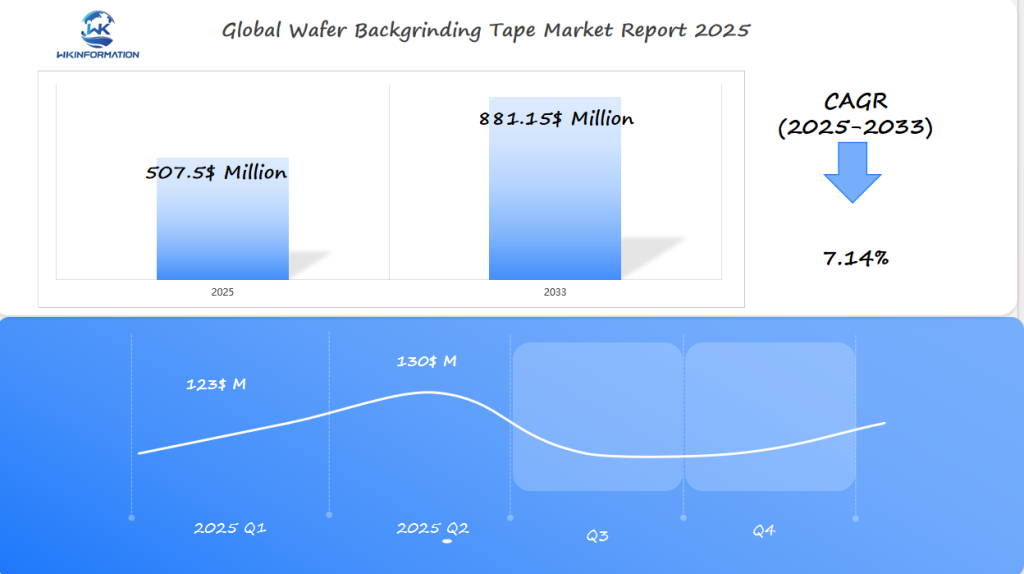

Wafer Backgrinding Tape Market Set to Reach $507.5 Million Globally by 2025, With Strong Demand in China, South Korea, and Japan

Wafer Backgrinding Tape Market is projected to reach $507.5 million globally by 2025, driven by the growing semiconductor industry in China, South Korea, and Japan.

- Last Updated:

Wafer Backgrinding Tape Market Q1 and Q2 of 2025

The Wafer Backgrinding Tape market is estimated to reach $507.5 million in 2025, with a CAGR of 7.14% from 2025 to 2033.

Key Highlights:

- Q1 2025 Forecast: Approximately $123 million

- Q2 2025 Forecast: An increase to $130 million

These growths are expected due to the increasing demand for semiconductor components and the growing complexity of microelectronics manufacturing.

As the need for smaller and more efficient semiconductors rises, advanced backgrinding tape technologies become essential.

Leading Contributors:

China, South Korea, and Japan are anticipated to be the primary contributors to this market.

- China’s rapidly growing electronics manufacturing industry

- South Korea’s dominance in semiconductor technology, especially for memory chips

- Japan’s involvement in the high-tech electronics sector

These factors ensure a sustained strong demand in the Wafer Backgrinding Tape market.

As the global semiconductor market continues to change, these countries will play a crucial role in driving the growth of the Wafer Backgrinding Tape market in 2025.

Analyzing the Wafer Backgrinding Tape Market: Upstream and Downstream Industry Chain

To truly understand the Wafer Backgrinding Tape Market, we need to take a close look at its industry chain, which includes both upstream and downstream segments.

Upstream Segment: The Backbone of Backgrinding Tapes

The upstream segment involves the production of high-quality materials used in backgrinding tapes, such as adhesives and base films. Companies specializing in these materials play a crucial role in determining the quality and performance of backgrinding tapes.

Downstream Segment: Fueling the Demand for Backgrinding Tapes

The downstream segment is driven by the demand from semiconductor manufacturers who use backgrinding tapes in the wafer processing stage. The growth of the semiconductor industry, particularly in regions like Asia-Pacific, directly influences the demand for backgrinding tapes.

The Interplay Between Upstream and Downstream Segments

The relationship between the upstream and downstream segments is critical in shaping the market dynamics of backgrinding tapes. Advancements in material science can lead to more efficient and durable backgrinding tapes, which in turn can enhance the semiconductor manufacturing process.

By understanding this intricate relationship, stakeholders in the Wafer Backgrinding Tape Market can better navigate the challenges and opportunities arising from the complex semiconductor supply chain.

Trends shaping the wafer backgrinding process and material usage

The evolution of wafer backgrinding is being shaped by trends such as the adoption of new materials and technologies. As the semiconductor industry continues to advance, the demand for thinner wafers has become a significant driving force behind the development of new backgrinding processes and materials.

Miniaturization of semiconductor devices

One of the key trends influencing wafer backgrinding is the miniaturization of semiconductor devices. As devices become smaller and more complex, the need for thinner wafers has increased. This trend is pushing the development of backgrinding tapes that can securely hold thinner wafers in place without causing damage during the grinding process.

Adoption of new materials

The adoption of new materials is another trend shaping the wafer backgrinding process. Advanced materials with unique properties are being used to improve the performance and reliability of semiconductor devices. These materials often require specialized backgrinding tapes that can handle their specific characteristics, such as increased fragility or unique surface properties.

Role of adhesive technologies

Adhesive technologies are also playing a crucial role in the evolution of wafer backgrinding. New adhesive technologies are being developed to provide stronger adhesion, improved thermal stability, and reduced contamination risk. These advancements are enabling the use of thinner wafers and more complex materials in semiconductor manufacturing.

This highlights the importance of continued innovation in backgrinding tape technology to support the ongoing advancements in the semiconductor industry.

The trends shaping the wafer backgrinding process and material usage are closely linked to the broader developments in the semiconductor industry. As the industry continues to evolve, it is likely that new trends and challenges will emerge, driving further innovation in backgrinding tape technology and related processes.

Challenges in wafer thinning and the impact on backgrinding tape

The wafer thinning process, a critical step in semiconductor manufacturing, poses several challenges that directly impact the requirements for backgrinding tapes. Wafer thinning is essential for producing thinner, more efficient semiconductor devices, but it also increases the fragility of the wafers, making them more susceptible to damage during handling and processing.

Increased Fragility

One of the primary challenges in wafer thinning is the increased risk of wafer breakage. As wafers become thinner, they are more prone to cracking and breaking, which can lead to significant losses in production. This fragility necessitates the use of backgrinding tapes that can securely hold the wafer in place without causing damage.

Precision Handling

The need for precise handling and processing is another challenge associated with wafer thinning. Thinner wafers require more careful handling to prevent damage, and backgrinding tapes must be designed to accommodate this need for precision. The tapes must be capable of withstanding the stresses of the grinding process while keeping the wafer securely in place.

The impact of these challenges on backgrinding tape is significant. Manufacturers of backgrinding tapes must develop products that can handle the increased fragility of thin wafers and meet the need for precise handling. This includes developing tapes with the right balance of adhesion and gentleness to prevent wafer damage.

- Backgrinding tapes must be designed to securely hold thin wafers in place.

- The tapes should be capable of withstanding the grinding process without causing wafer damage.

- Precision handling requirements necessitate the development of specialized backgrinding tapes.

The challenges in wafer thinning have a direct impact on the requirements for backgrinding tapes. As the semiconductor industry continues to push for thinner wafers, the demand for advanced backgrinding tapes that can meet these challenges will grow. Manufacturers must innovate to develop tapes that can securely hold thin wafers in place during the grinding process, ensuring the production of high-quality semiconductor devices.

Geopolitical factors affecting the semiconductor supply chain

Geopolitical tensions are reshaping the semiconductor supply chain landscape. The semiconductor industry, a critical component of modern technology, is highly susceptible to geopolitical influences, including trade tensions and export restrictions. These factors can disrupt the availability of crucial materials and components, such as backgrinding tapes, thereby affecting the overall semiconductor industry.

Impact of geopolitical factors on the semiconductor supply chain

The impact of geopolitical factors on the semiconductor supply chain is multifaceted. Here are some examples:

- Restrictions on the export of advanced semiconductor manufacturing equipment can hinder the development of cutting-edge technologies.

- Limitations on the supply of backgrinding tapes can affect the production of semiconductor wafers.

Strategies to mitigate risks

To mitigate these risks, companies are adopting diversification strategies, seeking alternative suppliers and exploring new markets. However, this shift also presents challenges, such as ensuring the quality and reliability of new suppliers.

Future outlook

The geopolitical landscape is expected to continue influencing the semiconductor supply chain in the foreseeable future. As such, industry stakeholders must remain vigilant and adaptable, developing strategies to navigate these challenges and ensure the resilience of their supply chains.

Segmentation by tape type and adhesive technology in the Wafer Backgrinding Tape Market

The Wafer Backgrinding Tape Market can be categorized into distinct segments based on tape type and adhesive technology, each with its unique characteristics.

Segmentation by tape type

The segmentation by tape type includes various categories such as UV-cured tapes, non-UV-cured tapes, and other specialized tapes.

UV-cured tapes are widely used due to their ease of removal after the backgrinding process.

Adhesive technology

Adhesive technology is another critical segment, with variations including acrylic, silicone, and other adhesive types.

The choice of adhesive technology depends on the specific requirements of the semiconductor manufacturing process.

Some key characteristics of these segments include:

- Ease of application and removal

- Adhesive strength and stability

- Compatibility with various semiconductor materials

Understanding these segments is crucial for manufacturers to tailor their products to specific needs within the semiconductor industry, enhancing overall efficiency and product quality.

By recognizing the different segments within the Wafer Backgrinding Tape Market, stakeholders can make informed decisions regarding product development and investment.

Application analysis across semiconductor packaging and assembly

Backgrinding tapes play a vital role in the semiconductor packaging and assembly process, providing a secure and stable environment for wafer handling. These tapes are designed to protect wafers from damage during the backgrinding process, which is crucial for producing high-quality semiconductors.

The application analysis of backgrinding tapes in semiconductor packaging and assembly reveals their importance in ensuring the integrity of wafers. The tapes are used to mask areas of the wafer that should not be ground, thereby preventing damage to sensitive components.

semiconductor packaging and assembly applications

In assembly applications, backgrinding tapes are used to facilitate the handling of wafers during various stages of the manufacturing process. This includes protecting the wafer from contamination and mechanical stress.

Key Applications of Backgrinding Tapes

- Wafer thinning and backgrinding

- Semiconductor packaging

- Assembly and integration

The table below summarizes the key features and benefits of backgrinding tapes in semiconductor packaging and assembly applications.

| Feature | Benefit |

| Adhesive technology | Secure wafer handling |

| Material composition | Protection from contamination |

| Tape thickness | Uniform grinding results |

Backgrinding tapes are a critical component in the semiconductor packaging and assembly process. Their application ensures the production of high-quality semiconductors by protecting wafers during the manufacturing process.

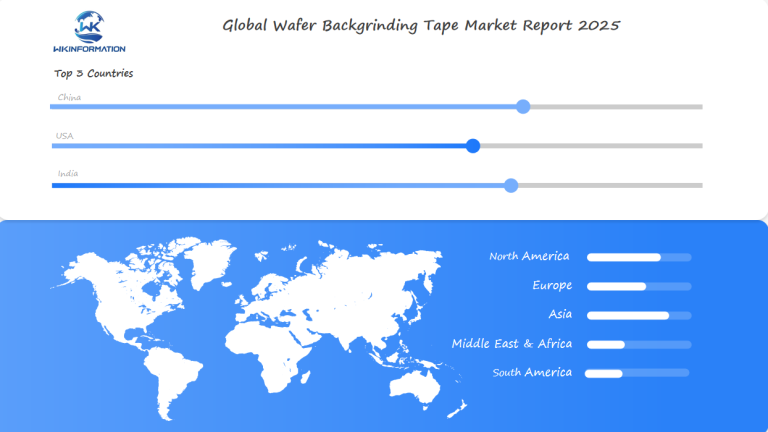

Global Regional Insights in the Wafer Backgrinding Tape Market

The global Wafer Backgrinding Tape Market is characterized by varied regional trends and market dynamics. Different regions exhibit unique growth patterns, driven by factors such as technological advancements, demand for semiconductor devices, and the presence of key industry players.

Regional Market Trends

- North America: Driven by semiconductor manufacturing and advanced electronics demand.

- Europe: Growth due to electric vehicles and renewable energy technologies.

- Asia-Pacific: Dominated by semiconductor hubs and government support.

Market Dynamics

Regional market dynamics vary significantly, with factors such as production capacity, technological innovation, and regulatory policies influencing the Wafer Backgrinding Tape Market. Understanding these dynamics is crucial for stakeholders to identify opportunities and challenges.

The Wafer Backgrinding Tape Market in different regions is also influenced by the availability of raw materials, labor costs, and the presence of supporting industries. For instance, regions with well-established supply chains and skilled workforce tend to attract more investments.

Taiwan’s Semiconductor Dominance Driving Backgrinding Tape Demand

The semiconductor industry in Taiwan is a major force behind the increasing demand for high-quality backgrinding tapes. Taiwan is home to some of the world’s leading semiconductor foundries and manufacturers, including Taiwan Semiconductor Manufacturing Company (TSMC), which plays a pivotal role in the global semiconductor supply chain.

These companies rely heavily on advanced backgrinding tapes for their wafer processing needs. The demand for backgrinding tapes in Taiwan is driven by the need for precision, reliability, and quality in semiconductor manufacturing. High-performance backgrinding tapes are essential for ensuring the integrity of wafers during the thinning process.

- Advanced Manufacturing Capabilities: Taiwan’s semiconductor manufacturers are at the forefront of technology, requiring the most advanced backgrinding tapes.

- High Volume Production: The large-scale production capabilities of Taiwanese foundries drive up the demand for backgrinding tapes.

- Innovation and R&D: Continuous innovation in semiconductor technology in Taiwan fuels the need for specialized backgrinding tapes.

As the global semiconductor industry continues to evolve, Taiwan’s role is expected to remain significant. This will likely sustain the demand for high-quality backgrinding tapes, driving further advancements in tape technology and manufacturing processes.

South Korea’s advancements in memory chip production

Advancements in memory chip production have positioned South Korea as a leader in the semiconductor sector. Companies such as Samsung and SK Hynix are at the forefront of this industry, driving innovation and manufacturing capabilities.

The demand for high-performance memory chips is increasing, driven by the need for faster, more efficient data processing in various applications, including artificial intelligence, data centers, and consumer electronics. To meet this demand, manufacturers are continually improving their production processes, including the use of advanced backgrinding tape technologies.

South Korea memory chip production

South Korea’s advancements in memory chip production have significant implications for the backgrinding tape market. The country’s manufacturers require high-performance backgrinding tapes that can support their production processes, ensuring the integrity and reliability of the semiconductor wafers during the thinning process.

The key factors driving the demand for backgrinding tape in South Korea include:

- Increasing demand for high-capacity memory chips

- Advancements in semiconductor manufacturing technologies

- Growing need for reliable, high-quality backgrinding tapes

As South Korea continues to lead in memory chip production, the demand for specialized backgrinding tapes is expected to grow. This trend is likely to drive further innovations in backgrinding tape technology, supporting the overall growth of the semiconductor industry.

Japan’s leading role in wafer processing and semiconductor technologies

Japan’s expertise in wafer processing has positioned it as a leader in the global semiconductor market. The country’s semiconductor industry is renowned for its innovative manufacturing processes and commitment to quality.

Demand for Backgrinding Tapes in Japan

The demand for high-quality backgrinding tapes in Japan is driven by its advanced semiconductor manufacturing capabilities. Leading Japanese companies are at the forefront of developing cutting-edge semiconductor technologies, further boosting the demand for specialized backgrinding tapes.

Commitment to Precision and Innovation

Japan’s semiconductor sector is characterized by its commitment to precision and innovation. The country’s expertise in wafer processing is complemented by its robust supply chain, which includes key suppliers of backgrinding tapes.

Multifaceted Role in the Global Industry

The role of Japan in the global semiconductor industry is multifaceted. Not only does it lead in wafer processing, but it also contributes significantly to the development of semiconductor technologies. This leadership is reflected in the country’s strong research and development infrastructure, which fosters innovation and collaboration among industry stakeholders.

Future Prospects

As the global demand for semiconductors continues to grow, Japan’s semiconductor industry is poised to play an even more significant role. The country’s focus on advancing wafer processing technologies and its commitment to quality will be crucial in meeting the evolving needs of the global semiconductor market.

Outlook for the Wafer Backgrinding Tape Market

Emerging trends and technologies in the semiconductor sector are driving the Wafer Backgrinding Tape Market towards a promising future. The market is expected to grow, driven by increasing demand from the semiconductor industry.

The Wafer Backgrinding Tape Market forecast indicates a positive outlook, with the market set to reach $507.5 million globally by 2025. This growth is attributed to the expanding semiconductor industry, where wafer backgrinding tape plays a crucial role in the manufacturing process.

Future trends in the semiconductor industry, such as the development of smaller, more complex chips, will continue to drive the demand for high-quality backgrinding tapes. Suppliers and manufacturers who adapt to these trends will be well-positioned to capitalize on the growing market.

The market outlook for wafer backgrinding tape is also influenced by advancements in adhesive technology and tape type. As manufacturers develop more sophisticated products, the demand for specialized backgrinding tapes is expected to increase.

The Wafer Backgrinding Tape Market is poised for growth, driven by the semiconductor industry’s expanding needs and emerging trends. Suppliers and manufacturers must stay ahead of these trends to capitalize on the market’s potential.

Competitive landscape and key suppliers in the backgrinding tape sector

The backgrinding tape sector is characterized by a competitive landscape with several key suppliers driving innovation and quality. Companies operating in this space are focusing on developing high-quality products and cutting-edge technologies to maintain their market position.

Major players in the backgrinding tape market

Major players in the backgrinding tape market are investing heavily in research and development to enhance their product offerings. This competitive environment is expected to drive advancements in wafer thinning and semiconductor manufacturing processes.

Established suppliers contributing to semiconductor industry growth

The presence of established suppliers in the backgrinding tape sector is contributing to the growth of the semiconductor industry. As demand for semiconductor devices continues to rise, key suppliers are poised to play a crucial role in meeting the needs of manufacturers.

Key suppliers in the backgrinding tape sector

Here are some of the key suppliers in the backgrinding tape sector:

- AI Technology, Inc. – United States

- AMC Co., Ltd – South Korea

- Denka Company Limited – Japan

- Force-One Applied Materials – United States

- Furukawa Electric Co., Ltd. – Japan

- Lintec Advanced Technologies (Europe) GmbH – Germany

- Loadpoint – United Kingdom

- Mitsui Chemicals America, Inc. – United States

- Nitto Denko Corporation – Japan

- Pantech Tape Co., Ltd. – South Korea

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Wafer Backgrinding Tape Market Report |

| Base Year | 2024 |

| Segment by Type |

· Uv-Cured Tapes · Non-Uv-Cured Tapes · Other |

| Segment by Application |

· Wafer thinning and backgrinding · Semiconductor packaging · Assembly and integration |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Emerging trends and technologies in the semiconductor sector are driving the Wafer Backgrinding Tape Market towards a promising future. The market is expected to grow, driven by increasing demand from the semiconductor industry.

The Wafer Backgrinding Tape Market forecast indicates a positive outlook, with the market set to reach $507.5 million globally by 2025. This growth is attributed to the expanding semiconductor industry, where wafer backgrinding tape plays a crucial role in the manufacturing process.

Future trends in the semiconductor industry, such as the development of smaller, more complex chips, will continue to drive the demand for high-quality backgrinding tapes. Suppliers and manufacturers who adapt to these trends will be well-positioned to capitalize on the growing market.

The market outlook for wafer backgrinding tape is also influenced by advancements in adhesive technology and tape type. As manufacturers develop more sophisticated products, the demand for specialized backgrinding tapes is expected to increase.

The Wafer Backgrinding Tape Market is poised for growth, driven by the semiconductor industry’s expanding needs and emerging trends. Suppliers and manufacturers must stay ahead of these trends to capitalize on the market’s potential.

Global Wafer Backgrinding Tape Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Wafer Backgrinding Tape Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Wafer Backgrinding TapeMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Wafer Backgrinding Tapeplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Wafer Backgrinding Tape Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Wafer Backgrinding Tape Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Wafer Backgrinding Tape Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofWafer Backgrinding TapeMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected size of the Wafer Backgrinding Tape Market by 2025?

The Wafer Backgrinding Tape Market is projected to reach $507.5 million globally by 2025.

What drives the demand for Wafer Backgrinding Tape in the semiconductor industry?

The demand for Wafer Backgrinding Tape is driven by:

- The expanding need for thinner wafers in semiconductor manufacturing

- Advancements in adhesive technologies

- The rising adoption of backgrinding tapes in various semiconductor packaging and assembly applications

What are the challenges associated with wafer thinning, and how do they impact backgrinding tape?

Wafer thinning poses several challenges, including increased fragility and the need for precise handling and processing. These challenges directly impact the requirements for backgrinding tapes, which must be capable of securely holding thin wafers in place during the grinding process.

How do geopolitical factors affect the semiconductor supply chain, including backgrinding tapes?

Geopolitical tensions, especially between major semiconductor-producing countries, can impact the global supply chain by disrupting the availability of essential materials and components, such as backgrinding tapes. Such disruptions often stem from complex interdependencies and vulnerabilities within the supply chain, which are exacerbated by political conflicts or trade disputes.

What are the key segments in the Wafer Backgrinding Tape Market based on tape type and adhesive technology?

The Wafer Backgrinding Tape Market can be segmented based on the type of backgrinding tape and the adhesive technology used, with different categories catering to specific needs within the semiconductor industry.

How is Taiwan’s semiconductor industry influencing the demand for backgrinding tapes?

Taiwan’s semiconductor industry is a major factor driving the demand for backgrinding tapes. Leading foundries and manufacturers in Taiwan heavily depend on top-notch backgrinding tapes for their wafer processing requirements.

What role does Japan play in wafer processing and semiconductor technologies, and how does it impact the backgrinding tape market?

Japan is a leader in wafer processing and semiconductor technologies, with several top companies playing a key role in the global semiconductor supply chain. This, in turn, is boosting the demand for high-quality backgrinding tapes.

What is the outlook for the Wafer Backgrinding Tape Market?

The outlook for the Wafer Backgrinding Tape Market is positive, with growth driven by the expanding semiconductor industry and emerging trends and technologies presenting opportunities for suppliers and manufacturers.