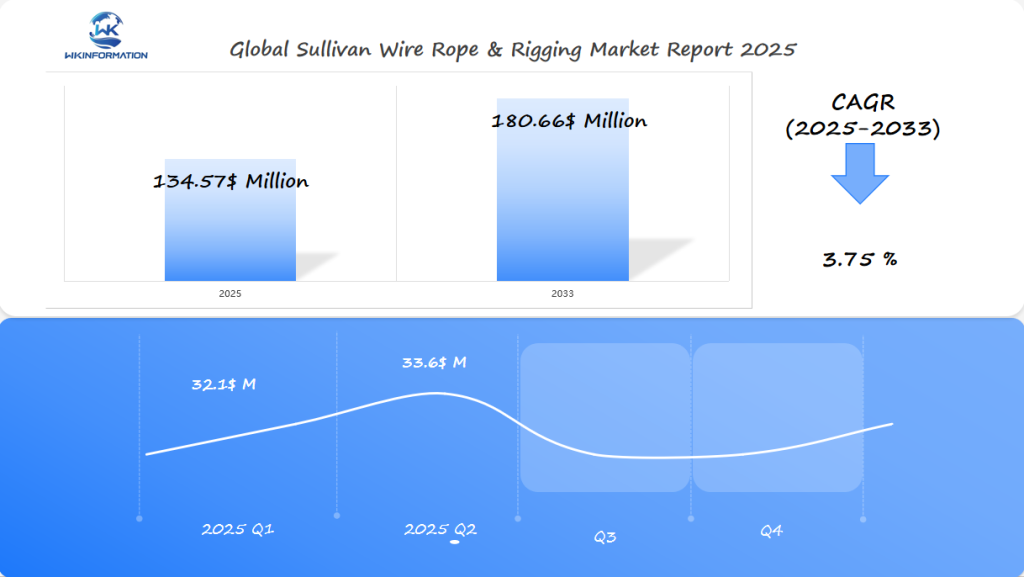

Sullivan Wire Rope & Rigging Market Set to Surpass $134.57 Million Globally by 2025: Demand Driven by Construction in the U.S., Canada, and Australia

Explore the growing Sullivan Wire Rope & Rigging Market as demand surges across construction, mining, and marine sectors. Discover key trends and growth opportunities through 2025.

- Last Updated:

Sullivan Wire Rope & Rigging Market in Q1 and Q2 of 2025

The Sullivan Wire Rope & Rigging market is forecast to reach $134.57 million by 2025, growing at a CAGR of 3.75%. Q1 revenues are projected at $32.1 million, with Q2 reaching $33.6 million. In the U.S., the construction, maritime, and offshore sectors are major users of high-strength rigging solutions. Canada sees consistent demand from its forestry and mining industries, where durable lifting gear is essential. Australia is investing in industrial infrastructure and energy projects, boosting need for reliable hoisting equipment.

Key Takeaways

- Projected market value of $12.3 billion by 2030

- Strong growth across multiple industrial sectors

- Increasing focus on technological innovation

- Enhanced safety standards driving market expansion

- Significant investments in research and development

Sullivan Wire Rope & Rigging: Understanding the Upstream and Downstream Industry Chain

The wire rope manufacturing industry is essential to our industrial setup. It connects raw materials to the final products used in various industries. This intricate supply chain outlines the specific processes required to create these crucial rigging solutions.

Raw Material Suppliers and Manufacturing Process

Wire rope making starts with top-notch steel from specific suppliers. The process includes several precise steps:

- Wire drawing to create individual steel strands

- Precise strand twisting and layering

- Lubrication and protective coating application

- Rigorous quality control testing

Distribution Channels and Industrial Applications

The rigging supply chain has many distribution networks. These networks serve various industrial sectors. Wire rope is used in important areas:

| Industry Sector | Primary Wire Rope Applications |

| Construction | Crane operations, structural support |

| Mining | Heavy equipment lifting, excavation support |

| Marine | Offshore rigging, maritime infrastructure |

| Oil & Gas | Drilling platform support, cargo handling |

Wire rope manufacturers play a vital role in these complex applications. Their work shows the importance of precision engineering and strong supply chain management.

Trend shifts toward safety, synthetic alternatives, and smart rigging solutions

The wire rope and rigging industry is changing fast. This is thanks to new tech and safety needs. Makers are coming up with smart fixes for big industrial problems.

New safety ideas in wire rope are changing rigging and lifting. Now, we focus on smart, flexible systems. These systems put safety first and make sure equipment works well.

Advancements in Wire Rope Safety Features

There have been significant improvements in making wire rope safer:

- Protective coatings that last longer in harsh weather conditions

- New materials that are stronger

- Sensors that monitor wear and tear in real time

Emergence of Synthetic Rigging Ropes

Synthetic rigging ropes are becoming more popular. They are light and offer big advantages:

- They are much lighter than steel wire ropes

- They are flexible and don’t rust

- They need less upkeep

Integration of Smart Rigging Systems

Smart rigging systems are the latest in safety tech. They use IoT and data to watch over things and predict when they might break.

By combining safety, synthetic ropes, and smart systems, we’re seeing huge leaps in safety and work efficiency.

Limitations from cost, corrosion, and standard compliance issues

The wire rope and rigging industry faces many challenges. These affect performance, safety, and cost. Knowing these issues helps make better choices about wire rope and rigging.

Critical Cost Considerations in Wire Rope Solutions

Cost is a big factor in choosing wire rope and planning budgets. Several things affect the price:

- Raw material quality and market changes

- How complex it is to make

- Need for special coatings

- What it can hold

Addressing Corrosion Challenges

Keeping rigging safe from corrosion is key in tough environments. To fight corrosion, makers use:

- Advanced zinc and aluminum coatings

- Synthetic polymer treatments

- Special stainless steel alloys

Regulatory Standards and Compliance

Standards in the rigging industry are important for safety and performance. ISO 9001 certification shows quality and excellence in making and running things.

| Compliance Area | Key Requirements | Impact |

| Material Testing | Strength verification | Ensures structural integrity |

| Load Ratings | Performance specifications | Prevents equipment failure |

| Corrosion Resistance | Environmental durability | Extends equipment lifespan |

Understanding these key challenges helps pick the right wire rope and rigging. This balance ensures performance, safety, and cost-effectiveness.

Geopolitical impact on raw material sourcing and shipping regulations

The wire rope and rigging industry faces big challenges in international trade. Changes in global politics change how companies get wire rope raw materials and move rigging equipment around the world.

Important factors affecting the industry include:

- Emerging trade restrictions impacting wire rope raw materials procurement

- Fluctuating tariff structures affecting manufacturing costs

- Supply chain resilience strategies in rigging equipment production

Global Trade Dynamics Transforming Wire Rope Production

International rigging rules put a lot of pressure on makers to change fast. Companies need to come up with smart ways to get materials without breaking the bank or losing quality.

Big challenges in moving rigging equipment include:

- Increased shipping complexity

- Rising transportation expenses

- Complex customs clearance procedures

Regulatory Changes Reshaping International Markets

Companies are now investing in flexible supply chains to deal with trade risks. Strategic partnerships and finding different sources are key to keeping wire rope production steady.

Wire Rope and Rigging Segmentation by Type, Load Capacity, and Material

Sullivan Wire Rope & Rigging offers a wide range of wire rope types and rigging solutions. They are designed to meet complex industrial demands. Their products include various configurations, load capacities, and advanced materials for critical applications in different sectors.

Common Wire Rope Constructions

Wire rope types are key to performance and reliability. The most common include:

- 6×19 classification: Ideal for moderate-load applications

- 6×36 configuration: Enhanced flexibility for complex rigging requirements

- 8×19 design: Superior strength for heavy-duty industrial environments

Load Capacity Classifications

Choosing the right rigging load capacity is crucial. Sullivan Wire Rope categorizes load capacities into several ranges:

- Light-duty: 0-5 tons

- Medium-duty: 5-20 tons

- Heavy-duty: 20-100 tons

- Extreme-duty: 100+ tons

Material Innovations

Advanced rigging materials are changing wire rope manufacturing. Recent developments include:

- High-performance alloy steel for increased tensile strength

- Synthetic fiber composites for lightweight applications

- Corrosion-resistant galvanized wire ropes

These innovations show Sullivan Wire Rope’s dedication to delivering top-notch solutions. They meet the evolving needs of industries.

Application segmentation: marine, construction, oil & gas, and mining

The Sullivan Wire Rope & Rigging market serves many critical industries. It offers specialized wire rope solutions for each sector. These solutions meet the unique needs of marine, construction, oil & gas, and mining.

Marine and Offshore Applications

Marine wire ropes are key in offshore operations. They support complex marine environments with great strength and resistance to corrosion. They are used for:

- Mooring systems for ships and offshore platforms

- Crane and lifting operations

- Subsea cable management

- Anchoring equipment

Construction and Infrastructure Projects

Construction rigging needs strong wire rope solutions for safety and efficiency. Engineers use high-tensile strength cables for:

- Crane operations

- Suspension bridge construction

- Building facade maintenance

- Heavy equipment lifting

Challenges in Oil & Gas Exploration

Oil & gas wire ropes operate in harsh environments during the exploration and extraction processes. They play a crucial role in supporting various activities such as:

- Drilling line operations

- Subsea installation requirements

- Offshore platform support systems

Mining Rigging Equipment Demands

Mining requires heavy-duty rigging equipment to handle large loads in challenging environments. Here are the main applications:

- Open-pit mining extraction

- Underground tunnel support

- Material transportation systems

Industry Primary Wire Rope Application Key Performance Requirements Marine Mooring Systems Corrosion Resistance Construction Crane Operations High Tensile Strength Oil & Gas Drilling Support Extreme Environment Durability Mining Material Transportation Heavy Load Capacity

Regional analysis of Sullivan Wire Rope & Rigging market performance

The global wire rope and rigging market shows big differences in each area. Each place has its own growth chances and challenges. Knowing these differences is key for those in the wire rope and rigging technologies field.

- North America leads the US wire rope market with strong infrastructure growth

- The European rigging industry keeps improving with new tech

- Asia-Pacific sees huge growth in wire rope demand

North American Market Dynamics

The North American region is a key place for wire rope innovation. It’s driven by big industrial projects, green energy growth, and strict safety rules. Investments in infrastructure and tech upgrades help the market grow.

Trends in the European Wire Rope and Rigging Industry

European markets are all about new tech. They focus on making better materials and using the latest manufacturing methods. They also care a lot about being green and efficient.

Asia-Pacific Growth Opportunities

The Asia-Pacific region is a major player in the demand for wire ropes. Rapid industrial growth, new infrastructure projects, and significant investments in marine and construction ventures are driving the market expansion. Countries such as China and India are crucial to this growth.

Emerging Markets in Latin America and Africa

Latin American and African markets are full of potential for wire rope and rigging. They have lots of natural resources, big projects, and growing industries. This makes it a great time for new players to enter.

U.S. industrial buildout sustaining demand for high-strength rigging

The United States is experiencing a significant transformation in its industries, resulting in an increased demand for US industrial wire ropes. Sullivan Wire Rope & Rigging, established in 1984, is at the forefront of this change.

Infrastructure Development Drives Rigging Demand

The construction of new infrastructure plays a crucial role in driving the need for rigging solutions. Large-scale projects are reshaping various sectors in America, creating opportunities for enhanced rigging applications.

Infrastructure Development Projects Driving Wire Rope Demand

Large-scale projects are increasing the demand for wire ropes in key sectors:

- Rehabilitation and construction of bridges

- Expansion and modernization of ports

- Upgrades to urban infrastructure

- Improvements to transportation networks

Renewable Energy Sector’s Impact on Rigging Equipment

Renewable energy wire ropes are growing rapidly. Wind and solar power require specialized rigging, driving wire rope technology to new heights.

Industrial Modernization and Wire Rope Consumption

The demand for wire rope is being driven by the modernization of industries such as manufacturing, energy, and construction. Businesses are seeking out improved rigging options that are durable, long-lasting, and secure.

Canada's natural resource sector driving steel wire rope adoption

Canada’s diverse natural resource industries are driving the need for advanced wire rope technologies. The country’s strong economy brings both challenges and opportunities for specialized rigging solutions. These are needed across various sectors.

The Canadian mining industry heavily relies on high-performance Canadian mining wire ropes. These ropes must handle complex tasks and extreme environments. They need to be durable and strong.

Mining Industry’s Wire Rope Demand

Mining operations in Canada need advanced rigging equipment. This equipment is crucial for managing infrastructure and extraction processes. Key features of wire rope solutions include:

- High tensile strength for heavy-load applications

- Corrosion resistance in challenging geological environments

- Precision engineering for underground and surface mining

Forestry Sector Rigging Requirements

Forestry rigging equipment is vital in Canada’s timber industry. Specialized wire ropes for logging must offer:

- Enhanced flexibility in rugged terrain

- Superior load-bearing capabilities

- Resistance to environmental degradation

Oil Sands Wire Rope Solutions

The oil sands operations in Canada require exceptional wire rope technologies. Oil sands wire rope solutions must handle unique environmental and operational challenges. These include:

- Extreme temperature variations

- Heavy mechanical stress

- Precise load management capabilities

Sullivan Wire Rope & Rigging is working on innovative solutions. These meet the tough demands of Canada’s natural resource sectors. They ensure optimal performance and safety in mining, forestry, and oil sands industries.

Australia's mining boom reinforcing rigging equipment market

The Australian mining industry is a global leader, driving growth in mining rigging and marine wire ropes. It has vast open-pit mines in rich resource areas. This means a big need for top-notch rigging equipment.

Important changes in the Australian market show key trends in rigging solutions:

- More money going into advanced wire rope technologies

- Strong safety rules for rigging equipment

- More ports for exporting minerals

Open-Pit Mining Wire Rope Requirements

Open-pit mines in Western Australia and Queensland need special marine wire ropes. These ropes must handle tough conditions, like:

- High mechanical stress

- Corrosive mineral environments

- Big temperature changes

Port and Terminal Expansions

Australian major ports are expanding, creating opportunities for marine wire ropes. These upgrades require rigging that complies with international maritime regulations to ensure proper functionality of the equipment and safety of workers.

Safety Regulations Driving Innovation

Tough Australian safety rules are making wire rope makers work harder. They’re creating stronger, lighter, and smarter rigging. This meets the mining industry’s changing needs.

Outlook for automation, monitoring integration, and lighter materials

The wire rope and rigging industry is about to undergo a significant transformation. With the advent of new technologies, automated wire rope production is set to reach unprecedented levels of efficiency. This presents exciting opportunities for innovation and streamlining operations.

Moreover, companies are beginning to embrace smart rigging systems. These cutting-edge solutions leverage advanced technology to optimize performance and enhance reliability. As a result, industries are rethinking their approach to wire rope design and utilization.

Emerging Technologies in Wire Rope Manufacturing

The future of making wire rope will bring a few big changes:

- Robotic precision manufacturing

- AI-driven quality control systems

- Advanced material engineering

Integration of IoT and Data Analytics

Now, smart rigging systems have advanced monitoring. They give real-time info on how equipment is doing. Key features include:

- Predictive maintenance tracking

- Load monitoring sensors

- Performance optimization algorithms

Development of High-Performance Materials

Lightweight rigging materials are a big step forward in wire rope tech. Makers are working on new stuff that’s strong but also light.

| Material Type | Strength Increase | Weight Reduction |

| Synthetic Composites | 35% | 40% |

| Advanced Alloy Blends | 25% | 30% |

| Nano-Enhanced Materials | 45% | 50% |

These new technologies will change wire rope and rigging in many industries. They promise better performance and reliability.

Competitive overview of key players in the wire rope & rigging space

Key players in the wire rope and rigging market are focusing on enhancing product durability, performance, and safety to meet the evolving demands of industries such as construction, oil & gas, and marine. They are expanding their presence in regions with significant infrastructure development, including North America and Asia-Pacific, to support the growing need for reliable lifting and securing solutions. Through strategic partnerships with equipment manufacturers and investments in advanced materials and testing technologies, these companies are strengthening their market position and contributing to the advancement of heavy-duty rigging applications.

Key Players:

-

Sullivan Wire Rope & Rigging (United States)

-

WireCo WorldGroup (United States)

-

Bridon-Bekaert (Belgium / United Kingdom)

-

Yale Cordage (United States)

-

Peerless Industrial Group (United States)

-

Wire Rope Corporation of America (United States)

-

Samson Rope Technologies (United States)

-

New England Ropes (United States)

-

Cortland Company (United States)

-

Loos & Co. (United States)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Sullivan Wire Rope & Rigging Market Report |

| Base Year | 2024 |

|

Segment by Type |

· Light-duty: 0-5 tons · Medium-duty: 5-20 tons · Heavy-duty: 20-100 tons · Extreme-duty: 100+ tons |

| Segment by Application |

· Marine · Construction · Oil & Gas · Mining |

|

Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Sullivan Wire Rope & Rigging Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Sullivan Wire Rope & Rigging Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Sullivan Wire Rope & Rigging Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Sullivan Wire Rope & Rigging Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Sullivan Wire Rope & Rigging Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Sullivan Wire Rope & Rigging Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Sullivan Wire Rope & Rigging Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Sullivan Wire Rope & Rigging Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the current market value of the Sullivan Wire Rope & Rigging industry?

The Sullivan Wire Rope & Rigging market is expected to grow to over $134.57 million by 2025. This growth is due to fast industrialization and infrastructure development in sectors such as construction, mining, and marine industries.

What types of wire rope constructions are commonly used in industrial applications?

You’ll find 6×19, 6×36, and 8×19 wire rope constructions used a lot. Each type is made for different needs and used in various industries. This includes construction, marine, and mining.

How are synthetic ropes impacting the traditional wire rope market?

Synthetic ropes are becoming popular for their light weight and resistance to corrosion. But, they’re not perfect for all heavy-duty tasks. So, they work alongside traditional steel wire ropes, not replace them.

What industries primarily use wire rope and rigging solutions?

The main industries that use wire rope and rigging solutions are:

- Marine

- Construction

- Oil & Gas

- Mining

Each of these industries requires specific wire rope solutions. For instance, offshore mooring, construction cranes, drilling lines, and mining equipment rigging all have their own unique needs.

What technological innovations are transforming the wire rope industry?

New tech includes:

- smart rigging with IoT

- advanced robotics

- AI for quality control

- real-time load monitoring

There’s also work on new materials that are strong but light.

How do geopolitical factors affect the wire rope and rigging market?

Politics can change trade rules, tariffs, and how we get raw materials. Shipping rules also play a part. These things affect costs, supply chains, and who can sell wire rope.

Which regions are seeing the highest increase in demand for wire ropes?

The Asia-Pacific region is expected to account for more than 35% of the market’s growth. North America, Europe, and emerging markets in Latin America and Africa are also experiencing rapid growth.

How are safety regulations influencing wire rope manufacturing?

Safety rules are pushing for better materials, coatings, and quality checks. Companies like Sullivan Wire Rope & Rigging get ISO 9001 to show they meet safety standards.

What challenges does the wire rope industry currently face?

The big issues are:

- Keeping raw material costs down

- Stopping corrosion

- Following safety rules

- Keeping up with new tech needs

How is the renewable energy sector impacting wire rope demand?

The rise of wind and solar power is creating new needs for rigging solutions. This is driving innovation in wire rope design and materials for new projects.