Crane Enclosed Conductor Bar Market Expected to Surpass $1.45 Billion by 2025 as Industrial Automation Grows in Germany, the U.S., and China

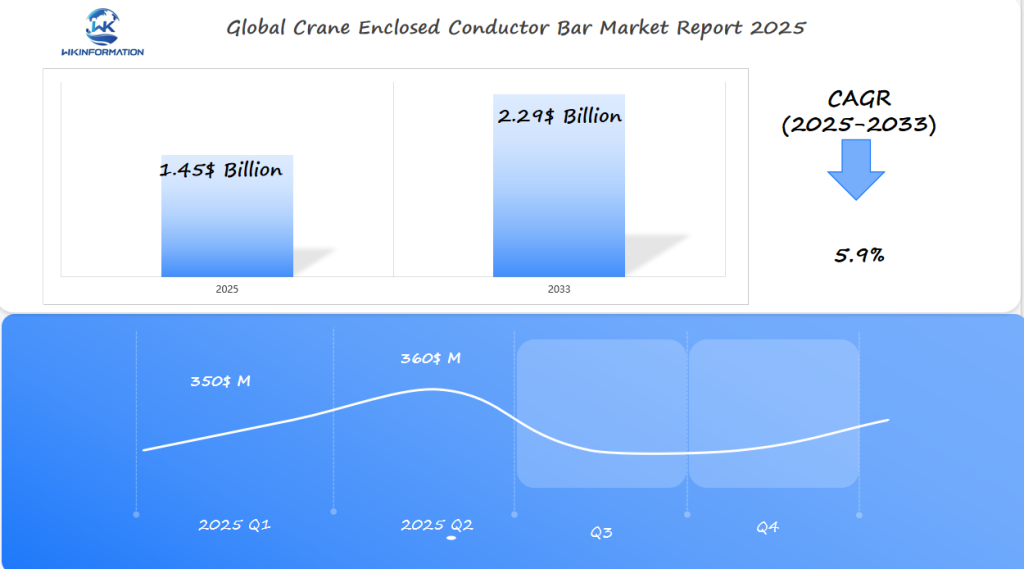

The Crane Enclosed Conductor Bar market is forecast to reach $1.45 billion in 2025, growing at a CAGR of 5.9%. In Q1 2025, the market is expected to generate around $350 million, with Q2 seeing an increase to $360 million due to ongoing industrial infrastructure projects and the adoption of automation solutions across various sectors.

- Last Updated:

Crane Enclosed Conductor Bar Market Q1 and Q2 of 2025

The Crane Enclosed Conductor Bar market is forecast to reach $1.45 billion in 2025, growing at a CAGR of 5.9%. In Q1 2025, the market is expected to generate around $350 million, with Q2 seeing an increase to $360 million due to ongoing industrial infrastructure projects and the adoption of automation solutions across various sectors.

This growth is primarily driven by the demand for safe and efficient power delivery systems in heavy industries such as construction, mining, and manufacturing. Germany, the U.S., and China are expected to be the key contributors to the market in 2025, with Germany’s industrial sector rapidly adopting advanced conductor bar systems for enhanced operational efficiency.

China’s growing manufacturing sector and the U.S.’s push towards smart factory solutions ensure a continued demand for these systems. As industries worldwide invest in automation and power distribution infrastructure, these countries remain vital markets for the Crane Enclosed Conductor Bar in 2025.

Upstream and Downstream Analysis in the Crane Enclosed Conductor Bar Market

The upstream and downstream analysis in the Crane Enclosed Conductor Bar Market reveals the intricate relationships between raw material suppliers, manufacturers, and end-users. This analysis is crucial for understanding the market’s dynamics and identifying opportunities for growth.

The supply chain dynamics play a vital role in the Crane Enclosed Conductor Bar Market. The industry relies heavily on the availability of raw materials such as copper and aluminum, which are used to manufacture conductor bars.

Understanding the Supply Chain Dynamics

The supply chain for Crane Enclosed Conductor Bars involves several key stakeholders, including raw material suppliers, manufacturers, distributors, and end-users. Understanding the interactions between these stakeholders is essential for analyzing the market’s trends and forecasting future growth.

Key Stakeholders in the Supply Chain

- Raw Material Suppliers: Provide copper, aluminum, and other necessary materials.

- Manufacturers: Produce Crane Enclosed Conductor Bars using raw materials.

- Distributors: Distribute Crane Enclosed Conductor Bars to end-users.

- End-Users: Use Crane Enclosed Conductor Bars in industrial applications.

The prices of these raw materials can significantly impact the production costs and, subsequently, the market price of Crane Enclosed Conductor Bars.

| Supply Chain Stakeholder | Role in the Market | Impact on the Industry |

| Raw Material Suppliers | Provide copper, aluminum, and other necessary materials | Prices affect production costs and market prices |

| Manufacturers | Produce Crane Enclosed Conductor Bars using raw materials | Influence market supply and product quality |

| Distributors | Distribute Crane Enclosed Conductor Bars to end-users | Affect market reach and customer satisfaction |

| End-Users | Use Crane Enclosed Conductor Bars in industrial applications | Drive demand based on industrial needs |

The Link Between Industrial Power Transmission Needs and Demand for Technology

The demand for conductor bar technology is closely linked to industrial power transmission needs. As industries expand and automate their operations, the demand for efficient power transmission solutions like Crane Enclosed Conductor Bars increases.

Understanding the upstream and downstream analysis of the Crane Enclosed Conductor Bar Market is essential for stakeholders to make informed decisions and capitalize on emerging opportunities.

Key trends driving the demand for industrial power transmission systems

1. Growth in Industrial Automation

-

Increased need for efficiency: As industries move toward more automated processes, there’s a rising demand for power transmission systems to ensure smooth and efficient operation of machinery and equipment.

-

Integration with robotics and AI: Robotics, AI, and machine learning systems require robust power transmission systems for high precision, uptime, and energy efficiency.

2. Expansion of Renewable Energy

-

Transmission from renewable sources: The growing reliance on solar, wind, and hydroelectric power sources is driving the need for reliable, long-distance power transmission systems.

-

Grid modernization: As renewable energy penetration increases, traditional power grids are being upgraded to better handle fluctuating energy loads, thereby enhancing demand for power transmission systems.

3. Industrial IoT (IIoT) and Smart Grids

-

Data-driven decision making: IIoT systems require real-time data collection and transmission, pushing the demand for more dynamic power management systems that can react to changing conditions.

-

Smart grids: These systems provide better energy distribution and can help reduce power loss, increasing the need for modern, adaptable power transmission solutions.

4. Shift Towards Energy Efficiency

-

Regulations and sustainability goals: Stricter regulations and corporate sustainability goals are pushing industries to adopt energy-efficient transmission systems that minimize energy wastage and reduce operating costs.

-

Electrification of industries: Electrification trends across transportation and manufacturing (e.g., electric vehicles, electrified machinery) require advanced power transmission systems.

Barriers to adoption and growth in the Crane Enclosed Conductor Bar sector

The adoption and growth of Crane Enclosed Conductor Bars in manufacturing facilities are challenged by several key factors.

One of the primary concerns is the high initial investment required for implementing these systems.

Challenges Facing the Industry

The Crane Enclosed Conductor Bar industry faces numerous challenges, including high initial costs and technological constraints.

High Initial Costs

- High upfront costs associated with purchasing and installing Crane Enclosed Conductor Bar systems.

- Limited flexibility and compatibility with existing manufacturing infrastructure.

- The need for specialized labor and training to maintain and repair these systems.

Technological Constraints

The industry is also constrained by technological limitations and economic factors.

Technological constraints include the complexity of integrating Crane Enclosed Conductor Bars with existing automation systems and ensuring reliable performance under various operating conditions.

Economic factors, such as fluctuations in raw material prices and the high cost of maintenance, further exacerbate the challenges faced by the industry.

To overcome these barriers, manufacturers must invest in research and development to improve the efficiency and cost-effectiveness of Crane Enclosed Conductor Bar systems.

Additionally, collaboration between industry stakeholders and advancements in technology can help mitigate the challenges and drive growth in the sector.

Geopolitical influences affecting material sourcing and industry regulations

Geopolitical factors significantly impact the sourcing of materials for the Crane Enclosed Conductor Bar Market. The complex interplay of international relations, trade policies, and tariffs affects the availability and cost of raw materials, thereby influencing market trends across various industrial sectors.

The Crane Enclosed Conductor Bar industry relies heavily on the import and export of raw materials such as copper and aluminum. Changes in trade policies, such as the imposition of tariffs, can disrupt the supply chain and lead to increased costs for manufacturers.

Impact of Global Politics on Material Sourcing

Global politics play a crucial role in shaping the material sourcing landscape for Crane Enclosed Conductor Bars. For instance, trade tensions between major economies can lead to tariffs on imported raw materials, increasing costs for manufacturers and potentially affecting market trends in various industrial sectors.

The following table illustrates the impact of geopolitical factors on material sourcing for the Crane Enclosed Conductor Bar Market:

| Trade Tariffs | Increased cost of raw materials | Potential price increase for Crane Enclosed Conductor Bars |

| International Trade Agreements | Reduced tariffs, increased supply chain stability | Potential decrease in prices, increased demand |

| Political Instability | Disruption in raw material supply chains | Potential shortages, increased prices |

The industry must navigate these geopolitical complexities to ensure a stable supply of raw materials. Companies may need to adapt their sourcing strategies, exploring alternative suppliers or investing in supply chain resilience to mitigate potential disruptions.

By understanding the geopolitical factors at play, businesses in the Crane Enclosed Conductor Bar Market can better anticipate and respond to changes in the global landscape, ultimately maintaining their competitiveness in various industrial sectors.

Segmentation by type and application in various industrial sectors

The Crane Enclosed Conductor Bar Market is diverse, with various types and applications across industrial sectors. This diversity is driven by the need for efficient and reliable power supply systems in industrial automation.

Types of Crane Enclosed Conductor Bars are categorized based on their design, functionality, and application. The main types include:

- Single-pole conductor bars

- Multi-pole conductor bars

- Slip ring conductor bars

Types of Crane Enclosed Conductor Bars

The Crane Enclosed Conductor Bar market offers various types to suit different industrial needs. The selection of a conductor bar type depends on factors such as the level of automation, power requirements, and environmental conditions.

| Single-pole | Simplified design for straightforward applications | Simple crane systems |

| Multi-pole | Complex design for multiple power supplies | Advanced automated crane systems |

| Slip Ring | Continuous power supply during movement | Rotating cranes and machinery |

Applications in Different Industries

Crane Enclosed Conductor Bars are used in various industries, including manufacturing, logistics, and construction. The application of conductor bar technology enhances operational efficiency and reduces downtime.

The demand for Crane Enclosed Conductor Bars is driven by the growth of industrial automation. As industries adopt more automated systems, the need for reliable power supply systems increases.

Application-driven analysis for cranes, automated systems, and manufacturing

In the world of industrial automation, crane enclosed conductor bars are crucial for the efficient functioning of cranes and manufacturing systems. These systems depend greatly on the dependable transmission of power to maintain uninterrupted operation.

Role in Enhancing Operational Efficiency

Crane enclosed conductor bars play a crucial role in enhancing operational efficiency by providing a reliable means of industrial power transmission. This reliability is essential for minimizing downtime and maximizing productivity in manufacturing facilities.

The use of crane enclosed conductor bars in cranes and automated systems ensures that power is transmitted efficiently, reducing the risk of electrical failures and associated maintenance costs. This, in turn, leads to increased productivity and reduced operational costs.

Some of the key benefits of using crane enclosed conductor bars include:

- Reliable power transmission

- Reduced downtime

- Increased productivity

- Lower maintenance costs

By enhancing operational efficiency, crane enclosed conductor bars contribute significantly to the overall performance of manufacturing facilities. Their role in ensuring reliable industrial power transmission makes them an indispensable component of modern manufacturing systems.

Regional Outlook for the Crane Enclosed Conductor Bar Market

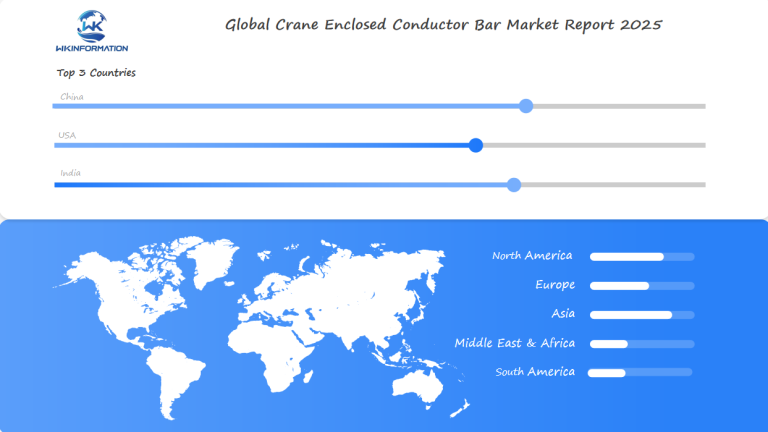

The adoption of warehousing and logistics automation is significantly impacting the regional dynamics of the Crane Enclosed Conductor Bar Market.

Different regions are experiencing varied growth patterns due to factors such as local industrial automation demands and infrastructure development.

Regional Market Trends

Regional market trends indicate a surge in demand for Crane Enclosed Conductor Bars in areas with significant industrial automation projects.

For instance, regions with expanding manufacturing facilities and logistics hubs are witnessing a higher adoption rate of these conductor bars.

warehousing and logistics automation

A closer look at the regional trends reveals that the growth is not uniform and is heavily influenced by local factors such as government policies, industrial growth, and technological advancements.

| Region | Growth Rate | Key Drivers |

| North America | Moderate | Industrial automation, warehousing |

| Europe | High | Manufacturing sector growth, logistics automation |

| Asia-Pacific | Rapid | Infrastructure development, industrialization |

Germany’s surge in demand for industrial automation and manufacturing facilities

Germany’s strong industrial base and ongoing infrastructure growth are driving the demand for automation solutions. This surge is largely attributed to the country’s commitment to enhancing its manufacturing capabilities and adopting advanced technologies.

The landscape of industrial automation in Germany is characterized by a strong emphasis on innovation and efficiency. As a result, the demand for crane enclosed conductor bars is increasing, driven by the need for reliable and efficient power supply systems in manufacturing facilities.

Germany’s Industrial Automation Landscape

Germany’s industrial automation sector is experiencing significant growth due to several factors, including:

- Increased investment in infrastructure development

- A strong focus on Industry 4.0 technologies

- Growing demand for high-efficiency manufacturing processes

The country’s infrastructure growth plays a crucial role in this context, as it enables the integration of advanced automation solutions. This, in turn, enhances the overall productivity and competitiveness of German manufacturing facilities.

Some of the key trends shaping Germany’s industrial automation landscape include:

- The adoption of smart manufacturing technologies

- The integration of AI and IoT in industrial processes

- The increasing use of robotics in manufacturing

These trends are expected to continue driving the demand for crane enclosed conductor bars, as manufacturers seek to optimize their operations and improve efficiency.

The U.S.’s expansion in warehousing and logistics automation

The U.S. warehousing and logistics sector’s shift towards automation is driving innovation and demand in the Crane Enclosed Conductor Bar Market. As companies invest in automated systems to enhance efficiency and reduce costs, the need for reliable and efficient power supply systems becomes increasingly important.

Impact on the Crane Enclosed Conductor Bar Market

The growing demand for automation in U.S. warehousing and logistics is significantly influencing the Crane Enclosed Conductor Bar Market. Companies are adapting to the changing demands by innovating and improving their products.

Some key factors driving this growth include:

- Increased investment in logistics and warehousing automation

- Growing demand for efficient and reliable power supply systems

- Advancements in technology leading to improved Crane Enclosed Conductor Bar systems

The market is becoming increasingly dynamic, with companies focusing on developing high-quality, durable, and efficient Crane Enclosed Conductor Bars that meet the evolving needs of the automation industry.

As the U.S. continues to expand its warehousing and logistics automation, the Crane Enclosed Conductor Bar Market is expected to witness significant growth, driven by the increasing demand for reliable power supply solutions.

China's infrastructure growth supporting conductor bar technology

China’s rapid infrastructure development is significantly boosting the demand for conductor bar technology across various industrial sectors. This growth is not only limited to the expansion of physical infrastructure but also encompasses the modernization of industrial facilities.

The country’s focus on infrastructure development has led to increased investments in manufacturing and logistics, sectors that heavily rely on conductor bar technology for efficient operations.

Advancements in Infrastructure

China’s infrastructure development is characterized by large-scale projects that include high-speed rail networks, smart cities, and industrial parks. These projects require advanced electrical supply systems, where conductor bars play a crucial role.

The adoption of conductor bar technology in these projects is driven by its reliability, efficiency, and ability to support heavy-duty applications.

Conductor Bar Technology in Industrial Sectors

As China’s infrastructure continues to grow, the demand for conductor bar technology is expected to rise. This trend is likely to influence market trends, with a shift towards more efficient and reliable electrical supply systems.

The growth in infrastructure is also expected to drive innovations in conductor bar technology, making it more adaptable to various industrial applications.

Future potential and growth outlook for the Crane Enclosed Conductor Bar Market

As industrial automation continues to rise, the future potential of the Crane Enclosed Conductor Bar Market looks increasingly promising. The market is expected to benefit from advancements in conductor bar technology, which will enhance the efficiency and reliability of industrial automation systems.

The increasing demand for automated solutions in various industries is driving the growth of the Crane Enclosed Conductor Bar Market. Emerging opportunities in sectors such as manufacturing, logistics, and warehousing are expected to further boost market growth.

Emerging Opportunities

The growth of the Crane Enclosed Conductor Bar Market is also driven by the need for more efficient and reliable power supply systems in industrial settings. Advances in conductor bar technology have led to the development of more sophisticated and efficient systems.

| Industry | Application | Growth Potential |

| Manufacturing | Automated production lines | High |

| Logistics | Automated warehousing | Medium-High |

| Warehousing | Automated storage and retrieval systems | Medium |

The table above highlights the growth potential of the Crane Enclosed Conductor Bar Market in various industries. The increasing adoption of automated solutions is expected to drive market growth.

As the market continues to evolve, we can expect to see new and innovative applications of conductor bar technology in various industrial settings. The future of the Crane Enclosed Conductor Bar Market looks promising, with growth driven by the increasing demand for industrial automation solutions.

Competitive landscape and key players in the conductor bar industry

As the demand for efficient industrial power transmission grows, the competitive landscape of the conductor bar industry is evolving. This evolution is driven by key players who are focusing on innovative solutions to enhance their presence in manufacturing facilities.

Here are some of the major companies operating in this industry:

- Alpha Industrial Components Inc. – United States

- Apex Crane Conductor Innovations Inc. – United States

- Beta Crane Technologies LLC – United States

- Chi Innovative Conductor Systems Corp. – United States

- Delta Crane and Conductor Systems Inc. – United States

- Epsilon Electrical & Conveyor Systems Ltd. – United Kingdom

- Eta Conductor Innovations LLC – United States

- Frontier Crane Engineering LLC – United States

- Gamma Conductor Solutions Ltd. – United Kingdom

- Iota Electric Engineering Inc. – United States

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Crane Enclosed Conductor Bar Market Report |

| Base Year | 2024 |

| Segment by Type |

· Single-pole · Multi-pole · Slip Ring |

| Segment by Application |

· Static Cranes · Mobile Cranes |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Crane Enclosed Conductor Bar Market is set for significant growth, driven by changing market trends and a competitive landscape that is adapting to the demands of industrial automation and power transmission needs.

Key Takeaways

- The market is influenced by various factors, including geopolitical influences and regional outlooks, which shape the industry’s future. Understanding these dynamics is crucial for stakeholders to make informed decisions.

- As the industry continues to evolve, it is essential to stay abreast of the latest market trends and competitive landscape. The growth outlook for the Crane Enclosed Conductor Bar Market remains positive, with emerging opportunities in industrial automation and manufacturing.

- Industry leaders are focusing on innovative strategies to stay ahead in the competitive landscape. As the market continues to grow, it is likely that we will see new developments and advancements in conductor bar technology.

Global Crane Enclosed Conductor Bar Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Crane Enclosed Conductor Bar Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Crane Enclosed Conductor BarMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Crane Enclosed Conductor Barplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Crane Enclosed Conductor Bar Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Crane Enclosed Conductor Bar Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Crane Enclosed Conductor Bar Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofCrane Enclosed Conductor BarMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is driving the growth of the Crane Enclosed Conductor Bar Market?

The growth of the Crane Enclosed Conductor Bar Market is driven by:

- The increasing demand for industrial automation

- Advancements in conductor bar technology

- The need for efficient power transmission systems

How does industrial automation influence the demand for crane enclosed conductor bars?

Industrial automation significantly influences the demand for crane enclosed conductor bars as they are used in various automated systems to enable reliable power transmission, reducing downtime and increasing productivity.

What are the barriers to adoption in the Crane Enclosed Conductor Bar sector?

The barriers to adoption in the Crane Enclosed Conductor Bar sector include:

- High initial costs

- Technological constraints

- The need for manufacturing facilities to be equipped to handle the production of these systems

How do geopolitical factors affect the Crane Enclosed Conductor Bar Market?

Geopolitical factors, such as trade policies, tariffs, and international relations, can affect the availability and cost of raw materials, thereby influencing market trends across various industrial sectors.

What is the regional outlook for the Crane Enclosed Conductor Bar Market?

The regional outlook for the Crane Enclosed Conductor Bar Market varies, with different regions showing different growth patterns due to factors like the increasing adoption of warehousing and logistics automation.

How is Germany’s industrial automation landscape impacting the Crane Enclosed Conductor Bar Market?

Germany’s strong industrial base and infrastructure growth are driving the demand for industrial automation, positively impacting the Crane Enclosed Conductor Bar Market.

What is the impact of the U.S.’s expansion in warehousing and logistics automation on the Crane Enclosed Conductor Bar Market?

The expansion of warehousing and logistics automation in the U.S. is influencing the Crane Enclosed Conductor Bar Market, with companies adapting to the changing demands and competitive landscape.

How is China’s infrastructure growth supporting the adoption of conductor bar technology?

China’s infrastructure growth is supporting the adoption of conductor bar technology, driving market trends across various industrial sectors.

What is the future potential of the Crane Enclosed Conductor Bar Market?

The future potential of the Crane Enclosed Conductor Bar Market looks promising, driven by advancements in conductor bar technology and increasing industrial automation, with emerging opportunities in the market.

Who are the key players in the conductor bar industry?

The key players in the conductor bar industry are focusing on industrial power transmission and manufacturing facilities, with market leaders adopting various strategies to stay competitive.