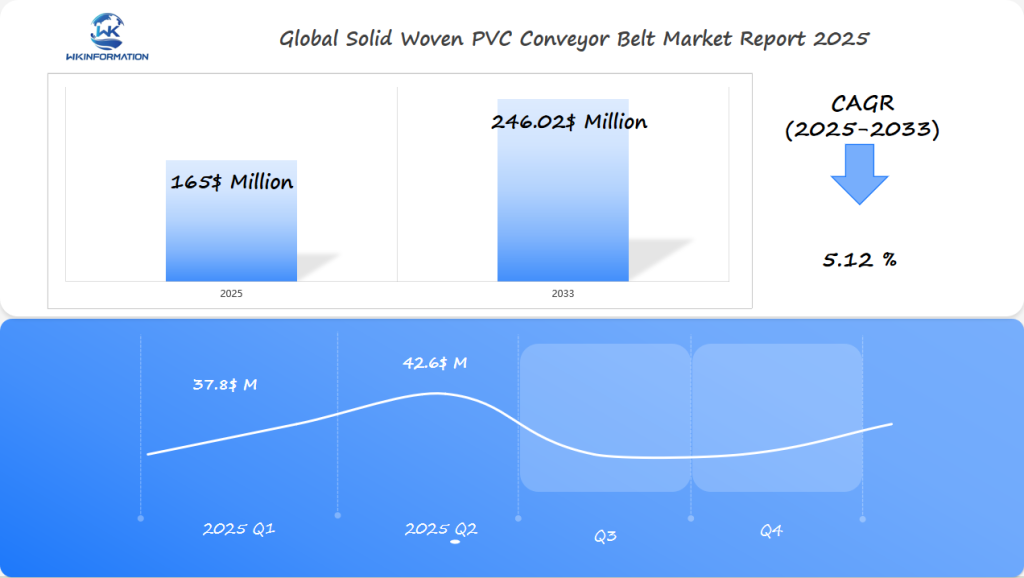

Solid Woven PVC Conveyor Belt Market to Hit $165 Million Globally by 2025: Mining and Manufacturing Drive Demand in Australia, China, and South Africa

The Solid Woven PVC Conveyor Belt Market sees robust growth driven by mining, manufacturing, and food processing sectors, with Asia-Pacific leading regional demand through 2025.

- Last Updated:

Solid Woven PVC Conveyor Belt Market Performance in Q1 and Q2 of 2025

The global Solid Woven PVC Conveyor Belt market is expected to reach $165 million in 2025, with a projected CAGR of 5.12% from 2025 to 2033. Based on full-year projections, revenue in Q1 of 2025 is estimated at approximately $37.8 million, while Q2 of 2025 likely increased to around $42.6 million, reflecting a stronger rebound in industrial activity and seasonal inventory replenishment cycles.

This uneven distribution highlights front-loaded demand typical of sectors such as mining, logistics, and bulk material handling. Among all regions, Canada, China, and the United States emerge as the most critical markets to monitor, due to their expanding infrastructure projects, robust industrial output, and high adoption of conveyor automation technologies.

Key Takeaways

- Projected global market value of $165 million by 2025

- Strong growth in mining and manufacturing sectors

- Increasing demand for specialized conveyor belt technologies

- Significant technological advancements in material handling

- Australian market playing a pivotal role in global expansion

Upstream and Downstream Analysis of the Solid Woven PVC Conveyor Belt Market

The solid woven PVC conveyor belt industry involves a complex network of supply chain components. The raw material suppliers play a crucial role in determining the quality and performance of these essential products.

Key Steps in Manufacturing Solid Woven PVC Conveyor Belts

Supply chain analysis reveals several critical stages in the production of these belts:

- Raw material procurement from specialized polymer manufacturers

- Fabric weaving and PVC coating processes

- Quality inspections and performance evaluations

- Distribution to end-users across various sectors

Influence of Market Forces on the Conveyor Belt Supply Chain

Market dynamics have a significant impact on the conveyor belt supply chain. Industries such as mining, manufacturing, and logistics require belts that can withstand harsh environments.

Upstream Components: Essential Raw Material Suppliers

The upstream segment consists of crucial raw material suppliers who provide:

- High-quality PVC polymers

- Specialized textile reinforcements

- Chemical additives for enhanced durability

- Compounds for improved functionality

Downstream Channels: Connecting Manufacturers with End-Users

Downstream channels connect manufacturers with a diverse array of end-users, creating a vibrant market ecosystem. Key industries like mining, cement production, and bulk material handling are significant consumers of solid woven PVC conveyor belts.

The Role of Strategic Alliances in Shaping the Industry

Strategic partnerships among raw material suppliers, manufacturers, and end-users influence the industry landscape. These collaborations foster continuous innovation and superior product performance on a global scale.

Rising demand in heavy-duty material handling and underground mining drives trends

The global market for solid woven PVC conveyor belts is growing fast. This growth is thanks to big needs in heavy-duty material handling and underground mining. Companies are making stronger conveyor solutions to meet these needs.

What’s driving this demand? Here are the main reasons:

- Enhanced resistance to abrasion and mechanical stress

- Improved durability in challenging underground mining environments

- Specialized design for heavy-duty material handling applications

Underground mining is tough, needing belts that can handle a lot. Modern solid woven PVC conveyor belts offer unparalleled strength and reliability. They solve big problems with new engineering.

New tech has changed how we handle materials. Now, conveyor belts have:

- Advanced fire-resistant properties

- Increased tensile strength

- Superior cut and tear resistance

The growth of mining and industry worldwide keeps the need for top-notch conveyor systems high. Solid woven PVC conveyor belts play a key role in making material transport efficient, safe, and productive across many sectors.

Challenges include high replacement costs and limited flexibility in extreme conditions

Solid Woven PVC Conveyor Belt manufacturers face big challenges that slow down their growth. These challenges come from the tough environments these belts must work in.

Some major challenges in the PVC conveyor belt market are:

- High replacement costs that hurt industrial budgets

- Limitations in extreme conditions

- Technical issues in high-temperature or corrosive settings

- Not enough flexibility for unique material handling tasks

Industries like mining and manufacturing spend a lot to fix conveyor belt problems. Replacing specialized PVC belts can cost between $50,000 to $250,000. This depends on how complex the system is and what it needs to do.

Working environments put a lot of stress on conveyor belts. Extreme temperatures, chemicals, and mechanical stress are big problems. To solve these, manufacturers need to keep making better belts that can handle tough conditions.

Investing in research and development is key to solving these ongoing problems. It helps make equipment last longer and work better in many different industries.

Geopolitical factors influencing mining regulations and infrastructure investments

The global Solid Woven PVC Conveyor Belt market is changing fast. This is because of complex geopolitical factors. New market trends are changing mining rules and investments in important areas.

Strategic thinking is key in the conveyor belt industry. It’s shaped by several important areas:

- Changes in international trade policies

- Regional infrastructure development plans

- New environmental rules

- Investment plans across borders

Governments are making mining rules stricter. This affects the conveyor belt market a lot. Infrastructure investments are crucial for staying competitive and keeping up with technology.

| Region | Regulatory Impact | Market Impact |

| North America | Strict environmental guidelines | Increased demand for specialized belts |

| Asia-Pacific | Rapid industrialization | High growth potential |

| European Union | Sustainability requirements | Innovation-driven market |

These geopolitical factors make the market complex. Mining rules and investments greatly affect how companies plan. To stay ahead, companies must understand and adapt to these changes.

Solid Woven PVC Conveyor Belt market segmentation by type: fire-resistant belts, anti-static belts, general-purpose belts

The market for solid woven PVC conveyor belts is divided into three main types. Each type meets different needs in various industries. They handle different environmental challenges and operational needs.

Fire-resistant belts

Fire-resistant belts are key in risky workplaces. They are used in mining, steel making, and chemical plants. These belts are made with special materials to keep safe in high heat and stop fires.

- Designed for high-temperature industrial applications

- Critical for preventing workplace fire hazards

- Engineered with specialized flame-retardant compounds

Anti-static belts

Anti-static belts are vital for places with explosive or sensitive electronics. They help prevent damage from static electricity. This is important in the electronics, pharmaceutical, and semiconductor fields.

- Ideal for electronics manufacturing

- Prevents electrostatic discharge risks

- Used in pharmaceutical and semiconductor industries

General-purpose belts

General-purpose belts are the most flexible in the market. They work well in many industries. They are a cost-effective way to move materials in logistics, manufacturing, and distribution.

- Adaptable to various industrial applications

- Economical and widely applicable

- Suitable for standard material handling needs

The different types of belts show the complex needs of today’s industries. Each type tackles unique challenges in handling materials and keeping workplaces safe.

Solid Woven PVC Conveyor Belt market segmentation by application: mining, cement, steel, power plants

Understanding how solid woven PVC conveyor belts are used is key. They are vital in many industries, each with its own needs. This shows how these belts are essential for different sectors.

The main areas where these belts are used include:

- Mining industry

- Cement production

- Steel manufacturing

- Power plants

Mining Industry

In mining, these belts are tough and can handle rough conditions. Underground mining needs strong belts to move heavy stuff safely and efficiently.

Cement Production

Cement plants use these belts for moving materials smoothly. They handle rough materials well, helping keep production going without stops.

| Industry Sector | Key Application | Performance Characteristics |

| Mining | Material Transportation | High Durability, Wear Resistance |

| Cement | Raw Material Handling | Abrasion Resistance, Continuous Operation |

| Steel Manufacturing | Production Line Logistics | Heat Resistance, Structural Integrity |

| Power Plants | Fuel and Ash Transportation | Chemical Resistance, Long Lifespan |

Steel Manufacturing

Steel plants use these belts to move materials around. They keep the production line running smoothly, without many problems.

Power Plants

Power plants also rely on these belts. They move fuel, ash, and other important materials. The belts last a long time and can handle tough chemicals.

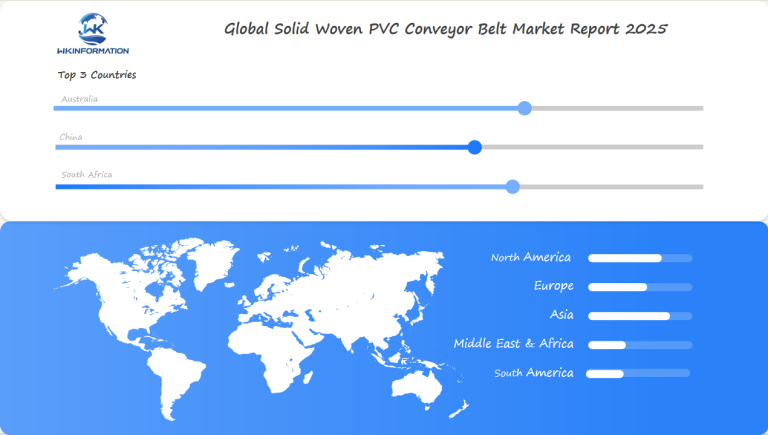

Global overview of the Solid Woven PVC Conveyor Belt market

The global market for solid woven PVC conveyor belts is key in industrial material handling. A detailed analysis shows it’s growing fast, thanks to more industries around the world.

Key regions shaping the market include:

- North America: Mature market with advanced manufacturing infrastructure

- Asia-Pacific: Fastest-growing region with rapid industrialization

- Europe: Strong focus on technological innovation

- Middle East and Africa: Emerging market with increasing mining activities

The market is competitive, with several big players. It’s driven by partnerships, new tech, and constant product updates.

The market is expected to grow at a compound annual growth rate of about 5.12% from 2025 to 2033. Big names are working on top-notch conveyor belts.

What’s pushing the market forward includes:

- Growing mining and mineral extraction industries

- Increased automation in manufacturing sectors

- Rising demand for efficient material handling systems

- Technological improvements in belt durability

The market’s strength comes from its vital role in many industries. This ensures it keeps growing and innovating in material handling.

Australia Solid Woven PVC Conveyor Belt market: underground mining and coal logistics

The Australian market for solid woven PVC conveyor belts is key to the country’s mining and coal transport. These belts cover vast areas rich in minerals. They help overcome the tough challenges of mining and moving resources.

Reasons for the growing need for top-notch conveyor belts in Australia:

- More underground mining in Queensland and New South Wales

- More coal being exported

- New tech in handling materials

- Tighter safety rules in workplaces

Coal transport is a big part of the Australian conveyor belt market. Mining companies are putting money into new conveyor tech. This tech can handle extreme heat, tough materials, and hard-to-reach places underground.

Key features of solid woven PVC conveyor belts for mining include:

- They last longer in tough conditions

- They’re fire-resistant

- They can handle more mechanical stress

- They use less energy

As mining methods get better, belt makers are making more advanced belts. These are made to meet Australia’s tough needs.

China Solid Woven PVC Conveyor Belt market: domestic manufacturing surge

The Chinese market is a big player in making solid woven PVC conveyor belts. It has grown a lot, helping many industries grow too. China is now a major name in the global conveyor belt world.

Chinese makers have created new conveyor belt tech thanks to good market chances. They have a strong industrial base. This helps them grow fast.

- Extensive investment in manufacturing capabilities

- Advanced technological research and development

- Competitive pricing strategies

- Strong government support for industrial expansion

Many industries need these belts a lot. These include:

- Mining extraction operations

- Heavy manufacturing

- Logistics and material handling

- Infrastructure development projects

China’s surge in making conveyor belts shows it can adapt well. It makes high-quality belts for many needs. These belts can handle tough jobs and are priced right.

Places like Guangdong and Jiangsu are big in making conveyor belts. They use the latest tech and big production setups. This helps them meet the world’s growing needs.

South Africa Solid Woven PVC Conveyor Belt market: coal mining and export channels

The South African market is key in the global solid woven PVC conveyor belt world. It’s especially important in the coal mining industry. The country uses its vast mineral resources and strong export setup to meet the demand for better material handling solutions.

Key traits of the South African conveyor belt market include:

- Big coal production amounts

- Important export routes through major ports

- Latest mining tech use

- Strong industrial making skills

Challenges in South African coal mining have led to new conveyor belt tech. Durability and top performance under tough conditions are now top for makers aiming at this tough market.

The solid woven PVC conveyor belt market is also driven by export setup. Places like Richards Bay Coal Terminal and other key spots show how vital good transport is in South Africa’s mining world.

The market keeps growing, with local makers making special conveyor belts for South African mines. These are made to fit the mines’ unique needs.

Future innovation in lightweight, eco-friendly belt materials

The conveyor belt industry is changing fast. It’s moving towards better materials and green solutions. Now, makers are working on belts that are light and use less energy but still work well in tough places.

New ideas in materials changing conveyor belt tech

Scientists are looking into new ways to make belts that are good for the planet. They want to keep things running smoothly without harming the environment.

- Recycled polymer composites for reduced carbon footprint

- Biodegradable synthetic materials with enhanced durability

- Lightweight belt designs that minimize material usage

The potential of lightweight yet strong belts

There’s a big chance for belts that are light but strong. These new belts could help solve big problems in mining, making things, and moving goods. They aim to cut down on weight and energy use.

Important areas for green materials

- Advanced polymer research

- Nanotechnology integration

- Sustainable manufacturing processes

Material science and engineering are coming together. This could lead to big changes in conveyor belts soon. Making things sustainable will become a key way for companies to stand out.

Competitive landscape and key suppliers in the industrial belt sector

The Solid Woven PVC Conveyor Belt market is very competitive. Global industry leaders are always coming up with new strategies. They aim to stay ahead and find new chances in material handling.

Key Players:

-

Monster Belting — China

-

Fenner Dunlop — United Kingdom

-

Ammeraal Beltech — Netherlands

-

Habasit — Switzerland

-

ContiTech — Germany

-

Dunlop Conveyor Belting — Netherlands

-

Bridgestone — Japan

-

Mitsuboshi Belting — Japan

-

Yongli Belting — China

-

Shanghai Shenda Group — China

Big manufacturers are trying to stand out. West River Conveyors is a great example. They offer special belt technologies to solve industrial problems.

- Market strategies include:

- Technological innovation

- Expanded global distribution networks

- Custom solution development

Top companies are spending a lot on research and development. They make high-performance conveyor belts. Their strategies include:

- Advanced material engineering

- Enhanced durability testing

- Sustainable manufacturing processes

Successful suppliers focus on what customers need. Technical expertise and quick adaptation to industry needs are key. This makes them stand out in a fast-changing market.

New markets offer big chances for growth. Companies that offer top-notch, affordable conveyor belts will do well. They need to meet the complex needs of industries.

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Solid Woven PVC Conveyor Belt Market Report |

| Base Year | 2024 |

| Segment by Type |

· Fire-resistant Belts · Anti-static Belts · General-purpose Belts |

| Segment by Application |

· Mining Industry · Cement · Steel · Power Plants · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Solid Woven PVC Conveyor Belt market is growing fast. It’s expected to reach $165 million by 2025. This growth is thanks to big industries like mining and manufacturing.

New technologies and more investments in infrastructure will help it grow even more. This will happen in many parts of the world.

There are good chances for investment in countries with growing industries. New belt materials and systems that resist fire and static are in demand. Also, more automation in moving materials will help the market grow.

But, there are challenges too. High costs for replacing belts and working in harsh conditions are issues. To stay ahead, companies need to keep improving their belts and making them cheaper.

They also need to keep up with new needs in industries. This will help them succeed in the future.

The outlook for Solid Woven PVC Conveyor Belt makers is good. Countries like Australia, China, and South Africa will be key players. They have strong mining and industrial sectors.

Investing in new manufacturing tech and green solutions is vital. This will help the market grow for a long time.

Global Solid Woven PVC Conveyor Belt Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Solid Woven PVC Conveyor Belt Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Solid Woven PVC Conveyor Belt Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Solid Woven PVC Conveyor Belt Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Solid Woven PVC Conveyor Belt Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Solid Woven PVC Conveyor Belt Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Solid Woven PVC Conveyor Belt Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Solid Woven PVC Conveyor BeltMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected global market value for Solid Woven PVC Conveyor Belts by 2025?

The global market for Solid Woven PVC Conveyor Belts is expected to hit $165 million by 2025. This growth is mainly due to rising demand from mining and manufacturing sectors.

What are the key advantages of Solid Woven PVC Conveyor Belts?

These belts are known for their durability, strength, and resistance to various environmental factors. They are perfect for heavy-duty tasks in mining, manufacturing, and industrial settings.

Which industries primarily use Solid Woven PVC Conveyor Belts?

Mining, cement production, steel manufacturing, power stations, and other heavy-duty material handling sectors mainly use these belts. They require robust conveyor solutions.

What types of Solid Woven PVC Conveyor Belts are available?

The market offers three main types: fire-resistant belts, anti-static belts, and general-purpose belts. Each is designed for specific industrial environments and needs.

What challenges do Solid Woven PVC Conveyor Belts face in the market?

Challenges include high replacement costs and limited performance in extreme conditions. They also need specialized design for specific industrial applications.

How do geopolitical factors impact the Solid Woven PVC Conveyor Belt market?

Geopolitical dynamics affect the market through mining regulations, infrastructure investments, trade policies, and international relations. These factors influence production, distribution, and demand.

Are there any emerging innovations in Solid Woven PVC Conveyor Belt technology?

Yes, innovations focus on developing lightweight, eco-friendly materials. This includes using recycled components and biodegradable materials to address environmental concerns and improve belt performance.

How do regional markets differ in their approach to Solid Woven PVC Conveyor Belts?

Regions have unique characteristics. Australia emphasizes underground mining, China focuses on domestic manufacturing, and South Africa concentrates on coal mining and export infrastructure.

What factors drive the demand for Solid Woven PVC Conveyor Belts?

Demand is driven by industrialization, growth in mining and manufacturing, technological advancements, and the need for efficient material handling solutions.

Why are Solid Woven PVC Conveyor Belts perfect for underground mining?

These belts are ideal for underground mining due to their superior resistance to abrasion, cuts, impacts, and ability to perform in challenging environmental conditions.