Cold Spray Technology Market Expected to Reach $1.06 Billion Globally by 2025 with Leading Growth in the U.S., Germany, and South Korea

Discover the expanding Cold Spray Technology Market trends, innovations, and growth opportunities. Analysis of key players, applications, and regional developments driving market expansion.

- Last Updated:

Cold Spray Technology Market Development and Q1 and Q2 of 2025 Forecast

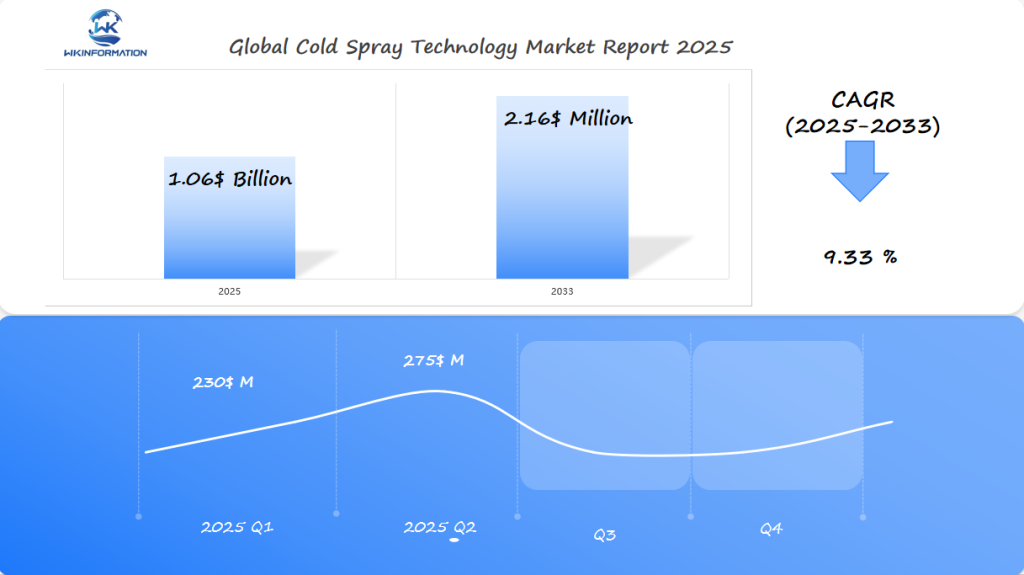

The Cold Spray Technology market is projected to reach $1.06 billion in 2025, exhibiting a strong CAGR of 9.33% through 2033. In Q1 of 2025, the market is estimated at approximately $230 million, increasing to around $275 million in Q2, fueled by growing adoption in aerospace, automotive, and electronics industries. The U.S., Germany, and South Korea lead this market with their advanced manufacturing capabilities and focus on innovative surface engineering solutions. Increasing demand for cost-effective repair and coating technologies, along with rising investments in additive manufacturing, supports this robust growth.

Key Takeaways

- Cold spray technology market projected to reach $1.06 billion by 2025

- Innovative coating method with minimal thermal impact

- Expanding applications across multiple industrial sectors

- Significant investment in research and development

- Growing demand for high-performance surface treatment solutions

Dissecting the Upstream and Downstream Industry Chain of Cold Spray Technology

Upstream Industry Chain

The upstream segment of cold spray technology involves the development and supply of core materials, equipment, and research innovation that enable the cold spray process:

- Raw Materials Suppliers: Providers of metal powders and advanced materials essential for cold spray coatings. These materials must meet stringent quality standards to ensure strong adhesion without melting.

- Equipment Manufacturers: Developers of high-velocity cold spray systems including nozzles, compressors, and control units. Innovation in equipment enhances coating precision and efficiency.

- Research & Development Entities: Universities, research institutes, and private R&D centers focusing on advancing cold spray methods, creating new applications, and improving material formulations.

Investment in this segment is critical as it drives technological improvements, enabling better performance and opening new industrial applications.

Downstream Industry Chain

The downstream industry chain focuses on the application sectors where cold spray technology is utilized to add value through surface treatment, restoration, or manufacturing enhancements:

- Aerospace Industry: Uses cold spray for component restoration, lightweight coatings, and corrosion resistance. North America leads with major aerospace firms adopting this technology.

- Automotive Industry: Innovations include lightweight components and improved durability coatings in vehicles. The demand for light materials drives adoption here.

- Manufacturing Sector: Incorporates cold spray for layer-by-layer additive manufacturing, repair of machinery parts, and green manufacturing processes with minimal thermal impact.

Geographically, Asia (notably South Korea) is rapidly expanding due to smart investments; Europe balances precision engineering with sustainability; North America leads in aerospace and defense applications.

Current Market Trends and Emerging Applications

The cold spray technology market is changing fast. New technologies are coming up in many fields. This is changing how we make and use materials.

Some big trends in the market are:

- More demand for light materials in cars and planes

- More focus on green manufacturing

- More use in making things layer by layer

- Being able to fix and restore materials better

New tech is making cold spray better and more efficient. Scientists are working on new ways to coat things. These new ways are opening up more uses for cold spray in different areas.

The car and plane industries are using cold spray a lot. They’re making complex shapes, saving materials, and making parts last longer. This is leading to more money spent on research and development.

Market trends show the market will keep growing. Companies see the benefits of using cold spray. It can make things better, help the environment, and save money.

Regulatory and Market Constraints Affecting Cold Spray Technology

The cold spray technology market has big regulatory hurdles. These rules shape how it grows and is used in different fields. Strict standards offer both hurdles and chances for makers and researchers.

Some big challenges for cold spray technology are:

- High initial investment costs for specialized equipment

- Limited skilled operator availability

- Complex certification processes in aerospace and defense sectors

- Regional variations in technological acceptance

Rules are key in shaping the tech world. Each field has its own rules that makers must follow closely. The aerospace and defense industries, in particular, demand rigorous quality control and performance standards.

| Industry Sector | Regulatory Challenge | Impact Level |

| Aerospace | Material Performance Certification | High |

| Automotive | Durability and Safety Standards | Medium |

| Manufacturing | Equipment Standardization | Medium-Low |

Companies need to invest in training and ongoing research to beat these rules. Making better cold spray tech that meets tough standards is key for growth and adoption.

Geopolitical Developments Driving Market Expansion

The cold spray technology market is seeing big changes because of complex global politics. Global trade is changing the industry’s shape. This is opening up new chances for growth in different countries.

Important changes in key areas are changing the game. Countries are seeing cold spray technology as a key way to improve manufacturing and materials science.

- International research collaborations are speeding up new discoveries

- Trade policies are now supporting advanced manufacturing tech more

- Governments are putting money into research and development

Even though there are tensions, they are making more money go into cold spray technology. Countries want to be independent in tech and have strong manufacturing. This has led to a lot of funding for new industrial methods.

Asia and Europe are showing a lot of growth. Technological transfer and strategic partnerships are key for growing the market. They help companies deal with the complex world of international trade.

Economic ties and new tech are starting a new chapter in global trade for cold spray technology. This has big effects on industrial competition and tech progress.

Segmentation Analysis by Type of Cold Spray Technology

The cold spray technology market is very diverse. It has two main types: low-pressure and high-pressure systems. These types help in making different products.

Each technology type has its own features:

- Low-Pressure Cold Spray Systems

- Ideal for delicate surface treatments

- Lower operational costs

- Suitable for precision manufacturing

- High-Pressure Cold Spray Systems

- Enhanced coating performance

- Higher deposition rates

- More robust industrial applications

Experts say that the type of technology is key to the market’s success. The choice of cold spray technology affects performance, efficiency, and capabilities.

New markets are showing interest in advanced cold spray technologies. The aerospace and automotive sectors are leading in adopting these technologies. This drive for innovation leads to solutions for tough industrial problems.

Applications Across Aerospace, Automotive, and Manufacturing Industries

Cold spray technology has revolutionized various sectors within large industries. It addresses complex engineering challenges through innovative approaches. This technique is ideal for surface modifications, repairs, and the creation of new products.

This technology is highly versatile. It finds applications in multiple domains, enhancing precision and advancing material properties.

Aerospace Component Restoration

In aerospace, cold spray works wonders for important parts. Engineers use it to:

- Fix expensive turbine engine parts

- Make aircraft structures better

- Put on light, protective coatings

- Do precision surface modifications

Automotive Industry Innovations

Car makers use cold spray to make cars better and last longer. They do things like:

- Apply coatings that stop corrosion

- Make surfaces wear-resistant

- Use new ways to make things lighter

- Regenerate precise parts

Changes in the Manufacturing Industry

Cold spray technology has greatly benefited the manufacturing industry by addressing significant challenges. Its applications include:

- Repairing machinery components

- Enhancing electronic devices

- Reviving precision tools

- Applying materials in innovative methods

This technology is revolutionizing production processes in sectors such as aerospace, automotive, and manufacturing, leading to substantial improvements.

Global Regional Highlights for Cold Spray Technology Markets

The global market for cold spray technology shows big differences in each region. Each area has its own chances and hurdles. The way market share and technology use vary across continents is interesting.

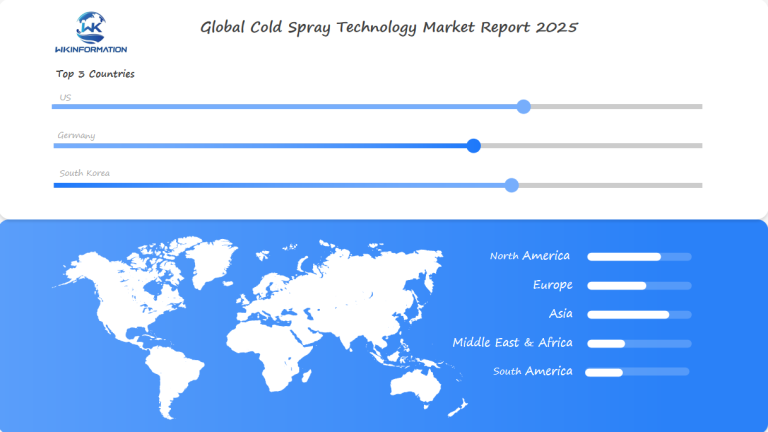

North America: Leading the Way with Aerospace and Defense

In North America, cold spray technology is booming thanks to the aerospace and defense sectors. The United States is a major player, with lots of money going into research. The region’s strengths include:

- High technological penetration

- Strong research infrastructure

- Significant government funding

- Robust manufacturing ecosystem

Asia: Rapid Growth through Smart Investments

Asian markets, especially China and South Korea, are growing fast. They’re gaining market share with smart industrial investments and new manufacturing skills.

Europe: Balancing Precision Engineering and Sustainability

European markets take a balanced approach to cold spray technology. Countries like Germany and Switzerland focus on precision engineering and new industrial solutions. Their strategy includes:

- Advanced material research

- Sustainable manufacturing processes

- Cross-industry technological integration

Emerging markets in Latin America and Africa offer big chances for cold spray technology growth. These areas are seeing more interest from industries looking for advanced manufacturing methods.

U.S. Market Outlook and Growth Drivers

The U.S. cold spray technology market is growing fast. This growth comes from new research and smart investments. The market size hit $320 million in 2024 and is expected to grow a lot more in the next ten years. Precedence Research sees a bright future for this advanced technology.

What’s Driving This Growth?

What’s driving this growth in the U.S. market includes:

- More demand from the automotive and transportation sectors

- Big investments in research for self-driving cars

- Improved manufacturing methods

- Strong growth in aerospace and defense

Promising Future Ahead

Top companies are leading the way in new tech. The U.S. market shows great promise, with growth expected to hit around $650 million by 2034. This growth rate is about 7.28% each year.

North America’s Leadership

North America, especially the U.S., leads the world in cold spray technology. The U.S. is key in pushing tech forward and growing the market. Research and development are opening up new chances in many fields, making the U.S. a world leader in this tech.

Germany's Market Position and Innovation Trends

Germany is at the forefront of cold spray technology, demonstrating strong leadership in Europe. The German market plays a crucial role in adopting new technologies, particularly in the industrial sector. According to Grand View Research, Germany holds a significant 23.5% share of the European market.

Key Trends Driving Innovation in Germany

Several important trends are shaping the innovation landscape in Germany:

- Advanced research in automotive and aerospace industries

- New developments in materials engineering

- High-precision manufacturing techniques

- Adoption of green technologies

Investment in Cold Spray Technology

German research institutions and manufacturers are driving technological advancements through substantial investments. Their well-established industrial infrastructure enables them to swiftly prototype and implement new cold spray technologies. The automotive, aerospace, and machinery sectors are at the forefront of this movement, exploring uncharted territories of technological possibilities.

Germany’s Contribution to Europe’s Cold Spray Leadership

Germany’s emphasis on research and development plays a vital role in maintaining Europe’s leadership position in cold spray technology. Dedicated teams are continuously discovering novel applications, enhancing material properties, and optimizing production processes.

South Korea's Expanding Market and Opportunities

The South Korean market is a key player in cold spray technology. It has strong government support and a dynamic industrial scene. This makes South Korea a major player in the Asian market growth.

Leading Sectors in Cold Spray Technology

South Korea has made big strides in research and development. Its electronics and automotive sectors are leading the way in cold spray technology. This has opened up big opportunities for market growth.

Key Drivers of Market Growth

- Strong government funding for advanced manufacturing technologies

- Substantial investments in research and development

- Growing demand in high-tech industrial sectors

Strengths of South Korea’s Market

South Korea’s market has several key strengths:

- Highly skilled technical workforce

- Advanced manufacturing infrastructure

- Commitment to technological innovation

International Interest and Collaboration

More and more international companies see the potential in South Korea. Collaborative partnerships and strategic market entry are key to tapping into the country’s tech ecosystem.

With government support, industrial demand, and tech expertise, South Korea is a big player in cold spray technology worldwide.

Forecasting Future Development and Technological Progress

The cold spray technology market is set for big changes. These changes will change how we make things in factories. Researchers are working on new ways to make cold spray systems better. They want to use them in more areas.

Market predictions include:

- Advanced material engineering for more sophisticated powder compositions

- Precision spray nozzle designs improving coating uniformity

- Integration with artificial intelligence for real-time process monitoring

New technologies will help the market grow. The global cold spray technology market expects to grow. This will happen because of new ways to make things cheaper and better.

Experts say we will see big improvements in aerospace, automotive, and electronics. Making things in a way that’s good for the planet will help cold spray technology grow. This could include:

- Reduced environmental impact manufacturing processes

- Enhanced material recycling capabilities

- Improved energy efficiency in coating applications

Combining advanced materials science with precision engineering looks promising. Companies that invest in research will lead the way. They will help cold spray technology grow worldwide.

Competitive Overview of Major Industry Players

Key players in the cold spray technology market are investing in research and development to refine deposition efficiency and expand the range of applicable materials. They are also targeting growth in sectors such as aerospace and defense across regions like North America and Europe, where demand for advanced surface coating and repair solutions is accelerating.

Key Players:

-

Centerline (Praxair) (Canada / United States)

-

VRC Metal Systems (United States)

-

Impact Innovations (Germany)

-

Kinexus (United States)

-

Plasma Giken (Japan)

-

Cold Jet (United States)

-

TWI Ltd (United Kingdom)

-

Bodycote (United Kingdom)

-

Oerlikon Metco (Switzerland)

-

Linde (Ireland / Germany)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Cold Spray Technology Market Report |

| Base Year | 2024 |

| Segment by Type |

· Low-pressure · High-pressure |

|

Segment by Application |

· Aerospace · Automotive · Manufacturing |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Cold Spray Technology Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Cold Spray Technology Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Cold Spray Technology Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Cold Spray Technology Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Cold Spray Technology Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Cold Spray Technology Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Cold Spray Technology Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Cold Spray Technology Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is Cold Spray Technology?

Cold spray technology is a new way to spray materials onto surfaces. It uses fast gas to deposit particles at low temperatures. This method doesn’t melt the particles like old methods do. Instead, it uses speed to create strong bonds.

Which industries primarily use Cold Spray Technology?

Cold spray technology is used in various industries such as:

- Aerospace

- Automotive

- Manufacturing

- Defense

- Electronics

It is particularly effective for applications such as repairing components, safeguarding surfaces, and creating coatings that resist wear.

What are the main advantages of Cold Spray Technology?

Cold Spray Technology offers several advantages, including:

- Low temperatures during the application process

- No thermal distortion of the substrate material

- Strong bonding between the coating and substrate

- Compatibility with a wide range of materials

- Reduction of oxidation during coating

- Improvement of material properties through the spray process

How does Cold Spray Technology contribute to sustainable manufacturing?

Cold Spray Technology contributes to sustainable manufacturing in several ways:

- Reducing waste: Instead of discarding damaged parts, we can repair them using cold spray technology, which minimizes waste generation.

- Using less energy: Cold spray processes typically require lower temperatures compared to traditional manufacturing methods, resulting in reduced energy consumption.

- Lowering environmental impact: By utilizing recyclable materials and avoiding the need for extensive machining or melting processes, cold spray technology helps decrease the overall environmental footprint of manufacturing operations.

Which countries are at the forefront of Cold Spray Technology development?

The United States, Germany, South Korea, and others are leading the way in Cold Spray Technology development. They invest in research, develop new applications, and support the growth of this technology.

What challenges does Cold Spray Technology currently face?

Cold Spray Technology faces several challenges:

- High costs

- Limited awareness

- The need for skilled workers

- Requirement of special equipment

- Ongoing research needs

These are the main challenges that Cold Spray Technology is currently facing.

What is the projected market growth for Cold Spray Technology?

The market is expected to grow significantly, potentially reaching $1.06 billion by 2025. This growth is primarily driven by demand in the aerospace, automotive, and manufacturing industries.

How does Cold Spray Technology differ from traditional thermal spray methods?

Cold spray doesn’t melt materials like old methods do. It uses fast gas to deposit particles at low temperatures. This causes less damage and better bonding.

What types of Cold Spray Technologies exist?

There are two main types of Cold Spray Technologies: low-pressure and high-pressure systems. Each type is designed for specific applications and has its own characteristics. Here are some key differences between the two:

- Gas Speed: Low-pressure systems typically have lower gas speeds compared to high-pressure systems. This means that the particles being sprayed may not reach as high velocities in low-pressure systems.

- Particle Acceleration: High-pressure systems are known for their ability to accelerate particles at much higher rates than low-pressure systems. This can result in better coating adhesion and density.

- Material Compatibility: Depending on the materials being used, one type of system may be more suitable than the other. Some materials may require higher gas speeds or specific particle acceleration techniques to achieve optimal results.

Understanding these differences can help determine which Cold Spray Technology is best suited for a particular application or project.

What future developments are expected in Cold Spray Technology?

We expect better nozzle designs, new powder materials, and more uses. There will also be better process control. These advancements will improve the technology.