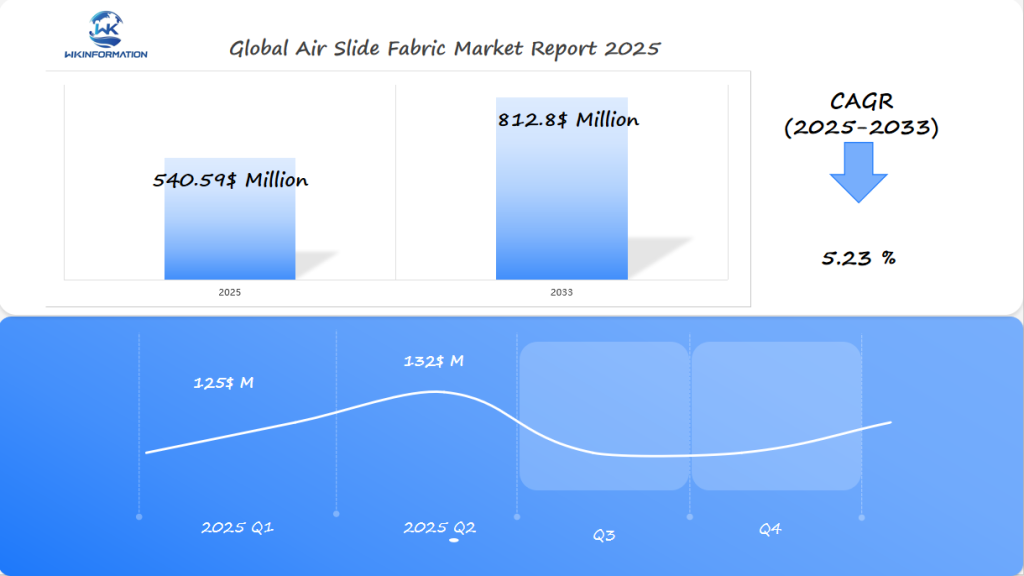

Air Slide Fabric Market Forecasted to Hit $540.59 Million Globally by 2025 with Key Growth in China, India, and Germany

The Air Slide Fabric Market is experiencing rapid growth driven by cement industry expansion and bulk material handling needs. Key players focus on innovative solutions to meet rising demand.

- Last Updated:

Air Slide Fabric Market Growth in Q1 and Q2 of 2025 and Regional Overview

The Air Slide Fabric market is forecasted to reach $540.59 million in 2025, with a CAGR of 5.23% through 2033. In Q1, market revenues are projected to be around $125 million, rising to approximately $135 million in Q2, driven by increased industrial bulk handling applications. China’s expanding construction and mining sectors are major demand drivers, supported by India’s growing industrial output and infrastructure investments. Germany’s advanced material technologies and quality standards further bolster the market.

Key Takeaways

- The global air slide fabric market is projected to reach $820 million by 2032.

- A strong 5.23% Compound Annual Growth Rate is anticipated.

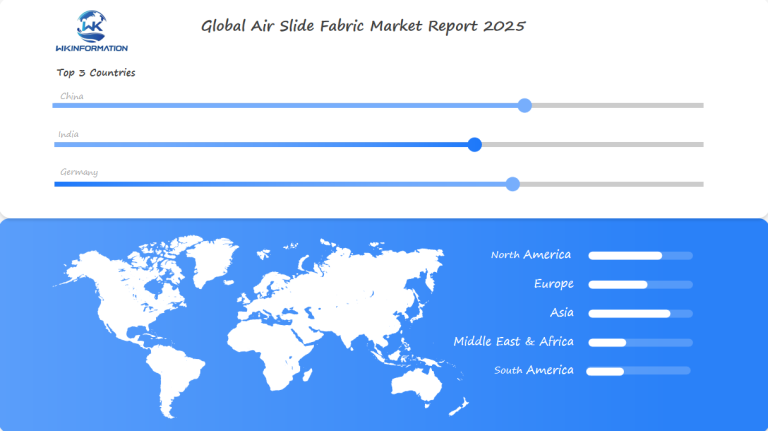

- China is emerging as a key growth center for market expansion.

- Multiple industrial sectors are driving demand for fabric technology.

- Technological innovation is crucial for market development.

Mapping the Upstream and Downstream Industry Web Supporting Air Slide Fabric Growth

The air slide fabric market is built on a complex network of industries. Upstream suppliers and downstream industries work together to create a dynamic system. This system drives innovation and growth in many sectors.

Raw material suppliers are key to the market’s success. Their production and decisions shape the air slide fabric industry’s growth and performance.

Raw Material Supplier Landscape

- Synthetic fiber manufacturers provide essential input for air slide fabrics

- Polyester and aramid producers drive technological advancements

- Quality and pricing of raw materials influence market competitiveness

Key End-User Industries Driving Demand

| Industry | Air Slide Fabric Application | Market Impact |

| Cement | Pneumatic material transport | Highest demand segment |

| Food Processing | Hygienic material handling | Growing market potential |

| Chemical | Specialized fabric requirements | Technological innovation driver |

| Mining | Bulk material transportation | Consistent market demand |

The relationships between upstream suppliers and downstream industries are crucial. Strategic collaborations and new technologies are changing material handling solutions. This is happening across many industrial sectors.

Emerging Market Patterns and Trends Defining the Air Slide Fabric Industry

The air slide fabric industry is going through big changes. New technologies and trends are leading the way. Manufacturers are working hard to create better fabrics for different needs.

New discoveries in material science are changing air slide fabric design. Scientists are making materials that perform better than ever before.

Technological Advancements in Fabric Design and Production

Big tech breakthroughs are changing the industry. Companies are using new methods to make fabrics better:

- Nano-coating technologies for improved durability

- Advanced weaving techniques for increased flexibility

- Precision engineering for better material resistance

Shift Towards Sustainable and Eco-Friendly Materials

Now, making fabrics that are good for the planet is key. Companies are working on green solutions. They want to cut down on waste and keep performance high.

| Sustainable Material Type | Performance Improvement | Environmental Impact |

| Recycled Polyester Fabrics | Enhanced Durability | Reduced Waste |

| Bio-Based Synthetic Fibers | Improved Flexibility | Lower Carbon Emissions |

| Biodegradable Composite Materials | Increased Wear Resistance | Minimal Environmental Footprint |

Smart tech and IoT are bringing new chances for pneumatic systems. These advancements are making air slide fabrics better. They’re also opening up new market chances.

The Role of Restrictions in Shaping Air Slide Fabric Market Development

The air slide fabric industry is facing many challenges. These include strict environmental rules and safety standards. These rules are changing how products are made and designed.

These rules are pushing the market to grow. Companies must follow complex rules in making air slide fabrics. This affects many parts of the production process.

Environmental Regulations Driving Fabric Innovation

Environmental rules are key to new technology in air slide fabrics. They include:

- Dust emission reduction mandates

- Sustainable material requirements

- Carbon footprint minimization strategies

How Safety Standards Are Changing the Market

Workplace safety rules are making companies create better air slide fabrics. These fabrics must work well and keep workers safe.

| Regulatory Focus | Market Impact | Innovation Response |

| Dust Control | Increased Demand | Advanced Filtration Designs |

| Worker Protection | Enhanced Product Development | High-Performance Materials |

| Environmental Compliance | Sustainable Manufacturing | Eco-Friendly Fabric Solutions |

Companies now see these rules as chances for growth. They are using them to improve air slide fabric technology.

How Geopolitical Factors Are Steering Market Directions for Air Slide Fabric

The global air slide fabric market is changing a lot because of complex geopolitical factors. Trade policies and regional economic conditions are changing how we handle industrial materials. This creates both challenges and opportunities for manufacturers and stakeholders.

Geopolitical dynamics are crucial in shaping the air slide fabric market’s future. Important factors include:

- Shifting global supply chains

- Regional economic development patterns

- International trade regulations

- Infrastructure investment strategies

Trade Policies Impacting Global Supply Chains

Recent trade policies have greatly affected the air slide fabric market. Manufacturers face complex international regulations that affect material sourcing, production, and distribution. The Asia Pacific region is especially important, with countries like China and India leading in infrastructure development.

| Region | Market Impact | Key Drivers |

| Asia Pacific | Dominant Market Position | Rapid Industrialization |

| North America | Steady Growth | Technological Innovation |

| Europe | Mature Market | Sustainable Development |

Regional Economic Conditions Driving Market Growth

Economic conditions in different regions greatly affect the air slide fabric market. Emerging markets see fast-growing demand because of infrastructure projects and industrial growth. The combination of geopolitical factors and economic development creates a complex but promising environment for air slide fabric manufacturers.

Understanding Different Types of Air Slide Fabrics and Their Significance in the Market

The air slide fabric market is complex, with many fabric types. Each type is crucial for industrial use. Knowing the differences is key for those looking for the best performance.

Polyester fabrics lead the air slide industry. They are chosen for their top-notch performance. This makes them vital in many industrial fields.

Polyester Air Slide Fabrics: Market Leader and Future Prospects

Polyester fabrics are the top choice for air slides. They have several benefits:

- Superior durability and wear resistance

- Cost-effective manufacturing processes

- Excellent chemical and thermal stability

- Versatile performance across different industrial environments

Emerging Opportunities for Aramid and Specialized Fabrics

Aramid fabrics are becoming more popular. They offer special properties for extreme industrial needs, especially in high-temperature settings.

Aramid fabrics stand out for their heat resistance and durability. Their increasing use shows a bright future for these fabrics in air slide applications.

Research is pushing the limits of fabric types. It aims to improve performance, sustainability, and efficiency in various industries.

Exploring Industries That Use Air Slide Fabrics

Air slide fabrics are key in material handling across many industries. They help move powdered and granular materials with great precision and reliability.

These fabrics are vital in various sectors, each utilizing their unique features to enhance material transport.

Cement Industry: Powering Material Flow Efficiency

The cement industry uses air slide fabrics the most. Cement plants depend on them for smooth powder transport.

- Enables precise material handling in cement production

- Supports high-volume powder transportation

- Reduces mechanical wear in conveying systems

Food Processing and Chemical Industries: Expanding Applications

Food processing and chemical industries are growing fast. They need top-notch material handling to keep products safe and intact.

| Industry | Key Application | Benefits |

| Food Processing | Ingredient Transportation | Hygienic Material Handling |

| Chemical Industry | Powder Chemical Conveying | Contamination Prevention |

Air slide fabrics are crucial in many industries. They show great flexibility in cement, food, and chemical sectors.

Regional Perspectives on Air Slide Fabric Market Expansion and Potential

The global air slide fabric market is full of growth and opportunities. Each region has its own way of developing, adding something special to the market. This makes the market very diverse.

Every region has its own way of using air slide fabric. This means different opportunities for companies. They are watching these trends closely to find new chances.

Asia Pacific: The Leading Region in Air Slide Fabric Market

The Asia Pacific region is currently at the forefront of the air slide fabric market. Its rapid growth can be attributed to:

- Fast industrial growth

- Significant investments in infrastructure

- Expanding manufacturing industries

- Advancements in technology

North America and Europe: Mature Markets with Steady Growth

In North America and Europe, the market is more stable. These regions focus on:

- Advanced manufacturing technologies

- Stringent environmental regulations

- High-quality product development

- Sustainable manufacturing practices

| Region | Market Characteristic | Growth Potential |

| Asia Pacific | Rapid Industrialization | High |

| North America | Technological Innovation | Moderate |

| Europe | Sustainable Solutions | Steady |

Asia Pacific is leading in growth, but mature markets are still important. They help the global industry grow and improve.

Growth Trends and Market Dynamics in China's Air Slide Fabric Sector

China is becoming a major player in the air slide fabric market. This is thanks to its strong infrastructure and manufacturing progress. The country’s focus on growth has made it a leader in air slide fabric technology.

Key Factors Contributing to China’s Growth in Air Slide Fabric Sector

- Extensive infrastructure projects nationwide

- Rapid industrial sector transformation

- Significant investments in manufacturing technologies

Infrastructure Development Driving Demand

Infrastructure growth is key to air slide fabric demand in China. Big projects like transportation networks and industrial facilities are boosting demand. This has opened up new chances for fabric makers.

| Infrastructure Sector | Air Slide Fabric Demand Impact |

| Cement Industry | High Growth Potential |

| Chemical Processing | Moderate Expansion |

| Mining Operations | Steady Requirement |

Technological Advancements in Manufacturing

China’s air slide fabric production has seen a big change thanks to new tech. Local makers are spending a lot on research. This has led to high-performance fabrics that meet tough industrial needs.

By using advanced materials and precise engineering, Chinese makers can now compete worldwide. They offer new solutions to complex problems.

India's Air Slide Fabric Market: Opportunities and Emerging Challenges

The Indian air slide fabric market is at a turning point. It’s driven by fast industrial growth and smart economic moves. India is a big player in the Asia Pacific market, seeing a lot of growth in air slide fabric making and use.

Several key factors are pushing India’s air slide fabric market forward:

- Expanding cement and chemical manufacturing industries

- Government initiatives like “Make in India”

- Infrastructure development projects

- Increasing focus on industrial modernization

Rapid Industrialization Fueling Market Growth

India’s fast industrial growth opens up big chances for air slide fabric makers. The cement, chemical, and food industries are driving up demand for special fabric tech. Strategic investments in manufacturing infrastructure help Indian companies boost their production.

Balancing Cost and Quality: Manufacturing Challenges

Indian manufacturers face significant challenges in keeping prices low while maintaining high-quality standards. To continue growing, they must improve production methods and invest in new technology.

Key challenges include:

- Reducing production costs

- Enhancing technological capabilities

- Meeting stringent international quality requirements

- Developing sustainable manufacturing practices

Germany's Air Slide Fabric Market: Current Status and Strategic Outlook

The German air slide fabric market is a leader in technology. It is known for its advanced industrial textiles. Germany’s strong manufacturing and focus on engineering excellence drive big changes in air slide fabric.

German market analysis shows several key advantages:

- World-class manufacturing capabilities

- Strong emphasis on research and development

- Cutting-edge technological innovations

- Stringent quality control processes

Technological Innovation Powering Market Leadership

Technology is key to Germany’s success in air slide fabric. German makers use the latest engineering and Industry 4.0 to create top-notch fabrics. These fabrics meet tough industrial needs.

Export Opportunities: Expanding Global Reach

German air slide fabric makers see more chances to sell abroad. Their fame for precision and quality opens new markets. This is true for industries like cement, food, and chemicals.

Key export markets include:

- China

- United States

- India

- Brazil

Germany’s air slide fabric market looks bright. It keeps investing in tech and green making. This makes Germany a top name in industrial textiles worldwide.

Anticipating Future Advancements and Market Shifts in Air Slide Fabric

The air slide fabric industry is about to undergo significant changes. New technologies and environmentally friendly initiatives are leading the way. Trends indicate a major shift in how we manage materials, with smart technology taking the lead.

Areas of Innovation

New technology will bring exciting transformations to air slide fabric systems. Companies are exploring various areas for innovation:

- Real-time monitoring using IoT sensors

- Predictive maintenance algorithms

- AI-driven performance optimization

- Improved durability of materials

Integration of Smart Technologies in Air Slide Fabric Systems

Smart technologies are changing pneumatic systems. Now, we can track material flow, temperature, and wear in real-time. This gives us deep insights into our industrial processes.

| Technology | Key Benefits | Potential Impact |

| IoT Sensors | Real-time tracking | Reduced downtime |

| Machine Learning | Predictive maintenance | Cost optimization |

| Advanced Materials | Enhanced durability | Longer product lifecycle |

Sustainability and Circular Economy: The Next Frontier

Sustainability is key in air slide fabric now. Companies are using eco-friendly materials and circular economy ideas. Recyclable fabrics and green production methods are popular in the market.

Combining smart tech with green practices opens up new uses for air slide fabric. This will benefit many industries, from clean energy to advanced manufacturing.

Competitive Highlights of Leading Air Slide Fabric Providers

Key players in the air slide fabric market are focusing on improving material strength, permeability, and heat resistance to enhance performance in bulk powder handling systems across industries like cement, food, and chemicals. They are expanding into emerging markets such as Southeast Asia and Africa, where industrial growth and infrastructure development are driving demand for efficient and durable pneumatic conveying solutions.

Key Players:

-

Flexco (United States)

-

Martin Engineering (United States)

-

Dunlop Conveyor Belting (Netherlands)

-

Fenner Dunlop (United Kingdom / United States)

-

Habasit (Switzerland)

-

ContiTech (Germany)

-

Bridgestone (Japan)

-

Ammeraal Beltech (Netherlands)

-

Bando Chemical Industries (Japan)

-

Fenner Dunlop Conveyor Belting (United Kingdom / United States)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Air Slide Fabric Market Report |

| Base Year | 2024 |

|

Segment by Type |

· Polyester Air Slide Fabrics · Aramid and Specialized Fabrics |

| Segment by Application |

· Food Processing · Chemical Industry |

|

Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Air Slide Fabric Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Air Slide Fabric Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Air Slide Fabric Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Air Slide Fabric Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Air Slide Fabric Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Air Slide Fabric Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Air Slide Fabric Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Air Slide Fabric Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

Which industries are the primary consumers of air slide fabrics?

The main users of air slide fabrics are:

- Cement

- Food processing

- Chemicals

- Mining

These industries require air slide fabrics for efficient and clean handling of bulk materials.

What are the key materials used in air slide fabric production?

The primary material used in the production of air slide fabric is polyester. This is due to its versatility and cost-effectiveness. Other materials such as aramid, cotton, and blended fabrics also play a role in the manufacturing process, each offering unique advantages for specific requirements.

Here’s a breakdown of the key materials used:

- Polyester: The main material used in air slide fabric production due to its versatility and affordability.

- Aramid: Used for its heat resistance properties.

- Cotton: Offers its own benefits for certain applications.

- Blended fabrics: Combines different fibers to achieve desired characteristics.

How are technological advancements impacting air slide fabric development?

New technologies are making fabrics stronger, more flexible, and durable. The industry is also adding smart technologies and IoT to improve pneumatic systems.

Which region is leading the air slide fabric market?

The Asia Pacific, especially China and India, leads the market. This is because of fast industrial growth, big investments in infrastructure, and growing manufacturing.

What are the key environmental considerations in air slide fabric production?

The focus is on making production more eco-friendly. There’s a push to reduce dust and meet tough environmental rules.

What challenges do manufacturers face in the air slide fabric market?

Manufacturers need to balance cost and quality. They must also follow strict rules and keep innovating to meet changing needs.

How are safety standards influencing air slide fabric development?

Safety standards are pushing for better air slide fabrics. This means making products that are safe and also improve handling efficiency.

What future trends are expected in the air slide fabric industry?

The future includes more AI and machine learning. There will be recyclable materials and growth in new sectors like renewable energy. Sustainable production will also be key.

How are geopolitical factors affecting the air slide fabric market?

Trade policies, economic conditions, and international partnerships are big factors. They affect supply chains and growth, especially for new markets.