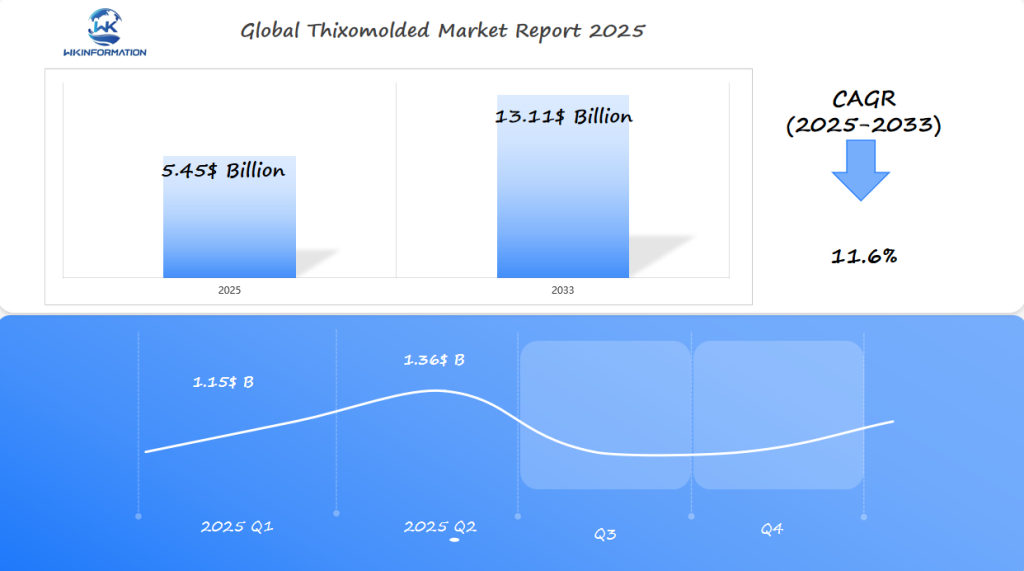

Thixomolded Market Set to Reach $5.45 Billion Globally by 2025: Manufacturing Surge in China, the U.S., and Italy

The Thixomolded Market is poised for explosive growth, projected to reach $5.45 billion globally by 2025 as manufacturing surges in China and the U.S.

- Last Updated:

Thixomolded Market in Q1 and Q2 of 2025

The Thixomolded market is expected to reach $5.45 billion in 2025, growing at a strong rate of 11.6% from 2025 to 2033. Revenue for the first quarter is estimated to be around $1.15 billion, increasing to $1.36 billion by the second quarter as more original equipment manufacturers (OEMs) start using magnesium alloy parts.

Key Factors Driving the Thixomolded Market

Several factors are driving the growth of the Thixomolded market:

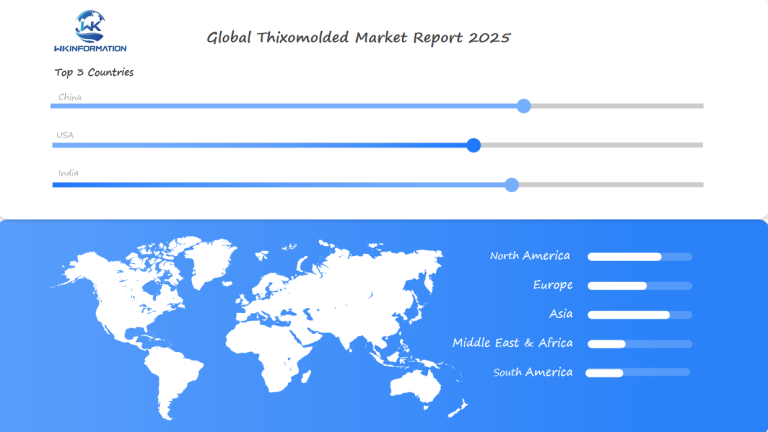

- China’s Dominance: China is the largest producer of thixomolded products globally, thanks to its extensive supply chain, cost-effective processing methods, and high demand for lightweight components in industries like electronics and e-mobility.

- U.S. Market Focus: The United States market is primarily driven by aerospace and medical device manufacturing, where thixomolding provides precise and durable solutions for compact designs.

- Italy’s Exploration: Italy’s automotive and industrial machinery sectors are actively exploring thixomolded alternatives to die-cast aluminum in order to reduce weight and gain design flexibility.

Technological Advancements and Environmental Regulations

Technological advancements in injection-molding machinery and the integration of automation systems are improving production efficiency and product quality. Additionally, increasing environmental regulations that promote recyclable and low-energy processes are benefiting the market as well.

Thixomolded market upstream and downstream industry chain insights

Upstream Industry Chain (Raw Materials and Equipment)

-

Raw Materials

-

Magnesium Alloys: Particularly Mg-Al-Zn (AZ) series like AZ91D.

-

Key suppliers: China Magnesium Corporation, US Magnesium LLC, Dead Sea Magnesium Ltd.

-

-

Alloying Elements: Aluminum, Zinc, Manganese.

-

Protective Gases: SF₆ (sulfur hexafluoride), CO₂ blends used in inert atmospheres during processing.

-

Trend: Push for alternatives due to environmental regulations on SF₆.

-

-

-

Thixomolding Machines and Tooling

-

Specialized injection molding machines with screw feeders, heating chambers, and die-casting molds.

-

Manufacturers: Toshiba Machine, UBE Industries, Buhler Group.

-

-

Mold design and simulation software: Dassault Systèmes, Siemens NX, Moldex3D.

-

-

Power & Utilities

-

High electricity consumption due to controlled atmosphere and heating—requires reliable power infrastructure.

-

Downstream Industry Chain (Applications and End-Use Markets)

-

Electronics

-

Lightweight, EMI-shielded housings for laptops, smartphones, tablets, and cameras.

-

Example: Use in magnesium alloy casings for Apple/Microsoft devices.

-

-

Automotive

-

Steering wheels, instrument panels, seat frames, gearbox housings.

-

Focus: Weight reduction for fuel economy and EV range.

-

Collaborators: OEMs and Tier-1 suppliers like Bosch, Magna.

-

-

Medical Devices

-

Magnesium’s biocompatibility opens use in orthopedic implants, surgical instruments, and lightweight devices.

-

Regulation-heavy segment requiring clean-room manufacturing.

-

-

Aerospace & Defense

-

UAVs, portable military equipment, and lightweight structural parts.

-

Driven by demand for strength-to-weight ratio and corrosion resistance.

-

-

Sporting Goods and Tools

-

Golf club heads, bicycle components, handheld power tools.

-

Emerging trends driving innovation in Thixomolded production

The Thixomolding industry is experiencing a surge in innovation, driven by emerging trends and the demand for lightweight, high-performance components. This shift is largely influenced by the growing need for efficient and cost-effective production processes.

Advances in Thixomolding technology have played a crucial role in this innovation. New technologies and manufacturing techniques are enabling the production of complex components with high precision and accuracy. This has opened up new opportunities for the use of Thixomolded components in various industries.

Advances in Thixomolding technology

The development of new Thixomolding technologies has been a key driver of innovation in the industry. These advancements have enabled the production of components with complex geometries and improved mechanical properties. As a result, Thixomolded components are increasingly being used in demanding applications.

Impact on the Automotive Sector

One of the key areas where Thixomolding is making a significant impact is in the automotive sector. The use of Thixomolded components in vehicles is becoming increasingly popular due to their high strength-to-weight ratio, corrosion resistance, and ability to be produced with complex geometries. As the demand for electric vehicles and lightweight vehicles continues to grow, Thixomolding is likely to play a crucial role in shaping the future of the automotive industry.

Emerging Trends Driving Innovation

The emerging trends driving innovation in Thixomolded production are expected to continue in the coming years, driven by the demand for more efficient and cost-effective production processes. As Thixomolding technology continues to evolve, we can expect to see new applications and industries adopting this technology.

Key restrictions slowing the global Thixomolded rollout

Despite its growing demand, the Thixomolded market is encountering several key restrictions that are slowing its global rollout. The industry is facing challenges that need to be addressed to ensure continued growth and adoption of Thixomolded components.

High production costs and limited awareness

One of the significant challenges facing the Thixomolded industry is the high production costs associated with this technology. The complex process of Thixomolding requires specialized equipment and skilled personnel, increasing the cost of production. Additionally, there is limited awareness about the benefits of Thixomolding among potential users, which can hinder its adoption.

The high production costs are largely due to the sophisticated machinery and the semi-solid state processing of metals, which requires precise control over temperature and pressure. This complexity not only increases costs but also limits the number of manufacturers who can produce Thixomolded components.

Apart from high production costs and limited awareness, the Thixomolded industry is also facing regulatory challenges and trade barriers. Regulatory challenges include compliance with various national and international standards, which can be complex and costly. Trade barriers, such as tariffs and quotas, can limit the import and export of Thixomolded components, affecting the global supply chain.

The industry is working to address these challenges through advocacy and regulatory engagement, aiming to simplify compliance and reduce trade barriers. By doing so, the industry hopes to facilitate a smoother global rollout of Thixomolded technology.

- High production costs due to complex machinery and processing requirements

- Limited awareness about the benefits of Thixomolding

- Regulatory challenges and compliance with national and international standards

- Trade barriers, including tariffs and quotas, affecting the global supply chain

Geopolitical factors reshaping Thixomolded sourcing and trade

Thixomolded sourcing and trade are being reconfigured by emerging geopolitical factors and trade policies. The Thixomolded market is highly sensitive to changes in global trade dynamics, with shifts in policies and tariffs directly impacting the industry.

Impact of Trade Policies on Thixomolded Imports and Exports

Changes in trade policies and tariffs are significantly affecting the import and export of Thixomolded components. This has led to a re-evaluation of sourcing strategies by companies to minimize risks associated with trade disruptions.

- Imposition of tariffs on imports

- Restrictions on exports to certain countries

- Shifts towards localized sourcing to reduce dependency on international trade

Shifts in Global Supply Chains

The Thixomolded industry is witnessing a significant shift in global supply chains due to geopolitical factors. Companies are diversifying their supply chains, exploring new markets, and investing in regions with more stable trade policies.

This shift is driven by the need to:

- Reduce reliance on single-source suppliers

- Mitigate risks associated with trade tariffs and restrictions

- Take advantage of emerging markets with favorable trade policies

The reconfiguration of global supply chains is expected to continue as companies adapt to the evolving geopolitical landscape.

Type segmentation in the Thixomolded market: alloy diversity and demand

The Thixomolded market is experiencing a significant change in type segmentation, driven by the variety of alloys used and demand trends. This change is mainly influenced by the increasing need for Thixomolded parts in different industries.

The role of alloy diversity in type segmentation

The wide range of alloys employed in Thixomolding plays a crucial role in determining the type segmentation of the Thixomolded market. Among these, magnesium alloys stand out as one of the most frequently utilized materials, owing to their exceptional characteristics such as a high strength-to-weight ratio and outstanding resistance to corrosion.

Magnesium alloys and other materials used in Thixomolding

The use of magnesium alloys in Thixomolding is widespread due to their versatility and the ability to produce complex geometries. Other materials used in Thixomolding include aluminum alloys and other specialized alloys, each offering distinct advantages depending on the application.

Demand trends in various industries

The demand for Thixomolded components is driven by various industries, including the automotive, aerospace, and electronics sectors. In the automotive industry, Thixomolded components are used to produce lightweight, high-performance parts. The aerospace industry utilizes Thixomolded components for their high strength, resistance to corrosion, and ability to withstand extreme temperatures.

- The demand for Thixomolded components in the automotive sector is driven by the need for lightweight, fuel-efficient vehicles.

- In the aerospace industry, Thixomolded components are used in the production of aircraft parts that require high precision and reliability.

- The electronics industry uses Thixomolded components for their thermal conductivity and electromagnetic shielding properties.

Understanding the demand trends in these industries is crucial for manufacturers to tailor their production and meet the specific needs of each sector.

Application analysis across automotive, aerospace, and electronics

Thixomolded components are becoming a crucial part of several key industries, including automotive, aerospace, and electronics. The unique properties of Thixomolded components, such as their high strength-to-weight ratio and ability to be molded into complex shapes, make them an ideal choice for various applications.

Use of Thixomolded components in automotive applications

In the automotive sector, Thixomolded components are used to produce lightweight, high-performance parts that enhance vehicle efficiency and reduce emissions. Some of the key applications include:

- Structural components

- Engine components

- Transmission parts

The use of Thixomolded components in automotive applications is driven by the need for lightweight materials that can withstand high temperatures and stresses.

Use of Thixomolded components in aerospace and electronics

In the aerospace industry, Thixomolded components are used in aircraft and spacecraft due to their high strength-to-weight ratio and resistance to corrosion. In the electronics sector, Thixomolded components are used in various applications, including casings and other components.

Some of the key benefits of using Thixomolded components in aerospace and electronics applications include:

- Reduced weight

- Increased durability

- Improved thermal management

The use of Thixomolded components in these industries is expected to continue growing as manufacturers seek to improve performance and reduce weight.

Global Thixomolded Activity by Major Economic Regions

Global activity in the Thixomolded market is concentrated in major economic regions. The Thixomolded industry is a global phenomenon, with various regions contributing to its growth and development.

The regional analysis of the Thixomolded market reveals diverse trends and developments across different parts of the world. Understanding these regional dynamics is crucial for identifying opportunities and challenges in the industry.

Regional Analysis of the Thixomolded Market

The Thixomolded market is analyzed across various regions, including North America, Europe, and Asia. Each region has its unique characteristics and trends shaping the industry.

North America

The North American market is driven by the automotive and aerospace sectors, with a focus on high-precision Thixomolded components.

Europe

Europe is witnessing significant growth in the Thixomolded market, driven by the automotive industry and industrial design applications.

Asia

The Asian market, particularly China, is experiencing rapid growth in Thixomolded component manufacturing, driven by increasing demand from the automotive and electronics sectors.

Key Trends and Developments in Major Regions

Several key trends are shaping the Thixomolded market across major regions. Some of the notable trends include:

- Increasing demand for lightweight components: The demand for lightweight Thixomolded components is on the rise, driven by the automotive and aerospace industries.

- Advances in Thixomolding technology: Technological advancements in Thixomolding are improving the quality and efficiency of Thixomolded components.

- Growing adoption in industrial design: Thixomolded components are increasingly being used in industrial design applications, driven by their versatility and aesthetic appeal.

As the global Thixomolded market continues to evolve, understanding regional trends and developments will be crucial for industry stakeholders. The regional analysis provides insights into the key drivers and challenges facing the industry in different regions.

Importance of Regional Analysis

The regional analysis of the Thixomolded market highlights the importance of understanding local trends and developments. By analyzing the market across different regions, industry stakeholders can identify opportunities and challenges, and make informed decisions about investments and resource allocation.

China's Rapid Investment in Thixomolded Component Manufacturing

China is quickly becoming a global leader in Thixomolded component manufacturing. This is due to significant government investment and a growing demand for high-performance components. As a result, the country is transforming its position in the global market and becoming a major hub for producing lightweight, high-quality parts used in various industries.

Growth of the Thixomolded Industry in China

The Thixomolded industry in China is experiencing rapid expansion, fueled by government support and increasing demand from sectors such as automotive, aerospace, and electronics. This growth is characterized by the development of a robust supply chain, advancements in manufacturing technology, and an increasing number of manufacturers entering the market.

Several factors are driving this growth, including government initiatives aimed at promoting the use of advanced materials and technologies. Additionally, the growing demand for lightweight components in various industries is pushing the demand for Thixomolded products.

The Chinese Thixomolded market is influenced by several key drivers and trends, including:

- Increasing government investment in advanced manufacturing technologies.

- Growing demand for lightweight, high-performance components in the automotive and aerospace sectors.

- Expansion of the supply chain, with more manufacturers and suppliers entering the market.

- Advancements in Thixomolding technology, leading to improved product quality and reduced production costs.

These trends are expected to continue driving growth in the Chinese Thixomolded market, positioning China as a leading player in the global industry.

U.S. Leadership in High-Precision Thixomolded Engineering

The U.S. is a global leader in Thixomolded engineering, using advanced technology to meet the needs of industries that require high-precision components. With its strong technological infrastructure, the U.S. has become a leader in Thixomolded engineering, serving the requirements of high-precision industries.

Advances in Thixomolding Technology in the U.S.

The U.S. has seen significant advancements in Thixomolding technology, driven by research and development in the field. Technological innovations have made it possible to produce complex components with high precision and reliability.

Investment in R&D has been a key factor in the development of new Thixomolding technologies, enhancing the U.S.’s position in the global market.

The demand for Thixomolded components in the U.S. is driven by several key industries, including aerospace, automotive, and electronics. Aerospace applications require high-precision components that can withstand extreme conditions, making Thixomolded components ideal for this sector.

| Industry | Key Applications | Demand Drivers |

| Aerospace | High-precision components, structural parts | Need for lightweight, durable components |

| Automotive | Engine components, transmission parts | Requirements for high-performance, lightweight parts |

| Electronics | Casing components, heat sinks | Demand for compact, high-performance electronic devices |

The U.S. market is known for its high level of innovation, with companies constantly pushing the limits of what can be achieved with Thixomolding. As a result, the U.S. continues to lead in high-precision Thixomolded engineering, driven by technological advancements and demand from key industries.

Italy’s Adoption of Thixomolded for Industrial Design Applications

Thixomolded technology is gaining popularity in Italy, especially in the industrial design sector, because it can produce high-precision components. The Italian market is known for its strong emphasis on design and innovation, with companies increasingly using Thixomolding to create unique and complex products.

Why Italian Industrial Designers Are Using Thixomolded Components

The use of Thixomolded components in Italian industrial design is driven by the need for:

- Precision

- Complexity

- Lightweight materials

Italian companies are using this technology to stay competitive globally and innovate in their industries.

Use of Thixomolded Components in Italian Industrial Design

Italian industrial design is known for its focus on aesthetics, functionality, and creative use of materials. Thixomolded components are being used in various products, improving their performance and design flexibility. The ability to create complex shapes and structures with high accuracy is a major benefit of Thixomolding technology.

Thixomolded components in Italian industrial design

The Italian Thixomolded market is seeing several key trends. There is a growing demand for lightweight, strong materials in industrial design applications. Additionally, there is an increasing emphasis on using Thixomolded components to produce intricate geometries and structures that cannot be made using traditional manufacturing methods.

The following table highlights some of the key trends and developments in the Italian Thixomolded market:

| Trend/Development | Description | Impact on Industry |

| Increased use of lightweight materials | Growing demand for materials that reduce overall product weight without compromising strength | Enhanced product performance and energy efficiency |

| Adoption of complex geometries | Use of Thixomolding to produce complex shapes and structures | Increased design flexibility and innovation |

| Advancements in Thixomolding technology | Continuous improvements in Thixomolding technology, including better surface finish and tighter tolerances | Improved product quality and reduced production costs |

As the Italian market continues to change, understanding these trends and developments will be important for companies looking to use Thixomolded technology in their industrial design applications. The potential for Thixomolded components to revolutionize the industry is immense, offering design flexibility and improved product performance.

Future development opportunities for the Thixomolded sector

Emerging trends and technologies are set to transform the Thixomolded sector, creating new opportunities for growth. As the industry evolves, it is crucial to identify and examine the potential opportunities and challenges that lie ahead.

Emerging trends and technologies

The Thixomolded sector is experiencing significant advancements in technology, including improvements in alloy development and Thixomolding machinery. These advancements are expected to enhance the quality and efficiency of Thixomolded components, making them more competitive in the market.

Some of the emerging trends in the Thixomolded sector include:

- The development of new magnesium alloys with improved properties, such as corrosion resistance and strength.

- Advancements in Thixomolding technology that enable the production of complex components with high precision and accuracy.

Potential applications and markets

The potential applications of Thixomolded components are vast, ranging from the automotive and aerospace industries to electronics and industrial design. As the technology continues to evolve, we can expect to see new markets and applications emerge.

Here is a detailed analysis of the potential applications and markets for Thixomolded components:

| Industry | Potential Applications | Market Trends |

| Automotive | Engine components, transmission parts | Increasing demand for lightweight components |

| Aerospace | Aircraft components, satellite parts | Growing demand for high-precision components |

| Electronics | Component housings, heat sinks | Increasing demand for miniaturization |

| Industrial Design | Complex geometries, customized components | Growing demand for innovative designs |

The future development of the Thixomolded sector is closely tied to the advancement of emerging trends and technologies. As the industry continues to evolve, it is essential to stay abreast of these developments and identify opportunities for growth and investment.

Competitive analysis of global Thixomolded technology suppliers

As the demand for Thixomolded products grows, the competitive landscape among technology suppliers is intensifying. The global Thixomolded market is characterized by a competitive landscape, with several key players vying for market share.

The increasing demand for Thixomolded components in various industries, such as automotive and aerospace, is driving the competition among technology suppliers. Companies are investing heavily in research and development to improve their manufacturing processes and stay ahead of the competition.

Key players in the Thixomolded market

Some of the key players in the Thixomolded market include companies that specialize in Thixomolding technology and equipment. These companies are focused on developing innovative products and solutions to meet the growing demand for Thixomolded components.

The key players are also engaging in strategic partnerships and collaborations to expand their market presence and improve their competitive position.

- Thixomat Inc. – United States

- Leggera Technologies – United States

- SSIM Technologies – Canada

- Amptech Corp. – United States

- X-Energy – United States

- GE Hitachi – United States

- Holtec – United States

- Advanced Materials Technologies – Singapore

- AGILITY – United States

- Magna International – Canada

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Thixomolded Report |

| Base Year | 2024 |

| Segment by Type |

· Magnesium Alloys · Other |

| Segment by Application |

· Automotive · Aerospace · Electronics |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Thixomolded market is rapidly evolving, driven by emerging trends and technologies. As highlighted in the overall analysis, the market is characterized by a diverse range of alloys and materials, with applications across various industries, including automotive, aerospace, and electronics.

Key findings indicate that the Thixomolded market is expected to reach $5.45 billion globally by 2025, driven by manufacturing surges in countries like China and the U.S. The growth of the Thixomolded industry is also influenced by advances in Thixomolding technology and the increasing adoption of Thixomolded components in industrial design applications.

As the Thixomolded market continues to grow, understanding the key drivers, trends, and challenges shaping the market will be essential. By analyzing the overall analysis and key findings, stakeholders can identify areas for future development and opportunities for growth in this rapidly evolving industry.

Global Thixomolded Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Thixomolded Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- ThixomoldedMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Thixomoldedplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Thixomolded Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Thixomolded Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Thixomolded Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofThixomoldedMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is Thixomolding technology?

Thixomolding is a manufacturing process used to produce high-precision, complex components, particularly in the automotive, aerospace, and electronics industries.

What are the benefits of using Thixomolded components?

Thixomolded components offer several benefits, including:

- High precision

- Complex geometries

- Reduced material waste

These advantages make them ideal for various industries.

What are the most commonly used materials in Thixomolding?

Magnesium alloys are one of the most commonly used materials in Thixomolding, due to their high strength-to-weight ratio and other beneficial properties.

How is the Thixomolded market expected to grow?

The Thixomolded market is expected to reach $5.45 billion globally by 2025, driven by increasing demand in various industries, particularly in China and the U.S.

What are the key challenges facing the Thixomolded industry?

High production costs, limited awareness, regulatory challenges, and trade barriers are some of the key challenges facing the Thixomolded industry.

How are geopolitical factors impacting the Thixomolded market?

Geopolitical factors, such as changes in trade policies and tariffs, are impacting the import and export of Thixomolded components, leading to a shift in global supply chains.

What are the emerging trends in the Thixomolded market?

Emerging trends in the Thixomolded market include:

- Advances in Thixomolding technology

- New applications in the automotive sector

- A growing demand for lightweight, high-performance components

Which regions are driving the growth of the Thixomolded market?

China, the U.S., and other major economic regions are driving the growth of the Thixomolded market, with a focus on high-precision, complex components.

What are the potential opportunities for future development in the Thixomolded sector?

Emerging trends and technologies, new applications, and markets are potential opportunities for future development in the Thixomolded sector.

Who are the key players in the Thixomolded market?

The Thixomolded market is competitive, with several key players competing for market share. This includes suppliers of Thixomolded technology and components.