Webbing Market Estimated to Reach $4.51 Billion by 2025: Textile Reinforcement Gains in India, Vietnam, and the U.S.

The Webbing Market continues to expand with rising demand in automotive, military, and sports sectors. Growth driven by technical textile innovations and manufacturing advancements in Asia-Pacific.

- Last Updated:

Webbing Market Performance in Q1 and Q2 of 2025

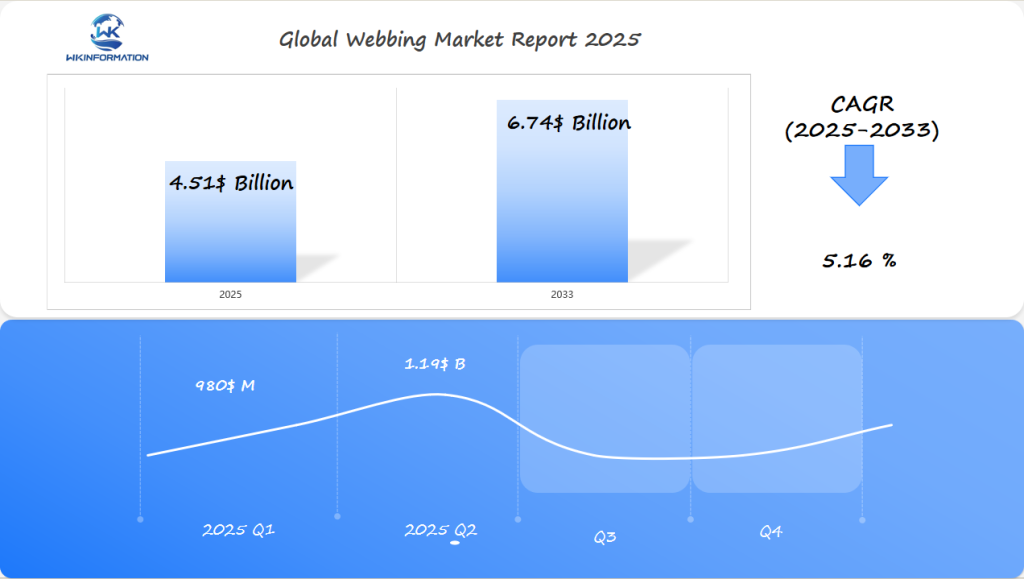

The Webbing market is forecast to reach $4.51 billion in 2025, with a CAGR of 5.16% from 2025 to 2033. Estimated figures indicate Q1 of 2025 saw revenues of around $980 million, followed by a stronger Q2 at approximately $1.19 billion, reflecting seasonal growth in the apparel, outdoor gear, and automotive safety segments. The uptick in Q2 is also linked to procurement cycles in defense and backpack manufacturing for summer inventories.

Among global regions, India, Vietnam, and the United States stand out due to their integrated textile manufacturing ecosystems, robust export bases, and scaling investments in tactical, safety, and lifestyle applications. Regional trade policy shifts and domestic capacity expansion are further reinforcing their market relevance.

Key Takeaways

- The global webbing market is projected to reach $4.51 billion by 2025.

- Textile reinforcement is driving market expansion across industries.

- India, Vietnam, and the United States are emerging as key manufacturing hubs.

- Advanced manufacturing techniques are improving webbing performance.

- There is an increasing demand from the automotive and safety sectors.

Webbing market upstream and downstream industry chain analysis

The webbing market is a complex web of suppliers, makers, and users. Looking into the supply chain gives us key insights into how the industry works together.

Upstream: Raw Material Suppliers

Raw material suppliers are crucial in making webbing. They use:

- Polyester fibers

- Nylon polymers

- Cotton and synthetic blends

- Specialized industrial-grade textiles

Manufacturers then turn these materials into webbing through weaving and processing. The way they make it affects the webbing’s quality and how well it works.

Downstream: End-User Industries

End-user industries are big drivers of demand. The auto, military, industrial, and outdoor markets all need webbing. Each one needs webbing that’s strong, durable, and performs well.

| Industry Segment | Webbing Application | Market Demand |

| Automotive Safety | Seat Belts | High |

| Military | Tactical Gear | Moderate to High |

| Industrial Lifting | Safety Harnesses | Steady |

| Outdoor Recreation | Equipment Straps | Growing |

The webbing supply chain shows how important innovation, quality materials, and smart making are. They help meet the needs of all these markets.

Trends fueled by outdoor gear, military, and safety apparel expansion

The webbing market is growing fast, thanks to new trends in many fields. Outdoor gear makers are now creating products that are both light and strong. They aim to meet the high standards of today’s consumers.

Military needs driving webbing innovation

Military needs are also driving webbing innovation. Defense groups look for materials that can handle tough conditions. They want materials that are:

- More durable in harsh environments

- Lighter for easier soldier movement

- Stronger for less weight

- Resistant to damage from the environment

Safety apparel market pushing webbing technology forward

The safety apparel market is also pushing webbing technology forward. Companies are making special webbing for safety gear. This gear is needed in many areas, like:

- Industrial safety equipment

- Protective work wear

- Emergency response gear

- High-visibility clothing

Technological advancements are pushing the boundaries of traditional webbing materials. Makers are spending a lot on research to create new, better products.

These trends are opening up new chances for webbing makers. They can now create advanced solutions for many industries.

Limitations: Synthetic Price Fluctuations and Durability Concerns

The webbing industry is facing big challenges that affect its growth. Prices for synthetic materials are a big deal for making products. Companies struggle with costs that can change a lot.

Webbing that lasts long is key for many industries. They need materials that can handle tough conditions well. The main issues are:

- Rapid changes in synthetic raw material costs

- Inconsistent performance in harsh environmental conditions

- Limited lifespan of certain synthetic webbing materials

- High replacement and maintenance expenses

Textile engineers are working on new solutions. Advanced polymer technologies and better manufacturing aim to make webbing last longer. Companies that invest in research can get ahead.

Success comes from finding a balance between cost and quality. Companies can do this by finding better materials, improving quality checks, and making synthetic materials better.

The technical textiles sector needs to stay flexible. This is especially true for synthetic material prices and how well they perform. Being quick to adapt will help lead the market in the future.

Geopolitical influences on textile production and military export contracts

The global webbing market sees big changes because of complex geopolitical factors. Trade policies and international relations greatly affect textile production and military export rules in key areas.

Several key factors shape the webbing industry’s geopolitical scene:

- Trade tensions between major textile-producing countries

- Export control mechanisms for military-grade materials

- Regional economic partnerships influencing textile manufacturing

National security is very important in military export rules. Countries closely watch textile production to keep strategic material supply chains safe and strong.

| Region | Geopolitical Impact | Textile Production Influence |

| United States | Strict export controls | Domestic manufacturing priority |

| China | State-driven industrial policies | High-volume production capabilities |

| India | Emerging trade partnerships | Expanding textile infrastructure |

Manufacturers face complex geopolitical challenges. Adaptability and strategic planning are key to staying competitive in the webbing market.

Webbing market segmentation by type: polyester, nylon, polypropylene, cotton

The webbing market includes different materials, each with its own benefits. These materials are chosen based on their performance, durability, and how they are used.

The main webbing materials are polyester, nylon, polypropylene, and cotton. Each has its own strengths for different uses.

Polyester Webbing: Performance and Market Dominance

Polyester webbing is known for its versatility and strength. It also stands up well to the environment. Its key features are:

- High tensile strength

- Excellent UV resistance

- Minimal stretching under load

- Widespread use in outdoor gear and safety equipment

Nylon Webbing: Durability and Flexibility

Nylon webbing is flexible and can handle impacts well. It’s valued for its toughness, especially in:

- Military gear production

- Automotive safety systems

- High-stress lifting applications

Polypropylene Webbing: Lightweight and Cost-Effective

Polypropylene webbing is a cost-effective option for those looking for lightweight materials. Its main benefits are:

- Low production costs

- Water-resistant properties

- Ideal for marine and outdoor applications

Cotton Webbing: Eco-Friendly and Specialized Markets

Cotton webbing is a green choice, popular in eco-friendly industries. It’s used in:

- Sustainable fashion

- Artisanal product manufacturing

- Organic textile production

Each webbing material has its own advantages. This lets manufacturers pick the best option for their needs in various fields.

Webbing market segmentation by application: apparel, automotive safety, military, industrial lifting

The webbing market is key in many industries, offering special solutions. It’s used in fashion and car safety, showing its wide use in making and design.

Webbing tech has grown to meet different needs. It’s used in clothes, car safety, military gear, and lifting. This shows how versatile webbing is.

Innovations in the Apparel Industry

Apparel webbing has transformed both fashion and sportswear. It provides durability, support, and style while also being moisture-wicking. This advancement benefits both athletes and fashion enthusiasts.

Automotive Safety Systems

Car safety belts use webbing tech. They’re made to handle big stresses and keep people safe. This is thanks to advanced materials.

Military Gear Requirements

Military gear needs top-notch webbing. It must be strong, durable in tough weather, lightweight, and quick to use. This is crucial for soldiers.

Industrial Lifting Solutions

Industrial lifting slings are also essential. They must be extremely durable for secure lifting in factories and construction sites.

The technology behind webbing continues to improve. It plays a crucial role in various aspects of our lives, demonstrating its significance in the modern world.

Global Regional View of the Webbing Market

The global webbing market is made up of various regions, each with its own specific needs and growth rates. The emergence of new markets is significantly impacting the textile industry. Every region has its unique characteristics that contribute to its growth and innovation.

Regions Experiencing Significant Growth in Webbing Demand

Some areas are witnessing a substantial increase in the demand for webbing:

- Asia-Pacific: Home to rapidly expanding economies

- North America: Leading the way in technology

- Europe: Prioritizing environmentally friendly manufacturing practices

- Middle East: Experiencing growth in both military and industrial sectors

Economic development and advancements in technology play a crucial role in shaping the dynamics of these markets. Each region has its distinct approach to webbing production, influenced by local expertise, consumer preferences, and industry requirements.

New markets present significant opportunities for growth, particularly in countries where manufacturing and technology investments are substantial. The analysis reveals a complex network of factories and market strategies at play.

Investments and emerging technologies continue to reshape the webbing market on a global scale. Each region presents its own unique prospects for growth and success.

India Webbing Market: Mass Production and Defense Applications

The India textile industry is a big player in webbing production. It uses strong manufacturing skills to change the global market. The country’s growth and government support make it a key player in textile technology.

The defense sector has helped India’s webbing market grow a lot. The military’s needs have led to new ways of making webbing. These new methods meet high quality standards.

Key Factors Driving Growth in India’s Webbing Market

- Advanced production techniques for high-strength webbing

- Increased investment in textile research and development

- Competitive pricing in global markets

India’s webbing making has some big strengths:

| Manufacturing Aspect | Competitive Advantage |

| Labor Cost | Significantly lower compared to Western markets |

| Production Capacity | Scalable infrastructure supporting large-volume orders |

| Technological Innovation | Rapid adoption of advanced textile manufacturing technologies |

Defense contractors and textile makers working together has helped a lot. This teamwork has led to new webbing solutions. These products are used in India and around the world.

India’s textile industry is changing fast. It’s growing and getting better at making webbing. This makes India a big player in textile solutions worldwide.

Vietnam Webbing Market: Low-Cost Manufacturing and Export Growth

The Vietnam manufacturing sector is a major player in the global webbing market. It leverages its low labor costs to attract textile producers from around the world. The government’s smart policies and strong infrastructure make Vietnam a top destination for producing goods for export.

Here are some key strengths of Vietnam’s webbing manufacturing industry:

- Highly skilled workforce with competitive wage structures

- Significant investments in textile infrastructure

- Streamlined export processes

- Growing technological capabilities

Vietnam’s focus on manufacturing for export has significantly increased in recent years. More and more large companies view Vietnam as an excellent location for producing high-quality webbing at lower costs. An increasing number of international brands are opting for Vietnam as their manufacturing hub. The combination of skilled workers, low costs, and government support makes it an ideal place for webbing production and exporting goods.

U.S. Webbing Market: Tactical Gear and Industrial Harness Systems

The U.S. tactical equipment market is leading the way in webbing technology, creating innovative solutions for safety and production that meet stringent standards across various industries.

Key Strengths of the U.S. Webbing Market

Some of the key strengths of the U.S. webbing market include:

- Advanced material engineering for high-performance tactical gear

- Compliance with rigorous industrial safety regulations

- Specialized domestic production capabilities

- Cutting-edge research in textile reinforcement technologies

Industrial harness systems play a significant role in the U.S. tactical equipment market, requiring exceptional strength and craftsmanship to ensure worker safety in demanding environments.

| Market Segment | Growth Potential | Key Applications |

| Military Tactical Gear | High | Personal Equipment Systems |

| Industrial Safety Harnesses | Medium-High | Construction, Rescue Operations |

| Specialized Webbing | Medium | Aerospace, Defense Technologies |

Domestic production is crucial for the U.S. to maintain its competitive edge. Companies invest heavily in research and development to create superior webbing products compared to those manufactured abroad.

U.S. webbing manufacturers continue to push boundaries and ensure that the country remains at the forefront of webbing technology.

Future innovations in bio-based fibers and high-tensile weaves

The webbing industry is about to undergo a significant transformation. Bio-based webbing materials are being developed with the goal of making production more environmentally friendly while maintaining quality.

High-tensile strength fibers are also undergoing improvements, with companies like Teijin Carbon leading the charge. They are creating materials that are both strong and eco-friendly.

Emerging strategies for sustainable textiles

New approaches for creating sustainable textiles are emerging, focusing on:

- Developing renewable sources of raw materials

- Implementing energy-efficient production methods

- Creating high-performance bio-based webbing materials

Advancements in bio-composite materials

In addition, advancements in bio-composite materials are being made, including:

- Enhanced durability through innovative formulations

- Reduction of carbon footprint through the use of renewable fiber technologies

- Minimization of waste through innovative manufacturing processes

The future of webbing lies in being both strong and environmentally conscious. Scientists are putting in great effort to develop high-tensile strength fibers that are sustainable and can meet rigorous standards.

Competitive positioning among textile reinforcement suppliers

The webbing market is very competitive. Industry leaders use new ways to stand out. They keep changing to get more market share and meet new needs.

Key Players:

-

American Cord & Webbing Co. — United States

-

Bally Ribbon Mills — United States

-

BioThane Coated Webbing — United States

-

E. Oppermann GmbH — Germany

-

Leedon Webbing Co. — China

-

Murdock Webbing Company — United States

-

Sturges Manufacturing Company — United States

-

Tennessee Webbing Products — United States

-

Webbing Products Pty Ltd — South Africa

-

Original Webbing — Malaysia

Suppliers use different strategies to be unique:

- Advanced material research and development

- Precision manufacturing techniques

- Customization for special uses

- Sustainable production

Top makers are spending a lot on new tech. Precision engineering and material science help them stay ahead.

The competitive scene shows a few key points:

- Fast tech adoption

- Improving global supply chains

- Forming partnerships with users

- Focus on quality and performance

New players are shaking things up. They bring new tech and flexible ways to make things. This push for better keeps everyone improving and opens doors for those who invest in research.

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Webbing Market Report |

| Base Year | 2024 |

| Segment by Type |

· Polyester Webbing · Nylon Webbing · Polypropylene Webbing · Cotton Webbing · Others |

| Segment by Application |

· Apparel Industry · Automotive · Military Gear · Industrial Lifting · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The webbing market is set to grow a lot, thanks to strong growth drivers. Market forecasts show big increases in textile use in many areas. This includes the military, cars, and outdoor gear.

Polyester and nylon webbing will lead the market. This is because people want strong and lasting textile products.

But, the market faces challenges. Fluctuating prices of synthetic materials and supply chain issues can raise costs. To tackle this, companies are investing in new tech and eco-friendly fibers.

Places like India, Vietnam, and the U.S. are becoming major production centers. They use their strong production and export setups to their advantage.

New tech in bio-based fibers and strong weave technologies will open up new market areas. Materials that are both strong and light are getting a lot of attention. This is from companies in aerospace, defense, and industrial equipment.

Partnerships between textile makers and users will be key to growth. They will help create webbing solutions tailored to specific needs.

By 2025, the global webbing market is expected to hit about $4.51 billion. This growth is steady, with a compound annual growth rate. Southeast Asia’s markets and defense upgrades will be key to this growth. This offers big chances for businesses and investors.

Global Webbing Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Webbing Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Webbing Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Webbing Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Webbing Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Webbing Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Webbing Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of WebbingMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market size for webbing by 2025?

The webbing market is expected to grow to $4.51 billion by 2025. This growth is driven by demand in India, Vietnam, and the United States.

What are the main materials used in webbing production?

The main materials used in webbing production are:

- Polyester

- Nylon

- Polypropylene

- Cotton

Each material has its own special qualities that make it suitable for specific applications across different industries.

Which industries are the largest consumers of webbing products?

The biggest users are outdoor gear, military, automotive safety, apparel, and industrial lifting. Each has specific needs for webbing.

What challenges are currently facing the webbing market?

Challenges include price changes in synthetic materials and concerns over durability. There’s also a need to meet stricter safety standards.

How are sustainability trends impacting webbing production?

Sustainability is becoming more important. There’s a focus on bio-based fibers and eco-friendly production methods to reduce environmental impact.

Which countries are becoming important in the webbing market?

India, Vietnam, and the United States are leading markets. They have advantages such as low costs, defense demand, and high-quality production.

What innovative technologies are being developed in webbing?

Innovations include high-tensile weaves and advanced bio-based materials. These aim to improve performance for specific uses.

How do geopolitical factors impact the webbing market?

Geopolitical factors such as trade policies, international relations, and regulations have a significant impact on the webbing market. These factors influence various aspects of the industry, including:

- Production: Geopolitical decisions can affect where webbing products are manufactured and how they are produced.

- Distribution: Trade agreements or disputes can impact the transportation and distribution of webbing products across borders.

- Overall dynamics: The relationship between countries and their political decisions can shape the demand and supply of webbing products globally.

What drives the demand for webbing in military applications?

The military requires strong and long-lasting materials that can withstand harsh environments. Additionally, these materials must prioritize safety.

How are consumer preferences changing the webbing market?

Consumers want lightweight, durable, and versatile webbing. They look for materials that are both functional and stylish.