Automotive Paint Robot Market Projected to Reach $1.36 Billion Globally by 2025 with Leading Growth in the U.S., Germany, and Japan

Discover the latest trends and growth prospects in the Automotive Paint Robot Market, featuring advanced automation solutions, key manufacturers, and regional expansion opportunities.

- Last Updated:

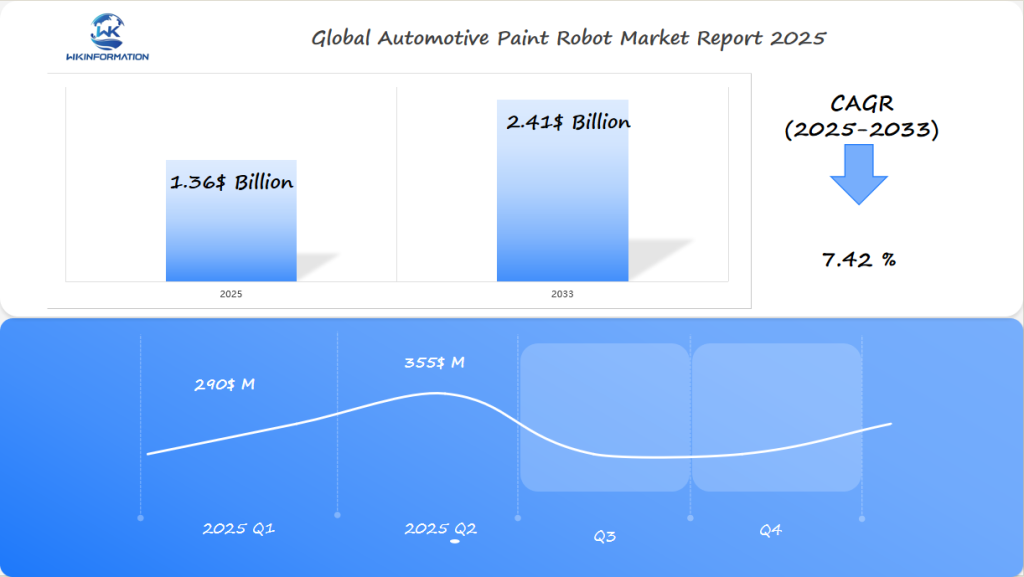

Automotive Paint Robot Market Growth and Q1 and Q2 of 2025 Forecast

The Automotive Paint Robot market is projected to reach $1.36 billion in 2025, supported by a CAGR of 7.42% through 2033. The start of the year is expected to reflect the cyclical nature of automotive production, with Q1 forecasted at approximately $290 million and Q2 climbing to around $355 million as vehicle assembly ramps up across global OEMs. Innovations in precision coating and energy-efficient robotic systems are boosting demand.

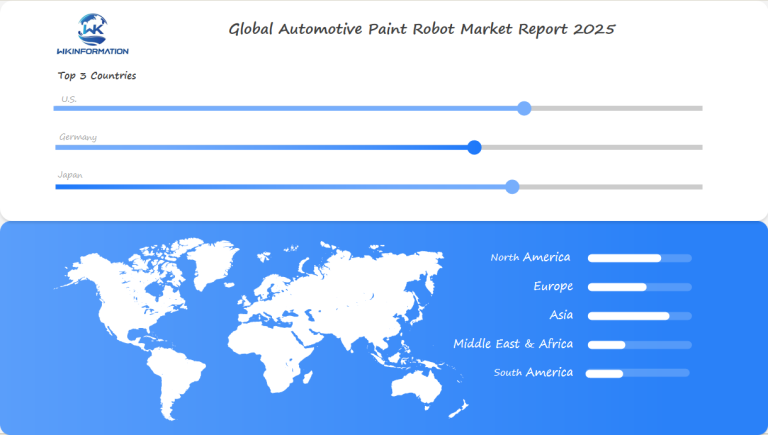

The U.S., Germany, and Japan emerge as the most strategic markets due to their well-established automotive manufacturing bases and aggressive automation investments. These countries are also spearheading the shift toward EV production, which increasingly relies on robotics for consistent, high-quality painting applications—making them essential to the segment’s global expansion.

Key Takeaways

- The global market for automotive paint robots is expected to reach $1.36 billion by 2025.

- The U.S. and Germany are at the forefront of technological advancements in this field.

- There is a growing emphasis on automated and sustainable painting technologies.

- Major automotive manufacturers are making significant investments in this area.

- Technological innovation is a key factor driving the expansion of the market.

Understanding the Upstream and Downstream Industry Chain Behind Automotive Paint Robots

The automotive paint robot industry is a complex mix of technology and manufacturing strategy. At its heart, it involves advanced robot parts and innovative paint tech. These elements drive today’s manufacturing methods.

Automotive paint robots have changed how we make things by adding new tech at every stage. The upstream part of this chain focuses on key parts that make things precise and efficient.

Key Components and Suppliers

The main parts of automotive painting systems include:

- Robotic arms with multi-axis articulation

- Sophisticated paint dispensing mechanisms

- Advanced sensor and control systems

- High-precision motion tracking technologies

Big names like Dürr Group are key in making new paint tech. They invest in automation and green tech. This has made painting more precise and cut down on harm to the environment.

End-User Industries and Applications

While cars are the main users, other fields are starting to use these robots too:

- Aerospace manufacturing

- Industrial equipment production

- Marine vessel construction

- Agricultural machinery fabrication

The growing use of automotive paint robots shows their wide appeal. They’re changing how we coat surfaces in many industries.

Market Dynamics and Emerging Trends Shaping the Future of Automotive Paint Robots

The automotive industry is going through big changes in paint robot technology. New market trends and green initiatives are leading the way. Companies are quickly adopting new painting methods that change how cars are made.

Technological Advancements Revolutionizing Paint Robots

New technology in paint robots has made car painting better. Some key improvements include:

- Enhanced precision targeting

- Faster painting speeds

- Advanced color matching algorithms

- Real-time quality control systems

Car makers are spending a lot on robots that are more accurate and efficient. Artificial intelligence integration lets robots handle different surfaces and paint needs better.

Sustainable Painting Strategies

Sustainability is a big factor in paint robot development. The industry aims to reduce its environmental impact by:

- Minimizing paint waste

- Reducing energy consumption

- Using eco-friendly paints

- Creating closed-loop recycling systems

These green painting methods cut down on carbon emissions and save money for car makers. The move towards eco-friendly tech is changing the market and pushing innovation in paint robots.

Key Restrictions Influencing Automotive Paint Robot Industry Expansion

The automotive paint robot industry is facing big hurdles that slow its growth worldwide. These challenges come from technical and economic barriers that makers must tackle.

Technical Challenges

Paint robots have big limitations that make them hard to use everywhere. They find it tough to paint complex car designs and keep paint quality steady on different materials. Makers face many big challenges:

- Precision painting for complex vehicle geometries

- Adapting to multiple surface textures and materials

- Minimizing paint waste and overspray

- Ensuring uniform coating thickness

Technical Complexities in Robotic Painting

Advanced programming is a significant technical challenge. Car manufacturers must invest heavily in developing robotic control systems that can handle various painting tasks. Advanced sensor technologies are crucial for achieving the level of accuracy required in automobile production.

Economic Investment Challenges

There are also big financial hurdles. Starting up robotic painting systems costs a lot, putting pressure on car makers’ budgets. Small and medium-sized businesses often can’t afford these costs, making it hard for them to update their painting methods.

But, creative companies keep working on solutions. They aim to lessen the economic and technical hurdles in car painting.

Geopolitical Factors Driving Market Evolution for Automotive Paint Robots

The market for automotive paint robots is changing a lot because of global politics. Trade policies and where things are made are making big changes. These changes affect how companies make and sell their products.

New global politics are changing how cars are made. Countries are moving their factories to get ahead in the world market.

Trade Policies Reshaping Manufacturing Strategies

New trade rules are bringing big challenges and chances for makers of paint robots. Some key things happening include:

- Tariffs on robot parts between big car-making countries

- Changes in supply chains to avoid economic risks

- New trade deals affecting how tech is shared

Regional Manufacturing Transformation

Changes in how things are made are greatly benefiting paint robots. Regions such as Southeast Asia and Eastern Europe are acquiring more technology, which creates new opportunities in the market.

Smart manufacturers are developing robots that can quickly adapt to different regulations and requirements in various locations. This capability enables them to navigate the complexities of the global market.

The ongoing shifts in global politics are driving paint robot manufacturers to develop improved, more versatile technology. This technology must accommodate diverse manufacturing standards and budgets across different regions.

Clear Segmentation of Automotive Paint Robots by Type

Robotic technology has changed the game in the automotive paint industry. It brings precision and speed to different robot types. Now, makers use advanced robots to make painting better and faster.

The market for automotive paint robots has three main types. Each has its own strengths and uses:

- Cartesian Robots: Great for straight lines and exact spots

- SCARA Robots: Best for painting on curved surfaces

- Articulated Robots: Most flexible for detailed painting jobs

Cartesian Robots: Precision in Linear Movements

Cartesian robots are top-notch for straight-line tasks. They work on X, Y, and Z axes, making them perfect for flat car parts. Their design ensures even paint and less waste.

SCARA Robots: Specialized Curved Surface Painting

SCARA robots are experts at painting on complex curves. Their special joints allow for smooth moves on tricky shapes like car doors and fenders.

Articulated Robots: The Most Flexible Painting Solution

Articulated robots are the most advanced technology in painting. With multiple joints, they can reach difficult areas and paint all parts of a car.

Applications Driving Demand in the Automotive Paint Robot Market

The market for automotive paint robots is rapidly expanding. This growth can be attributed to innovative applications of robots in the car manufacturing process. Today, robots are employed in various ways to enhance the efficiency and quality of car painting.

How Robots are Transforming Car Manufacturing

Robots have revolutionized the automotive industry by introducing accuracy and productivity into the production line. They address significant challenges associated with painting vehicles, resulting in improved and uniform paint finishes.

Exterior Painting Innovations

Painting the outside of cars is now done with robots. These robots can paint even the most complex parts of a car perfectly.

- Full vehicle body coverage

- Consistent layer thickness

- Reduced material waste

- Enhanced color uniformity

Interior Coating Processes

Painting the inside of cars needs special robots. These robots can paint dashboards and other parts with great care.

| Interior Coating Application | Robotic Advantage |

| Dashboard Painting | Uniform coverage and minimal overspray |

| Trim Component Coating | Consistent color matching |

| Complex Surface Finishing | Precision application techniques |

Specialty Finishes

Robots are now being used for advanced coatings, such as two-tone paint jobs and custom designs. This allows manufacturers to keep up with the latest trends in car design.

Global Regional Highlights Showing Growth Hotspots for Automotive Paint Robots

The global market for automotive paint robots is growing fast. Each region has its own chances for growth. Automotive factories are using new robotic painting tech to improve.

Robotic paint booths are changing how factories work all over the world. Global growth insights show big differences in how these technologies are used.

Asia-Pacific Market Expansion

The Asia-Pacific region is a major hub for automotive paint robot usage. The primary factors driving this trend include:

- Rapid growth in China and India

- Increased production of vehicles

- Significant investments in manufacturing facilities

China and India are at the forefront, with factories investing heavily in cutting-edge robotic painting technology.

European Technological Leadership

European manufacturers are at the forefront of robotic paint technology, with Germany leading the way known for its precision and innovative approaches.

North American Retrofit Opportunities

The United States has big chances to update old factory lines with new robotic paint tech. Factories are working on:

- Improving old systems

- Using smart factory methods

- Lowering costs with automation

These areas show how automotive paint robots are changing the world of making things.

The U.S. Automotive Paint Robot Market: Trends and Opportunities

The US automotive industry is changing how cars are made with new robotic painting systems. These systems help make cars better, faster, and more eco-friendly.

Robotic painting systems are key in today’s car making. Big car companies are spending a lot on these robots. The US market for automotive painting robots is growing fast. This is because of several important reasons:

- They make cars faster and paint them more accurately

- They use less paint, saving resources

- They help the environment by using less chemicals

- They keep workers safer

Adoption Rates in Major Automakers

Big car makers are leading the way in robotic painting. Ford, General Motors, and Tesla are using top-notch robotic painting systems. These systems make cars look great and work well.

Some key trends include:

- Multi-axis painting robots that can move in many ways

- Robots that use AI to sense and adjust

- Systems that watch and adjust in real time

- Robots that can quickly switch colors

Research and Development Initiatives

The car industry is always looking to improve robotic painting. They want to make painting better, faster, and greener. This is to meet the needs of today’s cars.

Robot makers and car companies are working together. This is leading to big improvements in painting technology. The US is staying ahead in car making thanks to these efforts.

Germany's Automotive Paint Robot Market: Current Status and Outlook

The German automotive industry is at the forefront of paint technology innovation, leading the way in the development of advanced automotive paint robot systems. Known for its precision engineering, Germany continues to push the boundaries of technology in the automotive sector.

Germany’s emphasis on Industry 4.0 has significantly transformed the landscape of paint robot technology. With the advent of smart systems, car painting processes have been elevated to new heights. These cutting-edge systems operate with unparalleled efficiency and accuracy, surpassing previous standards in the industry.

Innovation in Paint Robot Technology

German manufacturers have developed leading paint robot solutions that demonstrate remarkable capabilities:

- Advanced sensors for precise coating

- Self-adjusting and self-checking robots

- Improved color matching and uniform application

Integration with Industry 4.0

Combining digital tech with paint robots is a big win. Companies like Dürr have made smart paint shop solutions. These solutions save energy and make work more efficient.

Germany’s paint robot tech is leading the way. It focuses on:

- Using data for better maintenance

- Connecting manufacturing systems

- Painting in a way that saves energy

The future of automotive paint robots in Germany is bright. More research and development will bring new tech breakthroughs.

Japan's Growing Automotive Paint Robot Market: Drivers and Challenges

The Japanese automotive sector leads in robotic solutions, tackling big challenges in manufacturing. It uses new technologies to deal with labor shortages and improve production efficiency. Paint robots are key in this effort.

Japan is a world leader in robotics thanks to its tech skills. The car industry uses advanced paint robots. These robots help keep quality high and solve workforce problems.

Technological Innovation in Automotive Painting

Robotic solutions have changed automotive painting for the better. They bring big benefits:

- Enhanced precision in paint application

- Consistent color and finish quality

- Reduced human error

- Increased production speed

Addressing Workforce Challenges

Workforce automation is key for Japan’s manufacturing future. The aging population is a big challenge. Paint robots help solve this problem.

| Workforce Challenge | Robotic Solution |

| Declining working-age population | Automated paint application systems |

| High labor costs | Cost-effective robotic alternatives |

| Skill retention | Programmable consistent performance |

The Japanese automotive sector keeps investing in top robotic solutions. This ensures it stays competitive globally. It does this through tech innovation and smart workforce automation.

Forecasting Future Innovation and Market Expansion in Automotive Paint Robots

The automotive paint robot industry is about to undergo a significant transformation. New technologies are revolutionizing the way cars are painted, leading to a complete overhaul of the finishing process.

AI in painting is opening up new opportunities for more efficient and effective work. Companies are exploring intelligent systems that can dynamically adjust and optimize the painting process, reducing waste and enhancing the appearance of vehicles.

AI and Machine Learning Integration

Machine learning is transforming the way paint robots work in the automotive industry. It is bringing about improvements in:

- Color matching

- Equipment maintenance

- Quality control and defect detection

Leading companies such as Dürr are heavily investing in advanced robotic painting technology. They are establishing a major technology hub in Bietigheim-Bissingen, which signifies their ambitious plans for the future of automotive painting technology.

Collaborative Robot Technologies

Collaborative robots are changing the factory floor. They mix human skill with robot accuracy. This lets humans and robots work together, making painting more flexible and better.

Collaborative robots offer:

- More safety

- Flexibility in making things

- Less strain on workers

The future of car paint robots is about combining AI, machine learning, and human skills. As tech gets better, we’ll see smarter and more advanced painting in cars.

Competitive Landscape of Leading Automotive Paint Robot Providers

The automotive paint robot market is very competitive. Global leaders are always improving their technology to stay ahead. This makes the industry very dynamic.

Key Players:

-

FANUC – Japan

-

Kawasaki Robotics – Japan

-

Dürr – Germany

-

WL (Wuhan Onew) – China

-

Taikisha USA (Encore Automation) – United States

-

ABB – Switzerland

-

Graco Inc. – United States

-

Yaskawa Motoman – Japan

-

KUKA – Germany

-

Epson Robots – Japan

Market Share Dynamics

The market is highly competitive, with leading companies competing for technological dominance. They are striving to differentiate themselves in various aspects:

- Precision engineering in robotic paint application

- Providing tailored solutions for automobile manufacturers

- Enhancing automation processes

Strategic Partnerships and Acquisitions

Top paint robot makers are teaming up to grow their market. For example, the Dürr Group is boosting its core business with new automation and simpler structures.

New players are shaking things up by bringing in fresh tech and affordable options. This makes the market both dynamic and competitive.

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Automotive Paint Robot Market Report |

| Base Year | 2024 |

| Segment by Type |

· Cartesian Robots · SCARA Robots · Articulated Robots |

| Segment by Application |

· Exterior Painting · Interior Coating · Specialty Finishes |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The automotive paint robot market is full of chances for smart investments. It’s growing fast because of new tech and changing factory needs. Experts say it will keep growing, offering big chances for those who look into advanced painting robots.

Car makers are using paint robots more to make their production better and more precise. There are chances to invest in many areas, like new robotic systems, AI in painting, and green coatings. The market keeps getting better because of constant tech improvements.

Managing risks is key for those in the paint robot world. Risks include fast tech changes, economic issues, and shifts in car making. To succeed, investors should focus on flexible tech, have a varied portfolio, and watch for new trends in robot making.

Global Automotive Paint Robot Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Automotive Paint Robot Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Automotive Paint Robot Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Automotive Paint Robot Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Automotive Paint Robot Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Automotive Paint Robot Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Automotive Paint Robot Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Automotive Paint RobotMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market size for automotive paint robots by 2025?

The market for automotive paint robots is expected to grow to $1.36 billion by 2025. This growth is driven by more automation and the need for better painting technologies.

Which regions are leading in automotive paint robot technology?

The United States, Germany, and Japan are at the forefront of automotive paint robot technology. These countries have demonstrated the highest levels of innovation and adoption of this technology in the automotive industry.

What challenges do automotive paint robots currently face?

Robots face challenges like complex programming for different car designs. They also struggle to keep paint quality consistent. Plus, the cost of starting up robotic painting systems is high.

How are automotive paint robots contributing to sustainability?

These robots help reduce paint waste and lower energy use. They also support eco-friendly paints. This shows a big commitment to being green.

What new technologies are being developed for automotive paint robots?

New technologies include improved accuracy and quicker painting speeds. Robots are also becoming better at color matching. There are discussions about incorporating artificial intelligence and machine learning as well.

How are paint robots addressing workforce challenges?

In countries like Japan, robots help solve the problem of an aging workforce. They maintain high production quality while ensuring that manufacturing continues.

What applications do automotive paint robots serve?

Robots are used for:

- Painting car bodies

- Coating interior parts like dashboards

- Handling special jobs like two-tone finishes and custom designs

How are geopolitical factors impacting the automotive paint robot market?

Trade policies, tariffs, and changes in where cars are made affect the market. These changes impact the demand for paint robots, especially in new markets.

What future innovations are expected in automotive paint robot technology?

Future advancements include:

- Robots that work with humans, enhancing collaboration and efficiency

- More AI integration, leading to smarter and more autonomous systems

- Systems that can handle different car designs, providing greater flexibility