Compression Fittings Market Forecasted to Hit $3.4 Billion by 2025: Infrastructure Renewal and Fluid Systems Expansion in Germany, Brazil, and Vietnam

Discover insights into the Compression Fittings Compression Fittings Market growth, driven by infrastructure development and rising demand across industrial applications through 2025.

- Last Updated:

Compression Fittings Market Performance in Q1 and Q2 of 2025

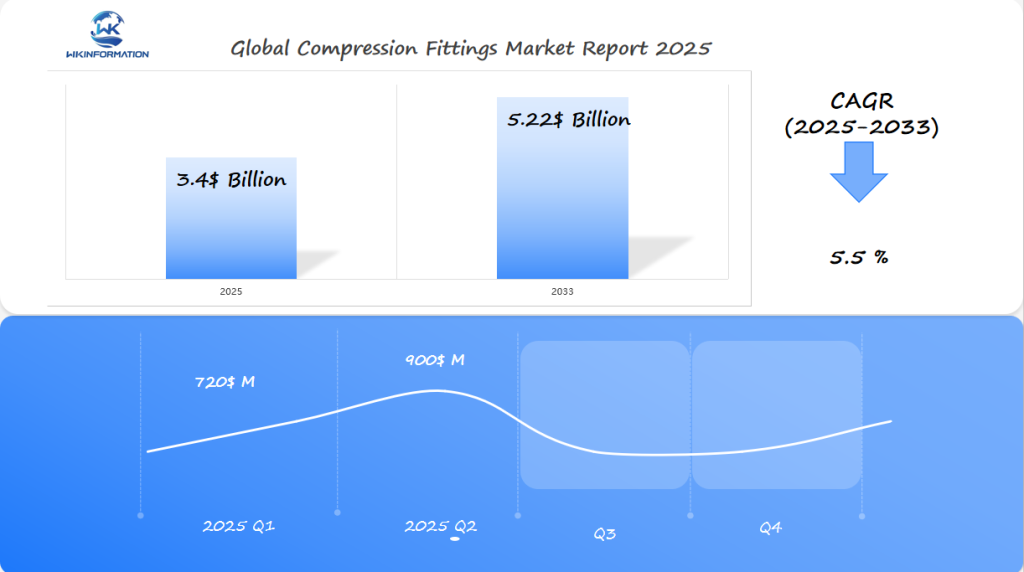

The Compression Fittings market is projected to reach $3.4 billion in 2025, underpinned by a CAGR of 5.5% from 2025 to 2033. Q1 market size is estimated at $720 million, with Q2 showing an increase to $900 million, driven by strong demand from the energy, chemical, and automotive industries. The Q2 rise is expected as construction and infrastructure projects ramp up in key industrial sectors, particularly in the oil and gas industry.

Key Takeaways

- Compression fittings market projected to reach $3.4 billion by 2025

- Infrastructure renewal driving significant market expansion

- Growing demand across water, energy, and construction sectors

- Technological innovations enhancing product performance

- Increased focus on reliable fluid control systems

Compression Fittings Market Upstream and Downstream Industry Chain Analysis

The compression fittings market is a complex web of suppliers and customers worldwide. Knowing this chain helps us understand how the market works and how it can grow.

Upstream: The Suppliers

At the top of the chain are the suppliers. They are crucial for the market’s success. These include:

- Raw material makers like brass, stainless steel, and aluminum

- Companies that focus on precision engineering

- Experts in making high-quality alloys

- Makers of special machinery and tools

Downstream: The Customers

On the other end, customers from various sectors drive demand. The main markets are:

- Construction and building projects

- Plumbing and water systems

- Energy and pipeline systems

- HVAC and mechanical engineering

Understanding the Connections

Looking closely at the chain shows how everyone is connected. Technological innovations and material advancements from suppliers affect what customers get. This is key for the market’s success.

Current Trends in the Supply Chain

Now, we’re seeing more partnerships and vertical integration. This makes the supply chain more efficient. Companies are working to cut costs without sacrificing quality.

Growth fueled by construction, plumbing, and energy pipeline demand

The compression fittings market is growing fast, thanks to big growth in key sectors. Investments in construction and energy pipelines are opening up new chances for better piping solutions.

What’s driving this growth? Here are the main factors:

- Rapid urban development in emerging markets

- Increasing infrastructure modernization initiatives

- Rising demand for efficient plumbing sector technologies

- Expansion of energy pipeline networks worldwide

In the construction world, compression fittings are key for managing fluids well. They are made to last and work great in homes, offices, and factories.

Energy pipeline projects are also a big deal. Compression fittings are a big help in tough places. They stop leaks, are easy to put in, and last a long time, even in harsh conditions.

The plumbing sector is always pushing for new ideas. Companies are making better compression fittings that meet high standards. This is especially important in areas where tech and infrastructure are changing fast.

Constraints include leakage issues and improper sizing challenges

The market for compression fittings faces big technical hurdles. These issues affect how well products work and how reliable they are. Keeping fluids from leaking is a major worry for those designing and making these systems.

Some big technical challenges in compression fittings are:

- Precise alignment requirements

- Material compatibility

- Pressure resistance

- Seal integrity

Getting the size right is key to avoiding system failures. If compression fittings are too small, it can cause problems. These include:

- Reduced system efficiency

- Increased maintenance costs

- Potential catastrophic equipment failure

- Compromised safety standards

Companies are putting a lot of effort into solving these problems. Innovative engineering approaches aim to make better seals and parts. This helps reduce the chance of leaks.

The industry keeps working to solve size and leakage problems. Teams are always trying to make compression fittings better. They want them to work well, last long, and be safe for many uses.

Geopolitical Influence of Urban Development and Water Infrastructure Investment

The market for compression fittings is changing a lot because of politics and urban planning. Governments all over the world see water infrastructure as key for growth and peace. They know it’s important for the economy and keeping society stable.

Politics is changing how people want compression fittings in different places. Countries that are growing fast are spending a lot on new infrastructure. This opens up big chances for makers and sellers.

- Urban development plans put a lot of money into fixing water systems

- Old city systems need a lot of new pipes

- Fast-growing cities need strong water networks

Investing in water systems shows a country’s dedication to growing cities in a green way. Both rich and poor countries are spending a lot on their water systems. This is making the market for compression fittings grow.

How different places handle urban growth and new tech is changing the market. It’s creating complex chances for companies all over the world.

Compression Fittings market segmentation by type: brass, stainless steel, plastic, aluminum

The compression fittings market has many types, each with its own benefits. People choose brass, stainless steel, plastic, and aluminum based on what they need. This includes how well the fitting works, the environment it’s in, and how much it costs.

Each material type of compression fitting has its own strengths. They are used in different places for various reasons:

- Corrosion resistance

- Temperature tolerance

- Mechanical strength

- Cost-effectiveness

Brass Compression Fittings

Brass fittings are often used in plumbing and water systems. They are good because they don’t corrode easily and are not too expensive. Brass fittings work well in temperatures that are not too hot or too cold.

Stainless Steel Compression Fittings

Stainless steel fittings are great for tough places. They can handle chemicals and high temperatures well. This makes them perfect for places like factories, chemical plants, and near the sea.

| Material Type | Key Strengths | Primary Applications |

| Brass | Cost-effective, moderate corrosion resistance | Residential plumbing, water systems |

| Stainless Steel | High durability, chemical resistance | Industrial processing, marine environments |

| Plastic | Lightweight, chemical inert | Low-pressure systems, chemical handling |

| Aluminum | Lightweight, good thermal conductivity | HVAC, automotive cooling systems |

Plastic Compression Fittings

Plastic fittings are special because they are light and don’t react with chemicals. They are great for places where you don’t need metal, like in systems with low pressure.

Aluminum Compression Fittings

Aluminum fittings are known for being light but strong. They are important in places where you need something that is both light and good at conducting heat. This is true for things like heating and cooling systems in buildings and cars.

Compression Fittings market segmentation by application: water supply, gas systems, HVAC, oil pipelines

Compression fittings are key in many areas, like water and gas systems, HVAC, and oil pipelines. They help move fluids and gases smoothly in homes and industries.

These fittings are used in many important areas. Each one has its own needs and rules:

- Water supply systems

- Gas distribution networks

- HVAC systems

- Oil pipeline infrastructure

Water Supply Systems

In water systems, compression fittings keep pipes connected well. They help avoid leaks in homes and cities.

Gas Distribution Networks

Gas networks require robust compression fittings to ensure the safe flow of gas. These fittings effectively prevent gas leaks and are designed to withstand high pressure.

HVAC Applications

HVAC systems use compression fittings for refrigerant and water lines. These fittings create a tight seal, which is crucial for controlling temperature and climate.

Oil Pipeline Infrastructure

Oil pipelines need top-notch compression fittings for harsh conditions. These fittings keep oil flowing smoothly over long distances.

| Application | Key Characteristics | Primary Materials |

| Water Supply | Leak-resistant connections | Brass, Stainless Steel |

| Gas Distribution | High-pressure tolerance | Brass, Aluminum |

| HVAC | Precise temperature control | Copper, Stainless Steel |

| Oil Pipelines | Extreme environment resistance | Stainless Steel, Alloy |

Each area has its own challenges. This pushes for new ideas in making and designing compression fittings.

Global dynamics of the Compression Fittings market

The global compression fittings market is changing fast. This change is due to new technologies and the growth of infrastructure. These factors are opening up new chances for makers and suppliers all over the world.

Regional growth patterns

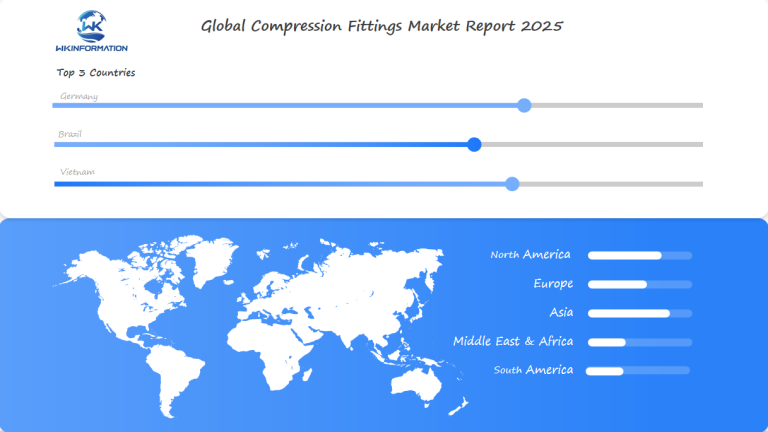

There are big differences in how the market grows in different places. In places like North America and Europe, the market is more mature. It focuses on making things precise and finding green solutions. But in the Asia-Pacific area, things are growing fast because of industrial growth.

- North America: High-precision manufacturing standards

- Europe: Green technology integration

- Asia-Pacific: Rapid infrastructure expansion

- Middle East: Energy sector infrastructure investments

Factors influencing market dynamics

Many things affect the market:

- Economic development rates

- Industrial modernization initiatives

- Infrastructure renewal projects

- Technological innovation cycles

Regional variations in fluid management

Every region has its own way of using compression fittings. Technological sophistication varies a lot. Each area has its own challenges and chances in managing fluids.

Tailoring solutions for regional markets

Smart manufacturers are now trying to understand the differences in each region. They make special solutions for each market’s needs. This way, they can stay ahead in a changing world market.

Germany's Compression Fittings Market: Leading the Way in Precision Plumbing and Green Buildings

The German market is at the forefront of innovation in compression fittings. It sets global standards in precision plumbing and green buildings. German manufacturers create top-notch solutions that are both high-tech and eco-friendly.

Green Building: A Key Focus for German Compression Fittings Makers

Green building is a significant priority for German manufacturers of compression fittings. They employ intelligent design and environmentally friendly materials to create products that are not only sustainable but also highly functional.

Here are some ways in which German manufacturers are incorporating sustainability into their products:

- Advanced precision engineering techniques

- Eco-friendly manufacturing processes

- High-performance material selection

- Compliance with strict environmental standards

The Impact of German Engineering on Compression Fittings

German engineering has had a profound impact on the compression fittings industry. Precision plumbing systems developed in Germany have gained a reputation for their reliability, durability, and minimal environmental impact.

| Market Characteristic | German Compression Fittings Performance |

| Innovation Level | High |

| Sustainability Focus | Exceptional |

| Global Market Influence | Significant |

| Manufacturing Precision | Top-tier |

German manufacturers are recognized as global leaders in green building practices. Their products consistently exceed industry requirements and often establish new benchmarks for both performance and sustainability.

Brazil Compression Fittings Market: Rapid Urban Utility Expansion

The Brazilian market is changing fast, especially in urban utility infrastructure. This change is boosting the growth of compression fittings. Brazil is becoming a key place for new piping solutions, especially in big cities.

Urban growth is changing Brazil’s infrastructure plans. Cities like São Paulo and Rio de Janeiro are getting big investments. These investments are in water, gas, and modern systems that need top-notch compression fittings.

Factors Driving Demand for Compression Fittings in Brazil

- Rapid urbanization increasing demand for advanced piping solutions

- Significant infrastructure investment in water and gas networks

- Growing need for corrosion-resistant and durable compression fittings

Growth Potential Across Market Segments

| Market Segment | Growth Potential | Key Challenges |

| Water Infrastructure | High | Aging Network Replacement |

| Gas Distribution | Medium-High | Regulatory Compliance |

| Industrial Applications | Medium | Technology Adaptation |

Companies are now making specialized compression fittings for Brazil’s fast-changing infrastructure. The market is full of chances for those ready to invest in new, top-quality solutions.

Vietnam Compression Fittings Market: Infrastructure Modernization

The Vietnamese market is changing fast, thanks to new infrastructure and growth. Vietnam is becoming a big player in Southeast Asia. It’s spending a lot on improving its infrastructure.

Several things are making the compression fittings market in Vietnam grow:

- Fast urban development projects

- More industrial zones

- More foreign investment

- Modern water and utility systems

Industrial growth is a big reason for the need for compression fittings. Sectors like electronics, cars, and green energy are growing fast. The Vietnamese government’s focus on infrastructure is opening doors for new technologies.

Global companies see Vietnam’s potential. They’re investing in:

- Advanced manufacturing

- Technology sharing

- Local partnerships

- Training programs

The market for compression fittings in Vietnam is set to grow a lot. This shows the country’s big plans for infrastructure and its growing industrial base.

Future trends toward corrosion-resistant and quick-connect designs

The compression fittings industry is changing fast. This change comes from new product ideas and better engineering. Companies are working hard to make corrosion-resistant materials. They want to make piping systems last longer and work better in many fields.

New quick-connect designs are making installation easier and faster. These designs help solve big problems in both work and home settings. They cut down on the time needed for setup and help avoid mistakes.

Advanced materials for durability

- Advanced polymers with enhanced durability

- Nano-engineered coating technologies

Intelligent design for efficiency

- Smart monitoring capabilities for real-time performance tracking

New trends in compression fittings bring big tech improvements. Engineers are using the latest in materials science. They aim to make fittings that last longer and work better, even in tough environments.

Companies are spending a lot on research for the next big thing in quick-connect designs. They want designs that are easy to use, last a long time, and are good for the planet. These changes will change how we build and maintain buildings worldwide.

Competitive field in piping component manufacturing

Key players in the compression fittings market are focusing on leak-proof design, corrosion-resistant materials, and tool-free installation to serve critical applications in plumbing, HVAC, oil & gas, and chemical processing industries. They are expanding into emerging markets such as Southeast Asia and Eastern Europe, where infrastructure development and industrial modernization are driving demand. Strategic collaborations with piping system manufacturers and investments in precision manufacturing technologies are helping these companies improve product reliability and strengthen their market share.

Key Players:

-

Gruner Brass Fittings Corp. (USA)

-

Watlow Electric Manufacturing Company (USA)

-

MID-AMERICA FITTINGS (USA)

-

Koolance, Inc. (USA)

-

MicroStrain (a LORD Company) (USA)

-

Labfacility (UK)

-

HUMMEL AG (Germany)

-

FLEXIRO (Germany)

-

NORMA Group (Germany)

-

FERRO S.A. (Poland)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Chart Recorder Market Report |

| Base Year | 2024 |

| Segment by Type |

· Brass · Stainless Steel · Plastic · Aluminum |

| Segment by Application |

· Water Supply · Gas Systems · HVAC · Oil Pipelines |

|

Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Compression Fittings Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Compression Fittings Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Compression Fittings Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Compression Fittings Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Compression Fittings Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Compression Fittings Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Compression Fittings Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Compression Fittings Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market value for compression fittings by 2025?

The market for compression fittings is expected to hit $3.4 billion by 2025. This growth is fueled by updates to infrastructure and the need for better fluid control systems in various fields.

Key Industries That Use Compression Fittings

Industries such as construction, water systems, gas networks, HVAC, and oil pipelines depend on compression fittings. These fittings are essential for the secure and effective transportation of fluids.

What materials are commonly used in compression fittings?

Common materials include brass, stainless steel, plastic, and aluminum. Each offers benefits like durability and cost-effectiveness, fitting different needs.

What are the main challenges in the compression fittings market?

The compression fittings market faces several challenges, including:

- Leakage

- Wrong sizing

- Ensuring products work well

To address these issues, manufacturers are focusing on improving designs and using higher-quality materials.

How do geopolitical factors impact the compression fittings market?

Policies regarding urban growth, infrastructure spending, and updates to water systems have an impact on demand. The level of urbanization and the specific infrastructure requirements differ from one region to another, creating various opportunities in each area.

What emerging trends are shaping the compression fittings industry?

Trends include materials that resist corrosion better, quick-connect designs, and smart fittings. Manufacturers are focusing on making products easier to install and last longer.

Which regions show the most potential for compression fittings market growth?

Brazil and Vietnam are growing fast due to urban growth, modernizing infrastructure, and expanding utility networks. Countries with big infrastructure projects are especially promising.

Why is Germany important in the compression fittings market?

Germany is known for its precise engineering and environmentally friendly construction. The country’s manufacturers are at the forefront of developing new compression fitting technology, particularly in the areas of sustainable and accurate plumbing.

How do compression fittings contribute to infrastructure development?

Compression fittings are crucial in the development of water, gas, and energy pipeline projects. They play a vital role in ensuring the safe and efficient transportation of fluids in critical infrastructure systems.

What factors drive innovation in compression fittings?

Innovation comes from customer needs for easier use, longer life, better performance, and adaptability. Advances in materials and design drive progress.