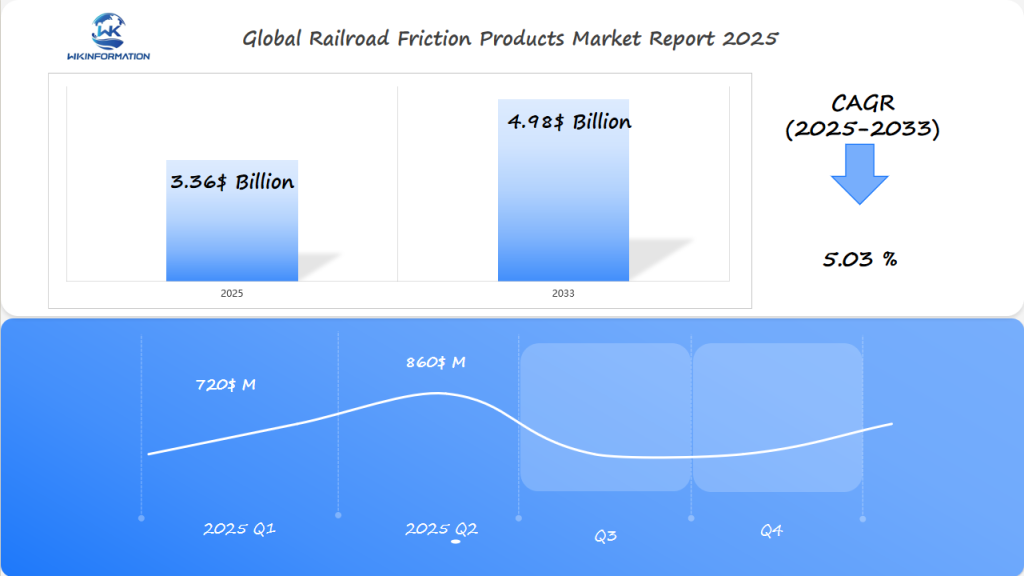

Railroad Friction Products Market to Surpass $3.36 Billion in 2025: Transit Safety Boosts Growth in China, Canada, and France

The Railroad Friction Products Market sees robust growth driven by increased rail safety measures and infrastructure investments. Rising demand for efficient braking systems fuels market expansion.

- Last Updated:

Railroad Friction Products Market Performance in Q1 and Q2 of 2025

The global Railroad Friction Products market is set to hit $3.36 billion in 2025, with a CAGR of 5.03% through 2033. Early-year performance suggests Q1 of 2025 achieved approximately $720 million, while Q2 is projected to reach $860 million, in line with seasonal rail maintenance and procurement budgets. The Q2 growth reflects stronger infrastructure spending and modernization of freight networks.

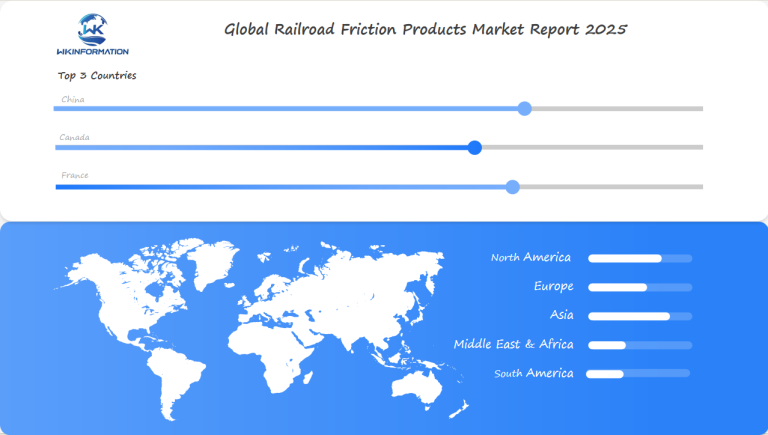

China, Canada, and France remain at the forefront of this segment, with ongoing rail freight expansions, aging rolling stock upgrades, and emissions-focused innovations in braking technology. With growing attention to sustainability and high-load transport efficiency, these markets represent key indicators of long-term momentum in rail-based logistics.

Key Takeaways

- Market projected to reach $3.36 billion by 2025

- Transit safety drives significant market expansion

- China, Canada, and France lead regional market growth

- Technological innovations enhance friction product performance

- Infrastructure investments support market development

Railroad Friction Products market upstream and downstream industry chain structure

The railroad friction products market has a complex chain. It connects suppliers, makers, and buyers. This chain is key to product quality, new ideas, and market changes.

Upstream Suppliers: Raw Material Production

At the start of the chain, suppliers give raw materials needed for making friction products. They focus on:

- High-performance metals

- Ceramic compounds

- Specialized friction-resistant materials

- Advanced polymer composites

Manufacturers: Product Design and Manufacturing

Manufacturers then turn these materials into high-tech friction products. They work with suppliers to make sure materials are top-notch. They also aim to create new solutions for buyers.

| Industry Chain Segment | Key Participants | Primary Responsibilities |

| Upstream Suppliers | Material Manufacturers | Raw material production and quality control |

| Manufacturers | Friction Product Companies | Product design and manufacturing |

| Downstream Buyers | Railroad Operators | Final product implementation and performance evaluation |

Downstream Buyers: Final Product Implementation

At the end of the chain, buyers like railroad companies check the products. They look at how well they last, how safe they are, and if they’re worth the cost.

This chain’s connection leads to constant improvement. It makes sure railroad friction products meet high safety and performance standards.

Increasing investment in rail safety and infrastructure modernizes friction tech

The railroad industry is going through a big change. This is thanks to a lot of money being put into making rail safer and more modern. Governments and transport groups are focusing on new friction technology. This is to make trains run better and keep passengers safe.

Some big changes in friction technology include:

- Creating brake pads that can handle high heat

- Smart braking systems with advanced sensors

- Friction parts made with precision to last longer

Research is leading to new friction solutions for rail. Ceramic-based composites and nanotechnology are changing how brakes work. They make brakes more reliable and efficient.

Big changes in how money is spent are changing the rail friction market. Big companies are spending a lot on research. They want to make new friction tech that meets tough safety rules.

These new technologies are making rail travel safer and more eco-friendly. They also make it cheaper for people all over the world.

Challenges from material degradation, heat resistance, and environmental mandates

The railroad friction products market is facing big challenges. These challenges test the limits of material engineering and environmental care. Material degradation is a big worry for makers of friction parts.

Key challenges in the railroad friction products industry include:

- Persistent material degradation under high-stress environments

- Demanding heat resistance requirements for high-speed rail systems

- Stringent environmental regulations impacting product development

Companies are spending a lot on research to fight material degradation. Advanced ceramic and composite materials are being looked into to make parts last longer and work better. The need for parts that can handle high heat is driving new ideas, especially for fast trains.

Environmental rules are changing how products are made. Now, friction products must be good for the planet and still work well. This means makers are working on greener solutions that don’t hurt the environment or performance.

Material science, engineering, and following rules are a tough mix for makers of railroad friction products. Those who figure out how to overcome these hurdles will have a big edge in the fast-changing transit tech world.

Geopolitical strategies in rail development and high-speed corridor projects

Geopolitical strategies are changing how rail development works around the world. Countries see high-speed corridors as key for economic growth and connecting with others globally. These projects show how transportation tech and global politics mix.

Important strategies in rail development cover several key points:

- Expanding transnational transportation networks

- Reducing economic dependencies

- Enhancing regional economic integration

- Promoting sustainable transportation solutions

China’s Belt and Road Initiative is a top example of smart rail development. It links continents with high-speed corridors, opening up big economic chances. European and North American countries are also investing in rail, seeing its value for modern transport.

The battle for high-speed corridors is more than just about moving things. It’s a high-tech diplomacy game where countries show off their engineering and economic strength. Rail projects help build soft power and global partnerships.

Friction product makers are keeping an eye on these strategies. They see each new high-speed corridor as a big market chance. The need for top-notch railroad friction products is growing as countries build advanced transport systems.

Railroad Friction Products market segmentation by type: brake shoes, brake pads, disc brakes, composition blocks

The railroad friction products market is complex, with many important types. Knowing these segments helps us see how technology and the industry are doing.

There are four main types that lead to new ideas in railroad friction technology:

- Brake shoes

- Brake pads

- Disc brakes

- Composition blocks

In-Depth Analysis of the Brake Shoes Segment

Brake shoes are an essential component of railroad friction systems. These curved metal pieces work in conjunction with drum brakes to bring trains to a halt. Manufacturers are actively seeking ways to enhance the durability and performance of brake shoes.

Emerging Brake Pads Market Trends

Brake pads are changing railroad friction technology. Made with new materials, they can handle more heat and last longer. The brake pads market is growing fast because of these new technologies.

Disc Brake Technological Adoption

Disc brakes are becoming more popular in rail travel. They stop trains better and need less upkeep. This makes them great for fast and freight trains.

Composition Blocks Demand Forecast

Composition blocks are important in railroad friction markets. They have special features for certain types of rail use. As more rail lines are built, demand for these blocks is expected to rise.

Railroad Friction Products market segmentation by application: freight trains, high-speed rail, metro systems, locomotives

The railroad friction products market covers many important transportation areas. Each area has its own needs and technology demands. This shows the complexity and innovation in the rail industry.

Railroad friction products are key for safe and reliable travel in different rail systems. The market includes:

- Freight trains

- High-speed rail

- Metro systems

- Locomotives

Freight Train Segment Analysis

Freight trains require durable friction products that can handle heavy loads and long journeys. The market seeks products that have a long lifespan, can withstand high temperatures, and perform effectively in challenging environments.

High-Speed Rail Market Trends

High-speed rail is a fast-growing area with special friction product needs. Companies are making new materials that cut down on wear, noise, and improve system reliability.

Metro Systems Demand Forecast

Urban metro systems need precise friction products for smooth travel and comfort. As cities grow, there’s a big push for better metro systems worldwide.

Growth of Locomotive Applications

New technology is improving locomotive friction products. Companies are working towards creating lighter and better components that will not only save energy but also reduce maintenance costs.

Global outlook for the Railroad Friction Products market

The global market for railroad friction products is changing fast. New technologies and strategies are being used. Market research shows big opportunities in many areas.

There are several important trends to watch:

- More money going into rail projects

- More need for better brake systems

- New tech in friction materials

Different parts of the world have their own market stories. North America is growing fast because of its big rail networks. Europe is all about new tech, and Asia is building its rail fast.

| Region | Market Growth Potential | Key Drivers |

| North America | High | Freight rail expansion |

| Europe | Moderate | High-speed rail technology |

| Asia-Pacific | Very High | Infrastructure development |

New markets offer big chances for makers of railroad friction products. The world market is set to grow a lot. This will be thanks to new tech, safety needs, and more rail lines.

China's Railroad Friction Products Market: High-Speed Expansion and Local Sourcing

The China market for railroad friction products has seen huge growth. This is thanks to its big plans for high-speed rail. Local makers have quickly come up with ways to meet the demand for top-notch railway parts.

Key Changes in China’s Railroad Friction Products Scene

Important changes in the Chinese railroad friction products scene include:

- Rapid setup of high-speed rail networks across many provinces

- Big investments in homegrown research and development

- Focus on cutting down on foreign suppliers

Local sourcing is key for Chinese rail tech makers. The government’s push for tech self-sufficiency has pushed companies to create top-notch friction products. These products must meet high standards.

Chinese makers are now competing worldwide with high-quality friction products. They use the latest materials and engineering. This has made China a big player in the railroad friction products market.

Current State of the Railroad Friction Products Market in China

Here are some key facts about the current state of the railroad friction products market in China:

- Now, 85% of rail parts are made in China

- Technological innovation helps keep prices low

- There’s a chance for more exports of advanced friction tech

The drive for more high-speed rail keeps the sector growing. Local sourcing is a big part of China’s success in transportation tech.

Canada Railroad Friction Products Market: Freight Rail Investment and Winter Durability

The Canada market for railroad friction products is at a key point. It faces challenges from extreme winter and big investments in freight rail. Canadian railways need advanced friction technologies to work well in temperatures below -40°C.

Key Factors in the Canadian Railroad Friction Products Market

Important factors in the Canadian railroad friction products market include:

- Extensive freight rail networks spanning over 77,932 kilometers

- Significant infrastructure modernization initiatives

- Specialized friction product development for arctic conditions

Canadian rail operators look for friction products that perform well in harsh weather. The need for winter durability has led to research on new materials. These materials help keep trains running smoothly in extreme cold.

Impact of Freight Rail Investment on Canada’s Transportation Scene

Investment in freight rail is changing Canada’s transportation scene. Big rail companies are spending a lot to improve friction systems. They focus on:

- Enhanced brake pad compositions

- Temperature-resistant friction materials

- Reduced maintenance downtime solutions

Emerging technologies promise to revolutionize friction product capabilities, ensuring reliable rail transportation across Canada’s challenging geographical landscapes.

France Railroad Friction Products market: high-tech metro and rail upgrades

The France market for railroad friction products is changing fast. This is thanks to new tech in rail infrastructure. SNCF is leading the way with investments in high-tech metro systems and modernizing the rail network.

Some big changes in the French rail sector include:

- Upgrades to the existing rail infrastructure

- New friction technologies being used

- More urban and intercity transport options

The rail upgrades in France are opening up new chances for makers of advanced friction products. Cities like Paris are getting big investments in modern metro systems. These systems need the latest in friction tech for safety and smooth running.

| Market Segment | Growth Potential | Key Technologies |

| Urban Metro Systems | High | Advanced Ceramic Composites |

| High-Speed Rail | Medium-High | Noise-Reduction Friction Materials |

| Regional Transportation | Medium | Wear-Resistant Brake Components |

France is at the forefront of innovation in railroad friction products. It’s expected to keep investing in the latest friction tech. This will keep the sector growing and advancing.

Future improvements in ceramic materials and noise-reduction solutions

The railroad industry is undergoing significant changes due to new technology. Ceramic materials play a crucial role in these advancements, contributing to the development of improved noise-reduction technologies.

These innovations are transforming the functionality of friction products, resulting in quieter trains and enhanced comfort for passengers.

Ongoing research on ceramic materials

Researchers are actively exploring various new ceramic materials with the following objectives:

- Increasing product lifespan

- Reducing weight

- Enhancing performance in high-temperature environments

- Minimizing noise levels

To achieve these goals, researchers are employing nano technology and precision engineering, which have the potential to improve product performance while also being environmentally friendly.

Enhancements in noise-reduction technologies

Scientists are also working towards enhancing existing noise-reduction technologies by investigating:

- Acoustic dampening ceramic composites

- Vibration-absorbing material structures

- Precision-engineered surface geometries

The ultimate aim is to create safer, more cost-effective, and quieter railroad products. However, further research and development efforts are required to bring these concepts to fruition.

Competitor positioning in the railway component ecosystem

The railroad friction products market is very competitive. Success depends on how well companies position themselves. Big players use new technologies and global partnerships to stay ahead.

Key Players:

-

Wabtec Corporation — United States

-

MASU (acquired by Wabtec) — India

-

Knorr-Bremse — Germany

-

Faiveley Transport — France

-

SKF — Sweden

-

Federal-Mogul — United States

-

Timken — United States

-

Amsted Rail — United States

-

ArvinMeritor — United States

-

NTN Corporation — Japan

Key strategies in market competition include:

- Technological innovation in friction material development

- Geographic expansion into emerging rail markets

- Strategic mergers and acquisitions

- Investment in research and development

Leading manufacturers aim to stand out by offering unique products. Precision engineering and special friction solutions are key to winning in the market.

Top companies are spending a lot on research. They want to make products that are safer, cheaper to maintain, and better for trains. Their success depends on meeting tough industry standards.

Global manufacturers grow by:

- Working together with international partners

- Setting up local manufacturing

- Testing and certifying products

- Creating sustainable products

The railroad friction products market keeps changing. New technologies and smart strategies help companies grow and stand out.

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Railroad Friction Products Market Report |

| Base Year | 2024 |

| Segment by Type |

· Brake Shoes · Brake Pads · Disc Brakes · Composition Blocks · Others |

| Segment by Application |

· Freight Trains · High-speed Rail · Metro Systems · Locomotives · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Railroad Friction Products market is full of chances for investors. It’s expected to grow a lot because of new technologies and more money going into high-speed rail. Investments in advanced materials and ways to reduce noise will shape the market’s future.

Places like China, Canada, and France are seeing a lot of rail updates. New friction materials, like ceramic composites and synthetic compounds, offer great chances for investors. Companies that innovate and keep up with market changes will do well.

Looking ahead, companies that focus on research, sustainability, and improving performance will stand out. The global transport sector’s focus on safety, efficiency, and being green will keep demand high. This will open up big chances for smart investors.

Global Railroad Friction Products Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Railroad Friction Products Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Railroad Friction Products Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Railroad Friction Products Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Railroad Friction Products Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Railroad Friction Products Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Railroad Friction Products Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Railroad Friction ProductsMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market value for Railroad Friction Products by 2025?

The Railroad Friction Products Market is expected to hit $3.36 billion by 2025. This growth is driven by a focus on transit safety and infrastructure in places like China, Canada, and France.

How do upstream and downstream relationships impact the Railroad Friction Products market?

The market’s chain involves suppliers, manufacturers, and buyers like rail companies. These relationships affect market dynamics, pricing, and innovation.

What are the main challenges in developing railroad friction products?

Challenges include material wear under harsh conditions and heat resistance for high-speed use. Meeting environmental rules is also a hurdle. Manufacturers are working on new materials and tech to solve these issues.

Which product types are most prominent in the Railroad Friction Products market?

The market mainly features brake shoes, pads, disc brakes, and composition blocks. Each type has its own market dynamics and growth rates, depending on the transportation sector.

How are geopolitical strategies influencing the Railroad Friction Products market?

Projects like China’s Belt and Road Initiative and European and North American high-speed rail are shaping demand. They create both opportunities and challenges for manufacturers.

What applications drive demand for Railroad Friction Products?

Demand comes from freight trains, high-speed rail, metro systems, and locomotives. Each area has unique needs, driving innovation and specialized products.

What future innovations are expected in Railroad Friction Products?

Expect advancements in ceramic materials, noise reduction, and smart braking. Research aims to improve performance, durability, and environmental impact.

How are different regions approaching Railroad Friction Products development?

- China focuses on high-speed rail

- Canada focuses on freight and winter solutions

- France focuses on metro systems and upgrades

Each region has its own strategy.

What factors are driving investment in Railroad Friction Products?

Investment is driven by rail safety, infrastructure updates, tech advancements, and demand for efficient, green transport.

How competitive is the Railroad Friction Products market?

The market is very competitive. Companies stand out through innovation, partnerships, expansion, and specialized products that meet changing needs.