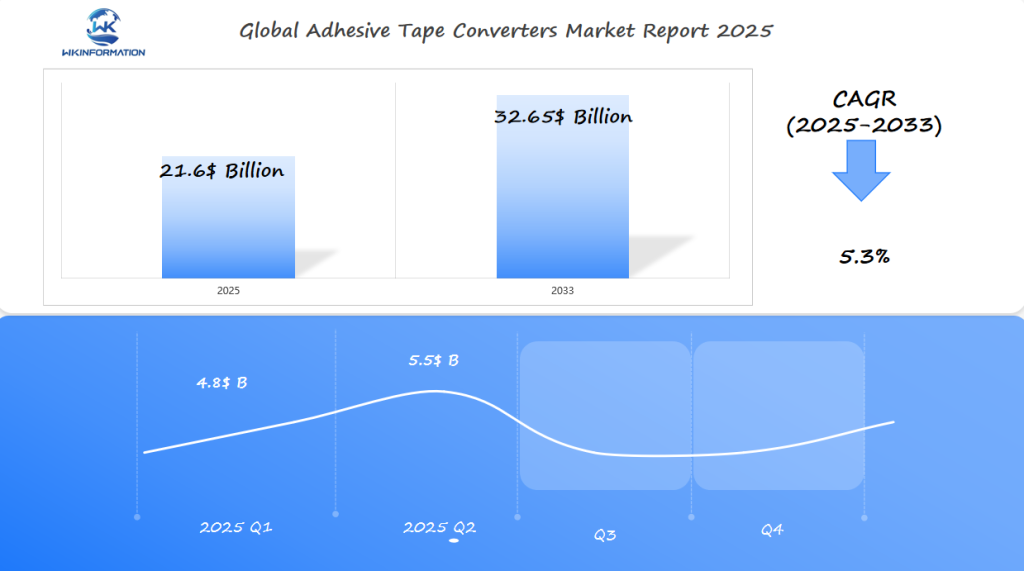

Adhesive Tape Converters Market Projected to Hit $21.6 Billion Globally in 2025: Innovation Drivers in Japan, Germany, and Mexico

Discover the latest trends and innovations driving the $21.6 billion Adhesive Tape Converters Market by 2025.

- Last Updated:

Adhesive Tape Converters Market in Q1 and Q2 of 2025

The Adhesive Tape Converters market is forecast to reach $21.6 billion by 2025, with a CAGR of 5.3% projected through 2033. Q1 revenues are expected at approximately $4.8 billion, rising to $5.5 billion in Q2 due to seasonal demand across construction, automotive, and electronics sectors.

Regional Insights

- In Japan, demand is bolstered by innovation in precision die-cut tapes for smartphones and displays.

- Germany is focusing on converting pressure-sensitive tapes for medical, automotive interiors, and industrial insulation applications.

- Mexico is expanding its footprint in flexible packaging and logistics, driving interest in cost-effective adhesive tape customization.

Sustainability Trends

Market players are prioritizing solvent-free, biodegradable, and high-performance acrylic solutions as sustainability becomes a differentiator.

Technological Advancements

The growth of e-commerce and electronics miniaturization is also pushing converters toward narrower slitting, multi-layer bonding, and thermal management applications.

Upstream and downstream analysis of the Adhesive Tape Converters industry

The supply chain dynamics play a crucial role in shaping the future of the Adhesive Tape Converters industry. Understanding the complexities of the supply chain is essential for identifying potential bottlenecks and opportunities for growth.

Understanding the supply chain dynamics

The Adhesive Tape Converters industry relies heavily on a complex supply chain that involves various stakeholders, from raw material suppliers to manufacturers and distributors. Effective supply chain management is crucial for ensuring the timely delivery of high-quality products.

The importance of raw material sourcing

Raw material sourcing is a critical component of the supply chain, as it directly impacts production costs and product quality. The industry relies on a range of raw materials, including adhesives, backing materials, and release liners.

Impact of raw material sourcing on production

The availability and cost of raw materials can significantly affect the production capacity and profitability of Adhesive Tape Converters. Fluctuations in raw material prices can impact the industry’s overall growth and competitiveness.

To mitigate these risks, manufacturers are adopting strategies such as strategic sourcing and supplier diversification. By building strong relationships with suppliers and investing in supply chain resilience, Adhesive Tape Converters can better navigate the challenges posed by raw material sourcing.

The future success of the industry

The industry’s ability to adapt to changes in the supply chain will be crucial for its future success. By understanding the dynamics of the supply chain and addressing the challenges associated with raw material sourcing, Adhesive Tape Converters can capitalize on emerging opportunities and drive growth.

Technology trends transforming adhesive tape formats and customization

Emerging technologies are reshaping the adhesive tape converters market, enhancing customization and product versatility. The industry is witnessing a significant shift towards more sophisticated and tailored adhesive solutions.

Advances in tape conversion technology

The tape conversion technology has seen substantial advancements, enabling manufacturers to produce a wide range of adhesive tapes with varying properties. Some key developments include:

- Precision coating: Allowing for more accurate and consistent application of adhesives.

- Advanced slitting techniques: Enabling the production of narrower and more complex tape configurations.

- Digital printing integration: Facilitating customized designs and labeling directly onto the adhesive tapes.

These technological advancements are not only improving the efficiency of the manufacturing process but also opening up new possibilities for customization and product innovation.

Customization trends in adhesive tapes

The demand for customized adhesive tapes is on the rise, driven by the need for specific solutions in various industries. Trends in customization include:

- Tailored adhesive properties: Manufacturers are offering tapes with customized adhesive strengths and properties to suit different applications.

- Custom designs and patterns: Digital printing technology allows for the creation of complex designs and patterns on adhesive tapes, catering to branding and aesthetic requirements.

- Specialized tape formats: The development of specialized tape formats, such as die-cut or laminated tapes, is meeting the specific needs of various industries.

As the industry continues to evolve, the ability to offer customized adhesive tape solutions will become increasingly important for manufacturers looking to differentiate themselves and meet the changing needs of their customers.

Material constraints and production bottlenecks limiting converter scale

Despite growth prospects, the adhesive tape converters market is constrained by material limitations and production bottlenecks. The industry faces significant challenges in sourcing high-quality materials and optimizing production processes to meet the increasing demand for adhesive tape converters.

Challenges in material sourcing and production

The production of adhesive tape converters relies heavily on the availability of high-quality raw materials. However, material constraints such as the scarcity of certain adhesives, backing materials, and release liners can hinder production. Moreover, fluctuations in raw material prices can impact the profitability of converter manufacturers.

Production bottlenecks are another significant challenge. These can arise from various factors, including outdated manufacturing equipment, inefficient production processes, and a lack of skilled labor. To overcome these bottlenecks, manufacturers must invest in modernizing their equipment and training their workforce.

To address production bottlenecks, adhesive tape converter manufacturers can adopt several strategies:

- Investing in advanced manufacturing technologies, such as automation and digital printing, to enhance efficiency and reduce waste.

- Implementing lean manufacturing principles to streamline production processes and minimize downtime.

- Developing strategic partnerships with suppliers to ensure a stable supply of high-quality raw materials.

By adopting these strategies, manufacturers can improve their production capacity, reduce costs, and enhance their competitiveness in the market.

The key to overcoming material constraints and production bottlenecks lies in innovation and adaptability. By leveraging new technologies and optimizing production processes, adhesive tape converter manufacturers can meet the growing demand for their products and drive growth in the industry.

Geopolitical impacts on sourcing base materials and distribution networks

Trade Wars and Tariffs

-

Impact: Countries may impose tariffs or quotas on specific materials, disrupting existing trade flows and raising costs. For instance, the U.S.-China trade war led to higher tariffs on Chinese steel and aluminum, which forced businesses to look for alternative suppliers or absorb higher costs.

-

Example: In 2018, the U.S. imposed tariffs on steel imports, which affected the availability and pricing of materials in industries like construction and automotive manufacturing.

Sanctions and Export Bans

-

Impact: Sanctions, especially from major global powers like the U.S., EU, or UN, can restrict access to critical raw materials. Countries subject to sanctions might be blocked from exporting certain materials, forcing companies to seek alternatives or local substitutes.

-

Example: Russia’s invasion of Ukraine in 2022 led to widespread sanctions that impacted the supply of certain metals like palladium and nickel, which are critical in the electronics and automotive industries.

Regional Conflicts

-

Impact: Conflicts in resource-rich regions can lead to disruptions in mining, extraction, and transport of essential materials. This results in shortages and increases in material prices, while also challenging logistics and distribution networks.

-

Example: The Middle East and parts of Africa are key suppliers of oil, and geopolitical tensions in these areas, like the conflicts in Syria and Libya, can directly influence global energy supply chains.

Political Instability

-

Impact: In countries with unstable political environments, sourcing base materials becomes risky. Political instability can lead to nationalization of industries, changes in export regulations, and even labor strikes, disrupting the steady flow of materials.

-

Example: Venezuela, with its vast oil reserves, has faced challenges in the oil industry due to political instability, affecting global oil markets.

Supply Chain Diversification

-

Impact: Geopolitical risks push companies to diversify their supply chains. Rather than relying on a single country or region, businesses may seek suppliers in politically stable regions or those that are geographically closer to reduce risks.

-

Example: The COVID-19 pandemic highlighted the vulnerabilities in global supply chains. Many companies began to shift manufacturing back to their home countries (a process known as “reshoring”) or diversify suppliers to ensure continuity.

By type: die-cut, laminated, and specialty converted tape segments

The Adhesive Tape Converters Market is segmented into various types, including die-cut, laminated, and specialty tapes, each serving distinct applications.

This segmentation allows for a more nuanced understanding of the market’s dynamics and growth prospects.

Die-cut adhesive tapes

Die-cut adhesive tapes are precision-cut to meet specific requirements, making them ideal for various industries, including electronics and automotive.

Their versatility and customizability drive their demand.

Laminated and specialty tapes

Laminated tapes offer enhanced durability and are used in applications requiring high resistance to environmental factors.

Specialty tapes, on the other hand, are designed for unique applications, such as in medical devices or construction.

These tapes are engineered to meet specific performance criteria, making them indispensable in their respective industries.

| Type of Tape | Application | Key Characteristics |

| Die-cut | Electronics, Automotive | Precision-cut, customizable |

| Laminated | Industrial, Construction | Durable, resistant to environmental factors |

| Specialty | Medical Devices, Aerospace | Engineered for specific performance criteria |

Application breakdown: electronics, automotive, medical, and construction

As technology advances, adhesive tapes are becoming increasingly integral to industries such as electronics, automotive, medical devices, and construction. The demand for adhesive tapes in these sectors is driven by their versatility, reliability, and the specific needs of each industry.

Adhesive tapes in electronics and automotive

Adhesive tapes in the electronics industry

In the electronics industry, adhesive tapes are used for various applications, including bonding, insulation, and protection. They are crucial in the manufacture of electronic components, such as smartphones, laptops, and televisions. The use of adhesive tapes in electronics is driven by the need for miniaturization, thermal management, and electrical insulation.

Adhesive tapes in the automotive sector

The automotive sector also heavily relies on adhesive tapes for bonding and sealing applications. Automotive adhesive tapes are used in vehicle assembly for tasks such as attaching emblems, molding, and trim. They offer advantages like reduced weight, improved durability, and enhanced aesthetics.

Other industries using adhesive tapes

In the medical industry, adhesive tapes are used for a range of applications, from wound care to medical device assembly. Medical adhesive tapes are designed to be hypoallergenic and gentle on the skin, making them suitable for use on patients with sensitive skin.

The construction industry utilizes adhesive tapes for various tasks, including sealing joints, bonding materials, and insulation. Construction adhesive tapes are valued for their strength, durability, and resistance to environmental factors like moisture and temperature fluctuations.

Across these industries, the demand for adhesive tapes is driven by their performance characteristics, such as adhesion strength, temperature resistance, and chemical stability. As industries continue to evolve, the development of new adhesive tape technologies is expected to further expand their applications.

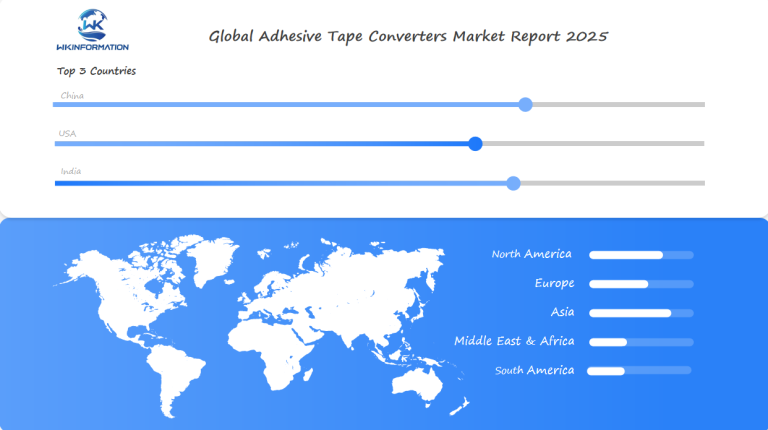

Regional developments shaping the Adhesive Tape Converters market

The global Adhesive Tape Converters market is experiencing significant regional developments that are influencing its future. As the industry continues to grow, understanding these regional dynamics is essential for stakeholders.

Regional market trends

Different regions are experiencing varying trends in the Adhesive Tape Converters market. North America is seeing a surge in demand due to the growth of the electronics and automotive sectors. In contrast, Europe is focusing on sustainable and eco-friendly adhesive solutions, driving innovation in the market.

Asia-Pacific is emerging as a significant growth region, driven by the expanding manufacturing sector in countries like China and India. This region is expected to present substantial opportunities for Adhesive Tape Converters in the coming years, as illustrated in the image below:

Emerging markets and growth opportunities

Emerging markets are playing a vital role in the growth of the Adhesive Tape Converters industry. Countries with developing manufacturing sectors are likely to drive demand for adhesive tape conversion solutions.

| Region | Growth Opportunities | Key Drivers |

| Asia-Pacific | Increasing demand from electronics and automotive sectors | Expanding manufacturing sector |

| North America | Growth in electronics and automotive industries | Technological advancements |

| Europe | Demand for sustainable adhesive solutions | Environmental regulations |

The table highlights the key regions, their growth opportunities, and the drivers behind these opportunities in the Adhesive Tape Converters market.

Regional adhesive tape converters market trends

Understanding these regional trends and emerging markets is essential for businesses looking to capitalize on the growth opportunities in the Adhesive Tape Converters industry.

Japan's Dominance in Micro-Precision and Industrial Tape Conversion

Japan’s technological expertise in micro-precision and industrial tape conversion has established a new standard in the global market. The country’s knowledge in this field has played a crucial role in driving innovation within the adhesive tape converters market.

Japan’s technological advancements

The adhesive tape converters market in Japan has witnessed substantial growth due to the country’s focus on technological advancements. Micro-precision tape conversion has been a key area of development, enabling the production of high-precision tapes used in various industries, including electronics and automotive.

Advances in technology have allowed Japanese manufacturers to improve the quality and functionality of adhesive tapes. This has been achieved through significant investments in research and development, as well as the adoption of cutting-edge manufacturing techniques.

Impact on the global market

The impact of Japan’s technological advancements in micro-precision and industrial tape conversion on the global market has been profound.

The global adhesive tape converters market has benefited from Japan’s innovations, with many countries adopting similar technologies to enhance their own manufacturing capabilities. This has led to a more competitive and dynamic global market.

- Increased adoption of micro-precision tape conversion technologies

- Improved product quality and functionality

- Enhanced global competitiveness

Germany’s Innovation in Automotive Adhesive Systems and Converter Design

Germany’s strong automotive industry is driving innovations in adhesive systems and converter design. The country’s expertise in manufacturing high-quality vehicles is complemented by its advancements in adhesive technology, which plays a crucial role in the production process.

Automotive adhesive systems

The use of adhesive tapes in the automotive sector is becoming increasingly prevalent due to their ability to bond different materials, reduce weight, and enhance vehicle safety. Automotive adhesive systems are being designed to withstand extreme temperatures and conditions, ensuring durability and performance.

German companies are at the forefront of developing these advanced adhesive systems, which are used in various applications, including bonding exterior parts, sealing, and insulation. The emphasis is on creating systems that are not only effective but also environmentally friendly.

Converter design innovations

Innovations in converter design are crucial for the efficient production of adhesive tapes. German manufacturers are investing in cutting-edge technology to improve the precision and speed of their converters. This includes the development of digital printing technologies and advanced material handling systems.

These advancements enable the production of highly customized adhesive tapes that meet the specific needs of the automotive industry. The ability to produce small batches with high precision is particularly valuable, as it allows for greater flexibility in manufacturing.

The integration of automation and smart technologies in converter design is also enhancing efficiency and reducing production costs. This trend is expected to continue, driving further innovation in the adhesive tape converters market.

As Mexico’s manufacturing sector continues to expand, it is fueling a rise in demand for converters. This growth is attributed to several factors, including the country’s strategic location, favorable trade agreements, and a skilled workforce.

Mexico's Manufacturing Growth

The manufacturing sector in Mexico has seen significant growth in recent years, driven by investments in various industries such as automotive, electronics, and aerospace. This growth has led to an increased demand for adhesive tape converters, which are crucial for the production of various components used in these industries.

Key Drivers of Manufacturing Growth in Mexico

1. Proximity to the US Market: Being close to the United States allows manufacturers in Mexico to ship their products quickly and at a lower cost.

2. Favorable Trade Agreements: Trade agreements like NAFTA and USMCA have made it easier for Mexican manufacturers to export their goods to the US and other countries.

3. Skilled Workforce: Mexico has a large pool of skilled workers who are trained in various industries, making it an attractive destination for manufacturing companies.

Impact on Converter Demand

The growth in Mexico’s manufacturing sector has directly impacted the demand for adhesive tape converters. As manufacturers expand their operations, they require more converters to meet their production needs. This has led to an increase in the demand for high-quality converters that can meet the specific requirements of various industries.

The demand for converters is expected to continue growing as Mexico’s manufacturing sector expands. This presents opportunities for converter manufacturers to invest in new technologies and improve their production capabilities to meet the increasing demand.

The future of adhesive tape converters in Mexico looks promising, with the country’s manufacturing sector poised for continued growth.

Future development in digital printing, automation, and green adhesives

The Adhesive Tape Converters Market is about to undergo a major change, thanks to advancements in digital printing, automation, and eco-friendly adhesives. These new trends are set to revolutionize the industry, allowing manufacturers to create top-notch, personalized adhesive tapes in a more efficient and sustainable manner.

Digital Printing in Adhesive Tapes

Digital printing technology is changing the game for adhesive tape production. It allows for high-quality printing, flexible designs, and fast turnaround times. This is especially beneficial for industries like electronics, automotive, and medical devices that require specific and intricate designs on their adhesive tapes.

Benefits of Digital Printing

Some of the key advantages of digital printing in adhesive tapes include:

- Enhanced customization capabilities: With digital printing, manufacturers can easily create unique designs for each order without the need for expensive setup processes.

- Improved print quality and resolution: Digital printers are capable of producing sharp and detailed images, ensuring that even the most complex designs come out perfectly.

- Reduced lead times due to variable data printing: Digital printing allows for quick changes in design or content, making it ideal for projects with tight deadlines or last-minute modifications.

- Increased flexibility for small batch production: Unlike traditional printing methods that require large quantities to be cost-effective, digital printing is economical for smaller runs as well.

Automation in Adhesive Tape Conversion

Another significant trend in the industry is automation in adhesive tape converters. By implementing automated systems, manufacturers can streamline their production processes, reduce labor costs, and improve product quality.

Automated systems are capable of handling intricate tasks such as die-cutting, laminating, and winding with precision and speed. This not only increases efficiency but also minimizes human error, resulting in consistent and high-quality output.

The Rise of Green Adhesives

As sustainability becomes a top priority for many businesses, green adhesives are gaining popularity in the adhesive tape industry. These adhesives are made from renewable materials and are designed to have minimal impact on the environment.

By using green adhesives in their products, manufacturers can reduce the ecological footprint of adhesive tape production and cater to the growing demand for eco-friendly solutions.

| Trend | Description | Impact |

| Digital Printing | High-resolution printing on adhesive tapes | Enhanced customization, improved quality |

| Automation | Automated production processes | Increased efficiency, reduced labor costs |

| Green Adhesives | Eco-friendly adhesive materials | Reduced environmental impact, sustainable products |

As the Adhesive Tape Converters Market continues to evolve, embracing these trends will be crucial for manufacturers to stay competitive and meet the changing needs of their customers.

Competitive strategies of major Adhesive Tape Converters globally

To gain a competitive edge in the Adhesive Tape Converters market, leading companies are leveraging advanced technologies and strategic partnerships. The industry is characterized by intense competition, with major players continually adapting their strategies to stay ahead.

Here are some of the major players in the global Adhesive Tape Converters market:

- 3M – United States

- Avery Dennison – United States

- Tesa SE – Germany

- Nitto Denko – Japan

- Scapa Group – United Kingdom

- Intertape Polymer Group – Canada

- Shurtape Technologies – United States

- Berry Global – United States

- Orafol – Germany

- Lintec Corporation – Japan

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Adhesive Tape Converters Report |

| Base Year | 2024 |

| Segment by Type |

· Die-cut · Laminated · Specialty |

| Segment by Application |

· Electronics · Automotive · Medical · Construction |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Adhesive Tape Converters Market is set for significant growth, driven by innovation and increasing demand across various industries. As discussed, the market is expected to reach $21.6 billion globally by 2025.

Summary of Key Findings

The market’s growth is influenced by technological advancements, regional developments, and evolving application areas. Die-cut, laminated, and specialty converted tape segments are driving the market forward, with electronics, automotive, medical, and construction being key application areas.

Future Outlook

Looking ahead, the Adhesive Tape Converters Market is expected to be shaped by trends such as digital printing, automation, and the development of green adhesives. As manufacturers continue to innovate and expand their capabilities, the market is likely to witness significant advancements in tape conversion technology, ultimately driving growth and meeting the evolving needs of various industries. The future outlook for the Adhesive Tape Converters Market summary indicates a positive trajectory, with market trends pointing towards increased adoption and application across diverse sectors.

Global Adhesive Tape Converters Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Adhesive Tape Converters Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Adhesive Tape ConvertersMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Adhesive Tape Convertersplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Adhesive Tape Converters Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Adhesive Tape Converters Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Adhesive Tape Converters Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofAdhesive Tape ConvertersMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected size of the Adhesive Tape Converters Market by 2025?

The Adhesive Tape Converters Market is expected to reach $21.6 billion by 2025.

What are the key drivers behind the growth of the Adhesive Tape Converters Market?

The growth is driven by trends shaping the industry, including:

- Advances in technology

- Increasing demand from various sectors such as electronics, automotive, medical, and construction

- Regional developments

How do raw material sourcing and supply chain dynamics impact the Adhesive Tape Converters industry?

The sourcing of raw materials and supply chain dynamics play a crucial role in the production of adhesive tapes, affecting the industry’s ability to meet demand and influencing potential bottlenecks and opportunities for growth.

What role does technology play in the Adhesive Tape Converters Market?

Advances in technology, including digital printing, automation, and developments in tape conversion technology, are transforming the adhesive tape formats and enabling greater customization, opening up new opportunities for manufacturers and end-users.

What are the challenges faced by the Adhesive Tape Converters Market?

The market faces challenges such as material constraints and production bottlenecks, which can limit the scale of converters and impact their ability to meet growing demand.

How is the Adhesive Tape Converters Market segmented by type?

The market is divided into three segments: die-cut, laminated, and specialty converted tape. Each segment has its own applications, growth potential, and trends influencing its development.

What are the major applications of adhesive tapes?

Adhesive tapes have a wide range of applications across various industries, including electronics, automotive, medical, and construction, driven by trends and the role they play in each sector.

How do regional developments influence the Adhesive Tape Converters Market?

Regional developments, including trends and growth opportunities in different areas, influence the market, with emerging markets presenting new opportunities.

What is Japan’s role in the Adhesive Tape Converters Market?

Japan is known for its leadership in micro-precision and industrial tape conversion, with its technological advancements influencing the worldwide market.

How is Germany contributing to the Adhesive Tape Converters Market?

Germany is known for its innovation in automotive adhesive systems and converter design, contributing to the growth and development of the market.

How does Mexico’s manufacturing growth affect the Adhesive Tape Converters Market?

Mexico’s growing manufacturing sector is driving up demand for adhesive tape converters, which in turn affects both demand and production levels.

What are the future trends expected to shape the Adhesive Tape Converters Market?

Future developments in digital printing, automation, and green adhesives are expected to shape the market, presenting new opportunities and challenges.

What are the competitive strategies employed by major Adhesive Tape Converters globally?

Major players are employing various strategies to gain market share, including market competition analysis and strategies for .