$16.89 Billion Encoder Code Wheels Market to Fuel Automation and Precision in the U.S., Germany, and South Korea by 2025

Explore growth trends in the Encoder Code Wheels Market, highlighting market size, key drivers, and future projections across industries like robotics and automotive.

- Last Updated:

Encoder Code Wheels Market Q1 and Q2 2025 Outlook

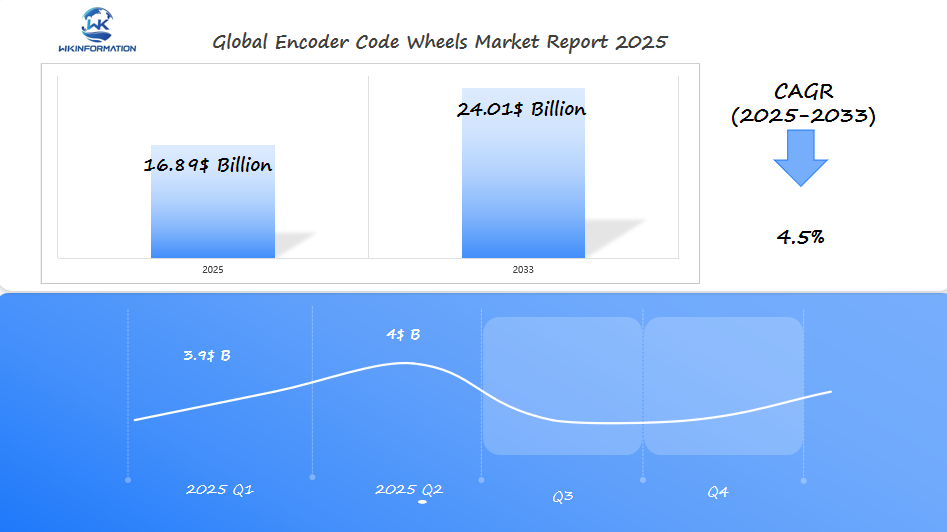

The encoder code wheels market is projected to reach $16.89 billion in 2025, with a 4.5% CAGR from 2025 to 2033. In Q1 2025, the market is estimated to generate approximately $3.9 billion, as the demand for precise rotational motion sensing solutions rises across industries like robotics, automation, automotive, and consumer electronics.

The U.S., Germany, and South Korea are expected to lead the market, driven by technological advancements in automation systems and robotics. By Q2 2025, the market is forecasted to grow to $4 billion, with South Korea and Germany continuing to be at the forefront of industrial automation and electronics innovation, while the U.S. remains a dominant player in developing cutting-edge technologies in robotics and motion control.

Key Takeaways

- Encoder code wheels market to hit $16.89 billion by 2025.

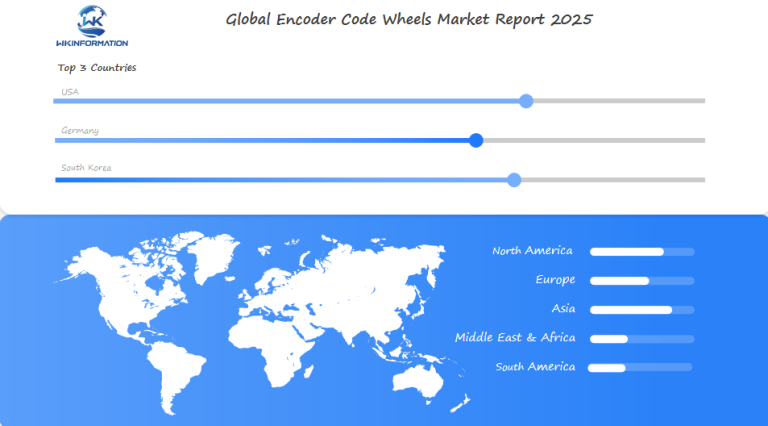

- U.S., Germany, and South Korea are key regions for automation advancements.

- Core to precision engineering and industrial automation systems.

- Driving growth in robotics, manufacturing, and aerospace sectors.

- Global demand for automation efficiency fuels innovation in encoder technologies.

Understanding the Encoder Code Wheel Industry: Upstream and Downstream Connections

The encoder code wheel industry relies on a complex network of suppliers and customers. Let’s break down the key players in this industry:

Upstream Players

Upstream refers to the initial stages of the supply chain, where raw materials are sourced. In the case of encoder code wheels, the following components are crucial:

- Raw Materials: Stainless steel and glass are essential materials used in the production of encoder wheels.

- Calibration Systems: Electronic parts makers and software developers contribute to the calibration systems that ensure accurate functioning of the wheels.

Manufacturing Process

Manufacturing hubs play a significant role in shaping these raw materials into high-precision products. Key locations such as the U.S. Midwest and Germany are known for their advanced manufacturing capabilities. Here’s how the process works:

- Material Shaping: Advanced tools and machinery are employed in these manufacturing hubs to shape stainless steel and glass into precise forms required for encoder wheels.

- High Accuracy Standards: The manufacturing process adheres to strict quality control measures to ensure that the final products meet the high accuracy standards demanded by various industries.

Downstream Connections

Downstream refers to the later stages of the supply chain, where finished products are delivered to end-users. In this case, distributors play a vital role in connecting manufacturers with specific industries:

- Robotics Companies: Distributors work closely with robotics companies, supplying them with encoder code wheels that are integral components in robotic systems.

- Industrial Automation Firms: Similarly, industrial automation companies rely on these wheels for their automated processes and machinery.

Efficiency in supply chains directly impacts the reliability of precision technology across global markets.

Specialized Applications

Certain sectors require specialized components for their operations. This is where suppliers of rare earth magnets and optical sensors come into play:

- Aerospace Industry: Rare earth magnets are critical in aerospace applications, where lightweight yet powerful solutions are necessary.

- Medical Devices: Optical sensors find extensive use in medical devices, enabling precise measurements and diagnostics.

Distribution Networks

To ensure timely delivery of these specialized components, robust distribution networks are essential:

- Factories producing automated machinery or medical devices require a steady supply of rare earth magnets and optical sensors.

- Distribution channels must be efficient enough to transport these components from their sources to the respective factories.

This interconnected system ensures that encoder code wheels meet the stringent requirements set by precision technology sectors.

Quality Assurance Measures

Maintaining high standards of quality is paramount in industries dealing with precision technology:

- Material Inspections: Quality checks on raw materials occur at every stage of production to verify their suitability for demanding applications.

- Performance Testing: Finished encoder wheels undergo rigorous testing procedures to assess their performance under various conditions.

By continuously improving these supply chains through better logistics management and communication systems, manufacturers can minimize delays and maintain consistent accuracy levels required for precision technology advancements.

Key Trends in the Encoder Code Wheel Market: Automation and Precision Technology

Automation and precision technology are changing the encoder code wheels market. The upstream industry is key, offering advanced materials and parts for these new technologies. Now, makers focus on using lighter, stronger materials to meet the need for precision in robotics and machines.

How Automation is Impacting the Encoder Code Wheel Market

- Automated production lines cut down on mistakes and increase production.

- Suppliers and makers work together to meet upstream industry and user needs.

The Role of Precision Technology in Shaping the Industry

- Laser etching and nanotechnology improve the accuracy of code wheels.

- The car and space industries are pushing for better code wheels with sub-micron precision.

How AI is Revolutionizing Quality Control Processes

Companies like Renishaw and Heidenhain are using AI to check quality from start to finish. These steps make products more reliable and save money for users in the long run.

Future trends show a smarter way of making things. The upstream industry and users will work together better. This will make encoder code wheels even better and more efficient. Additionally, trade policies will also play a significant role in shaping the future of this market by influencing supply chain dynamics and material sourcing strategies.

Challenges in the Development and Application of Encoder Code Wheels

Encoder code wheels face many challenges that slow their use in different fields. The need for technical accuracy and material limits are big issues. These problems make it hard for makers to keep costs down while still making high-quality products.

For the downstream industry, these issues can slow down new ideas in automation and robotics.

Technical Barriers

Ensuring accuracy in high-vibration or extreme-temperature environments

Cost Pressures

High R&D expenses raising prices for end-users

Integration Struggles

Adapting legacy systems to new encoder technologies

Manufacturers must deal with compatibility issues when selling parts to car, plane, and industrial clients. For example, optical encoder wheels might not work well in dusty places without the right protection. This means downstream industry partners often need special solutions.

Also, problems in the supply chain can make it hard to get products out worldwide. This is seen in the shortages of semiconductors, which can delay the making of encoders.

Working together between engineers and users is crucial. Testing in real-life situations can show problems, like magnetic interference in factories. Companies like Heidenhain and Renishaw now offer special help to their clients. They focus on making things better through trial and error.

Even with these challenges, progress is being made. Advances in materials science and AI, such as those highlighted in this report on AI advancements, help solve problems. By working closely with the downstream industry, the sector can meet growing needs without losing quality.

Geopolitical Influence on the Encoder Code Wheel Market

Geopolitical changes affect global supply chains, impacting encoder code wheel production and trade. Trade policies, tariffs, and alliances shape market dynamics. For U.S. businesses, geopolitical influence impacts sourcing, as sanctions or agreements change material access.

Trade barriers and regional partnerships are now core considerations for manufacturers to maintain competitiveness.

Here are some key factors influencing the encoder code wheel market:

- U.S. export controls on precision components disrupt global encoder code wheel exports.

- EU environmental regulations push suppliers to adopt greener manufacturing practices.

- Asia-Pacific trade pacts prioritize local suppliers, limiting foreign market entry.

Companies adapt by diversifying suppliers and investing in local production. For instance, German firms use EU suppliers to dodge tariffs. Geopolitical shifts also drive innovation, as firms seek alternatives to restricted technologies. Staying agile to policy changes ensures stability in an unpredictable global landscape.

Market leaders closely watch geopolitical trends, balancing risk and opportunity. Strategic partnerships and policy awareness will define success in this evolving landscape.

Types of Encoder Code Wheels: Optical, Magnetic, and Capacitive Types

Encoder code wheels come in three main types, each suited to different needs. Optical encoders, magnetic, and capacitive systems differ in how they track motion and position.

| Type Technology Strengths Weaknesses Optical Encoders | Light-sensing discs | High precision, fast response | Sensitive to dust/particles |

| Magnetic | Magnetic fields | Rugged, cost-effective | Lower resolution |

| Capacitive | Electrical fields | Resists contamination | Complex calibration |

Optical encoders use light beams and patterned discs to measure rotation. Companies like Heidenhain and MicroE Systems produce these for robotics and precision machinery. Magnetic types rely on magnets, making them durable in dusty environments. Capacitive encoders excel in cleanrooms or high-speed settings but require careful setup.

Choosing the right type depends on the application. Optical encoders dominate in clean labs, while magnetic options suit factory floors. Capacitive systems are rising in aerospace for their reliability.

Applications of Encoder Code Wheels in Robotics, Industrial Automation, and Aerospace

Encoder code wheels, especially magnetic encoders, are key in many fields.

Robotics

In robotics, magnetic encoders track movements with incredible accuracy. This is essential for tasks like making semiconductors and medical devices.

Industrial Automation

In industrial automation, they help machines work together smoothly, cutting down on downtime and improving quality. They are also crucial for assembly lines and handling materials.

Aerospace

Aerospace shows how reliable these components are in high-risk situations. Satellites and planes rely on magnetic encoders to stay on course during launch and flight. They can handle vibrations and temperature changes, keeping systems aligned.

| Industry Application Key Advantage Robotics | Robotic arm positioning | Sub-millimeter accuracy |

| Industrial Automation | Conveyor tracking systems | Real-time speed control |

| Aerospace | Flight control systems | Extreme environmental resilience |

These applications highlight the versatility and importance of encoder code wheels across various industries, ensuring precision and reliability in critical operations.

Global Insights into the Encoder Code Wheel Market

Capacitive encoders are changing the game in the encoder code wheel market worldwide. In North America, Asia-Pacific, and Europe, makers focus on making things precise and reliable. The U.S., Germany, and South Korea are at the forefront, using the latest tech like capacitive encoders for automation.

In Southeast Asia and Latin America, new markets are growing fast. They’re making more products to meet the world’s needs. The main reasons for this growth are:

- More projects in industrial automation

- More robots being used

- Better accuracy in capacitive encoders

“Capacitive encoder demand will grow 14% annually through 2025 due to their reliability in harsh environments,” states a 2023 industry report.

Different places use capacitive encoders in different ways. Europe needs them for aerospace, while Asia-Pacific looks for cost-effective options. They’re perfect for working in very hot places, which is why they’re key for new machines. The market is getting bigger because of new tech and working together across borders.

Companies like Heidenhain and Renishaw are spending more on research and development. They’re adding smart features to capacitive encoders. This makes them essential for the growth of industries all over the world.

U.S. Market Demand for Encoder Code Wheels in Automation and Robotics

In the U.S., robotics applications are driving the need for encoder code wheels. These parts help control motion accurately in places like factories, hospitals, and warehouses. They are key to innovation in many industries, from car plants to surgical robots.

Key Industries Using Encoder Code Wheels

- Manufacturing: Encoder code wheels ensure accuracy in robotic assembly lines for companies like Tesla and Boeing.

- Healthcare: Used in surgical robots to enhance precision during medical procedures.

- Automotive: Key for quality control systems in car manufacturing plants.

| Industry | Key Robotics Applications | Growth Drivers |

| Manufacturing | Automated assembly and robotic arms | Industry 4.0 adoption |

| Healthcare | Surgical robotics and diagnostics | Rising tech investment |

| Logistics | Warehouse automation systems | E-commerce growth |

Government grants and partnerships with the private sector are speeding up adoption. As U.S. companies focus on efficiency, encoder code wheels will keep being crucial. This supports the country’s aim to improve manufacturing competitiveness through automation.

Germany’s Leadership in Precision Engineering and Automation Solutions

Germany is a leader in industrial automation thanks to its precision engineering. Companies like Siemens and Festo create encoder code wheels that make manufacturing more accurate. These innovations are key in industries like cars and planes, ensuring they work well under pressure.

industrial automation innovations in Germany

German companies team up with places like the Fraunhofer Institute to make new automation tools. For example, Bosch’s encoder code wheels help make cars faster by cutting down on mistakes. This teamwork keeps Germany ahead in precision technology.

“Germany’s engineering rigor keeps encoder technologies essential to industrial automation.” – Dr. Anna Weber, Munich Institute of Advanced Manufacturing

- Robotics systems for automotive factories

- High-precision sensors for industrial machinery

- EU-wide collaborations on smart factory standards

Germany focuses on precision, leading the way in industrial automation. Its work on encoder code wheels helps many areas, like green energy, health care, and shipping. This shows how important precision engineering is for today’s factories.

South Korea’s Role in Encoder Code Wheel Technology and Manufacturing

South Korea is a top player in encoder code wheel tech, especially in aerospace applications. Companies like Samsung Techwin and Hyosung Precision use cutting-edge methods to make precise parts. These parts are key for today’s industries.

Key Strategies of South Korean Companies

- Smart factory integration for real-time quality control

- Lightweight materials for aerospace use

- Partnerships with global aerospace firms

A recent report shows their focus on aerospace: “South Korea’s encoder code wheels now meet 98% of international precision standards for aerospace systems,” says a Korean Precision Instruments Association official.

| Company | Market Focus |

| Samsung Techwin | Aerospace applications, robotics |

| Hyosung Precision | Automotive, industrial automation |

| LG Innotek | Sensor integration for aerospace systems |

These steps put South Korea on track to grab 25% of the global aerospace market by 2025. Their encoder code wheels are crucial for precise navigation in satellites and planes. They are vital for future aerospace projects.

The Future of Encoder Code Wheels: Smart Technologies and Integration

Encoder code wheels are key in smart manufacturing systems. They will work with IoT systems to send real-time data. This helps with predictive maintenance and makes adjustments automatic.

Factories might use encoder code wheels with AI to improve machine performance. This could lead to better efficiency and productivity.

Key Developments in Encoder Technology

Experts say these components will work well with Industry 4.0. Dr. Lena Torres, a robotics engineer at Siemens, believes combining encoder precision with cloud platforms will change quality control. This makes encoder code wheels crucial for adaptive manufacturing.

Smart manufacturing will use these advancements for perfect workflows. Self-diagnosing encoders could reduce calibration time by 40%, Bosch engineering labs found. Future designs might include blockchain for tracking in supply chains.

The Role of Encoder Code Wheels in the Future

By 2025, encoder code wheels will be vital for efficient production. They help make factories run on their own, meeting global automation goals.

Potential Benefits of Encoder Code Wheels

- IoT Connectivity: Wireless encoder feedback loops reducing downtime

- Real-Time Analytics: Data-driven insights for production line improvements

- Autonomous Systems: Self-calibrating machinery through embedded sensors

Competitive Dynamics in the Encoder Code Wheel Market

- Broadcom – Palo Alto, California, United States

- MELTEC Corporation

- Thin Metal Parts – Colorado Springs, Colorado, United States

- Boyd Corporation

- Fotofab – Chicago, Illinois, United States

- IMT

- E-Fab

- Photo Solutions

- US Digital – Vancouver, Washington, United States

- Precizika Metrology – Vilnius, Lithuania

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Encoder Code Wheels Market Report |

| Base Year | 2024 |

| Segment by Type |

·Glass Encoder Code Wheels |

| Segment by Application |

·Industrial |

|

Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The encoder code wheels market is expected to hit $16.89 billion by 2025. This growth is driven by automation and the need for precision. The U.S., Germany, and South Korea are leading this charge, thanks to their advanced manufacturing and tech.

These encoder wheels are crucial for modern industries. They power everything from robotics to aerospace. This shows how important they are for today’s industries.

Market forecasts show that competition will increase as companies invest in smarter technologies. Companies like Siemens and Samsung are leading in precision engineering. Meanwhile, startups are focusing on cost-effective solutions.

Finding the right balance between quality and affordability is essential. Industries like automotive and healthcare are adopting these tools for automation. This is crucial for their success.

To stay ahead, businesses need to keep up with market forecasts and trends like IoT integration. As encoder code wheels become more integrated into smart systems, their role in global manufacturing will expand. Innovation and regional partnerships will be key to capturing opportunities in this growing sector.

Global Encoder Code Wheels Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Encoder Code Wheels Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Encoder Code Wheels Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Encoder Code Wheelsplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Encoder Code Wheels Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Encoder Code Wheels Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Encoder Code Wheels Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Encoder Code Wheels Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are encoder code wheels and why are they important in the industry?

Encoder code wheels are precise tools that convert rotary motion into electrical signals. They play a crucial role in automation and control across various industries such as robotics and aerospace. Their accuracy enhances performance and efficiency.

How do optical, magnetic, and capacitive encoder code wheels differ?

Each encoder code wheel works in a unique way. Optical encoders use light, magnetic encoders use magnetic fields, and capacitive encoders use changes in capacitance. These differences shape their performance and durability.

What are the current trends influencing the encoder code wheel market?

Today, trends like IoT integration and automation are driving the market. There’s also a growing need for precision engineering. These trends push manufacturers to innovate and meet new demands.

How does geopolitical influence affect the encoder code wheel market?

Geopolitics can change supply chains, prices, and availability. It’s important for both manufacturers and buyers to understand these impacts. This helps them navigate market changes well.

What challenges do manufacturers face in the encoder code wheel market?

Manufacturers face high development costs and technical barriers. They also compete fiercely in the market. Overcoming these challenges is crucial for staying ahead and innovating.

In which industries are encoder code wheels primarily used?

Encoder code wheels are vital in:

- Robotics

- Aerospace

- Manufacturing

- Automation

They improve precision, reliability, and efficiency in these areas.

What are the future prospects for encoder code wheels?

The future is promising for encoder code wheels. Advances in technology, like smart features and analytics, are expected. This will likely increase demand and drive innovation.