Glue Laminated Beam Market Expected to Reach $7.8 Billion by 2025: Green Construction Push in Germany, Canada, and Japan

The Glue Laminated Beam Market sees robust growth as German construction firms embrace sustainable building materials, driving global demand for eco-friendly structural solutions.

- Last Updated:

Glue Laminated Beam Market Performance in Q1 and Q2 of 2025

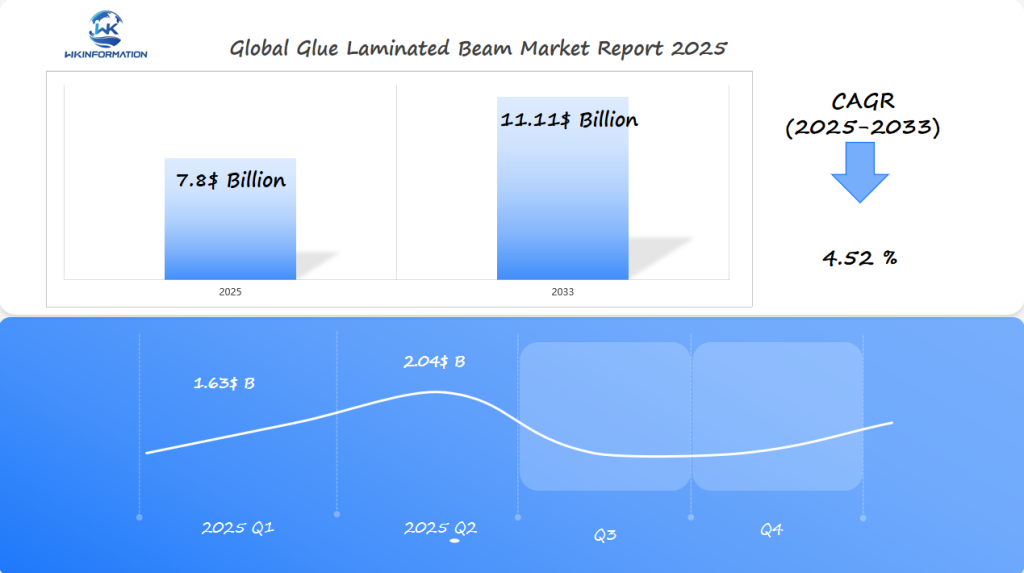

With a 2025 projected value of $7.8 billion, the Glue Laminated Beam (Glulam) market is expanding at a CAGR of 4.52% through 2033. Performance in Q1 of 2025 is forecast at $1.63 billion, while Q2 climbs to about $2.04 billion, driven by construction seasonality, especially in temperate regions where building activity accelerates in spring. Growth is notably supported by demand for eco-friendly structural solutions in commercial and residential buildings.

Key Takeaways

- The market is projected to reach $7.8 billion by 2025

- Sustainable construction is driving industry growth

- Germany is leading in green building material innovations

- Technological advancements are improving beam manufacturing

- Engineered wood solutions are gaining market prominence

Glue Laminated Beam Market Upstream and Downstream Industry Chain Analysis

Upstream Industry Chain

The upstream sector of the glue laminated beam (glulam) market primarily involves raw material sourcing and initial processing. Key components include:

- Raw Material Supply:

- Timber sourcing: Sustainable forestry practices supply the wood necessary for glulam production. Species such as softwoods (pine, spruce, fir) are commonly used due to their strength and availability.

- Adhesives and resins: High-performance adhesives are essential to bond layers of timber securely. Innovations in eco-friendly, fire-resistant adhesive systems are crucial upstream inputs.

- Wood Processing and Preparation:

- Timber is dried, graded, and cut into lamellas (thin wood layers). Proper preparation ensures structural integrity and quality of the finished beams.

- Technological Inputs:

- Advanced machinery for precision cutting, lamination, and pressing. Automation and digital technologies enhance production efficiency and product consistency.

Midstream Industry Chain

This stage focuses on the manufacturing of glue laminated beams:

- Beam Fabrication:

- Layers of wood lamellas are glued under pressure using specialized presses to form straight, curved, or custom profile beams.

- Fire-resistant treatments and quality inspections ensure compliance with safety standards.

- Product Customization:

- Tailoring beams to specific architectural or structural requirements through computer-aided design (CAD) and automated fabrication techniques.

Downstream Industry Chain

The downstream chain covers distribution, application, and end-user engagement:

- Distribution Channels:

- Suppliers distribute glue laminated beams through building material wholesalers, direct sales to construction firms, or specialized engineered wood product dealers.

- Applications:

- Residential construction: supporting roofs, floors, open living spaces.

- Commercial buildings: facilitating large spans with aesthetic appeal.

- Infrastructure projects: bridges and public buildings emphasizing sustainability and resilience.

- End Users:

- Architects and engineers specifying glulam for sustainable designs.

- Contractors utilizing beams for structural frameworks.

- Developers investing in eco-friendly materials aligned with low-carbon building policies.

Trends Driven by Sustainable Architecture and Timber Engineering Innovation

The glue laminated beam market is changing fast. This is thanks to sustainable architecture and new timber engineering ideas. Architects and engineers are now using these green building options more. They see them as better than old materials.

Some big trends in timber engineering are:

- Eco-friendly design that cuts down on carbon

- Advanced computer models for complex designs

- Using renewable materials in buildings

- Improving performance with precise engineering

Sustainable architecture is a big reason for these changes. Designers are finding new ways to use glue laminated beams. They make buildings stronger and use less energy.

| Innovation Category | Key Characteristics | Market Impact |

| Computational Design | Advanced algorithmic modeling | Increased structural precision |

| Material Performance | Enhanced strength-to-weight ratios | Reduced environmental load |

| Sustainable Manufacturing | Low-carbon production processes | Decreased carbon emissions |

The mix of sustainable architecture and timber engineering is opening up new areas. It’s making building greener and more beautiful. It’s all about finding a balance between looks and strength.

Challenges from fire safety standards and structural load limitations

Glue laminated beams face big challenges in fire safety and structural load. Builders must follow strict building codes. These codes set high standards for engineered wood products.

Fire safety is a top concern for glue laminated beams. Timber structures need special treatments to fight fires and follow building rules. Scientists are working on new ways to make these beams safer in fires.

- Advanced intumescent coating technologies

- Specialized fire-resistant adhesive systems

- Engineered wood assemblies with enhanced char protection

Structural load limits are another big issue for engineers. Architects and builders must figure out how much weight these beams can hold. This is to keep the structure strong over time.

| Fire Safety Challenge | Mitigation Strategy | Performance Improvement |

| Combustibility | Intumescent coating | 60-90 minute fire resistance |

| Structural Degradation | Specialized adhesive systems | Enhanced thermal stability |

| Load-Bearing Capacity | Engineered char protection | Maintained structural integrity |

Building codes keep getting tougher, making manufacturers work harder. Innovative research in fire safety and structural engineering leads to better wood construction.

Geopolitical emphasis on low-carbon buildings and timber housing policy

Global governments are focusing more on low-carbon buildings to cut carbon emissions in construction. Timber housing policy is key for sustainable building, with rules driving big changes in the market.

Several strategies are shaping government rules for green construction:

- Implementing carbon pricing for construction materials

- Offering tax breaks for low-carbon building projects

- Setting strict energy efficiency standards

- Encouraging the use of renewable materials in design

The European Union is leading in timber housing policy. Countries like Sweden and Finland are using glue laminated beams in their green building standards. These rules give big economic benefits to architects and developers for choosing low-carbon building methods.

In the United States, local and state governments are adopting new building codes for green construction. Timber-based construction is seen as a key way to lower the built environment’s carbon footprint.

Nations are changing the construction world towards a greener future. They’re using advanced materials like glue laminated beams and strong government rules.

Glue Laminated Beam market segmentation by type: straight beams, curved beams, custom profile beams

The glue laminated beam market offers three main types. Straight beams, curved beams, and custom profile beams meet different needs in building design. Each type has its own strengths for modern construction.

Straight Beams

Straight beams are the most common and reliable choice. They are strong and dependable for homes and businesses. Architects and engineers often pick them for their clear load-carrying ability and easy setup.

- Ideal for standard rectangular building designs

- High load-carrying capacity

- Cost-effective manufacturing

Curved Beams

Curved beams add beauty and flexibility to building designs. Engineered with precision lamination techniques, they allow for complex shapes.

- Enables complex architectural geometries

- Supports innovative design concepts

- Provides enhanced structural performance

Custom Profile Beams

Custom profile beams are the ultimate in design flexibility. They let builders create beams that fit exact project needs. This freedom is great for homes, businesses, and big projects.

Glue Laminated Beam Market Segmentation by Application

The glue laminated beam market is very versatile. It’s used in many construction areas. Engineers and architects see its value in both homes and big public projects.

Glue laminated beams are key in various construction fields:

- Residential Construction: Enabling spacious, open floor plans

- Commercial Buildings: Supporting large-span structures

- Bridges: Providing sustainable structural solutions

- Public Infrastructure: Delivering resilient architectural elements

Each area has its own needs. In homes, these beams add beauty and strength. Architects love how they make big spaces without looking cluttered.

| Application | Key Characteristics | Market Growth Potential |

| Residential Construction | Lightweight, Design Flexibility | High |

| Commercial Buildings | Large Span Capabilities | Medium-High |

| Bridges | Durability, Corrosion Resistance | Medium |

| Public Infrastructure | Sustainable, Lightweight | Growing |

In commercial buildings, glue laminated beams help create big, open spaces. For bridges, they offer a strong yet light solution. This reduces the weight of the bridge while keeping it strong.

Public projects are also turning to glue laminated beams. They’re a green choice that’s good for the environment. They’re perfect for government and city projects.

Global overview of the Glue Laminated Beam market

The global market for glue laminated beams is growing fast. This is thanks to green building and new timber engineering. Experts say the market will grow even more, with more use in homes and businesses.

Market share by region

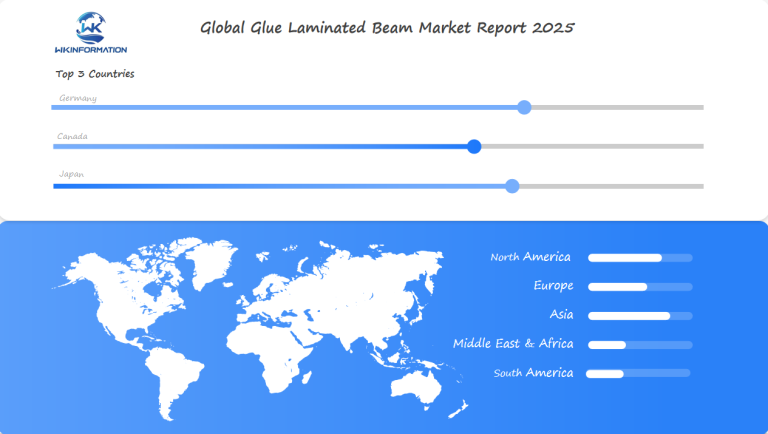

Looking at the market share by region, we see some interesting facts:

- North America is ahead with its advanced timber building methods

- Europe is strong in eco-friendly building rules

- Asia-Pacific is seeing more demand for urban projects

Experts think there’s a lot of room for glue laminated beams. Sustainable architecture and green building are driving growth. Companies are working on new ways to make them to meet the demand.

Factors driving market growth

What’s making the market move? Here are a few key points:

- More people care about the environment

- New tech in timber engineering

- Support from governments for green materials

New markets in Southeast Asia and Latin America are full of potential. New tech and good prices will shape the future of glue laminated beams.

Germany's Glue Laminated Beam Market: Eco-Regulations and Public Infrastructure

The German market leads in sustainable construction, with glue laminated beams key in public projects. Eco-regulations make Germany a green building leader, pushing timber engineering innovation.

Key developments in the German market include:

- Advanced sustainability standards for construction materials

- Government incentives for low-carbon building solutions

- Increased investment in renewable timber technologies

Public projects drive glue laminated beam use. Urban plans now focus on green materials to cut carbon and keep buildings strong.

Eco-regulations in Germany seek top-notch, green building solutions. Glue laminated beams fit the bill with:

- Exceptional structural strength

- Reduced environmental impact

- Superior thermal efficiency

Municipalities in Germany are using new timber construction methods. They’re in government buildings, transport, and schools. These projects show a strong push for green urban growth.

Canada Glue Laminated Beam market: timber housing and export development

The Canadian market leads in timber housing innovation, using its vast forests to boost global production. With over 347 million hectares of productive forest land, Canada is a leader in sustainable wood engineering.

Canada’s timber housing sector has several key strengths:

- Advanced wood processing technologies

- Sustainable forest management practices

- Strong research and development infrastructure

- Strategic geographic positioning for export opportunities

Export chances for glue laminated beams have grown a lot. Canadian makers aim at big markets like the United States, Japan, and Europe. These places want top-notch timber for building.

New tech has made Canadian glue laminated beams more competitive. Precision engineering and strict quality control have made Canadian makers top in timber housing.

Market forecasts show big growth ahead. This is because of more demand for green building materials and Canada’s skill in wood engineering.

Japan Glue Laminated Beam market: compact building and seismic resilience

The Japanese market leads in innovative building designs, focusing on compact and safe structures. Glue laminated beams are key for solving urban construction challenges. They help architects and engineers meet the needs of tight spaces and safety.

Glue laminated beams in Japan offer:

- Exceptional space optimization for dense urban environments

- Superior structural performance during seismic events

- Lightweight yet robust construction materials

- Advanced engineering for earthquake-resistant structures

Seismic resilience drives innovation in glue laminated beam technology. Japanese engineers have created special techniques. These improve building strength in earthquake-prone areas.

- Increased flexibility in building frameworks

- Enhanced energy absorption during ground movements

- Reduced structural damage potential

Using glue laminated beams in Japan shows a smart way to build cities. It balances space needs with safety. As cities grow and seismic risks stay, these solutions will be more important.

Future outlook toward cross-laminated hybrids and automation in fabrication

The future of glue laminated beams is exciting, with new cross-laminated hybrids leading the way. These hybrids are changing the game for green building. Researchers are working hard to create new materials that mix old timber tech with new fabrication methods.

The Role of Automation

Automation is making big waves in the industry. Companies are using smart robots to make complex timber parts quickly and accurately. This shows a big move towards smarter and more flexible making processes.

Key Areas of Focus

- Advanced cross-laminated hybrids with enhanced structural performance

- Robotic precision in timber component manufacturing

- Integration of AI-driven design optimization

- Sustainable material development

The Impact of Digital Technologies

Digital tech is changing timber engineering. Automated fabrication techniques let makers create detailed and custom timber parts with great accuracy.

| Technology | Potential Impact | Implementation Timeline |

| 3D-Printed Interfaces | Enhanced Structural Connections | 2-3 Years |

| Robotic Assembly | Increased Production Efficiency | 1-2 Years |

| AI Design Optimization | Material Performance Improvement | 3-5 Years |

The mix of green design and new making tech is set to change glue laminated beam making. Builders and designers are ready to make buildings that are better, more flexible, and kinder to the planet.

Competitor landscape in engineered wood solutions

Key players in the glue laminated beam market are focusing on sustainable sourcing and innovative design techniques to meet the rising demand for eco-friendly and architecturally flexible building materials. They are expanding into fast-growing regions like Asia-Pacific and Eastern Europe, where green construction and timber-based infrastructure are gaining momentum. Strategic collaborations with architects and construction firms, along with investments in advanced manufacturing and certification standards, are helping these companies strengthen their market position and respond to evolving industry needs.

Here are some of the top players in the Glue Laminated Beam market:

-

Mayr-Melnhof Holz Holding AG (Austria)

-

Western Forest Products (Canada)

-

Moelven (Norway)

-

Boise Cascade (USA)

-

Binderholz GmbH (Austria)

-

Pfeifer Holding GmbH (Austria)

-

Canfor (Canada)

-

Schilliger Holz AG (Switzerland)

-

Timber Technologies L.L.C (USA)

-

Glu-Lam Sales Co., Inc. (USA)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Glue Laminated Beam Market Report |

| Base Year | 2024 |

| Segment by Type |

· Straight Beams · Curved Beams · Custom Profile Beams |

|

Segment by Application |

· Residential Construction · Commercial Buildings · Bridges · Public |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Global Glue Laminated Beam Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Glue Laminated Beam Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Glue Laminated Beam Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Glue Laminated Beam Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Glue Laminated Beam Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Glue Laminated Beam Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Glue Laminated Beam Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Glue Laminated Beam Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are glue laminated beams?

Glue laminated beams, or glulam, are made by sticking many layers of wood together. They are strong and flexible, making them great for building projects.

Why are glue laminated beams considered eco-friendly?

Glue laminated beams are considered eco-friendly for two main reasons:

- Sustainable wood sourcing: Glue laminated beams use wood that comes from sustainably managed forests. This means that for every tree that is harvested, new trees are planted to ensure the forest ecosystem remains intact and continues to thrive.

- Reduced environmental impact: When compared to other construction materials like steel or concrete, glue laminated beams have a lower carbon footprint. The production of steel and concrete involves energy-intensive processes that contribute significantly to greenhouse gas emissions. In contrast, the manufacturing process of glue laminated beams requires less energy and produces fewer emissions.

By choosing glue laminated beams as a building material, we can promote sustainable forestry practices and reduce our overall environmental impact.

What are the primary applications of glue laminated beams?

Glue laminated beams are versatile and find applications in various construction projects. Here are some of the key areas where these beams are commonly used:

- Residential buildings: Glue laminated beams are often used in the construction of homes, providing structural support for roofs, floors, and open spaces.

- Commercial buildings: Offices, retail spaces, and other commercial structures utilize glue laminated beams for their strength and aesthetic appeal.

- Bridges: Glue laminated beams can be employed in bridge construction, offering durability and the ability to span long distances.

- Specialized structures: Certain buildings with unique architectural designs or specific load-bearing requirements may rely on glue laminated beams for their structural integrity.

The versatility of glue laminated beams makes them suitable for a wide range of applications in both residential and commercial construction projects.

How do glue laminated beams perform in seismic regions?

They do well in areas that shake a lot. Their design helps buildings stand strong and move a little, which is good for keeping people safe.

What types of glue laminated beams are available?

You can find straight, curved, and custom beams. Each type is made for different building needs.

Are glue laminated beams fire-resistant?

Wood can catch fire, but modern beams are treated to be safer. They meet strict safety rules when used right.

Which countries are leading in glue laminated beam production?

Germany, Canada, and Japan are at the top. They lead in making buildings green, using wood well, and being creative with engineering.

What technologies are emerging in glue laminated beam production?

New technology includes making beams stronger and more flexible. There’s also better ways to make them and new designs to try.

How do glue laminated beams compare to traditional building materials?

They are stronger, more flexible, and better for the planet. They often have less impact on the environment than steel or concrete.

What factors are driving market growth for glue laminated beams?

The growth in the market for glue laminated beams is driven by several key factors. These include the rise of green building trends, the implementation of laws that benefit the planet, advancements in wood engineering, and an increasing number of people opting for eco-friendly buildings.

Another significant factor contributing to the growth of the market for glue laminated beams is the growing awareness among consumers regarding sustainable construction practices and the desire for eco-friendly building materials.