

| Americas | Offshore energy projects | Ruggedized cable durability |

Emerging economies in Africa and the Middle East are also boosting demand for basic cabling infrastructure. This creates new chances for growth. Now, makers focus on making cables that can adapt to different needs.

- Asia-Pacific: 6.2% annual growth through 2030

- Europe: 4.8% growth driven by EU green shipping policies

- North America: 5.5% rise linked to offshore wind projects

Global market insights highlight the importance of new materials and custom designs. To stay ahead, it’s crucial to keep up with these changes.

Norway’s Leadership in High-Performance Shipbuilding Cables for Marine Sustainability

Norway is a world leader in making high-performance cables for the sea. The country focuses on marine sustainability to create innovative solutions. These cables are essential for ships and offshore platforms.

Eco-Friendly Practices in Cable Manufacturing

Companies like SubCable Technologies AS and NorCable Group use eco-friendly materials. They design cables that are energy-efficient and meet strict standards. This approach reduces harm to the environment.

- ISO 14001 environmental management certifications

- Recyclable cable components

- Partnerships with green energy suppliers

Future Goals for Sustainable Cable Production

By 2025, Norway plans to supply 40% of Europe’s marine cable needs. They aim to make cables that last longer and need fewer replacements. This will help reduce waste and support environmental goals.

China's Growing Demand for Shipbuilding Cables in Commercial and Military Applications

China’s shipbuilding industry is experiencing rapid growth, significantly altering the global maritime landscape. The demand for high-quality cables is soaring, driven by both commercial shipbuilding and military applications. This surge reflects China’s commitment to modernizing its economy and defense sectors.

The need for durable and reliable cables is driving innovation in military tech. At the same time, commercial shipbuilding for trade and tourism is increasing demand for affordable solutions. Companies are working hard to meet the needs of both sectors.

From big container ships to destroyers, China’s shipyards are using the latest cable technology. This makes China a major player in building the world’s maritime infrastructure.

The U.S.’s Investment in Advanced Maritime Electrical Systems

The U.S. is investing more in maritime electrical systems. This is to modernize both naval and commercial fleets. High-voltage power distribution and smart grid systems are key to this effort. Companies like General Electric and ABB are working with U.S. shipyards to bring in new technologies.

- Naval projects focus on electrified propulsion for submarines and surface ships

- Commercial ports adopt AI-driven energy management systems

- Renewable energy integration reduces reliance on fossil fuels

| Program | Focus | 2023 Funding |

| Naval Innovation Initiative | Electric ship architectures | $450M |

| Smart Port Initiative | Grid modernization | $220M |

| Maritime Tech Accelerator | Prototype testing | $180M |

Now, advanced tech like solid-state circuit breakers and fiber-optic sensors are common in new ships. The Department of Energy works with private companies to create lithium-ion battery systems for hybrid ships. These changes aim to lower emissions and improve efficiency.

Shipbuilders like Huntington Ingalls Industries see a 30% rise in orders for electric systems. This move shows a focus on maritime electrical systems that are both innovative and reliable. As other countries move forward, U.S. investments keep the country at the forefront of this field.

The Future of Shipbuilding Cables: Lightweight and High-Efficiency Solutions

Ships are getting bigger and more complex. This means we need lightweight solutions and high-efficiency cables for the future trends in maritime tech. Companies like Nexans and TE Connectivity are using new materials. They use carbon-fiber-reinforced polymers and aluminum-based conductors.

How New Materials Are Changing Shipbuilding Cables

- Carbon composites reduce cable mass by up to 30% compared to traditional copper.

- New insulation materials lower energy loss, boosting high-efficiency cables performance.

- 3D-printed cable designs allow customization for tight ship spaces.

These changes help the planet too. Lighter ships use less fuel, which means less pollution. High-efficiency cables also support hybrid propulsion systems. By 2030, 60% of new ships will use these technologies.

Future Trends in Shipbuilding Cables

Looking to the future, future trends include AI for predictive maintenance. Lightweight solutions will have sensors to check wear and tear. This tech cuts downtime by 40%.

These innovations help shipbuilders meet strict environmental and safety rules. The next wave of shipbuilding cables will make maritime operations safer, greener, and cheaper.

Competitive Landscape in the Shipbuilding Cables Market

The shipbuilding cables market is full of competition and innovation. Companies like Nexans, Prysmian, and Southwire are using new materials and following global standards. They aim to make cables that are light, efficient, and reliable for all kinds of ships.

Key Players in the Shipbuilding Cables Market

Here are some of the major companies operating in the shipbuilding cables market:

- Prysmian Group – Italy

- KEI Industries Limited – India

- RR Kabel – India

- Lapp India – India (subsidiary of Lapp Group, Germany)

- SAB Cable – Germany

- Helkama Bica – Finland

- Wilson Cables – Singapore

- Unika Cables – Turkey

- Nexans SA – France

- Polycab Wires – India

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Shipbuilding Cables Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Naval, commercial, and luxury marine vessels rely heavily on specialized shipbuilding cables for their operations. From military vessels requiring high-security and durability standards, to commercial ships needing reliable power distribution systems, to luxury yachts demanding sophisticated communication networks, each sector has unique cable requirements.

As maritime technology continues to advance, the demand for innovative cable solutions grows. The integration of smart technologies, increasing focus on sustainability, and stringent safety regulations will continue to shape the evolution of shipbuilding cables across all vessel types. The success of marine operations across these sectors depends significantly on the quality, reliability, and performance of their cable systems.

Global Shipbuilding Cables Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Shipbuilding Cables Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Shipbuilding CablesMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Shipbuilding Cables players and Regional Insights

-

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

-

- Key Differentiators and Strategic Moves

Chapter 3: Shipbuilding Cables Market Segmentation Analysis

- Key Data and Visual Insights

-

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

-

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

-

- Historical Data and Growth Forecasts

- Regional Growth Factors

-

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Shipbuilding Cables Emerging and Untapped Markets

- Growth Potential in Secondary Regions

-

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Shipbuilding Cables Consumer Insights

- Demographics and Buying Behaviors

-

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofShipbuilding Cables Market Insights

Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the size of the shipbuilding cables market and what are the key drivers of growth?

The shipbuilding cables market is expected to grow to $1.21 billion by 2025. This growth is driven by trends like electrification and the need for advanced systems. The maritime industry’s expansion in Norway, China, and the U.S. also plays a role.

How do upstream and downstream processes affect shipbuilding cable production?

Upstream processes involve getting raw materials, which affects the cable’s quality and cost. Downstream, manufacturing and distribution ensure cables meet standards and are delivered efficiently.

What are the key trends impacting the shipbuilding cables market?

Key trends such as vessel electrification, maritime expansion, and sustainability are shaping the shipbuilding cables market. These trends aim to enhance product performance while also prioritizing environmental responsibility.

What challenges do manufacturers face in producing shipbuilding cables?

Manufacturers face challenges like technological hurdles and regulatory compliance. They also need to innovate and improve efficiency while considering environmental concerns.

How do geopolitical factors affect the shipbuilding cables market?

Geopolitical tensions and trade policies can disrupt supply chains. They affect pricing and competitive dynamics, showing the market’s reliance on international relations.

What are the different types of shipbuilding cables available in the market?

The market offers power, data, and communication cables. Each type is designed for specific maritime applications and performance needs.

In which sectors are shipbuilding cables predominantly used?

Shipbuilding cables are crucial in naval, commercial, and luxury marine vessels. They provide reliable performance under various conditions.

What global trends are influencing the shipbuilding cables market?

The shipbuilding cables market is shaped by various factors such as international demand, emerging markets, and trading shifts. Countries are adapting to maritime needs and technological advancements to stay competitive in the industry.

How is Norway contributing to the shipbuilding cables market?

Norway is a leader in producing high-performance cables, with a strong emphasis on sustainability and quality. These factors are crucial for the future of marine construction and technology.

What role does China’s economy play in the shipbuilding cables market?

China’s growth and military strategies boost demand for cables in commercial and military sectors. This significantly impacts innovation and consumption trends.

What investments is the U.S. making in maritime electrical systems?

The U.S. invests in advanced systems, driven by technology and government initiatives. These aim to enhance efficiency and capabilities in the shipbuilding cables market.

What does the future hold for shipbuilding cables?

The future will see a shift towards lightweight, high-efficiency solutions. Emerging technologies and material innovations could redefine functionality and reduce costs in the maritime industry.

Who are the key players in the shipbuilding cables market?

The competitive landscape includes various key players. Each uses market strategies and strengths to face challenges and seize opportunities in the sector.