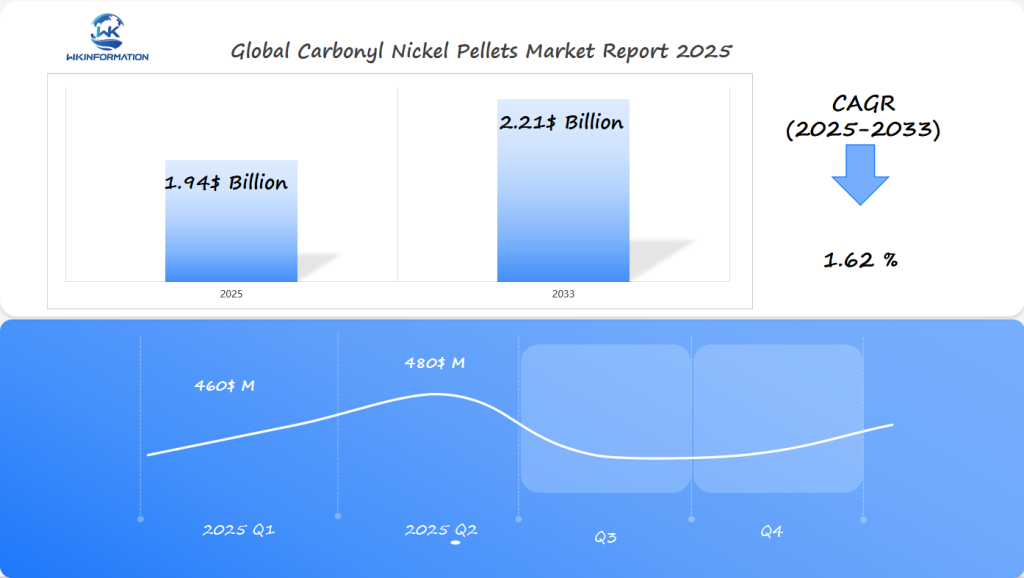

$1.94 Billion Carbonyl Nickel Pellets Market to Fuel Growth in the U.S., Russia, and China by 2025

Explore the expanding Carbonyl Nickel Pellets Market driven by rising demand in aerospace, electronics, and chemical industries. Get insights on market trends, key players, and growth prospects.

- Last Updated:

Projected Market Insights for Carbonyl Nickel Pellets in Q1 and Q2 of 2025

The Carbonyl Nickel Pellets market is expected to reach a market size of $1.94 billion in 2025, with a CAGR of 1.62% from 2025 to 2033. In Q1, the market is projected to generate approximately $460 million, driven by the growth of industries requiring high-quality nickel materials such as electronics, energy storage, and aerospace.

By Q2, the market is forecast to grow to around $480 million, supported by the increasing demand for high-performance alloys and batteries. The U.S., Russia, and China are expected to be the leading players in this market, with Russia and China being major producers of nickel and the U.S. focusing on high-tech manufacturing.

Exploring the Upstream and Downstream Industry Chains for Carbonyl Nickel Pellets

The carbonyl nickel pellets market is a complex system. It involves many stages of making and using these pellets. The global supply chain is key in shaping the industry’s future. Big players are working hard to meet changing market needs.

Nickel production is a detailed process. It turns raw materials into high-quality pellets for many industries. The supply chain has several important steps:

- Raw material extraction from nickel ore deposits

- Processing and refinement of nickel concentrates

- Carbonyl decomposition and pellet formation

- Quality control and purification

Raw Material Sourcing Strategies

Leading companies in nickel production are prioritizing better sourcing strategies. They actively seek out regions abundant in minerals and implement innovative extraction techniques to enhance efficiency.

Overview of Industrial Applications

Carbonyl nickel pellets are used in many important areas. These include:

- Electronics manufacturing

- Battery technology development

- Metallurgical processes

- Advanced material engineering

The market is always changing. New technologies and growing demand for pure nickel products are driving this change.

Key Trends in the Carbonyl Nickel Pellets Market

The carbonyl nickel pellets market is changing fast. This is thanks to new technology and changing needs in the industry. New trends are making production better and products purer, especially for high-purity nickel pellets.

New tech is making a big difference in making nickel pellets. Companies are using better methods to make products that are cleaner and work better in many fields.

Technological Advancements in Production

Here are some big changes in making carbonyl nickel pellets:

- Improved ways to handle chemicals

- Better systems for cleaning the product

- New filters to catch tiny particles

- Cleaner ways to make products to protect the environment

Shift Towards High-Purity Products

The market is moving towards high-purity nickel pellets. This is because industries need better materials. This is true for electronics, battery making, and advanced metal work.

The importance of high-purity nickel pellets is huge in today’s tech world.

Companies are spending a lot on research to meet higher quality standards. This keeps carbonyl nickel pellets important for new industrial uses.

Challenges in the Production and Purification of Carbonyl Nickel Pellets

The carbonyl nickel pellets industry faces complex challenges. It needs to follow environmental rules and keep up with market changes. Manufacturers must find a balance between new technology and keeping costs low.

Producing carbonyl nickel pellets is tough. It involves solving many problems in a detailed way. This includes dealing with environmental and economic issues.

Environmental Regulations and Compliance Strategies

Environmental rules have changed how carbonyl nickel pellets are made. Companies must use new ways to control emissions. They need to meet strict government standards.

- Develop low-emission production methodologies

- Invest in filtration and purification systems

- Reduce carbon footprint through innovative techniques

Cost Factors and Market Volatility Management

Market changes are big challenges for carbonyl nickel pellet makers. Prices for raw materials and global economic changes make it hard to predict business.

| Cost Factor | Impact Level | Mitigation Strategy |

| Raw Material Pricing | High | Long-term supply contracts |

| Energy Expenses | Medium | Energy-efficient technologies |

| Regulatory Compliance | High | Proactive environmental investments |

To overcome production challenges, a detailed plan is needed. Investing in cleaner technologies and adapting to market changes are key. These steps are vital for the sector’s growth.

Geopolitical Influence on the Carbonyl Nickel Pellets Market

The global carbonyl nickel pellets market is at a key point. It’s influenced by international trade, geopolitical strategies, and new technologies. Geopolitical factors play a big role in shaping the market in major countries.

Global market dynamics have changed how countries handle nickel production and trade. The mix of national interests and international relations makes things complex for makers and traders.

Impact of Trade Policies on Market Transformation

Trade policies play a crucial role in influencing the carbonyl nickel pellets market. Here are some significant ways in which they impact the industry:

- Protectionist measures are changing cross-border nickel deals.

- Bilateral agreements are reshaping regional supply chains.

- Restrictions on technology transfer are affecting production.

“The future of carbonyl nickel pellets is increasingly defined by geopolitical negotiations and strategic national interests.” – Global Market Analysts

Regional Supply and Demand Patterns

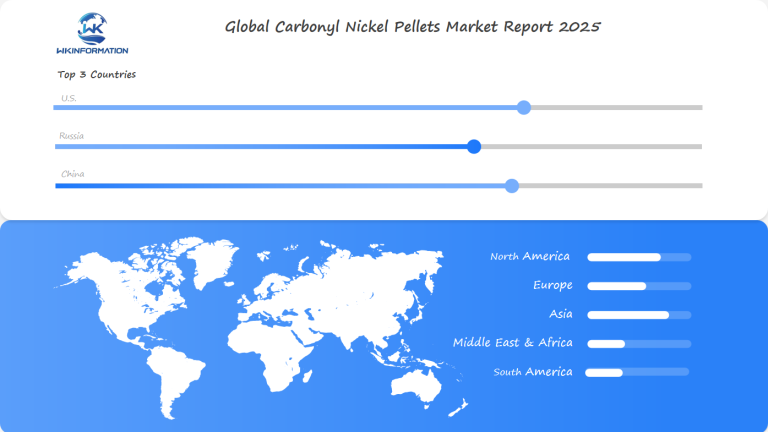

Supply and demand vary by region, creating complex market dynamics. The United States, Russia, and China are key players. Each country brings its own geopolitical view to industrial production.

Companies face challenges like international rules, tech limits, and national goals. They must stay competitive in this fast-changing market.

Types of Carbonyl Nickel Pellets: Properties and Uses

The carbonyl nickel pellets market has many types, each for different needs. Knowing about these types helps makers and researchers pick the right materials.

Carbonyl nickel pellets differ by their sulphur content. This affects their properties and uses. These differences help them work well in various fields.

Sulphur-Free Nickel Pellets

Sulphur-free nickel pellets are top-notch. They have:

- Exceptional purity levels

- Minimal environmental contamination

- Superior electrochemical performance

- Ideal for high-precision electronic applications

Low-Sulphur and High-Sulphur Varieties

The market has two main sulphur-content types:

| Pellet Type | Sulphur Content | Primary Applications |

| Low-Sulphur Nickel Pellets | 0.01-0.1% | Battery technology, electronic components |

| High-Sulphur Nickel Pellets | 0.1-1% | Metallurgical processes, industrial manufacturing |

The electrochemical performance changes with sulphur content. Sintered plate technology with carbonyl nickel powder boosts activity and energy in Ni-MH batteries.

Applications of Carbonyl Nickel Pellets in Electronics, Batteries, and Metallurgy

Carbonyl nickel pellets play a crucial role in various industries today. Their unique properties make them a game-changer in multiple fields, including electronics, batteries, and metallurgy. These metals are essential for advancing technology and manufacturing processes.

Carbonyl nickel pellets find applications in several key areas:

- Electronics industry: Used in the production of electronic components and devices.

- Battery technology: Contributing to the development of efficient and long-lasting batteries.

- Metallurgical processing: Enhancing metalworking processes and improving material properties.

- High-performance component fabrication: Enabling the creation of specialized parts for demanding applications.

Role in High-Performance Electronics

In the world of electronics, these pellets play a crucial role. They are used to create intricate devices where their exceptional conductivity and durability make them ideal for manufacturing circuit boards and semiconductors.

“Nickel powder is a fundamental building block in advanced electronic components” – Materials Science Institute

Importance in Battery Technology

Batteries have improved a lot with carbonyl nickel pellets. They help batteries hold more energy. This means electric cars, phones, and green energy systems last longer.

Use in Metallurgical Processes

Metallurgy uses these pellets to make strong alloys. Their special mix helps make materials for planes, cars, and big machines.

| Industry | Application | Significance |

| Electronics | Circuit Manufacturing | High Conductivity |

| Battery | Energy Storage | Enhanced Performance |

| Metallurgy | Alloy Development | Structural Integrity |

The electroplating and high-temperature alloy sectors need a lot of these pellets. They use over 80% of the world’s supply.

Global Insights into the Carbonyl Nickel Pellets Market

The global carbonyl nickel pellets market is evolving rapidly with significant developments occurring in various regions. Growth projections indicate a substantial potential for expansion.

Analyzing the global market provides valuable insights into the regional variations within the carbonyl nickel pellets industry. This presents opportunities for strategic investments and growth.

Regional Market Shares and Strategic Positioning

Each major region has its own way of making and using carbonyl nickel pellets:

- Asia-Pacific is a dominant growth center

- North America leads in tech innovation

- Europe focuses on green production

- Southeast Asia is growing fast in industry

Emerging Markets and Investment Opportunities

Developing economies hold a lot of growth potential. Investors are drawn to places with strong factories and tech skills.

There are big chances for growth in:

- Advanced electronics making

- Battery tech

- High-performance metal work

- Green materials

The carbonyl nickel pellets market is where tech meets industry.

For those in the market, knowing the local scene, tech levels, and new trends is key. The world is changing, offering both challenges and chances for growth and new ideas.

U.S. Market Demand for Carbonyl Nickel Pellets in Electronics and Batteries

The U.S. electronics and battery sectors are seeing a big increase in demand for carbonyl nickel pellets. The United States, with its strong manufacturing base, is a key player worldwide in this market.

Several factors are driving the growth of the carbonyl nickel pellets market in the U.S.:

- Expanding electric vehicle production

- Advanced electronics manufacturing

- Increasing demand for high-performance battery technologies

- Investments in renewable energy storage solutions

Growth Drivers in the U.S. Market

Technological advancements are changing how the electronics industry gets its materials. Carbonyl nickel pellets are now crucial for making precise electronic parts and advanced batteries.

Key Industries Fueling Demand

Several strategic industries are boosting carbonyl nickel pellets demand in the U.S.:

- Aerospace technology

- Renewable energy sector

- Consumer electronics

- Electric vehicle manufacturing

The battery sector is a major driver for carbonyl nickel pellets growth. Companies are looking for purer and more refined materials for the latest energy storage tech.

Russia’s Role in Nickel Production and Supply Chain for Global Markets

Russia’s nickel production is key to the global supply chain. Nornickel, the top mining company, leads in making carbonyl nickel pellets. This has a big impact on markets around the world.

Russia has a lot of mineral resources, making it important in the nickel market. Its unique geology lets it produce a lot. This affects trade and supply chains globally.

Strategic Nickel Resources and Production Potential

The Russian nickel sector has many strengths:

- Extensive mineral deposits in Siberian and Arctic regions

- Advanced extraction and processing technologies

- Significant investment in mining infrastructure

- Competitive production costs

Global Supply Chain Dynamics

Russian nickel production shapes global market trends. The country’s exports and production levels affect prices and availability. This shapes the international metal market.

“Russia’s nickel resources represent a critical component of the global industrial supply ecosystem.” – International Mining Report

Geopolitics also play a big role in Russia’s market influence. Strategic partnerships and trade agreements help it stay competitive in making and distributing carbonyl nickel pellets.

China’s Dominance in Carbonyl Nickel Pellet Production and Consumption

The Chinese market has become a key player in the global carbonyl nickel pellets industry. It has changed how production and consumption happen. China’s strong manufacturing and economic position have reshaped the nickel pellet world.

China leads in making carbonyl nickel pellets. It has several strengths:

- Advanced technological infrastructure

- Massive production capacity

- Competitive cost structures

- Sophisticated research and development initiatives

Domestic Market Dynamics

The demand for carbonyl nickel pellets in China is growing fast. This is thanks to key sectors like electronics, battery making, and metal industries. The internal market is big and supports constant innovation and growth.

| Sector | Consumption Growth Rate | Annual Demand (Metric Tons) |

| Electronics | 12.5% | 35,000 |

| Battery Manufacturing | 18.3% | 48,500 |

| Metallurgy | 9.7% | 22,000 |

Export Strategy and Global Impact

China’s plan for exporting carbonyl nickel pellets is smart. It has a big impact on the global market. China’s strong production helps set prices and shape supply chains worldwide.

China keeps changing the global carbonyl nickel pellets market. It sets new standards for making things efficiently and innovatively.

The Future of Carbonyl Nickel Pellets: Innovations in Energy Storage and Industry

The carbonyl nickel pellets market is evolving rapidly, driven by advancements in technology and sustainable production methods. Industries are seeking improved energy storage solutions, while researchers are investigating alternative materials and refining manufacturing processes.

How Technology is Transforming Carbonyl Nickel Pellets

Innovative technologies are reshaping the application of carbonyl nickel pellets. We are now able to enhance their quality and environmental friendliness, resulting in reduced ecological impact and enhanced efficiency.

Emerging Technologies and Applications

Big changes are happening in carbonyl nickel pellets:

- Advanced battery technology for electric vehicles

- Production of high-quality electronics

- Precision metalworking

Sustainable Production Methods

Now, making carbonyl nickel pellets is all about being green. Companies are trying new ways to be kinder to the planet:

- Green ways to get the nickel

- Using solar power to make them

- Recycling to make new pellets

| Innovation Category | Key Developments | Potential Impact |

| Energy Storage | Nano-structured nickel materials | More power and better batteries |

| Sustainable Production | Low-carbon extraction methods | Less pollution |

| Manufacturing | Precision pellet engineering | Better materials |

The future of carbonyl nickel pellets is bright. Ongoing research and development are leading to big leaps in energy storage and industry use.

Competitive Dynamics in the Carbonyl Nickel Pellets Market

The global carbonyl nickel pellets market is very competitive. Top companies like Nornickel, Jinchuan Group, and Vale hold about 65% of the market. Their strategies have led the industry and kept them at the top.

- Nornickel – Russia

- Jinchuan Group – China

- Vale – Brazil

- Glencore – Switzerland

- Anglo American – UK

- BHP – Australia

- Sumitomo Metal Mining Co., Ltd. – Japan

- Sherritt International Corporation – Canada

- ERAMET – France

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Carbonyl Nickel Pellets Market Report |

| Base Year | 2024 |

| Segment by Type |

· Low-Sulphur Nickel Pellets · High-Sulphur Nickel Pellets |

| Segment by Application |

· Electronics · Battery · Metallurgy |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The carbonyl nickel pellets market continues to grow steadily, driven by demand from automotive, aerospace, and chemical industries. High-performance materials like nickel-based superalloys and catalysts remain key drivers. The shift toward electric vehicles and renewable energy applications presents significant opportunities. However, challenges such as price volatility and regulatory pressures persist.

Stakeholders should focus on understanding market trends and consumer behavior to optimize strategies. Investing in sustainable production and leveraging emerging applications can ensure long-term growth. Collaboration and innovation will remain critical for navigating challenges and capitalizing on opportunities.

Global Carbonyl Nickel Pellets Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Carbonyl Nickel Pellets Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Vacuum Arc RemeltingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Carbonyl Nickel Pelletsplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Carbonyl Nickel Pellets Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Carbonyl Nickel Pellets Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Carbonyl Nickel Pellets Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofCarbonyl Nickel Pellets Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are carbonyl nickel pellets?

Carbonyl nickel pellets are pure nickel particles made through a special chemical process. This process involves nickel carbonyl decomposition. They are used in advanced manufacturing, electronics, and battery technologies.

How are carbonyl nickel pellets different from traditional nickel products?

Carbonyl nickel pellets have higher purity than traditional nickel products. They have very low impurities. This makes them perfect for high-performance uses in electronics, advanced batteries, and precise metallurgical processes.

What industries primarily use carbonyl nickel pellets?

Carbonyl nickel pellets are primarily used in various industries that require high-quality nickel materials. These industries include:

- Electronics manufacturing: Carbonyl nickel pellets are used in the production of electronic components such as connectors, switches, and circuit boards.

- Battery technology: They play a crucial role in the manufacturing of rechargeable batteries, including nickel-metal hydride (NiMH) and nickel-cadmium (NiCd) batteries.

- Aerospace: Carbonyl nickel pellets are utilized in the aerospace industry for the production of lightweight and high-strength components used in aircraft and spacecraft.

- Automotive components: These pellets are employed in the manufacturing of automotive parts like fuel cells, electric vehicle batteries, and various engine components.

- Electrical engineering: Carbonyl nickel pellets find applications in electrical engineering for the production of specialized electrical contacts and connectors.

- Metallurgical applications: They are also used in specialized metallurgical processes where specific properties of nickel are required.

These industries rely on carbonyl nickel pellets due to their unique properties such as excellent corrosion resistance, high thermal conductivity, and good mechanical strength.

What are the major geographic markets for carbonyl nickel pellets?

The main markets for carbonyl nickel pellets are:

- United States

- China

- Russia

- Key industrial areas in Europe

These countries play a significant role in the production, consumption, and technological innovation of carbonyl nickel pellets.

What environmental challenges exist in carbonyl nickel pellet production?

Manufacturers face strict environmental rules on emissions, waste, and chemical processing. They need to keep investing in green production and follow regulations.

How do geopolitical factors impact the carbonyl nickel pellets market?

International trade policies, resource availability, and geopolitical tensions affect the market. Strategic partnerships also play a big role in pricing and supply chains.

What types of carbonyl nickel pellets are available?

There are three types of carbonyl nickel pellets available: sulphur-free, low-sulphur, and high-sulphur. Each type is designed to meet specific industrial requirements and performance standards.

What technological trends are shaping the carbonyl nickel pellets market?

New trends include advanced production methods and a growing need for pure products. Sustainable manufacturing and innovations in energy storage are also key.

What future applications are expected for carbonyl nickel pellets?

They will be used in advanced battery technologies, next-generation electronics, and renewable energy storage. They will also be needed in emerging industries that require high-quality metallic materials.

How are companies competing in the carbonyl nickel pellets market?

Companies compete by innovating, improving product quality, forming partnerships, and investing in R&D. They also expand their global manufacturing.