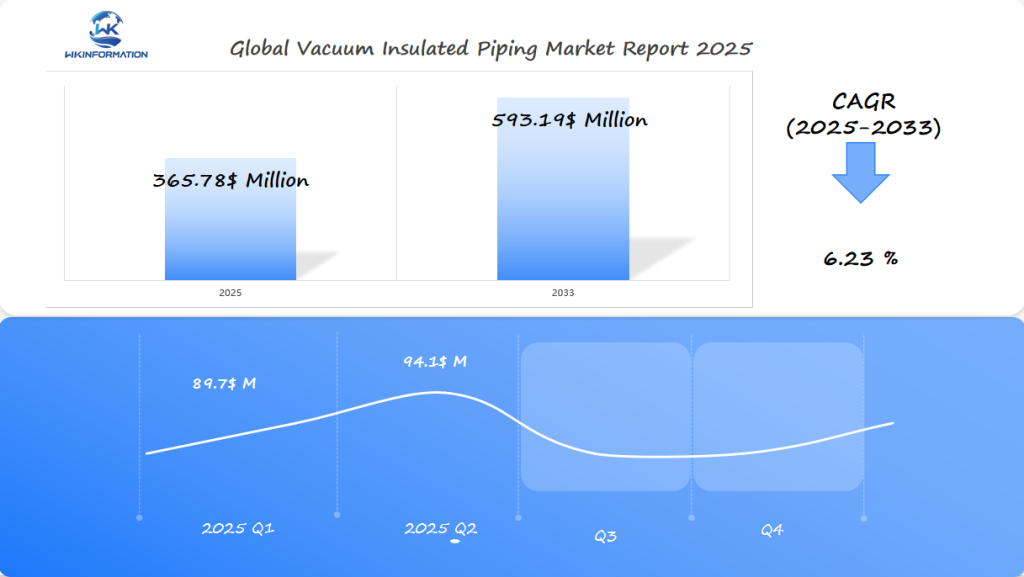

Vacuum Insulated Piping Market Poised to Surpass $365.78 Million Globally by 2025: Infrastructure Growth in the U.S., China, and Germany

Explore the Vacuum Insulated Piping Market trends, drivers, and growth opportunities as the industry expands due to rising demand in LNG infrastructure and cryogenic applications.

- Last Updated:

Vacuum Insulated Piping Market in Q1 and Q2 of 2025

The Vacuum Insulated Piping (VIP) market is projected to reach $365.78 million in 2025, growing at a CAGR of 6.23%. Q1 revenues are expected to be $89.7 million, increasing to $94.1 million in Q2. In the U.S., investments in LNG terminals, cryogenic labs, and aerospace fueling systems are driving demand. China is expanding its hydrogen economy and medical gas infrastructure, supporting wide-scale VIP deployment. Germany is focusing on high-purity gas transport for pharmaceutical and chemical sectors.

Key Takeaways

- Global market projected to exceed $365.78 million by 2025

- Increasing demand in LNG and cryogenic transportation sectors

- Technological advancements driving market expansion

- Growing emphasis on energy-efficient infrastructure solutions

- Significant investments in research and development

Understanding the Vacuum Insulated Piping Market: Upstream and Downstream Dynamics

The vacuum insulated piping market is a complex world of innovation and manufacturing. These pipes are key for moving cryogenic materials in various industries. They link raw materials to advanced users in a detailed chain.

Raw Material Landscape

At the base of the vacuum insulated piping industry are raw material suppliers. They provide:

- High-grade stainless steel for strength

- Advanced thermal insulation materials

- Special vacuum-sealing parts

Manufacturing Precision

Creating vacuum insulated pipes requires top-notch skills. The process makes a double-walled pipe with a vacuum layer. This ensures the best thermal performance.

End-User Industries

Many industries need vacuum insulated piping, including:

- Liquefied Natural Gas (LNG) infrastructure

- Pharmaceutical and healthcare sectors

- Aerospace and cryogenic research facilities

- Industrial gas transport systems

These sectors use the pipes’ unique thermal properties. They move sensitive materials at extreme temperatures. This shows the importance of advanced manufacturing in today’s industries.

Emerging trends in cryogenic transport, LNG, and industrial efficiency

The world of industrial gas transport is changing fast. New ideas in cryogenic transport and LNG infrastructure are leading the way. These innovations are changing how we manage heat and save energy.

New insulation technologies are changing how we handle extreme temperatures. Scientists and engineers are exploring new ways to improve performance. They are looking at:

- Advanced nano-ceramic insulation materials

- Multi-layer vacuum insulation systems

- Intelligent thermal barrier coatings

- Quantum-enhanced insulation techniques

Advancements in Insulation Technology

Modern insulation is key for keeping industries efficient. Vacuum insulated piping uses new materials. These materials cut down on heat transfer and save energy.

| Technology | Performance Improvement | Typical Application |

| Nano-ceramic Insulation | 95% thermal resistance | LNG Transportation |

| Multi-layer Vacuum Systems | 98% heat transfer reduction | Cryogenic Storage |

| Quantum Barrier Coatings | 99% thermal efficiency | Industrial Processing |

Integration with Smart Monitoring Systems

The future of cryogenic transport is smart monitoring. Now, we have systems that track temperatures in real-time. They also predict when maintenance is needed and work more precisely.

- IoT-enabled temperature sensors

- AI-driven performance optimization

- Automated leak detection mechanisms

- Remote diagnostic capabilities

These new technologies are raising the bar for industrial efficiency. They are changing how we handle extreme temperatures in critical industries.

Market limitations tied to high installation costs and technical precision

The vacuum insulated piping market has big hurdles to overcome. High installation costs are a major problem. This is especially true for small and medium businesses looking to use new piping tech.

Technical challenges are a big issue too. Making these pipes requires very high precision and special skills. Not many companies have these abilities.

Cost Barriers for Small and Medium Enterprises

Small businesses face significant financial challenges when considering vacuum insulated pipes. There are major obstacles to entering this market:

- Expensive initial capital investments

- High-precision manufacturing requirements

- Limited technical expertise within organizations

- Complex training and implementation processes

Challenges in Retrofitting Existing Infrastructure

Adding vacuum insulated pipes to old systems is very hard. Companies need a lot of money and special skills to do it.

Manufacturers need to find ways to make things cheaper and offer better help. This can help lower costs and make it easier to install these pipes.

Geopolitical factors affecting industrial gas transport and supply chain logistics

The world of vacuum insulated piping is closely tied to global politics. Governments see the value of these technologies in managing energy. They are key to keeping our energy systems running smoothly.

Politics greatly shape the market for vacuum insulated piping. Each area has its own plan. These plans affect how gas is moved and how infrastructure is built.

Impact of Trade Policies on Market Dynamics

Trade policies play a significant role in shaping the vacuum insulated piping market. Here are some key factors to consider:

- Tariff regulations that impact the transportation of equipment across borders

- International agreements that facilitate energy projects

- Legislation governing the movement of gas

Regional Energy Strategies and Demand Influences

Energy plans in different areas change the demand for vacuum insulated piping. Clean energy shifts are especially big in changing what the market needs.

| Region | Energy Strategy | VIP Market Impact |

| North America | LNG Export Expansion | High Growth Potential |

| Europe | Hydrogen Infrastructure | Moderate Market Expansion |

| Asia-Pacific | Industrial Modernization | Rapid Market Development |

Rules to protect the environment are making natural gas more popular. This increase in demand is good for vacuum insulated piping in many industries.

Segmentation of Vacuum Insulated Piping by pipe diameter, material, and insulation layer

The vacuum insulated piping market is where advanced materials meet industrial needs. It involves choosing the right pipe diameter, insulation, and custom solutions. These choices help meet complex industrial demands.

Choosing the right pipe diameter is key for vacuum insulated piping systems. Engineers must think about many factors when designing these pipes.

Standard vs. Customized Piping Solutions

Vacuum insulated piping falls into two main categories:

- Standard piping configurations

- Customized piping solutions

Customized solutions offer great flexibility for industries needing precise temperature control. These pipes are made to fit specific needs in various sectors.

Material Science Innovations

New insulation materials have greatly boosted piping performance. Advanced composite materials offer better thermal resistance and last longer.

| Pipe Diameter Range | Typical Application | Insulation Performance |

| 50-100 mm | Pharmaceutical Transport | High Precision Thermal Control |

| 150-300 mm | LNG Infrastructure | Extreme Temperature Resistance |

| 400-600 mm | Industrial Cryogenics | Maximum Thermal Efficiency |

By carefully choosing pipe diameter and insulation, engineers can create strong, efficient piping systems. These systems are designed to meet specific industrial needs.

Application segmentation across energy, healthcare, aerospace, and manufacturing

Vacuum insulated piping is a key technology in many fields. It’s used in energy, healthcare, aerospace, and manufacturing. Each field uses it in special ways.

The market shows how vacuum insulated piping fits into different industries. It shows how well these technologies adapt to various needs.

LNG and Natural Gas Applications

In the energy industry, vacuum insulated piping is essential. It facilitates the transportation of liquefied natural gas (LNG) while maintaining low temperatures. This ensures that the temperature remains optimal during both transportation and storage.

Benefits of Vacuum Insulated Piping in LNG and Natural Gas Applications

- Efficient LNG transportation infrastructure

- Reduced thermal energy losses

- Enhanced safety in critical energy management

Medical and Pharmaceutical Innovations

In healthcare, vacuum insulated piping is key for critical cryogenic gas management. It’s used in medical and pharmaceutical labs. It helps move sensitive materials and keeps things very cold.

Aerospace and Satellite Technology Requirements

The aerospace field needs top-notch thermal control. Vacuum insulated piping helps with this. It’s used in satellite tech and space missions for keeping things at the right temperature.

- Extreme temperature resistance

- Lightweight design considerations

- High-performance thermal insulation

Manufacturing Precision Applications

Advanced manufacturing uses vacuum insulated piping for temperature control. It’s used in electronic making, testing, and other precise work. These systems help keep things just right.

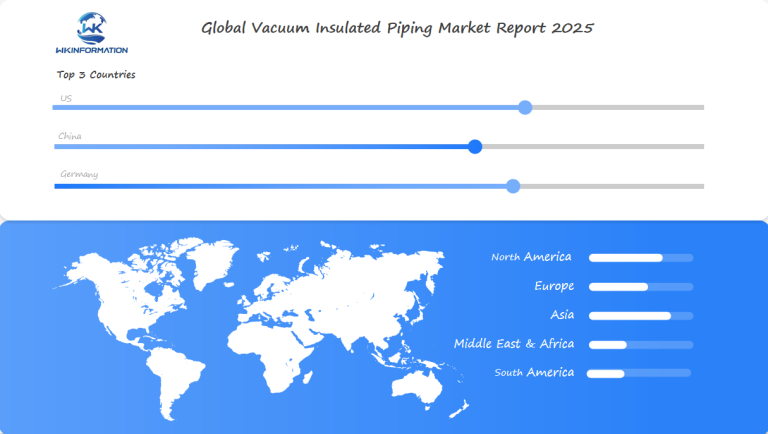

Regional developments in the global Vacuum Insulated Piping market

The global vacuum insulated piping market is changing fast in different parts of the world. This change is due to economic and technological factors. A detailed look at the market shows how vacuum insulated piping is growing in various ways.

North America: LNG Export Infrastructure Expansion

In North America, the vacuum insulated piping market is growing fast. This growth is mainly because of the big push in LNG infrastructure. The United States is a big player in natural gas exports, which means there’s a lot of demand for new piping solutions.

- Significant investments in LNG export terminals

- Increasing focus on energy efficiency

- Technological advancements in cryogenic transport

Europe: Clean Energy Transition Driving Innovation

In Europe, the push for clean energy is driving big changes in the vacuum insulated piping market. Hydrogen is a key part of this, with countries like Germany and the Netherlands leading the way in new infrastructure.

Asia-Pacific: Rapid Industrialization Sparks Cryogenic Demand

The Asia-Pacific region is leading the growth in the vacuum insulated piping market. Fast industrial growth in countries like China and India is creating huge demand for cryogenic transport solutions.

- Massive infrastructure investments

- Growing natural gas consumption

- Expanding manufacturing capabilities

Each region offers its own special chances for vacuum insulated piping technologies. This shows how different economic plans and tech levels are shaping the market. The market keeps changing, driven by energy shifts, new infrastructure, and industrial progress.

U.S. infrastructure and LNG facilities driving domestic demand

The U.S. market for vacuum insulated piping is growing fast. This growth comes from new infrastructure and more LNG facilities. The market is expected to hit USD 300 million by 2034, showing big potential in many fields.

Clean energy projects are pushing for better piping tech. The U.S. government is backing big efforts to update our infrastructure. This opens up new chances for makers and users of vacuum insulated pipes.

Government Support for Clean Energy Infrastructure

Both the federal and state governments are investing in new energy solutions. They’re focusing on:

- Updating LNG export terminals

- Creating new cryogenic transport systems

- Building sustainable energy infrastructure

Expansion of LNG Export Terminals

The Gulf Coast is becoming a key area for LNG export. Vacuum insulated piping technologies are key for safe and efficient transport in these new facilities.

Aerospace, medical, and food processing industries are increasingly adopting vacuum insulated piping. They recognize its importance in safely and accurately handling cryogenic fluids.

China's rapid industrial growth and cryogenic transport needs

The China market is a key driver in industrial growth and tech innovation, especially in cryogenic transport. The fast-growing economy has led to a huge demand for advanced piping solutions in many important sectors.

China’s big investments in LNG imports have led to big steps in vacuum insulated piping tech. The country’s fast-growing industries show a lot of promise for special cryogenic transport systems.

Investments in LNG Import Infrastructure

China is making significant progress in energy infrastructure. Key points include:

- Large investments in coastal LNG receiving terminals

- Expanding natural gas pipeline networks

- Increased use of clean energy technologies

Domestic Manufacturing Capabilities

Chinese manufacturers have quickly become experts in making vacuum insulated pipes. They are now major players in the global cryogenic transport market.

| Industry Sector | Vacuum Insulated Piping Application | Growth Potential |

| Chemical | Specialized Cryogenic Transport | High |

| Semiconductor | Precision Cooling Systems | Very High |

| Aerospace | Advanced Material Handling | Extremely High |

China’s government policies and industrial innovation are working together. This is driving the country’s fast progress in cryogenic transport technology.

Germany's energy transition and demand for advanced piping systems

The Germany market is leading the way in energy transition. It’s pushing for new solutions in hydrogen infrastructure and industrial uses. Vacuum insulated piping is key in the country’s plan to use more renewable energy, especially in cars and chemical plants.

There’s a big push in the Germany market for better piping systems. New partnerships are helping to bring in the latest hydrogen infrastructure tech.

Hydrogen Infrastructure Development

Germany’s shift towards clean energy is transforming its industrial landscape. The emphasis is on:

- Constructing larger hydrogen production facilities

- Establishing hydrogen transport networks throughout the nation

- Implementing cutting-edge vacuum insulated piping

Industrial Applications in Automotive and Chemical Sectors

The car and chemical industries are key in Germany’s tech shift. Vacuum insulated piping is important for these sectors because it:

- Helps transport cryogenic materials accurately

- Reduces heat loss

- Supports green manufacturing

Germany keeps leading in sustainable industrial solutions by investing in top-notch vacuum insulated piping.

Innovations in Leak Detection and Thermal Performance

The vacuum insulated piping market is undergoing a significant transformation. New technologies in leak detection and thermal performance are at the forefront of this change. These advancements are revolutionizing how industries maintain the seamless operation of their critical systems.

Scientists and engineers are actively developing innovative solutions that leverage IoT integration and intelligent monitoring techniques to enhance piping systems. These efforts are set to redefine industry standards for identifying leaks and optimizing thermal efficiency.

IoT and AI-Powered Monitoring Systems

Smart monitoring is changing how we maintain vacuum insulated piping. Some key advancements include:

- Real-time sensor networks for constant tracking

- Predictive maintenance algorithms using artificial intelligence

- Advanced leak detection systems that react in microseconds

Next-Generation Insulation Materials

New insulation materials are making a big impact on thermal performance. va-Q-tec’s va-Q-shell pipe technology is a game-changer. It offers insulation ten times better than old materials.

Researchers are working on new insulation materials. They aim to combine:

- Lightweight composite structures

- Improved thermal resistance

- Longer-lasting and more durable materials

These new developments will greatly enhance efficiency, safety, and performance. They will benefit many industries, from energy to aerospace.

Leading manufacturers and competitive strategies in VIP technologies

Key players in the vacuum insulated piping market are focusing on enhancing thermal efficiency, minimizing heat loss, and supporting cryogenic applications across industries such as healthcare, energy, and aerospace. They are expanding operations in high-demand regions like North America and Asia-Pacific, where the need for reliable cryogenic transport systems is growing rapidly. Through strategic collaborations with industrial gas suppliers and investments in advanced insulation technologies, these companies are reinforcing their market position and enabling the safe, efficient handling of liquefied gases in critical applications.

Key Players:

-

Fujikin (Japan)

-

Thermo Fisher Scientific (United States)

-

Alfa Laval (Sweden)

-

Swagelok (United States)

-

Parker Hannifin (United States)

-

Kitz Corporation (Japan)

-

Spirax Sarco (United Kingdom)

-

TLV (Japan)

-

Mueller Industries (United States)

-

Mueller Steam Specialty (United States)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Lumber Market Report |

| Base Year | 2024 |

| Segment by Type |

· 50-100 mm · 150-300 mm · 400-600 mm |

| Segment by Application |

· Energy · Healthcare · Aerospace · Manufacturing |

|

Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Lumber Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Lumber Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Lumber Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Lumber Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Lumber Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Lumber Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Lumber Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Lumber Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is Vacuum Insulated Piping (VIP) and why is it important?

Vacuum Insulated Piping is a special piping system for cold uses. It has a double wall with a vacuum layer to cut down heat transfer. It’s key in LNG transport, healthcare, and space, where keeping things very cold is vital.

How do Vacuum Insulated Pipes differ from traditional piping systems?

Vacuum insulated pipes use new insulation tech, like a vacuum layer, to keep cold better. This design helps keep temperatures steady, especially in very cold uses. It works better in tough industrial settings.

What are the primary industries using Vacuum Insulated Piping?

The main industries that use Vacuum Insulated Piping (VIP) are:

- LNG transport

- Healthcare

- Space

- Chemical

- Energy

These industries rely on VIP for precise temperature control and efficient gas transportation. It plays a crucial role in safeguarding sensitive materials throughout storage and transportation processes.

What are the key challenges in implementing Vacuum Insulated Piping?

There are several significant challenges that come with implementing Vacuum Insulated Piping:

- High costs

- The need for precise technology

- Complex manufacturing processes

- Integration into existing systems

These advanced systems can make it difficult for small businesses to get started.

How are technological innovations improving Vacuum Insulated Piping?

New technologies such as IoT sensors, AI monitoring, improved insulation, and new materials are making significant improvements to Vacuum Insulated Piping (VIP) systems. These advancements enhance thermal performance, enable better leak detection, and increase overall system efficiency. Additionally, smart technologies are being used for maintenance and tracking purposes.

Which regions are driving the growth of the Vacuum Insulated Piping market?

The growth leaders in the Vacuum Insulated Piping market are North America, Europe, and Asia-Pacific. The U.S., China, and Germany are leading the way in both using and manufacturing these advanced pipes.

What are the future prospects for Vacuum Insulated Piping?

The market is expected to grow significantly. This is due to the increasing demand for energy conservation, growth in LNG (liquefied natural gas) sector, and emerging requirements for cryogenic transportation.

Some of the key trends driving this growth include:

- Adoption of hydrogen as an energy source

- Shift towards clean energy solutions

- Increased utilization of vacuum insulated piping in semiconductor manufacturing processes

- Application of vacuum insulation technology in space exploration and satellite systems